DPM Spray Modeling in 5 steps

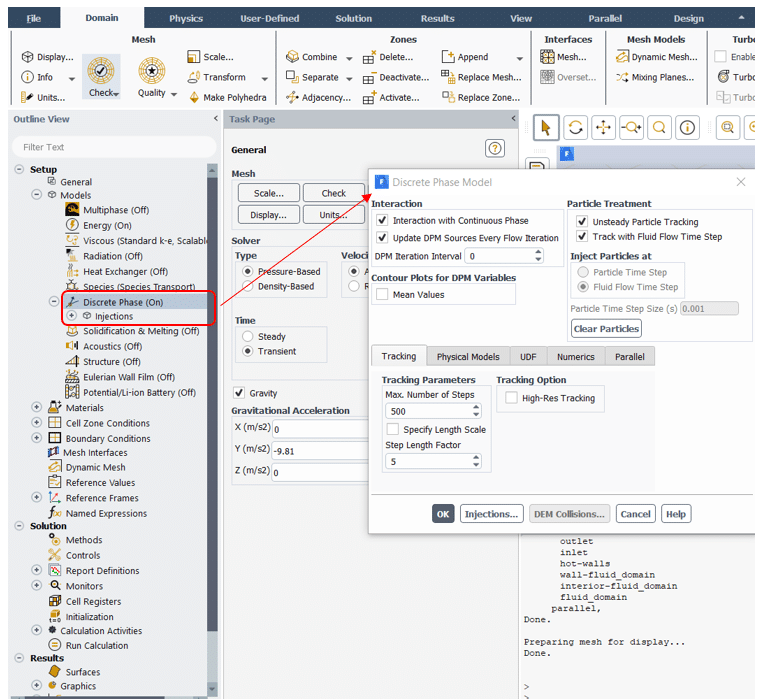

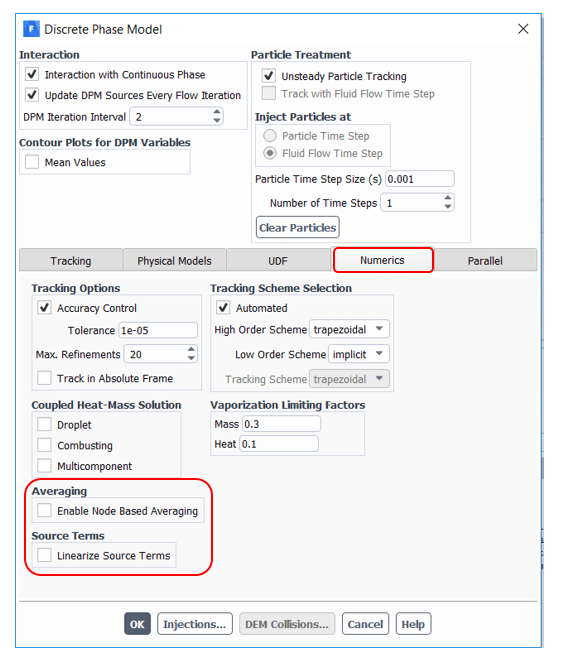

In this article, we present the main steps through simulating spray modeling using DPM, in 5 steps, from general settings to post-processing and also you can see useful tips. To start with, select the Discrete phase in the Models tab of ANSYS Fluent software; so you can set the general settings in the appeared window(Figure 1).

Figure1

Step I: General settings

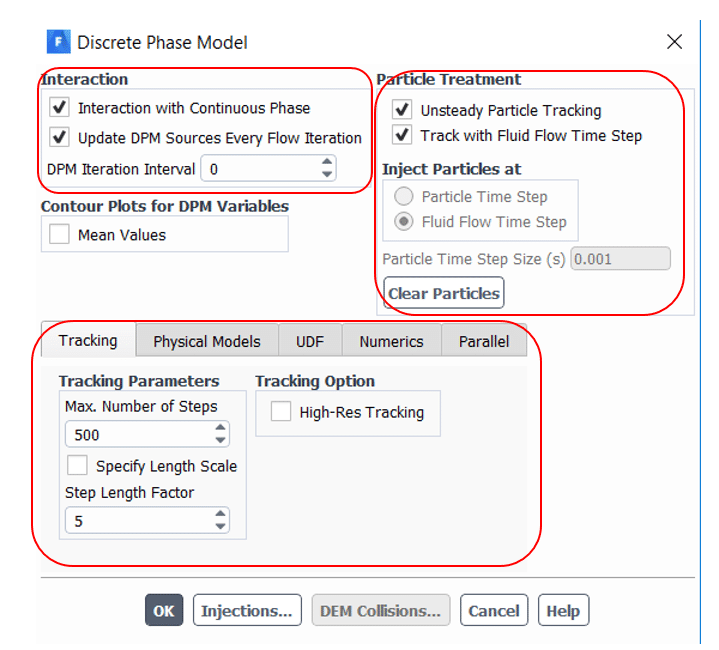

You can see in figure 2 that the first window consists of three main parts, including the Interaction part, the Particle treatment part, and several tabs relating to more details. We will delve into them separately.

Figure 2

- Interaction

Its title introduces this section which refers to the assumptions that need to be made for interaction between continuous flow and particles.

- Interaction with Continuous Phase

If we want to consider the mutual influence of particles and continuous flow on each other, We need to activate it. This type of simulation is known as two-way coupling.

- Update DPM Sources Every Flow Iteration

it activates by default in transient simulations; therefore, the DPM sources update after each flow iteration. On the other hand, to update DPM sources after any desired flow iterations, you can use DPM Iteration Interval. it is recommended to use a larger number in steady-state simulations for more stability.

Tracking

- Number Of Steps: We can use in steady-state simulations to define the maximum number of time steps to follow particles if they remain in the fluid domain. The higher number results in better convergence, and 500 to 2000 is recommended.

- Step Length Factor: You can use to control time step size for the motion of the particles. The smaller value results in higher accuracy of trajectory.

- Particle Treatment:

- Unsteady Particle Tracking: It activates by default in transient simulations, it means the particles tracking equations solve in unsteady form as well as the continuous phase.

- Track With Fluid Flow Time Step: By activating this option, the time step size of the discrete phase equals the time step size of the continuous phase, the other choice is to define Particle Time Step Size In addition, you can set particles injection time at “Inject Particles at”; it should be coordinated with the Particle time step or Fluid flow time step.

*** Tips

In DPM modeling, three main time steps exist: the Flow time step used to solve continuous phase, the Particle time step used to solve particle equation, and Injecting time step, which refers to the injection of particles, in general, it isn`t necessary to define values for each time step unless we want to use the transient simulation for it.

The configurations depend on our simulation state. To categorize them, we need to consider state-state simulation and unsteady-state simulation.

- Steady-state simulation: You need to define Two parameters. First, the Number of continuous phase iterations per DPM iteration means injecting particles after every defined iteration, secondly, Particle time step size that is the time step size for particle integration.

- Unsteady-state simulation: There are two available options. Use particle time step size to inject particles at every particle time step or use fluid flow time step to inject particles at every flow time step.

- Smaller time steps result in more accurate simulation and prevent divergence in special problems with fast injection velocity, small drop size, sudden changes, etc.

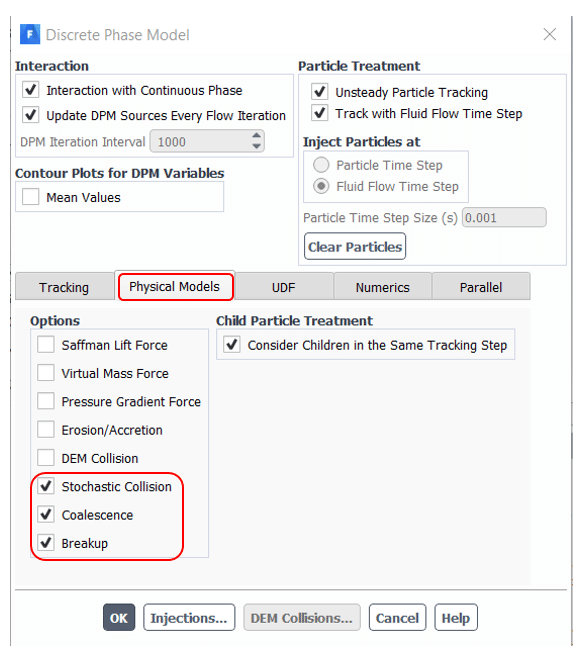

Step II: Discrete Phase Model=> Physical Models

&

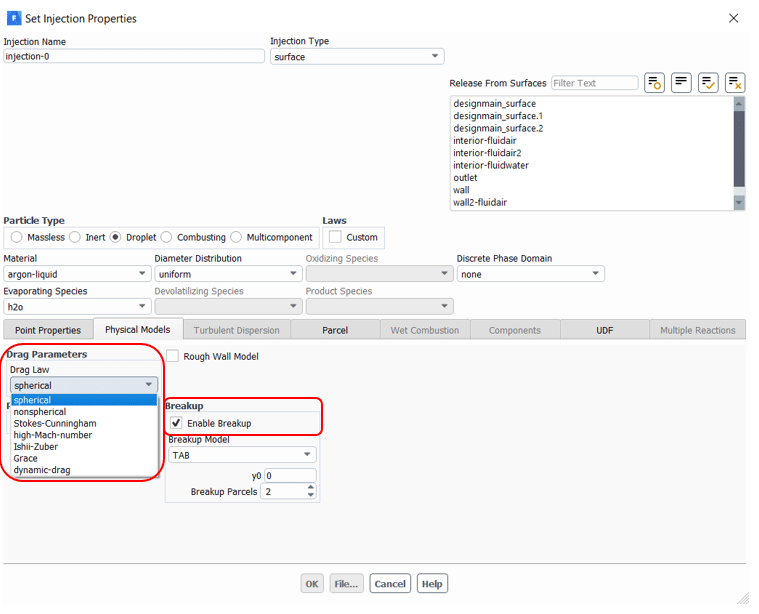

Set injection Properties=> Physical Models

In the Physical Models part, you need activate three options:

Stochastic Collision & Coalescence

Fluent provides an alternative in simulations that tracking droplets is vital to estimate the number of collisions between particles. The more particle collision, the more computational cost.

Breakup

It provides options in the injection part to control droplet breakup. Only available with unsteady-particle tracking.

Enable Breakup

4 different options. TAB model is applicable to many engineering spraying. It is based upon Taylor`s analogy.

Drag Law

It contains several options. By choosing Spherical, the particles assumes to have a spherical shape.

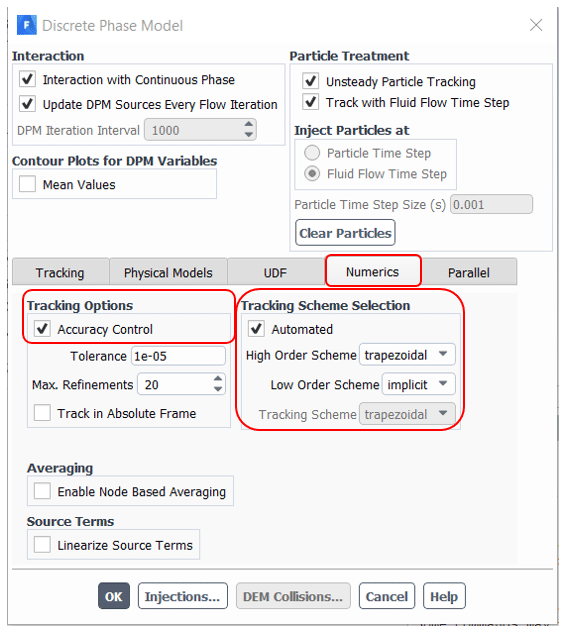

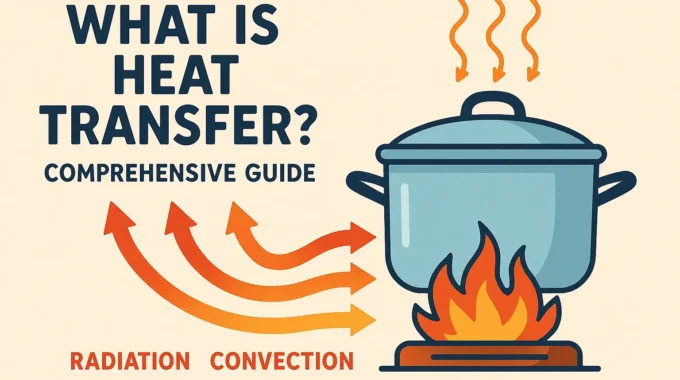

Step III: Discrete Phase Model=> Numerics

This section provides settings to control tracking particles and heat and mass transfer equations.

Tracking Options, Accuracy Control: It controls the integration of the particle equation and keeps the errors within the specified tolerance.

Tracking Scheme Selection: We need choose two schemes. One is for Higher-Order Scheme between Trapezoidal and Runge-Kutta and the other for Lower Order Scheme between Implicit and Analytical. The solver will automatically switch between higher-order and lower-order schemes based on the stability range of each scheme.

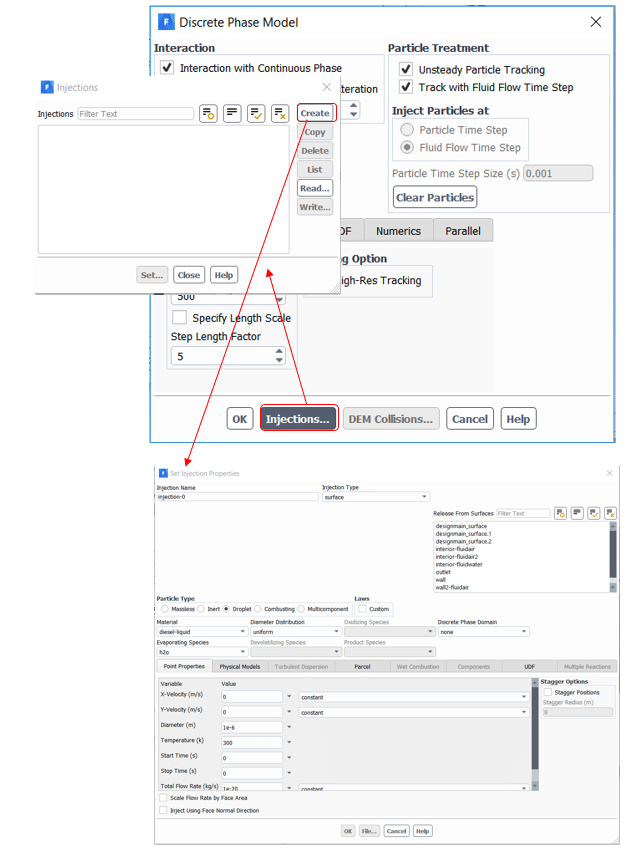

Step IV: Discrete Phase Model=> Injection

All settings related to injection of particles are available in the appeared window, including particle type, particle material, velocity, diameter, etc.

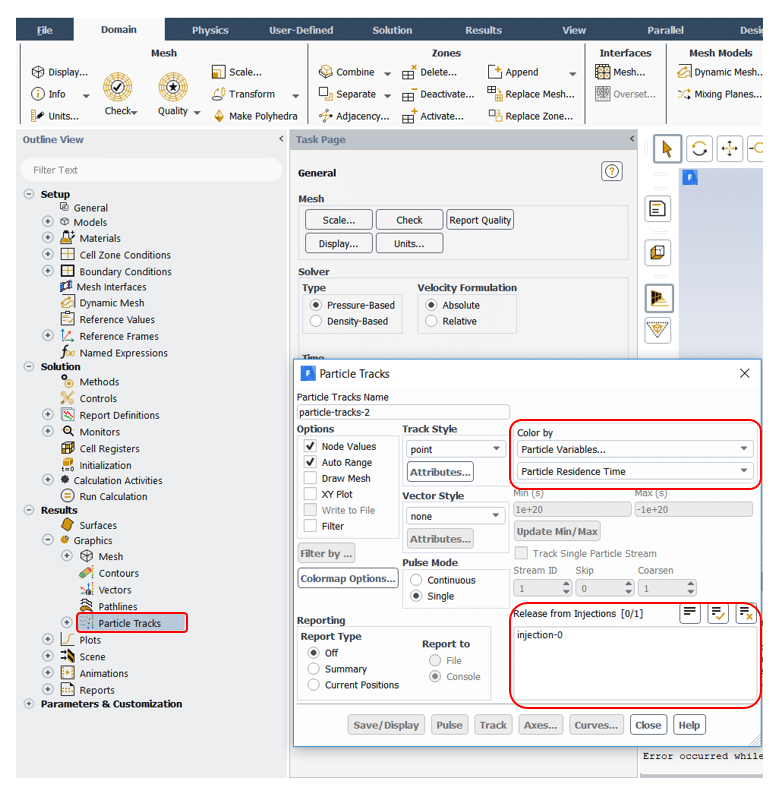

Step V: Post-Processing

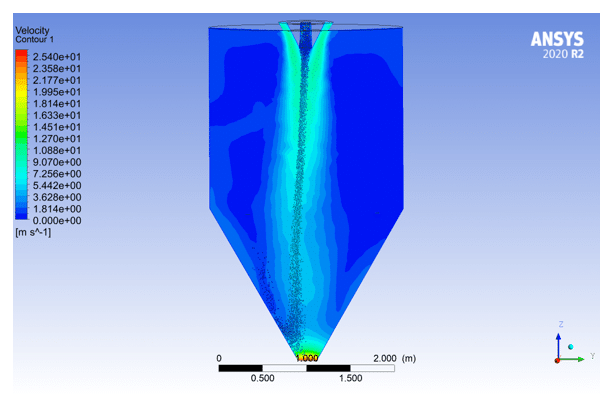

In most DPM spraying simulations, the behavior and changes of particles during the motion and effects of continuous phase on them are our field of interest, in some cases, the continuous phase could be important as well.

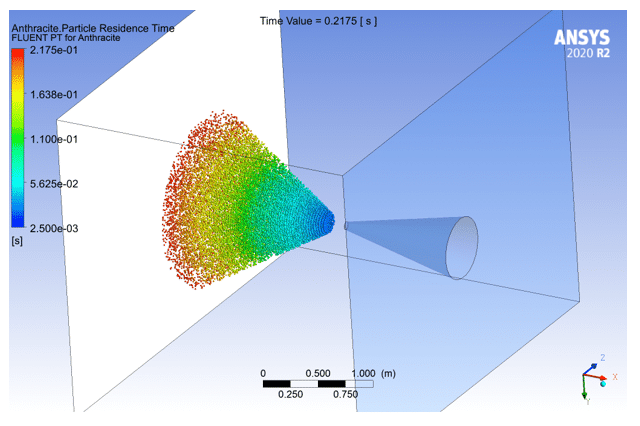

Fortunately, Ansys Fluent provides a separate part in the graphics section to track particles as well as possible (Graphics=> Particle Tracks). It shows in the below picture, every particle released from every injection displays by different variables, including particle diameter, particle residence time, velocity, temperature, etc. Each of them has its specific usage. For example, to monitor drop size, we need to use particle diameter, or when we want to figure out how long it takes for the particles to leave the domain, we need to check resistance time. Despite all these features, UDF is necessary for many desired variables like drop size distribution, penetration length, etc. It depicts one of the export results of simulations and discussed below ( click on links for more information).

One of the essential variables in DPM simulations is penetration length which presents the length from inlet to where the mass of the particle beyond that is less than 10% of the total mass in the domain.

Notice that, It wrongly defines as the distance from the inlet to the farthest particle in some articles.

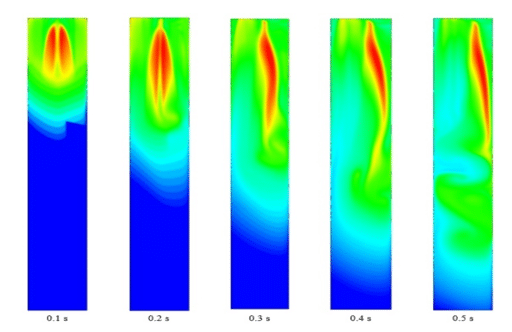

As it said before, it needs UDF for accurate results, but as a simple way, the particle’s residence time, you can investigate and track manually in different time steps .

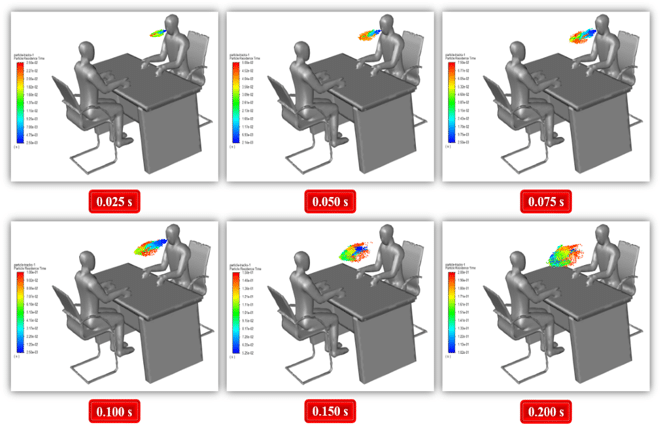

For example, consider a case simulating a person behind a desk and an infected customer, the injected coronavirus particles should be followed by displaying contour in different time steps. Check the contour below.

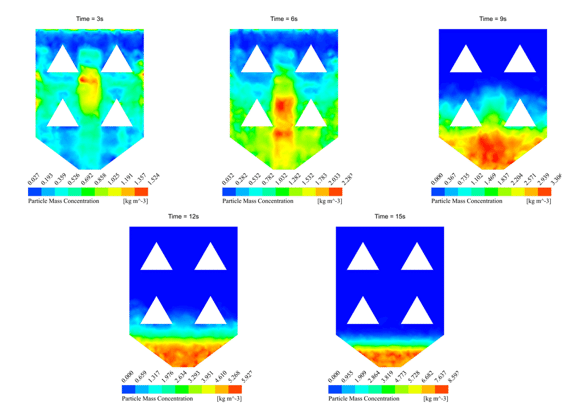

Particle concentration mass is another vital variable that shows where the particles are located after a while. It becomes very handy when simulation aims to predict sedimentation zone or, like the below example, how to design geometry to keep the particles in the vicinity of hot zones after injection to increase evaporation process.

The particle residence time is shown in the below contour related to the color spraying simulation. It depicts how long the injection of particles lasts in the domain, obviously, the particles injected sooner, the more they last in the air.

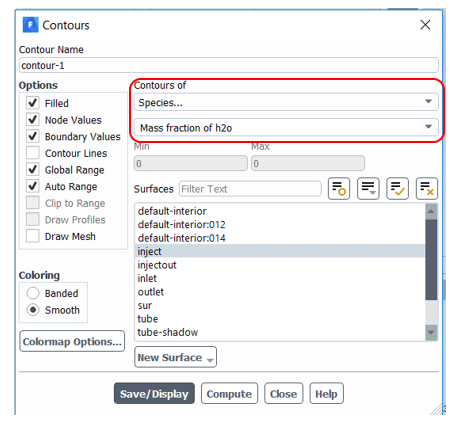

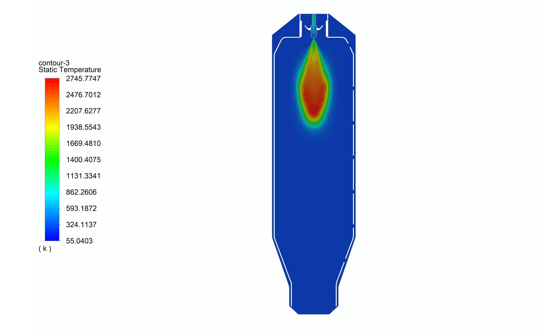

The continuous phase results are also available in Graphics=> Contour. Standard variables used in every simulation exist, and when temperature distribution or vaporization process and spray-induced flow need to be investigated, It is essential to display contours of species as well, here are some examples of exported continuous phase contours.

Surface Evaporation of a Water Droplet: Vapor Mass Fraction

*** Tips About DPM:

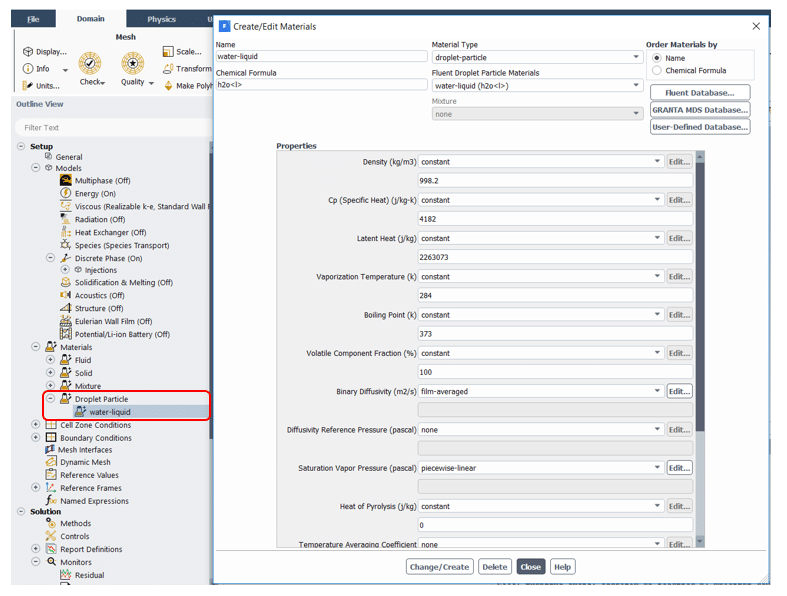

- To simulate the evaporation process of droplets, we need to consider the thermophysical properties of Material accurately, saturation vapor pressure, Binary diffusivity, latent heat, boiling point, and specific heat , these parameters are accessible in the Materials section(check the figure below), notice that the droplet’s evaporation temperature should be higher than the particle’s injection temperature. So the temperature of particles must reach the evaporation temperature firstly to start vaporizing.

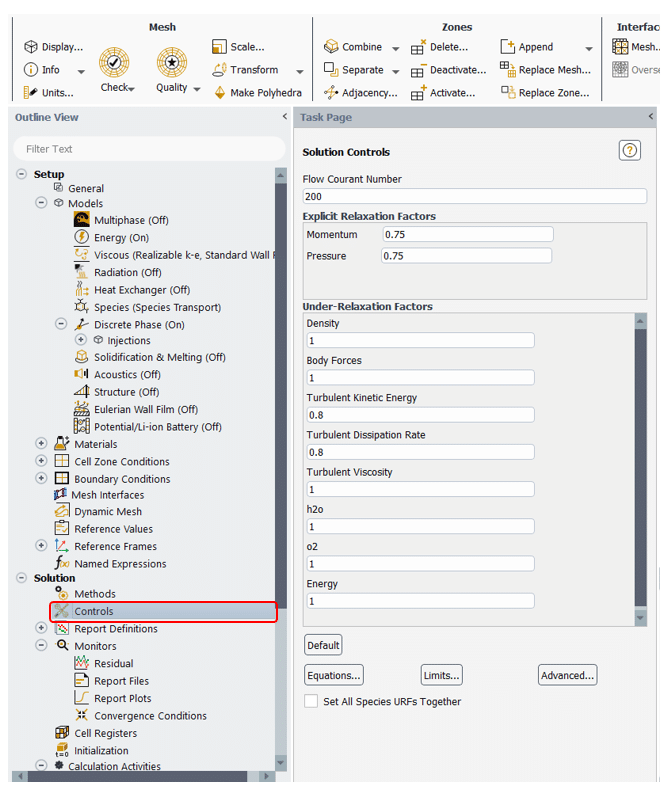

To control the instability of the solution, we need to define proper under-relaxation factors located in the Solution=> Control part(figure below). Default values are acceptable in most cases unless the solution becomes unstable and doesn’t reach a satisfying convergence. It means the residuals should be less than 10e-3 except for energy, radiation, and mixture fraction that should be less than 10e-6.

start the calculation by default values, and if the solution becomes unstable, lower the values and continue the calculation, in addition, it is better not just to follow the residual values but to monitor variables of interest.

The convergence problem mainly causes by high source terms generated in cells. You can solve by using the node-based averaging method or trying source term linearization, the linearization process for momentum, energy, and also you can boost species by activating Linearize Source Terms in the Numerics Furthermore, if there is no mass transfer, you can use along with Node Based Averaging. It spreads a load of DPM source into neighboring cells by collecting data on mesh nodes. As a result, it reduces grid dependency and improves convergence in steady-state simulations, you can see these items in the figure below.

Comments (0)