Bosch Common Rail Injector Simulation

Bosch Common Rail Injector Introduction and Purpose of the Case Study

The Bosch fuel injection system delivers the metered quantity at high pressure to mix with compressed air inside the combustion chamber for efficient combustion, And The Bosch Common Rail Fuel Injection System (Bosch CRS) is an innovative, efficient, and economic high-pressure injection technology that makes today’s vehicles more attractive than ever before.

The Bosch Common Rail System consists of a high-pressure pump, rail, and injector, that injects the precise amount of fuel into the combustion chamber at the right time and in quantity, this can be actuated with a solenoid on the injector, it control also the duration and timing by the ECU (Electronic Control Unit).

Features:

- Operates up to 2,050 bar pressure of injection equal to the weight of a sedan on the nail of a human.

- Multiple injections of up to 8/stroke

- Maintains the quality and performance

- Has undergone hydro-erosion machining process for intricate hole size that is equal to one-third the human hair diameter

- World’s most sophisticated typical rail diesel injector design

- Designed and engineered with every component representing a unique technology

An injector is a device used to atomize a liquid (decompose it into fine droplets), also the injector is simply a sprayer that converts a liquid stream into a spray, A comprehensive definition of an injector is a type of pump that converts the compressive energy of fluid into dynamic energy (velocity) using the venturi effect of a convergent-divergent nozzle. Other names such as atomizer and ejector (injector or nozzle) are also given.

Injectors are used when there is a need for rapid fluid injection, such as fuel injection in the combustion chamber or the need for a higher exchange rate with the surroundings. In general, an injector will be used whenever a controlled spray of fluid is desired.

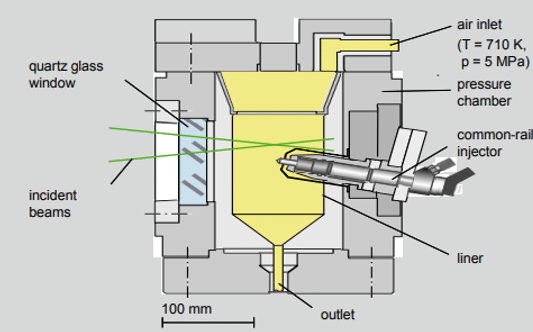

In this work, we will simulate a Bosch common rail injector, bosch common rail injector has seven holes, And other conditions are given, this is as follows, and a schematic of this injector is provided following figure:

- Injection pressure = 1600 bar

- Orifice diameter = 0.167 mm

- Injection profile is given

- Spray chamber:

- Airflow velocity = 0.05 m/s

- Air temperature = 710 K

- Air pressure = 50 bar

- Fuel: EN 590 summer diesel fuel

Figure 1: Bosch Common Rail Injector

Bosch Common Rail Injector Analyze the Experimental Setups: Injector

Common rail is a fuel injection system found in modern diesel engines, also the fuel is supplied to the engine under pressure with electronically controlled precision in common rail systems, it provides a level of flexibility that can be exploited for class-leading levels of emission control, power and fuel consumption.

Fuel is distributed to the injectors from a high-pressure accumulator in the common rail system, called the rail, a high-pressure fuel pump feeds the rail, also the pressure in the rail and the start and end of the signal that activates the injector for each cylinder are electronically controlled. Advantages of the common rail system include flexibility in controlling the injection timing and injection rate.

Cavitation is expected in this injector under the high injection pressure in most of the injection duration.

The typical discharge coefficient for this injection condition is 0.7 ~ 0.8.

- The initial jet diameter should be smaller than the nozzle diameter

- Injection velocity can be computed from the injection pressure and the discharge coefficient

Analyze the Experimental Setups: Fuel

This section discusses the fuel used and its components, diesel fuel is any liquid fuel specifically designed for use in a diesel engine, a type of internal combustion engine in which fuel ignition takes place without a spark due to compression of the inlet air and then fuel injection. Therefore, diesel fuel needs good compression ignition characteristics. Most people usually use a single component to represent the natural diesel fuel.

Species to represent the diesel fuel:

n-heptane (C7H16):

- Diesel fuel contains a large percentage of n-heptane

- n-heptane is a good choice for diesel fuel combustion;

- n-heptane has very different evaporation characteristics from the real diesel

fuel, so it is not appropriate for diesel spray study

n-dodecane (C12H26): Cummins model

n-tridecane (C13H28): UIUC model

n-tetradecane (C14H30): UW model

Multi-component fuel model

Analyze the Experimental Setups: Ambient

- Airflow velocity = 0.05 m/s

- Air temperature = 710 K

- Air pressure = 50 bar

- Low air velocity => jet will go almost straight in injection direction

- Under 710K, the evaporation rate is high

- The air density is pretty high + high injection pressure => fast atomization

- Breakup length should be short

- Droplet deceleration rate could be high => RT breakup is important

- The spray chamber condition is similar to typical diesel in-cylinder spray

- Spray angle is rough 9~10

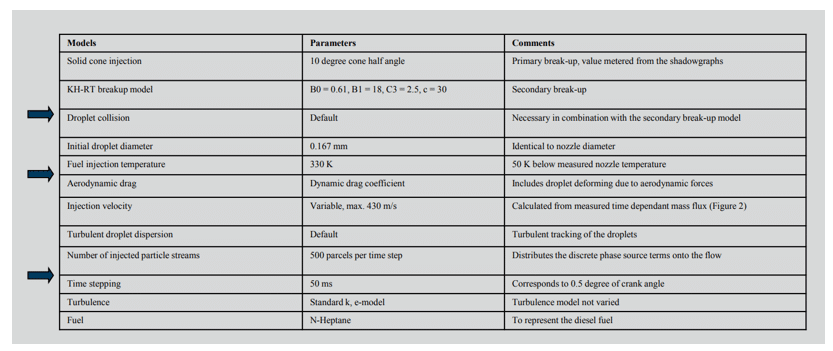

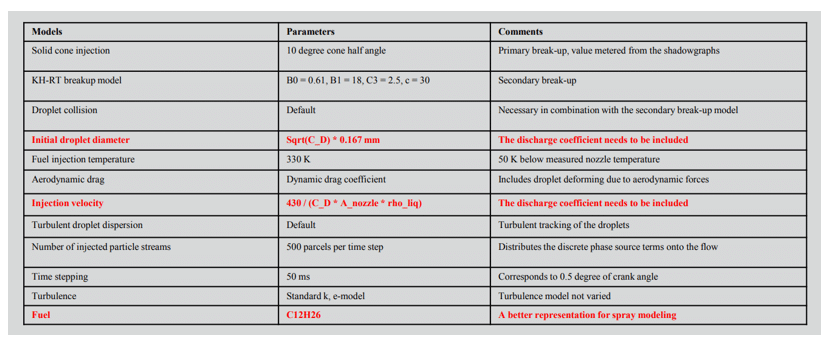

Model Settings by the Authors

And the improved model settings in this model are as following figure:

As you can see in the tables above, a series of rows have been modified with different colors.

In this work, the solid cone injection method has been used for the injection, the wave model is appropriate for high-speed injections, where the Kelvin-Helmholtz instability is believed to dominate droplet breakup ( ). Because this breakup model can increase the number of computational parcels, you may initially wish to inject a modest number of droplets.

In the KH-RT breakup model, B0, B1, C3, and c equal 0.61, 18, 2.5, and 30, respectively.

Where B0 and B1 are model constant breakup time constant, respectively.

Due to the comments, we used the secondary breakup where ANSYS FLUENT offers two droplet breakup models: the Taylor analogy breakup (TAB) model and the wave model, the TAB model is recommended for low-Weber-number injections and is well suited for low-speed sprays into a standard atmosphere, for Weber numbers greater than 100, the wave model is more applicable. The wave model is popular for use in high-speed fuel-injection applications.

Also, set the droplet collision in the form of default and change the initial droplet diameter.

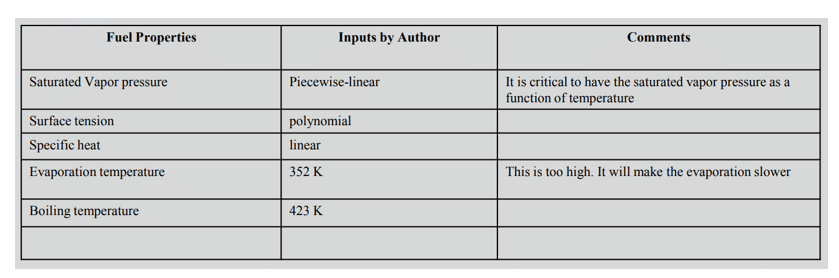

Change the injection velocity and fuel type to C12H26 better representation for spray modeling, the injected particle streams are 500 parcels per time step, and the time-stepping injection is 50 ms, you can see the fuel specifications in the following table:

Where in fuel property, inputs by author and description are given.

To define a piecewise-linear function of temperature for a material property, do the following:

In the Create/Edit Materials dialog box, choose piecewise-linear in the drop-down list to the right of the property name, therefore the Piecewise-Linear Profile dialog box will open automatically.

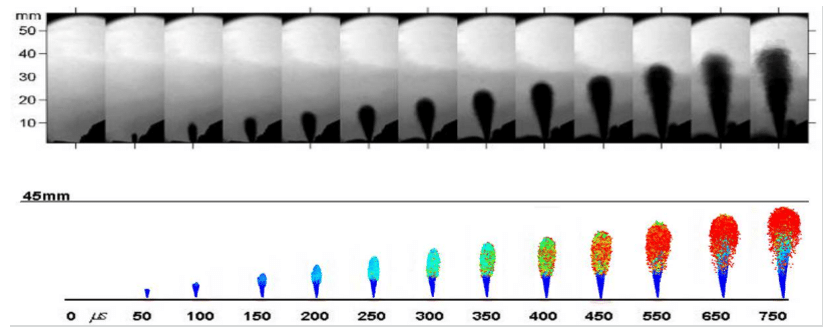

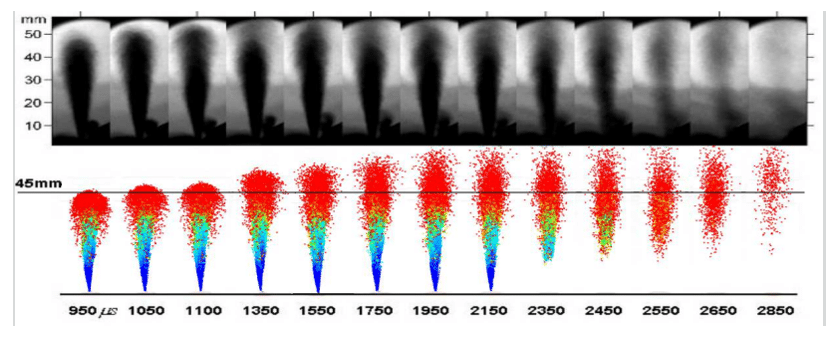

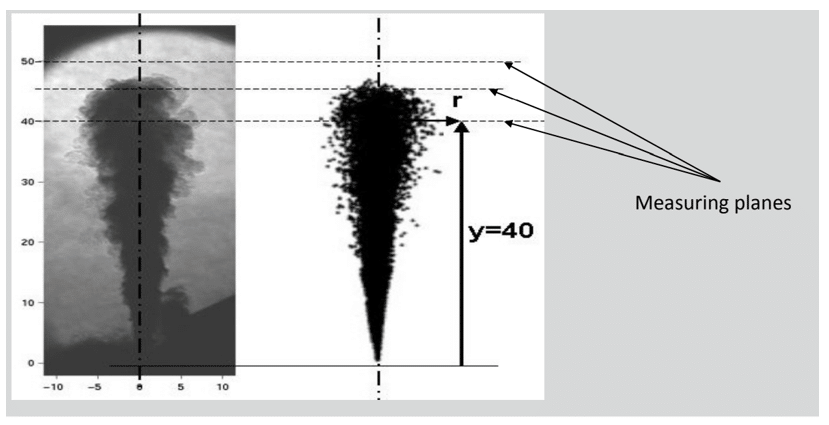

Analyze the Results: Shape of the spray

According to the following simulations, the shape of the spray was as follows:

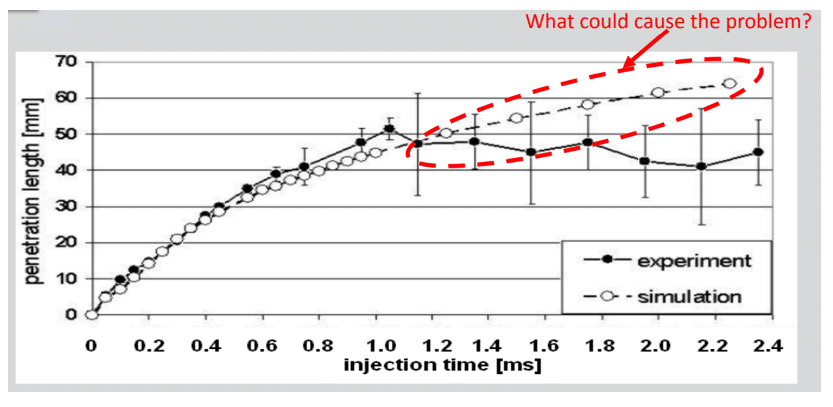

Analyze the Results: Penetration Length

As you can see in the figure below, The model prediction of the progression of the spray penetration length in time is compared with experimental data. The comparison indicates that the model until 1.4 ms Simulation and experimental model have less error than each other, but the error increases from 1.4 ms onwards.

The conclusions we can draw from this chart are as follows:

Observation of the penetration length

- The predicted penetration length grows almost linearly with time at the beginning, which agrees well with the experimental data

- The predicted penetration length is growing without reaching a “steady-state” condition, while the experimental data shows an obvious steady-state penetration length

- Question: Why should we expect the penetration length to become steady-state in this case?

- Question: Under what conditions the penetration length cannot reach

steady-state condition?

- Possible reasons for the mismatch:

- The definition of the penetration length is wrong

- The atomization or evaporation is not correctly predicted

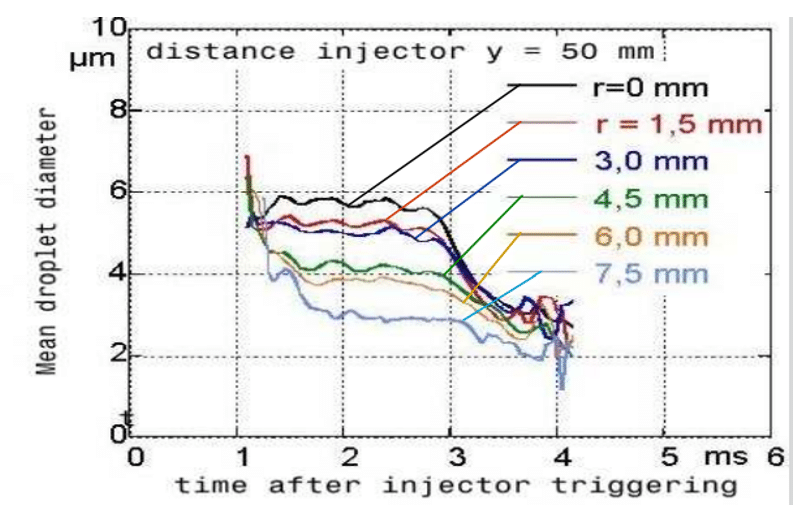

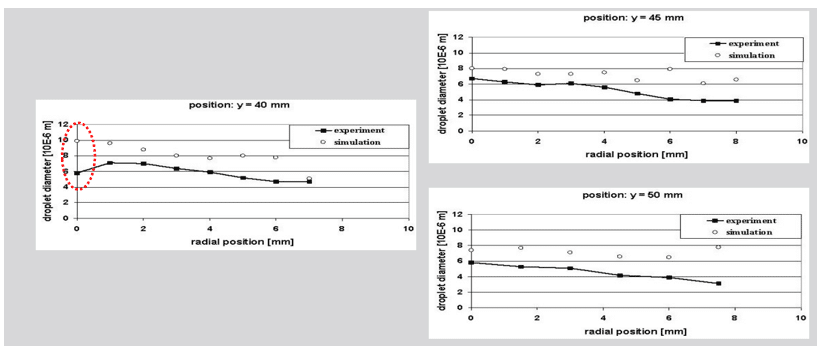

Analyze the Results: Drop Size Distribution

- Observation:

- Drop size reduces from the center

- Drop size drops significantly at the beginning of the injection and remains almost constant till the end of injection.

Comments (0)