CFD Project Outsourcing

Outsource your CFD project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including CFD Consultant, CFD Training, and CFD Simulation.

The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is the Dense Discrete Phase Model (DDPM)?

The dense discrete phase model (DDPM) is a Lagrangian parcel-based approach that models particle collisions and uncorrelated translations using the kinetic theory of granular flows (KTGF). This approach has numerous advantages over the Eulerian two-fluid model (TFM). These include better resolution of particle clusters and bubbles, more natural incorporation of particle size distributions, and better handling of crossing particle jets/clusters. In this study, results from the DDPM are compared to dedicated experiments and TFM simulations over a wide range of fluidization velocities, particle sizes, and bed loadings. Special attention was given to ensure that the frictional effects typical of such dense particle flows are accounted for. The DDPM proved capable of reproducing the excellent fit to experiments achieved by the TFM on a significantly coarser mesh.

The Dense Discrete Phase Model (DDPM) is an extension of the Discrete Phase Model (DPM), which is used in simulations of computational fluid dynamics (CFD) to represent the motion and behavior of dense particle-laden flows. The Dense Discrete Phase Model (DDPM) is an example of an extension of the DPM. DDPM is a Lagrangian technique, like DPM, but it contains extra models for the effects of particle-particle interactions, particle collisions, and inter-phase momentum transfer. DDPM is analogous to DPM in this regard.

In DDPM, the particles are represented as separate entities that interact with the flow of the fluid and with one another through drag, lift, gravity, and contact forces. These interactions take place in the framework of DDPM. The motion of the particles is governed by equations of motion, which take into account the consequences of particle-particle collisions in addition to the forces acting on the particles themselves. Although the particles are assumed to be spherical and have a constant size, the model can also be modified to accommodate non-spherical particles.

In DDPM, the particles are represented as separate entities that interact with the flow of the fluid and with one another through drag, lift, gravity, and contact forces. These interactions take place in the framework of DDPM. The motion of the particles is governed by equations of motion, which take into account the consequences of particle-particle collisions in addition to the forces acting on the particles themselves. Although the particles are assumed to be spherical and have a constant size, the model can also be modified to accommodate non-spherical particles.

Simulations of industrial processes involving dense particle-laden flows, such as fluidized bed reactors, cyclone separators, and pneumatic conveying systems, frequently use DDPM as a modeling and simulation tool. DDPM can provide insights into the distribution, concentration, and velocity of particles in a flow by modeling the behavior of dense particle-laden flows. These insights can be utilized to optimize the Design and operation of industrial processes.

One thing holding DDPM back is that it can be pretty expensive to compute, particularly for large-scale simulations involving many particles. To get over this constraint, DDPM is frequently combined with other modeling strategies, such as the Eulerian-Eulerian or Eulerian-Lagrangian approaches, which simulate the fluid flow and the particles at the same time. This allows for a more accurate representation of the whole system.

What is the Discrete Element Method (DEM)?

The discrete element method (DEM) is intuitive in which discrete particles collide with other surfaces during an explicit dynamic simulation. Typically, each DEM particle represents a separate grain, tablet, shot peen, etc. DEM does not apply to situations in which individual particles undergo complex deformation. Therefore, DEM is, conceptually, more straightforward than the smoothed particle hydrodynamic (SPH) method in which groups of particles collectively model a continuum body. For example, DEM is well-suited for particle mixing applications. In this application, DEM models the initially separated blue and white particles, and rigid finite elements are used to model two mixing augers and the box-shaped container. Another example of using DEM for a mixing application is described in the Mixing of granular media in a drum mixer.

The Discrete Element Method (DEM) is a numerical modeling technique that is used in Computational Mechanics to mimic the behavior of granular materials, such as powders, grains, and soils, as well as other complex systems, such as colloids, foams, and biological tissues. DEM is also used to describe the behavior of colloids, microscopic particles that make up biological tissues. The discrete element method (DEM) is a particle-based technique, which means that rather than modeling the system as a continuous medium, it simulates the behavior of the system’s constituent particles at the individual level.

In DEM, the particles are modeled as discrete entities, and their interactions with one another are modeled as contact forces. These contact forces include normal, tangential, and frictional forces. Equations of motion, which consider the locations and velocities of the particles as well as the forces that act on them, are responsible for determining how the particles move about in space. Depending on the purpose of the modeling, the particles can be represented by either rigid or deformable bodies.

In geotechnical engineering, where DEM is used to predict the behavior of soils and rocks, simulations of industrial operations involving granular materials, such as powder handling, Mixing, and transportation, are popular applications for DEM. DEM can provide insights into the flow and deformation of granular materials and the production of structures and patterns, such as arches, bridges, and shear bands.

One of the drawbacks of DEM is that it can be costly to compute, particularly for large-scale simulations involving many particles. This constraint is typically circumvented by combining DEM with other modeling approaches, such as the Finite Element Method (FEM) or Computational Fluid Dynamics (CFD), which simulate fluid flow or the solid structure surrounding the granular material. Another way to circumvent this problem is to employ a higher-resolution DEM.

How can DDPM and DEM be applied in CFD simulation Engineering?

Dense Discrete Phase Model (DDPM)

DDPM is a method utilized in Computational Fluid Dynamics (CFD) to simulate the behavior of a continuous fluid phase containing a high concentration of discrete particles. This approach expands upon the conventional Discrete Phase Model (DPM) by incorporating the volume fraction of the particles. This enables the simulation of turbulent particle fluxes, which have the potential to influence the fluid flow field as a result of substantial heat, momentum, and mass transfer between the phases.

Implementations in CFD

Multiphase Flows

DDPM is utilized to simulate multiphase flows characterized by densely distributed particulates, including fluidized beds, sediment transport, and pneumatic conveying systems.

Heat Transfer

DDPM is capable of incorporating the thermal interactions that occur between solid particles and the fluid in systems where solid particles are involved in heat transfer.

Reactions

DDPM can be utilized to analyze chemical engineering processes involving significant particle-to-particle interactions, such as catalytic reactors or combustion systems.

Discrete Element Method (DEM)

DEM is a numerical method for simulating the behavior of particulate system assemblies. It computes the motion and interactions of a substantial quantity of particles, encompassing phenomena such as friction, cohesion, and collisions.

Implementations in CFD

Granular Flow Analysis

DEM is widely employed in numerous engineering disciplines, including pharmaceuticals, agriculture, and mining, to simulate the behavior of granular materials.

Equipment Design

It facilitates the optimization and design of equipment, such as mixers, conveyors, and hoppers, that handle particulate materials.

Coupled CFD-DEM Simulations

DEM can be utilized in conjunction with CFD to generate a comprehensive simulation of fluid flow and particle dynamics for systems in which fluid-particle interactions are crucial.

Implementing DDPM and DEM in CFD

Define the Problem

Concisely outline the engineering problem, encompassing the physical phenomena that require modeling, the fluid and particle properties, and the boundary conditions.

Model Selection

Determine the relative significance of particle-particle interactions and particle concentration when deciding between DDPM and DEM.

Software Setting

Employ CFD software, such as ANSYS Fluent, which possesses functionalities for both DDPM and DEM that support both techniques.

Meshing

The objective is to generate a computational mesh that strikes a balance between capturing crucial flow characteristics in a fine-grained manner and maintaining a reasonable computational cost.

Boundary Conditions

Establish suitable boundary conditions for the fluid and particulate, taking into account pertinent interfaces such as inlets, outlets, walls, and other significant locations.

Solver Configuration

Establish the appropriate physical models (e.g., heat transfer and turbulence) and configure the coupling between the discrete particles and the fluid phase.

Simulation

Execute the simulation while verifying the physical plausibility and convergence of the results.

Post-processing

Conduct an examination of the simulation outcomes in order to acquire a deeper understanding of the fluid-particle interactions, flow patterns, and particle distributions.

Validation

To ensure the veracity of the simulation results, compare them to experimental data or established benchmarks.

Conclusion

DDPM and DEM provide engineers with potent instruments for simulating intricate particulate systems within a fluid. Engineers can redesign and optimize systems in a variety of sectors, including energy production and pharmaceuticals, by comprehending the capabilities and limitations of each technique.

MR CFD services in the DDPM and DEM Simulation for Engineering and Industries

With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, the MR-CFD team is ready to offer extensive modeling, meshing, and simulation services. Simulation of using magneto-hydrodynamic (MHD) body force for increasing the performance of cyclone

The following Project simulates an hourglass using DEM and DDPM models:

An Hourglass equipped with a DPM model was simulated for this research, and the results of that simulation were analyzed with the help of the ANSYS Fluent software. This CFD project is carried out, and a CFD investigation is carried out. The current model was created in SpaceClaim utilizing the three-dimensional modeling software.

The DPM model was utilized in this study as part of the investigation of the hourglass simulation. Using the Ansys Fluent program, we could also monitor the path the particles took inside the hourglass. Although the DPM strategy for CFD solutions is an excellent way to lower the costs of computing particle flow studies, this approach does not provide valid answers when simulating dense particles in concentrations more significant than 10% by volume.

This technique is predicated on an explicit numerical algorithm that analyzes particles’ interaction by analyzing the particles’ contact and motion. The user of the DEM model can consider the motion of particles as the mass of a moving point, which considers the particles’ shape and volume. This is made possible by the DEM model’s ability.

In addition, an injection-style file was utilized to deposit 92,000 particles into the hourglass in no time. In addition, the equations describing fluid flow are solved by employing the laminar model. After the simulation, the values for the particle tracking in the hourglass are retrieved, and the animation is then appended.

DDPM and DEM in ANSYS Fluent

A concise synopsis of each model and their customary implementations within the Fluent simulation environment is provided below.

Discrete Phase Model (DDPM)

In ANSYS Fluent, the behavior of discrete solid or liquid elements within a continuous fluid phase is simulated using the Discrete Phase Model. An expansion of the Discrete Phase Model (DPM), this model proves to be especially advantageous in situations involving a comparatively high particle volume fraction and the inability to disregard particle interactions.

Important Characteristics of DDPM:

- Considers particle-particle interactions.

- Appropriate for fluxes containing dense particles in which the volume fraction is significant.

- This principle can be integrated with the continuous phase to consider heat, momentum, and mass transfer.

- It is frequently implemented in fluidized beds, cyclone separators, and pneumatic conveying, among other applications.

Discrete Element Model (DEM)

It is essential to simulate systems in which particle interactions are significant using the Discrete Element Model in ANSYS Fluent in order to predict granular flow behavior. DEM is frequently employed in conjunction with DDPM when the system’s prevalent factor is particle-particle interaction.

The fundamental attributes of DEM:

- An exhaustive exposition of particle-particle and particle-wall interactions is furnished.

- Capable of simulating the mechanical properties of granular substances.

- Capable of capturing particle clustering, blending, and segregation.

- Widely employed in sectors involving the processing of powders, bulk materials, and particulate systems.

DDPM and DEM Integration

The integration of the DDPM and DEM in ANSYS Fluent offers a comprehensive instrument for simulating particle flow. This integration enables the simulation of flows containing a significant concentration of particles, in which an accurate representation of the physics requires consideration of both the hydrodynamic and mechanical interactions between particles and the fluid phase.

Typically, when configuring a simulation using DDPM and DEM in ANSYS Fluent, the following steps are required:

- The material properties of the particles and the fluid are to be defined.

- Configure the initial and boundary conditions for both phases.

- Select suitable physical models to represent inter-phase interactions, such as heat transfer and drag force.

- The DEM parameters, including the contact models and coefficients for adhesion, friction, and restitution, should be specified.

- Initialize the simulation and execute it with an adequate number of iterations or time steps in order to achieve a converged solution.

Bear in mind that the intricacy of these models frequently necessitates meticulous calibration and validation in comparison to experimental data in order to ascertain the accuracy and dependability of the simulation outcomes.

DDPM and DEM MR CFD Projects

In certain circumstances, demisters made of wire mesh can also be utilized to filter solid particles out of a gas stream. The wire mesh can function as a filter by capturing the particles brought into contact with it as they move through the mesh. However, the efficiency of wire mesh demisters for particle separation and filtration depends not only on the size and properties of the particles but also on the flow rate and other operating parameters. Wire mesh demisters are most commonly used in laboratories and industrial settings.

Demisters made of wire mesh are frequently utilized in many industrial applications, including processing oil and gas, processing chemicals, and managing air pollution. In these situations, wire mesh demisters can clean gas streams by filtering out liquid droplets and solid particles, enhancing product quality, cutting emissions, and safeguarding subsequent equipment.

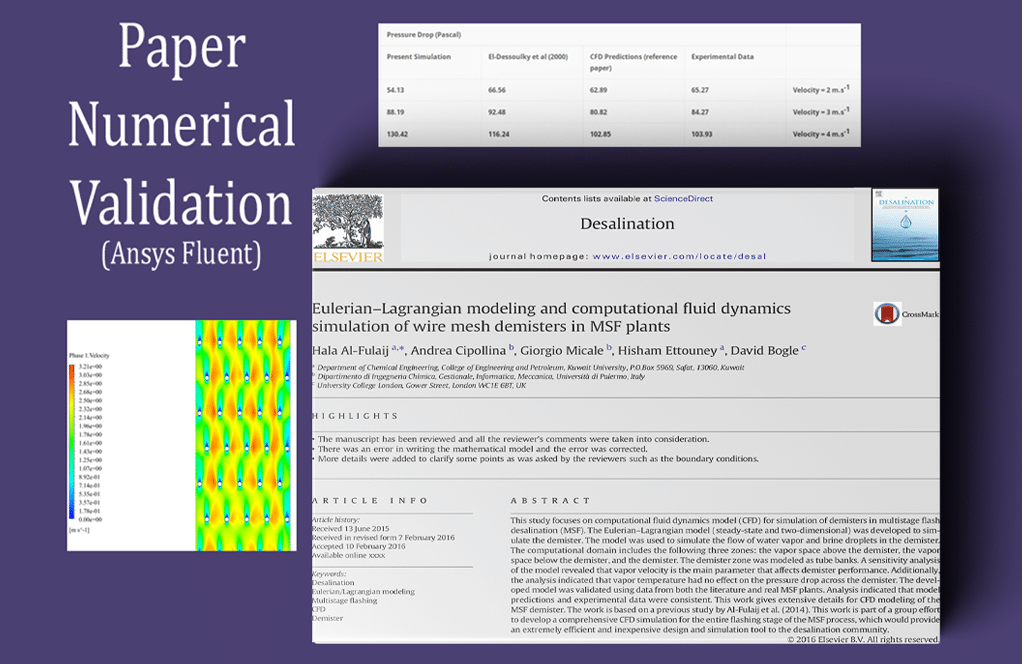

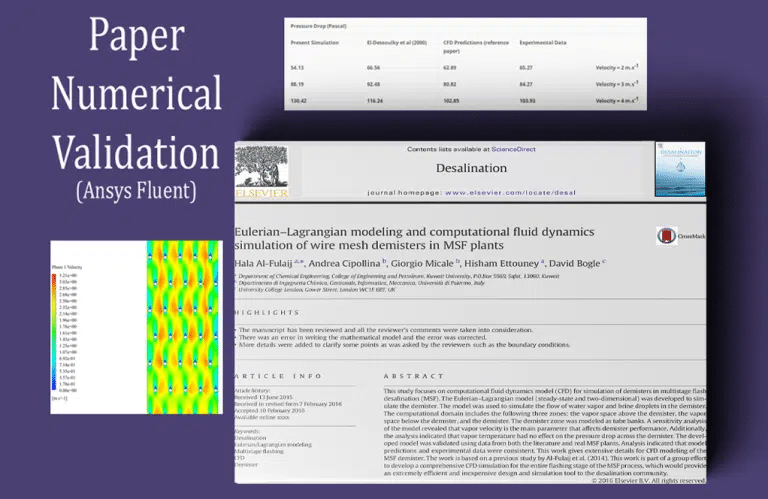

Using ANSYS Fluent, the current challenge attempts to model the movement of water vapor as it travels through a demister filled with saltwater droplets. The information in this simulation comes from a research paper titled “Eulerian-Lagrangian modeling and computational fluid dynamics simulation of wire mesh demisters in MSF plants,” which can be found here. The findings are analyzed and evaluated in light of the findings presented in the paper. There is a connection between this demister and a multistage flash (MSF) desalination plant. The demister we have here is made up of a set of metal wire mesh, and its job is to separate the saltwater droplets from the water vapor stream. Therefore, a multiphase flow model needs to be defined to specify the flow in this modeling.

The Eulerian-Lagrangian perspective on computational fluid dynamics (CFD) is utilized in this simulation. As a result, the dense discrete phase model (DDPM) is coupled with the Eulerian multiphase model. Therefore, a continuous phase, which is connected to water vapor, has been defined, and a discrete phase, which is related to saltwater droplets, has also been defined. Following their journey through the metal wire mesh, water vapor and discrete droplets of salt water enter the system from the bottom of the device. They then leave the device from the top. This research aims to determine the pressure drop from flow through these wire meshes.

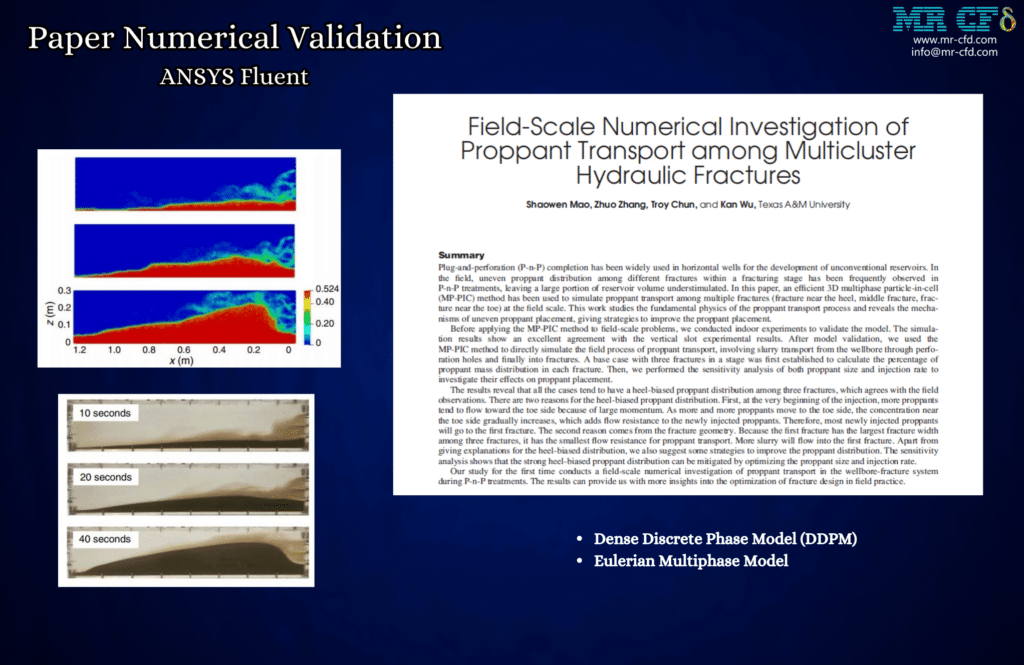

Field-Scale Numerical Investigation of Proppant Transport among Multicluster Hydraulic Fractures

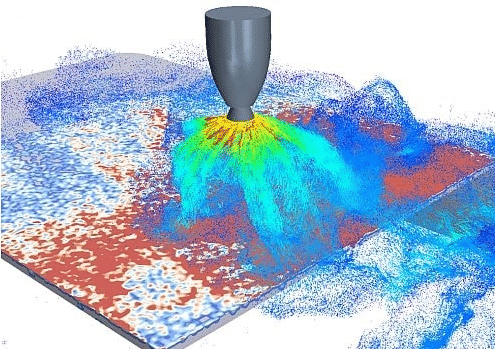

The process is injecting a high-pressure mixture of water, sand, and chemicals into a wellbore to induce fractures in the deep-rock formations. Proppant, such as sand or other particle material, is employed to maintain the openness of fractures, so facilitating the unhindered movement of oil or gas.

The transportation of proppant within these fractures is a crucial factor that impacts the effectiveness and outcome of hydraulic fracturing.

As depicted in the animation, the proppants promptly settled upon injection, creating a dune at the base of the slot. Contours clearly demonstrate that proppants were effectively conveyed to the other end of the slot within 10 seconds of insertion. The dune had rapid vertical growth.

Following 17 seconds of simulation, the dune height had nearly doubled compared to that of 10 seconds. To assess the precision of the simulation, the experimental findings displaying the proppant volume fraction are chosen for comparison with the simulation results. The results demonstrate a strong concurrence, as depicted in the picture below. According to the collected data, the inaccuracy is less than 12%.

A

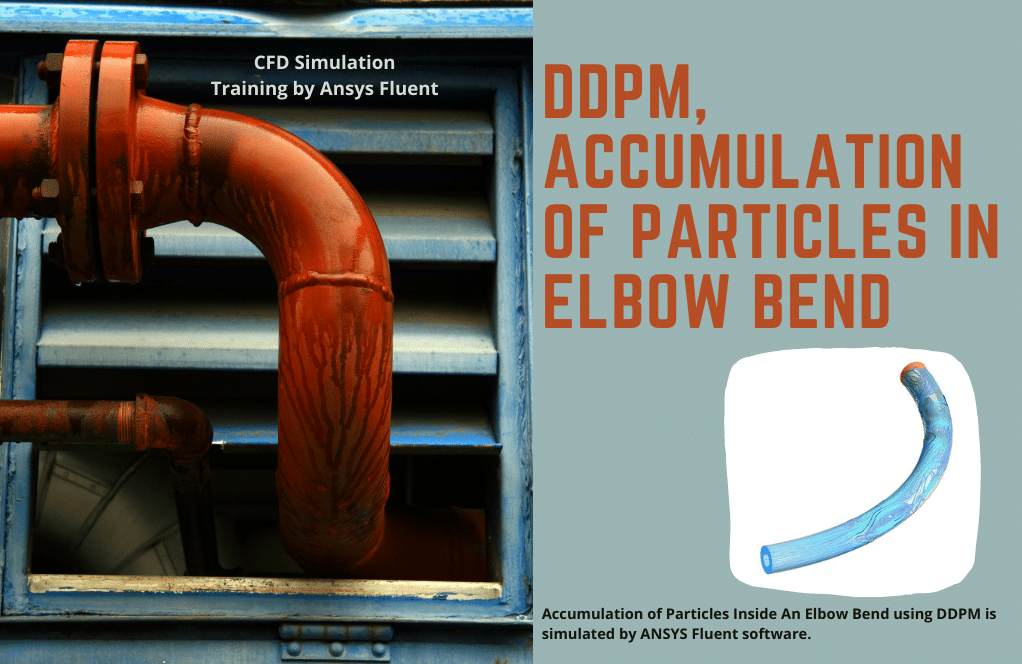

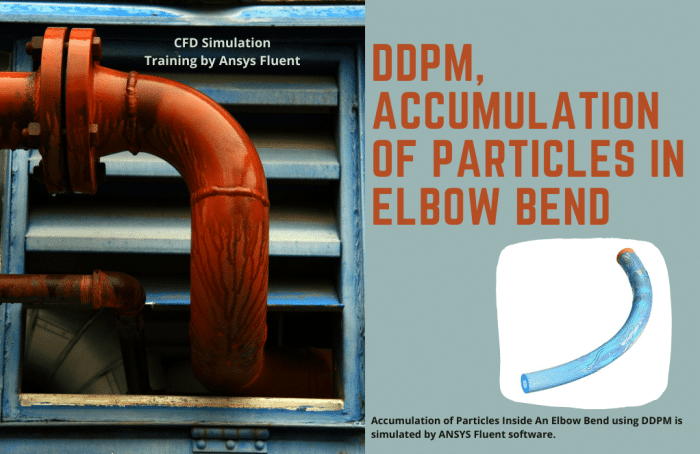

In the current project, we have conducted a simulation of a basic elbow flexion. Nevertheless, the rapid injection would lead to a concentrated aggregation of particles.

Subsequently, the results of the pressure and velocity fields are illustrated for both particles and the air-fluid flow beneath the images. It has been found that the air velocity increases when the flow reaches the bend section.

Furthermore, the temperature of the fluid near the hot inner wall is greater than that on the opposite side of the pipe. Moreover, the high temperature spreads gradually throughout the fluid flow and particles.

Curiously, the DPM particle computations yielded identical findings: velocity and pressure were elevated at the precise positions. Furthermore, the presence of streamlines suggests the formation of many vorticities in the vicinity of the bend, a characteristic that is particularly relevant for erosion simulations.

DDPM and DEM Application in Industrial Companies

DDPM and DEM are methodologies employed in computational modeling to analyze and simulate the behavior of particulate systems. Mining, pharmaceuticals, agriculture, food processing, and other sectors that rely heavily on the manipulation of bulk materials and particulate flow will find these techniques especially beneficial. Listed below are some industrial company applications of DDPM and DEM:

DDPM (Dense Discrete Phase Model)

DDPM is an extension of the Discrete Phase Model (DPM) that is capable of handling high particle loadings where interactions between particles become significant.

– Chemical Engineering: Chemical engineering can utilize DDPM to optimize reaction rates and efficiency by simulating the distribution of catalyst particles in fluidized beds during reactor design and analysis.

– Oil and Gas: DDPM can forecast the impact of sand particles in the flow, thereby facilitating the development of erosion mitigation strategies for pipelines and equipment.

– Pharmaceuticals: DDPM can assist in the design of powder blending and tablet coating processes to guarantee product quality and uniformity.

– Environmental Engineering: DDPM can be utilized in environmental engineering to simulate the dispersion of pollutants in the atmosphere or water, thereby assisting in the evaluation of environmental impacts.

Discrete Element Method (DEM)

In order to simulate the behavior of particle systems in which the interaction between individual particles is explicitly resolved, DEM is utilized.

– Mining and Mineral Processing: DEM is utilized in the mining and mineral processing industry to optimize the design and operation of equipment, including conveyors, chutes, mills, and crushers, through the prediction of wear patterns and particulate flow.

– Agriculture: DEM can simulate the flow of cereals and seeds for equipment design in the handling and processing of these granular materials, thereby reducing breakage and increasing efficiency.

– Food Industry: DEM can be utilized to design equipment that handles particulate foods gently and to simulate the behavior of such foods during processing in order to ensure quality.

– Construction and Civil Engineering: DEM can be utilized in the construction and civil engineering sectors to forecast flow patterns and avert complications such as bridging and rat-holing when designing silos and hoppers.

– Pharmaceutical applications: DEM can be employed to simulate the tablet manufacturing process, encompassing die loading, compression, and tablet ejection, with the aim of detecting and resolving challenges associated with cohesion, adhesion, and breakage.

Industrial companies can incorporate both DDPM and DEM into their design and optimization processes in order to increase output, decrease expenses, and improve product quality. Through the utilization of simulations that replicate the behavior of particles in the real world, these techniques enable engineers to anticipate and resolve potential issues prior to their manifestation in operational settings.

MR CFD Industrial Experience in the DDPM and DEM Field

Some examples of DDPM and DEM industrial projects recently simulated and analyzed by MR CFD in cooperation with related companies are visible on the MR CFD website.

You may find the Learning Products in the DDPM and DEM CFD simulation categories in the Training Shop. You can also benefit from the DDPM and DEM Training Package, which is appropriate for Beginner, Intermediate, and Advanced users of ANSYS Fluent. Also, MR CFD is presenting the most comprehensive DPM Training Course for all ANSYS Fluent users, from beginners to experts. Get more familiar with DPM Concepts.

Our services are not limited to the mentioned subjects. The MR CFD is ready to undertake different and challenging projects in the DDPM and DEM modeling fields that our customers order. We even carry out CFD simulations for any abstract or concept Design you have to turn them into reality and even help you reach the best strategy for what you may have imagined. You can benefit from MR CFD expert Consultation for free and then Outsource your Industrial and Academic CFD project to be simulated and trained.

By outsourcing your Project to MR CFD as a CFD simulation consultant, you will not only receive the related Project’s resource files (Geometry, Mesh, Case, and Data, etc.), but you will also be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings (preprocessing, processing, and postprocessing) in the ANSYS Fluent software. Additionally, post-technical support is available to clarify issues and ambiguities.

Portfolios

-

Sale