Injector CFD Simulation Training Package, 3 Projects by ANSYS Fluent

Original price was: $320.00.$249.00Current price is: $249.00. $124.50 Student Discount

- Master liquid-gas interaction modeling in fuel injectors with VOF techniques: Gain knowledge in turbulence modeling particular for high-speed injector flows.

- Apply sophisticated three-phase models involving air interactions, vapor, and liquid fuel with mixture techniques.

- Simulate correct compressible flow physics high-pressure diesel injection: diesel injection at high pressure, penetration length analysis.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Comprehensive ANSYS Fluent Injector Simulation Training

Overview of Injector CFD Simulation Training

This specialized training package delivers in-depth instruction on Computational Fluid Dynamics (CFD) simulation of fuel injectors using ANSYS Fluent. Designed for automotive engineers, combustion specialists, and graduate researchers, this comprehensive course combines theoretical foundations with practical simulation skills essential for modern injector design optimization and performance analysis.

Industrial Applications and Simulation Importance

Critical Role in Modern Engine Development

Fuel injectors represent critical components in internal combustion engines, directly influencing combustion efficiency, emissions formation, and overall engine performance. As emission regulations become increasingly stringent, advanced simulation capabilities are essential for developing next-generation injector technologies that optimize fuel atomization, mixing, and combustion processes.

Core Simulation Modules and Techniques

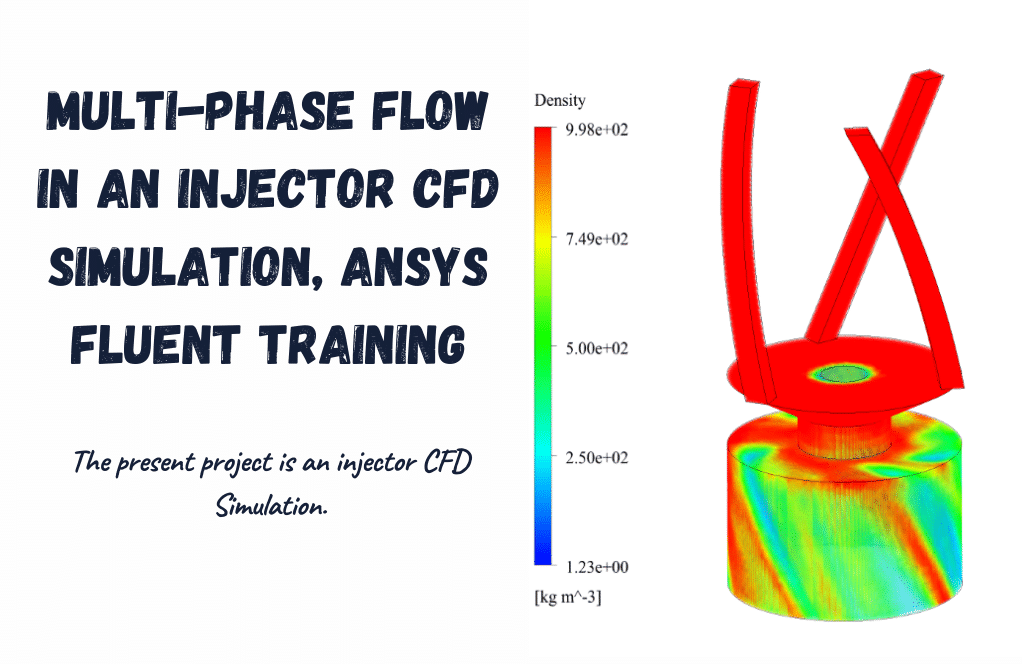

Two-Phase Flow Fundamentals in Injectors

The Multi-Phase Flow in an Injector CFD Simulation (Two-Phase) module establishes essential foundations for simulating the interaction between liquid fuel and surrounding gas. Participants will master various multiphase modeling approaches in ANSYS Fluent, including Volume of Fluid (VOF), Eulerian-Eulerian, and Mixture models. The course covers critical aspects such as:

- Geometric considerations for accurate injector nozzle representation

- Mesh generation strategies for capturing high-velocity gradients

- Boundary condition setup for pressure-driven and velocity-driven injection

- Turbulence model selection and wall treatment for high-speed flows

- Post-processing techniques for analyzing spray characteristics

Advanced Multi-Component Simulation

Three-Phase Flow Modeling Techniques

Building on two-phase fundamentals, the Fuel Injector CFD Simulation, Three-Phase Flow module addresses the complexities of systems involving liquid fuel, fuel vapor, and ambient gas interactions. This advanced module explores:

- Implementation of species transport models for multi-component fuels

- Phase change modeling for evaporation and condensation phenomena

- Interphase mass, momentum, and energy transfer mechanisms

- Droplet dynamics including breakup, coalescence, and dispersion

- Temperature-dependent property modeling for realistic fuel behavior

- Solution strategies for handling numerical challenges in three-phase simulations

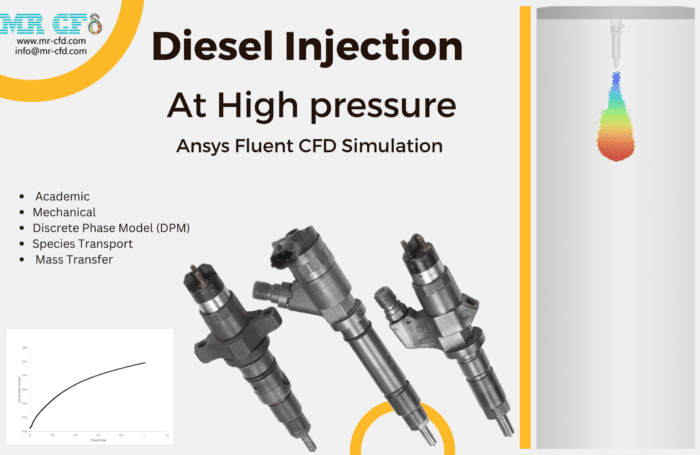

High-Pressure Injection Analysis

Diesel Injection Performance Evaluation

The Diesel Injection At High Pressure, Penetration Length Analysis module focuses on high-pressure diesel injection systems, which present unique simulation challenges due to extreme pressure differentials and complex rheological behavior. This specialized module covers:

- Compressible flow modeling for high-pressure injection conditions

- Cavitation modeling and its impact on spray formation

- Quantitative analysis methods for spray penetration length

- Parametric studies of injection pressure, nozzle geometry, and ambient conditions

- Validation techniques comparing simulation results with experimental measurements

- Correlation development between operating parameters and spray characteristics

Practical Implementation and Validation

Hands-On Simulation Methodology

Each module includes comprehensive step-by-step tutorials with prepared case files that guide participants through the complete simulation workflow. The training emphasizes practical approaches to:

- Geometry simplification and preparation for efficient simulation

- Structured and unstructured meshing strategies for injector components

- Solution initialization and stabilization techniques

- Convergence monitoring and troubleshooting

- Result interpretation and performance metric extraction

Learning Outcomes and Applications

Industry-Relevant Skills Development

Upon completion of this training package, participants will possess both theoretical understanding and practical skills needed to:

- Design and optimize injector geometries for improved atomization

- Predict spray characteristics under various operating conditions

- Evaluate the impact of fuel properties on injection performance

- Support engine development with accurate injector performance data

- Troubleshoot injection-related issues in existing engine designs

Each module provides foundation files, comprehensive documentation, and example cases that can be adapted to specific research or industrial applications, enabling immediate implementation of learned techniques.

Reviews

There are no reviews yet.