Diesel Injection At High Pressure, Penetration Length Analysis

$160.00 $80.00 Student Discount

- The project focuses on simulating diesel injection at high pressure under varying environmental pressures.

- The primary objectives are to analyze the diesel spray’s penetration length

- The simulation employs a two-way Discrete Phase Model (DPM) to capture the interaction between the diesel droplets and the surrounding air

- the geometry of the diesel injector and combustion chamber was created in SpaceClaim, and The mesh was generated using ANSYS Meshing. The final mesh comprises 1,250,256 cells, balancing computational accuracy and efficiency.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Simulation and Analysis of Diesel Spray Penetration Length and Jet Angle Under High Injection and Environmental Pressures Using ANSYS Fluent

Description

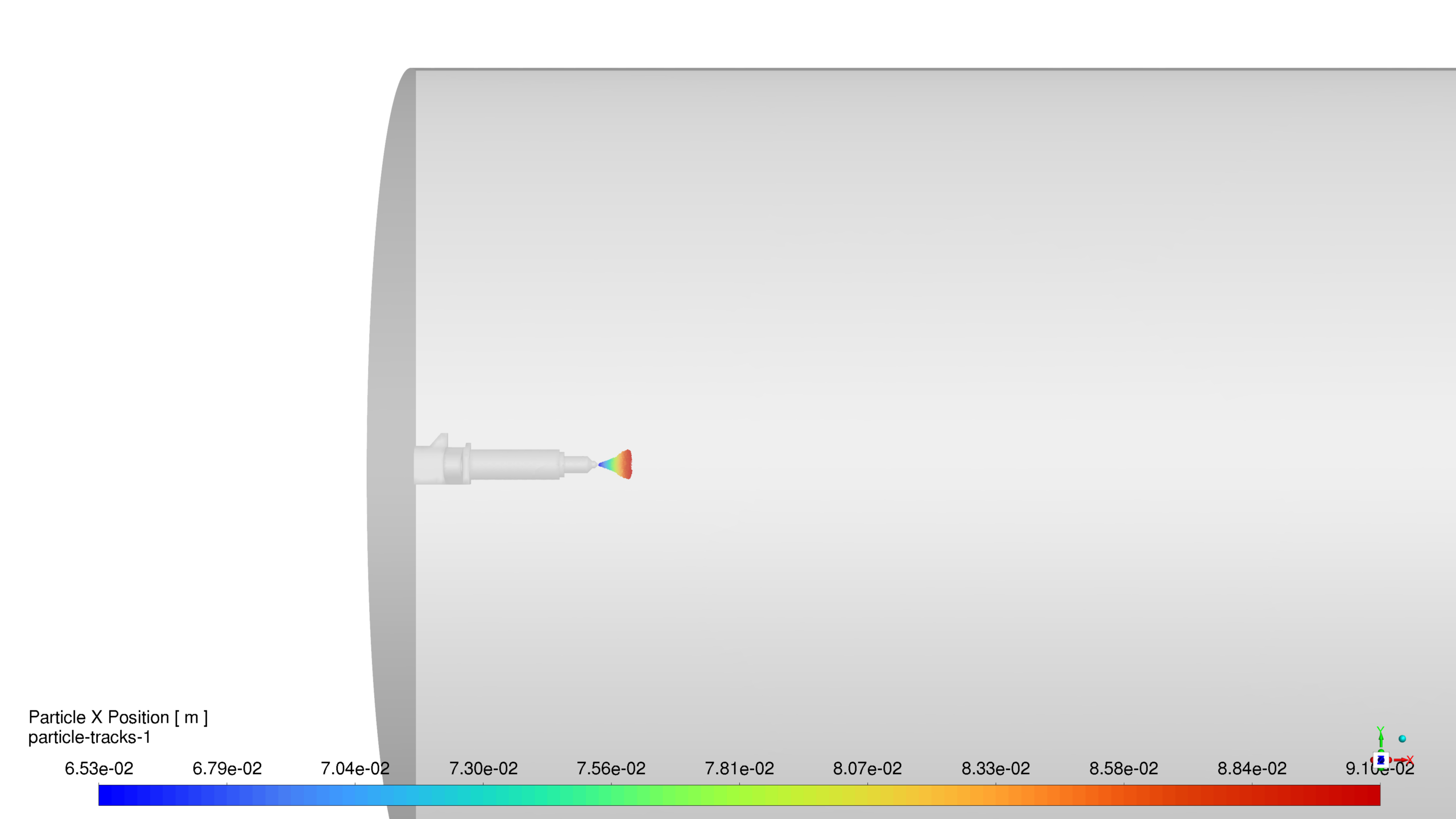

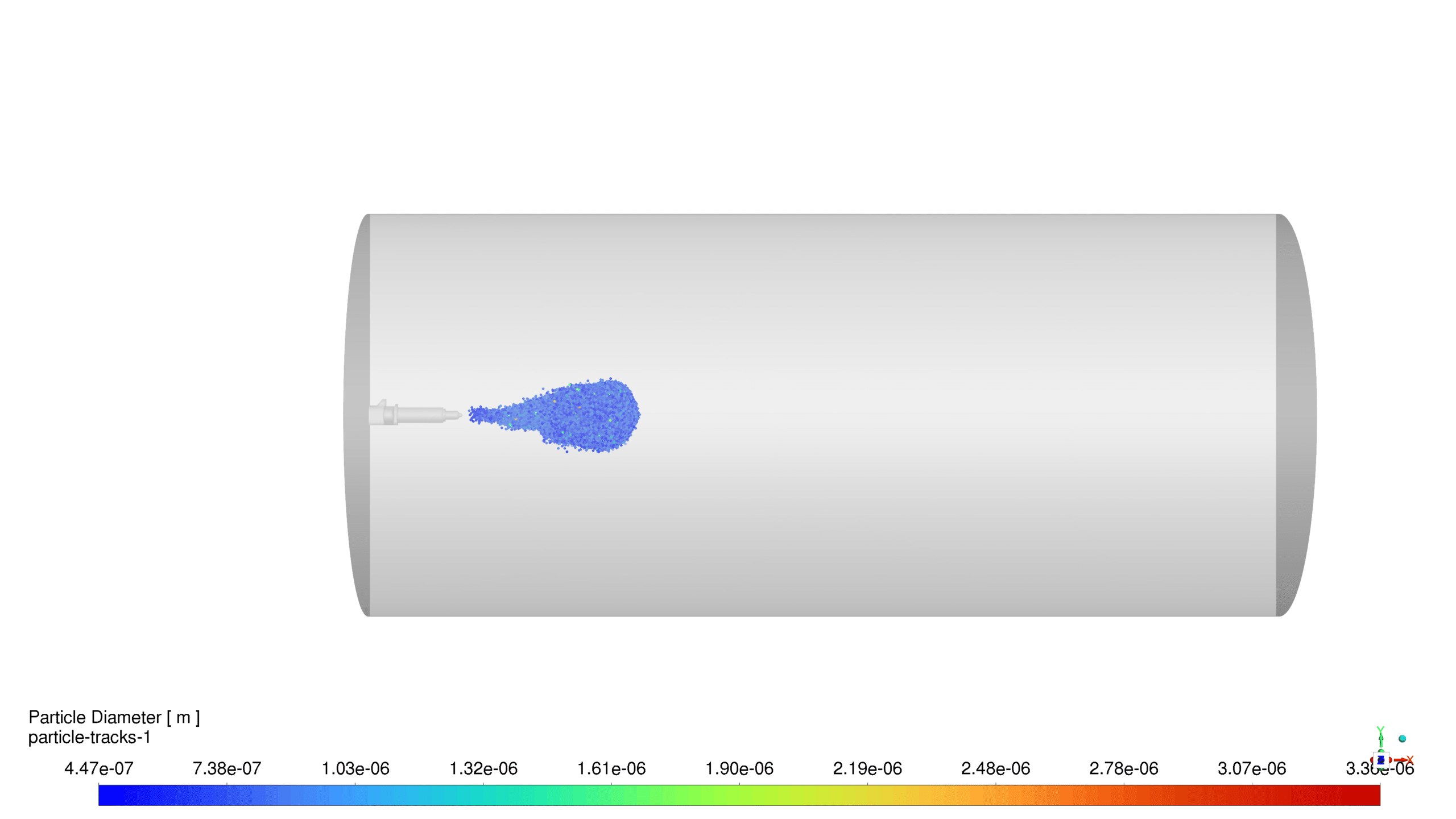

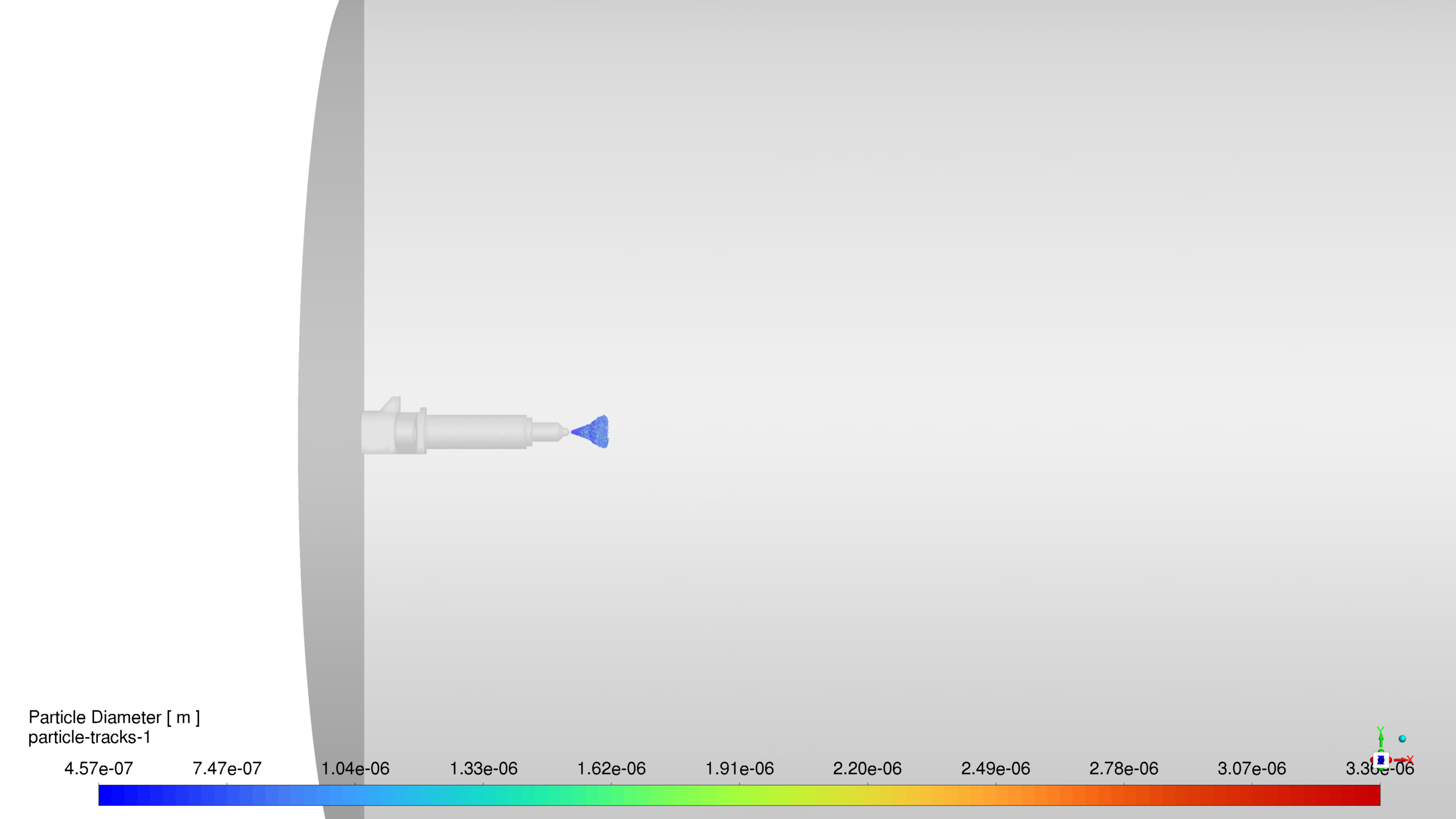

The project focuses on simulating diesel injection at high pressure (500 ) under varying environmental pressures (10 bar). The primary objectives are to analyze the diesel spray’s penetration length and jet angle, which are critical parameters for optimizing combustion efficiency and reducing emissions in diesel engines. The simulation employs a two-way Discrete Phase Model (DPM) to capture the interaction between the diesel droplets and the surrounding air. The results are visualized through animations and plots of velocity, pressure, and droplet diameter at two different time steps.

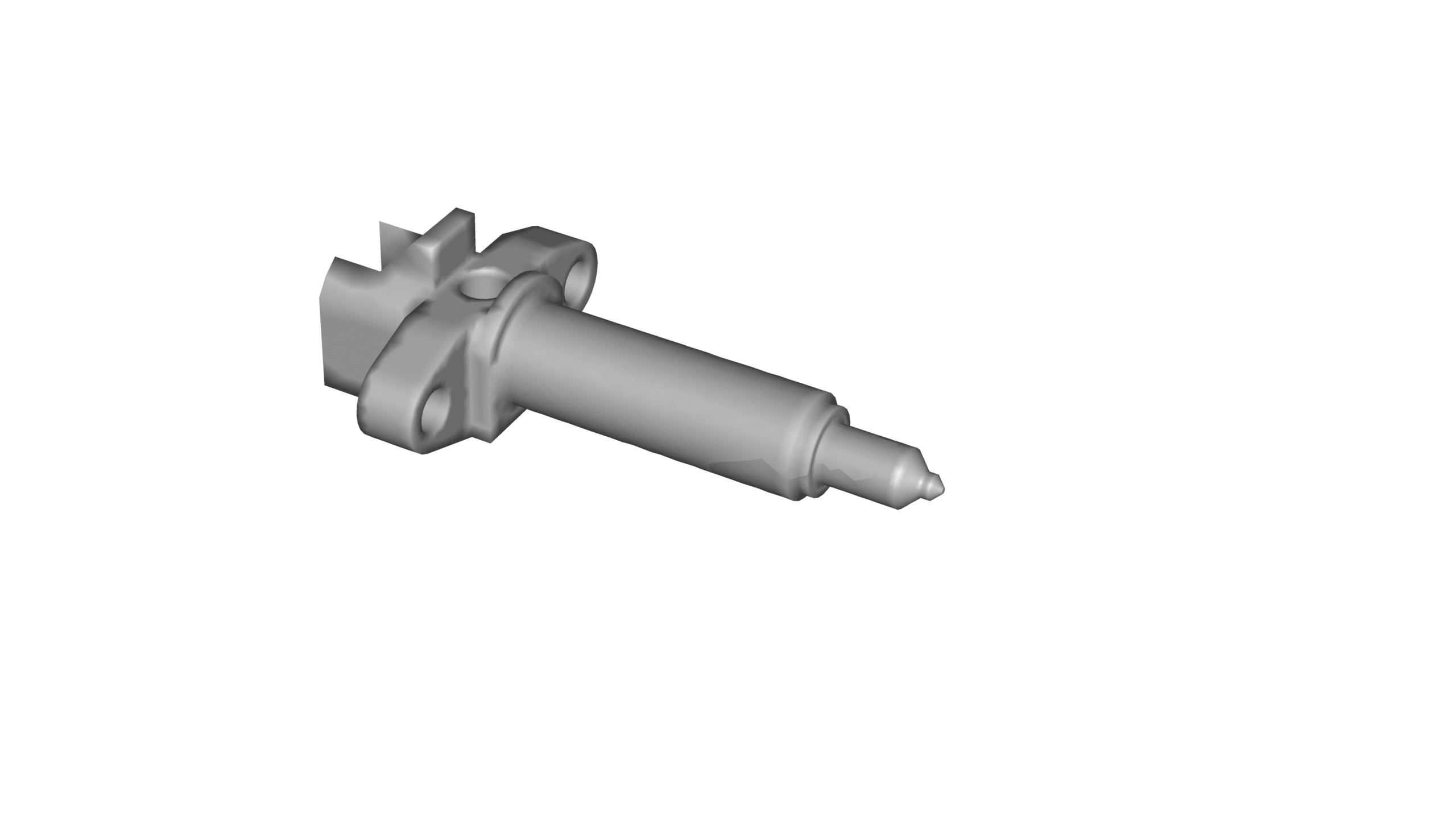

The geometry of the diesel injector and combustion chamber was created in SpaceClaim, ensuring an accurate representation of the nozzle and spray region.

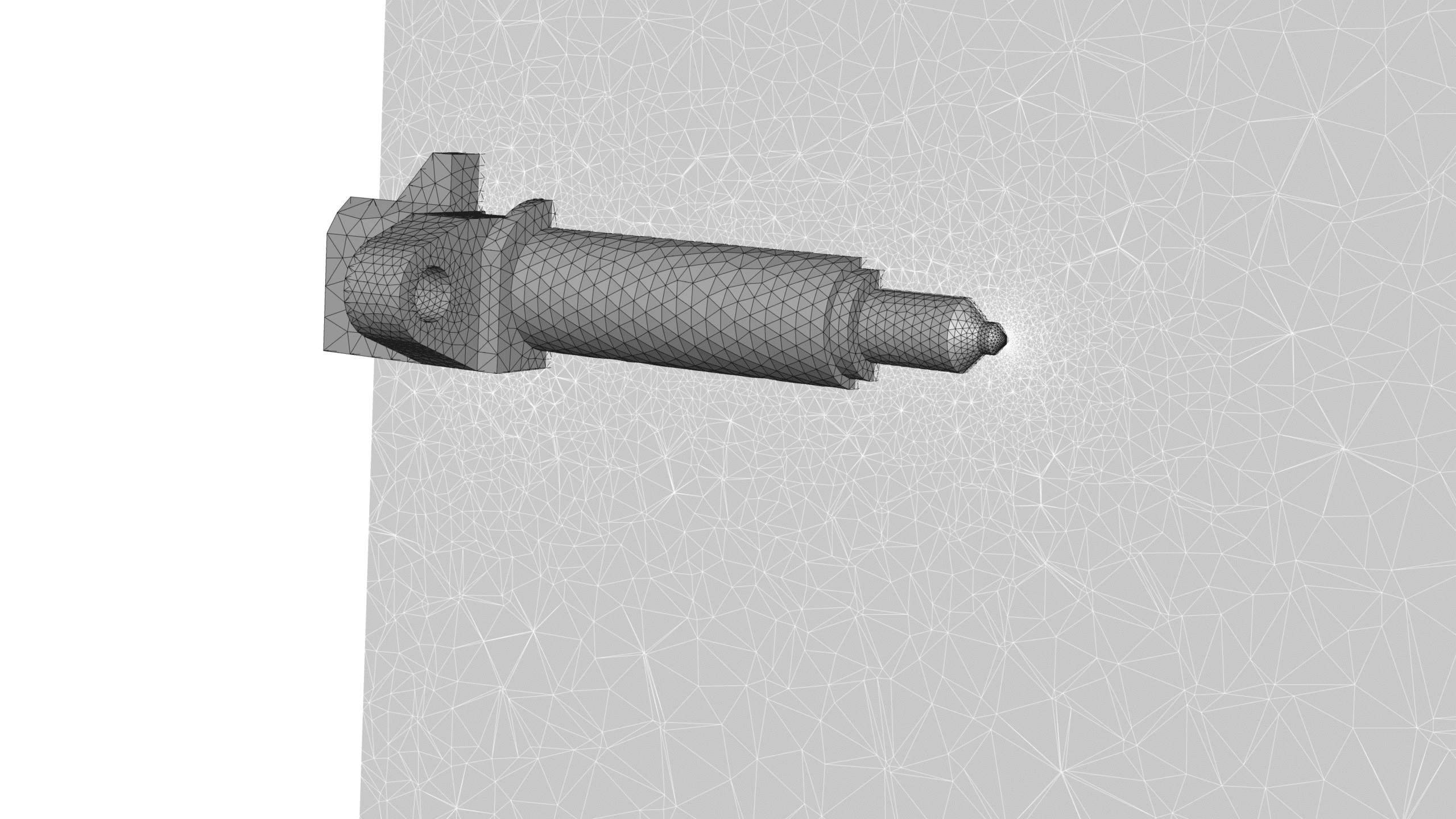

The mesh was generated using ANSYS Meshing. It focused on refining the region near the injector nozzle to capture the high gradients in velocity and pressure. The final mesh comprises 1,250,256 cells, balancing computational accuracy and efficiency.

Methodology

Solver: The simulation was performed using ANSYS Fluent; the solver was configured to handle multiphase flow dynamics, specifically the interaction between the discrete phase (diesel droplets) and the continuous phase (air).

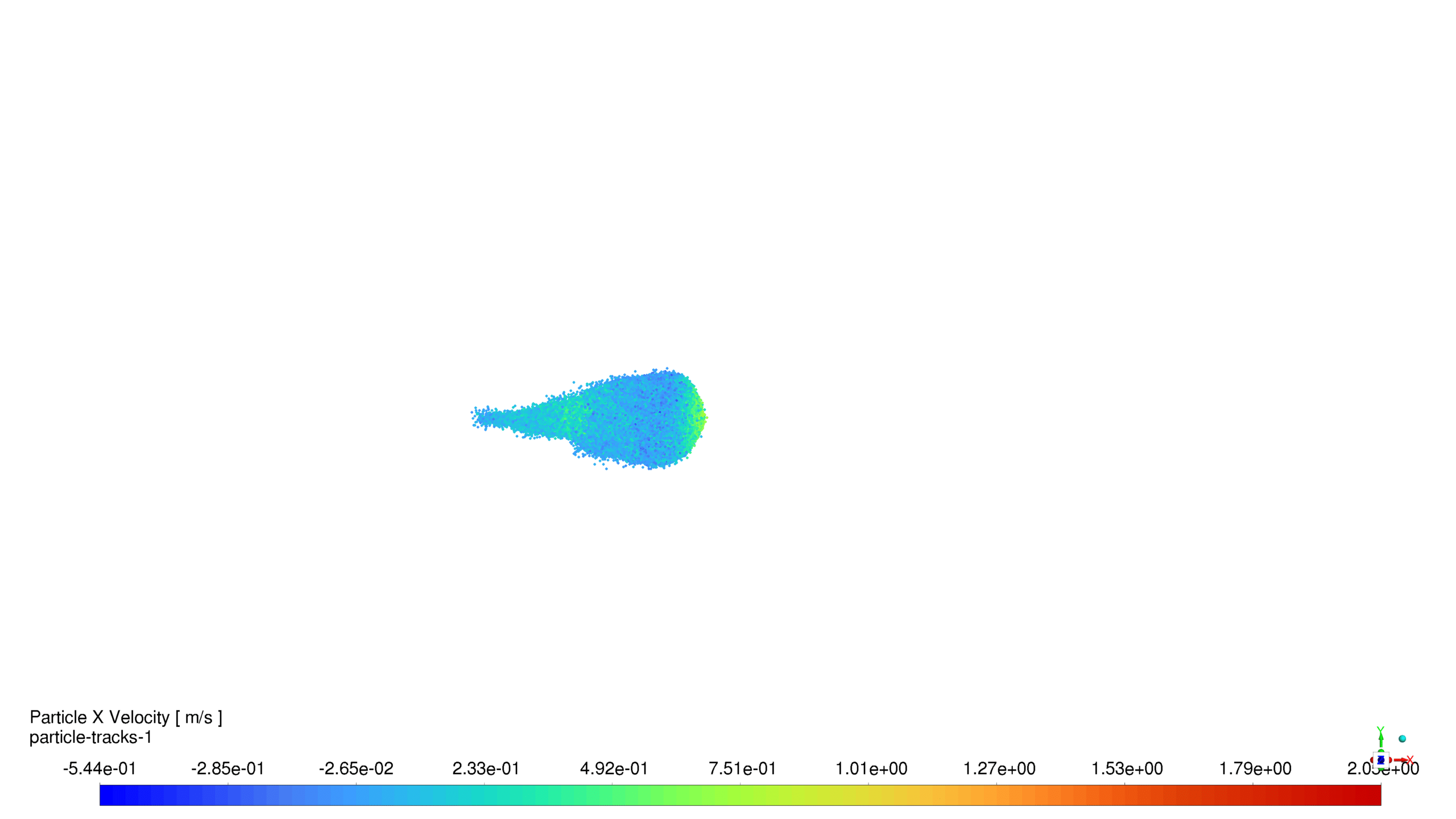

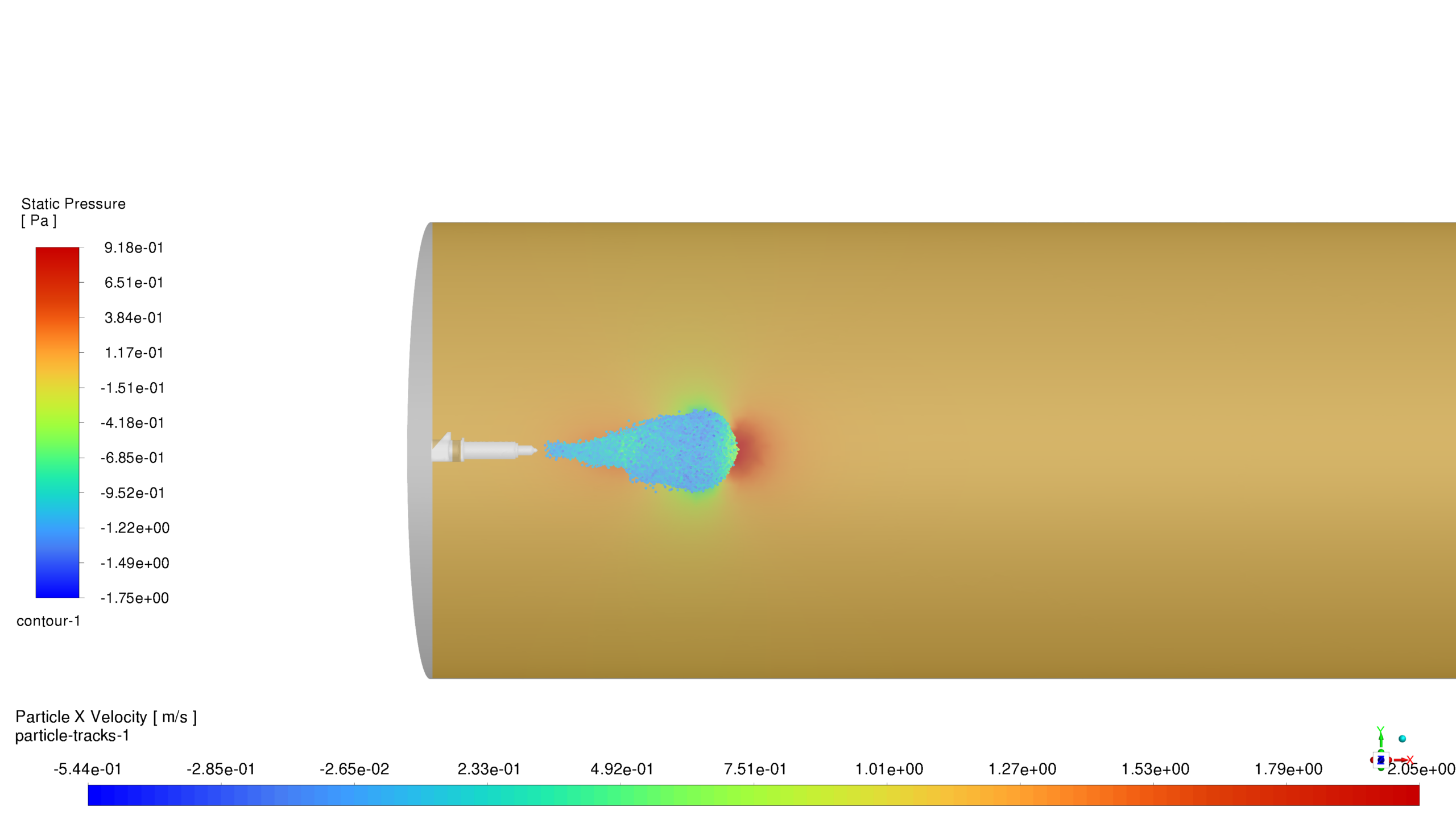

Discrete Phase Model (DPM): The two-way coupled DPM was employed to simulate the interaction between the diesel droplets and the surrounding air. This approach accounts for the momentum and energy exchange between the discrete and continuous phases, ensuring a realistic representation of the droplet behavior.

Turbulence Model: The k-epsilon (realizable) turbulence model was selected for its robustness and accuracy in predicting turbulent flows. This model is particularly well-suited for high-Reynolds-number flows and provides reliable results for the turbulent mixing and dispersion of diesel droplets in the air.

Boundary Conditions:

Injection Pressure

- Injection Pressure: 500 bar

The high injection pressure ensures fine atomization of the diesel fuel, forming tiny droplets and improved mixing with the surrounding air.

Environmental Pressure

- Environmental Pressure: 10 bar

The simulation was conducted under elevated environmental pressure conditions, representing combustion chamber environments in diesel engines.

Fuel Properties

Fuel Type: Diesel

The diesel fuel was modeled with the following properties:

-

- Density: 830 kg/m³ (typical for diesel fuel at standard conditions)

- Viscosity: 2.7 mPa·s (dynamic viscosity at 20°C)

Injection Type

- Injection Type: Pressure Swirl Atomizers

Pressure swirl atomizers were used to simulate the injection process. This injector type is commonly used in diesel engines to achieve a fine spray pattern and uniform fuel distribution.

Results

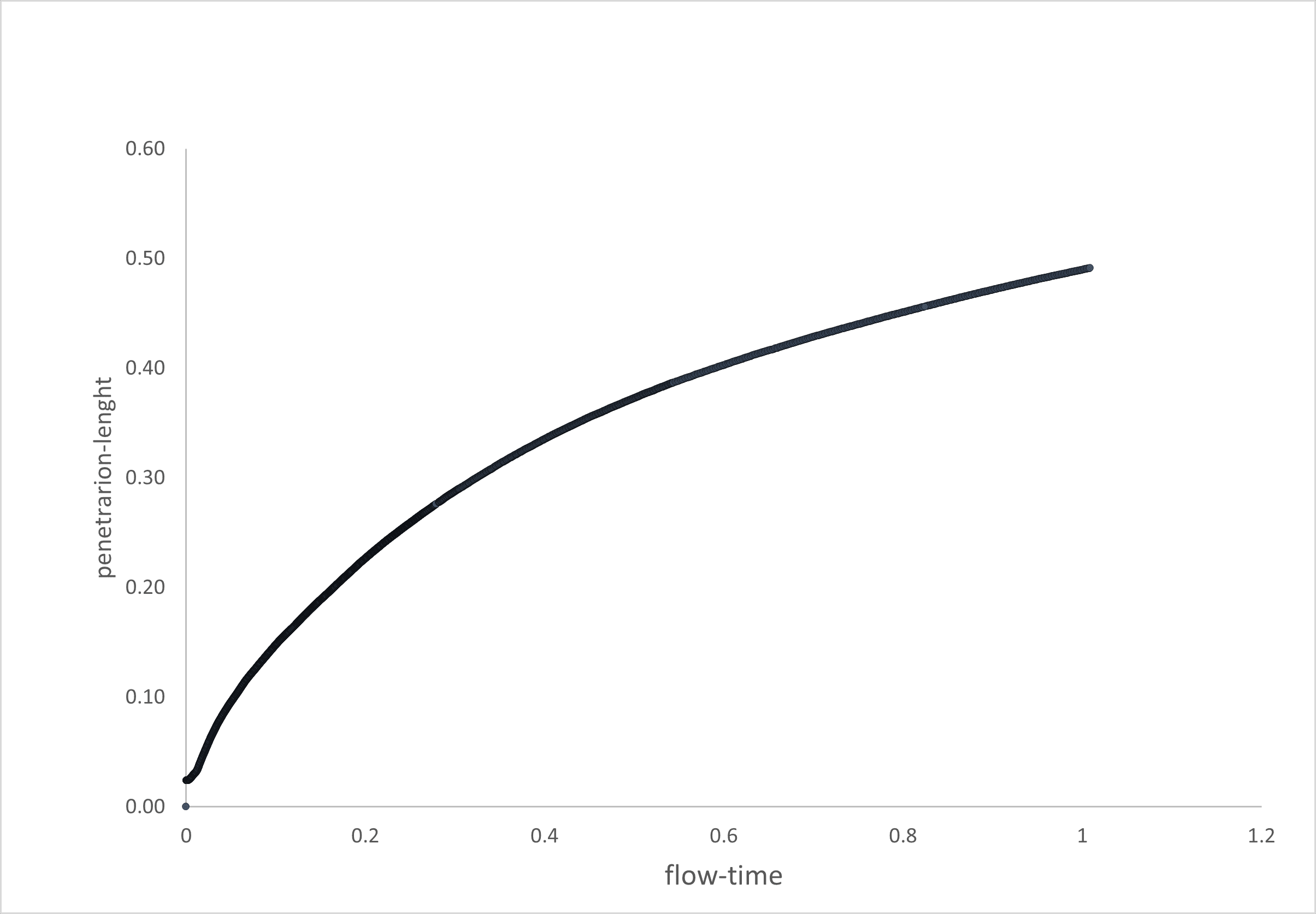

Penetration Length

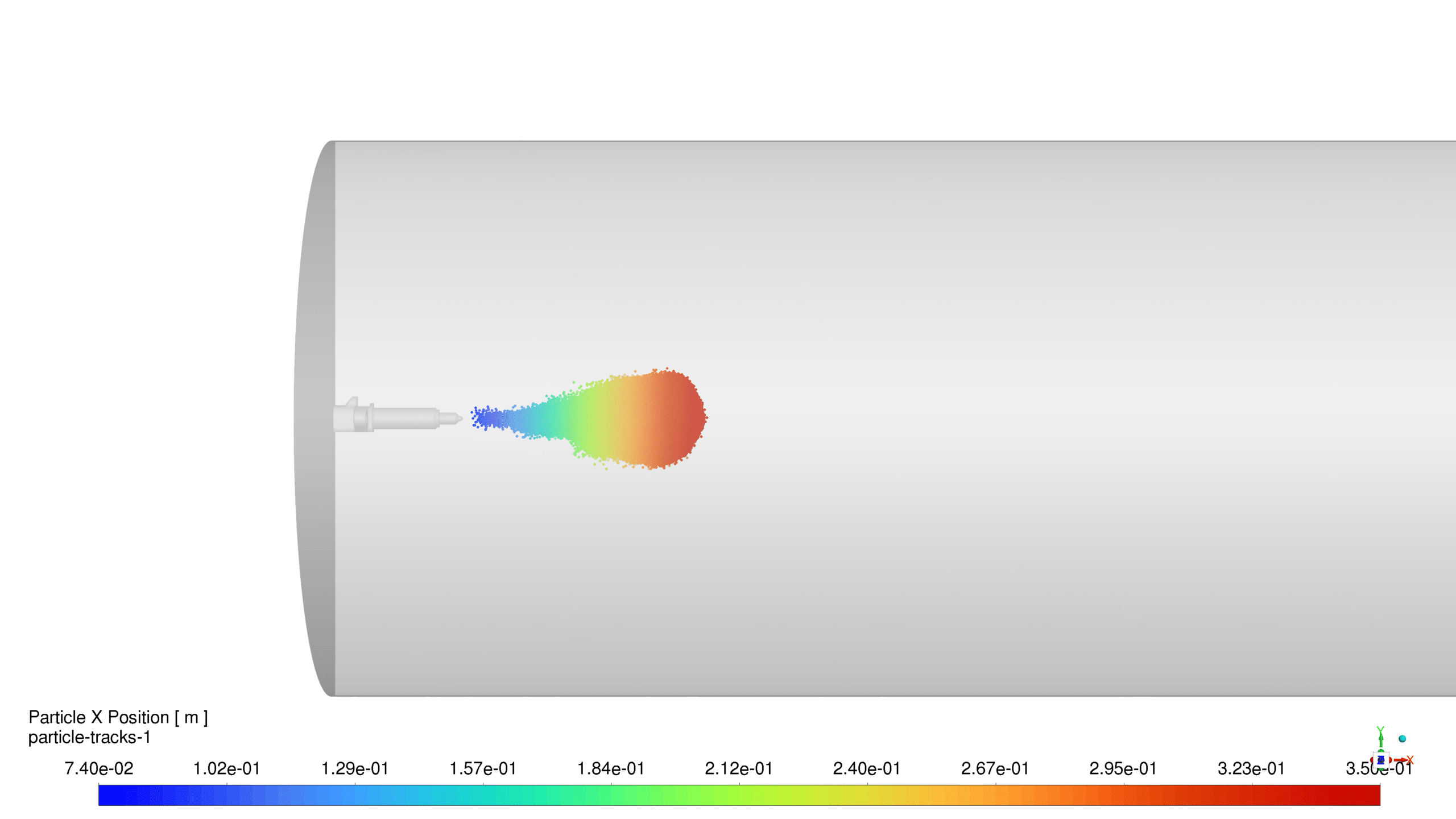

- Spray Dynamics: The graph provides insights into the dynamics of the spray, particularly how it penetrates the surrounding medium (likely air) over time. The initial rapid increase in penetration length is consistent with the high injection pressure (500 bar) mentioned in the simulation setup.

- Atomization and Dispersion: The slower increase and eventual stabilization of the penetration length suggest that the spray droplets are undergoing atomization and dispersion, which is influenced by factors such as turbulence, droplet size, and environmental pressure.

- Injector Design: The data can be used to evaluate and improve the design of pressure swirl atomizers, ensuring that they produce the desired spray characteristics under specific operating conditions.

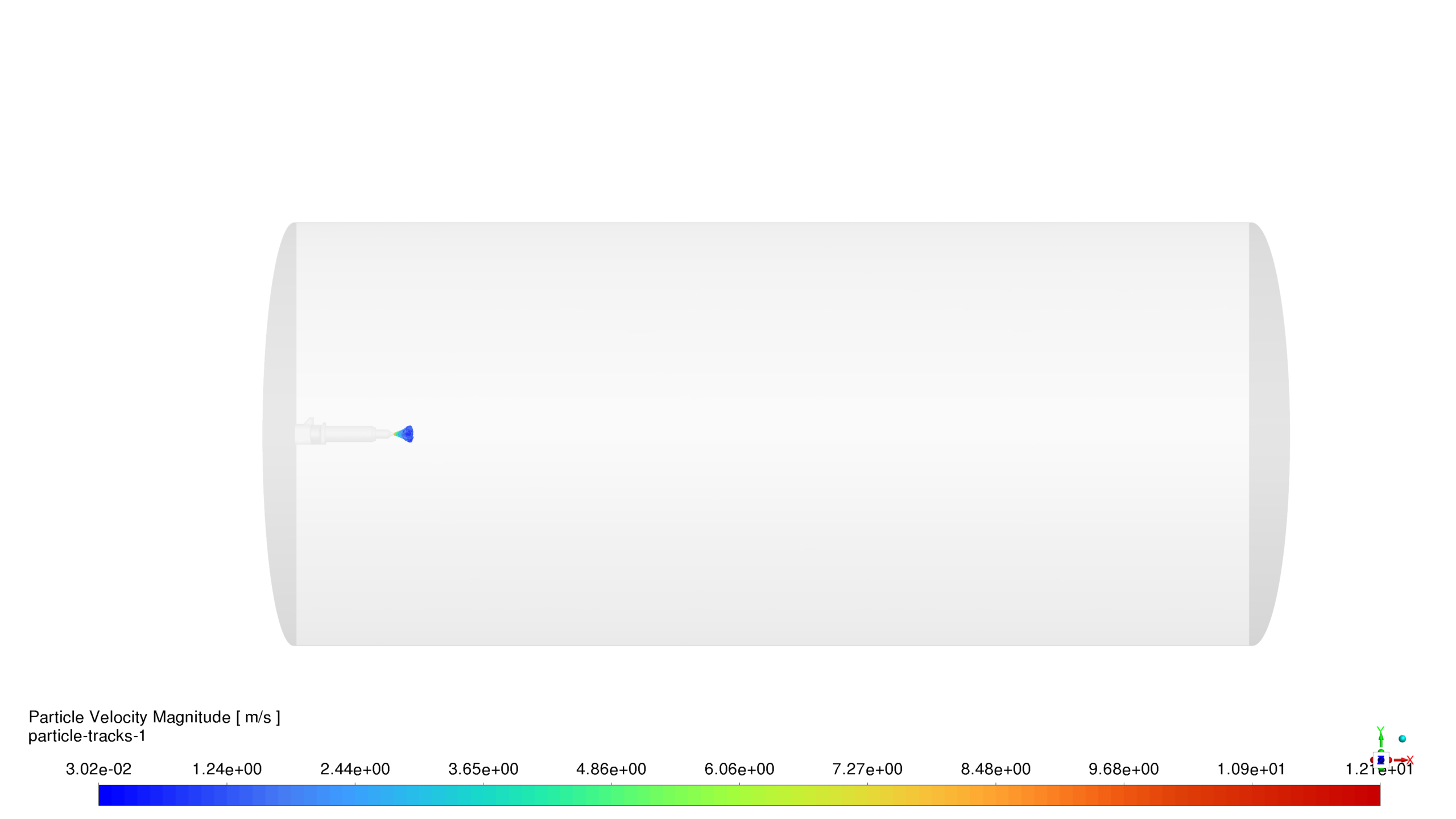

Velocity Contours: At both time steps, the velocity was highest near the nozzle exit and decreased as the spray propagated into the chamber.

Pressure Contours: The pressure distribution showed a high-pressure region near the nozzle, which dissipated as the spray expanded.

Droplet Diameter Distribution: The droplet diameter was small in the 500 bar injection case, indicating better atomization of the fuel. This is critical for efficient combustion and reduced emissions.

Animations: Animations were created to visualize the transient behavior of the spray. The animations clearly show the development of the spray, including the formation of vortices and the interaction between the droplets and the surrounding air.

Reviews

There are no reviews yet.