CFD Project Outsourcing

Outsource your CFD project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including CFD Consultant, CFD Training, and CFD Simulation.

The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is Fluid Solid Interaction (FSI)?

The Multiphysics study of the interactions between fluids and structures is known as fluid-structure interaction (FSI). The structure may experience pressure and heat loads from the fluid flow. These loads could result in structural deformation strong enough to influence fluid flow. As the degree of fluid-structure interaction grows, undesirable impacts on your product could become more pronounced. To assure safety, dependability, and lifetime, use ANSYS simulation to understand better the phenomena occurring with your product.

ANSYS provides various solutions for every scenario involving fluid-structure interaction to offer the required level of authenticity. Within ANSYS CFD, fundamental fluid-structure interaction issues can be fully resolved. An impeller revolving in a mixing tank exemplifies this rigid body motion.

One-way coupling, an automated, user-friendly solution from ANSYS, can be used as the fluid-structure interaction increases and the problem requires a more thorough review. One-way coupling automatically transmits and maps the data to the other system after solving the initial CFD or ANSYS Mechanical simulation. An illustration of this would be to automatically transfer the data from the fluid flow simulation around a cone flow meter to calculate the subsequent structural response.

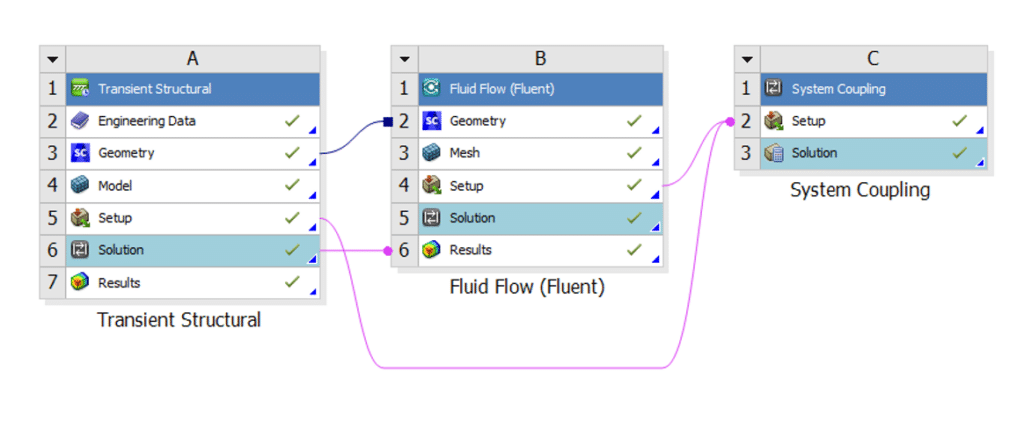

You may utilize System Coupling to do two-way coupled FSI simulations for the most challenging and strongly linked fluid-structure interaction problems—simultaneous setup and solution of the structural and fluid simulations. Data is automatically transmitted between the two solvers to provide reliable and accurate answers as the problem is being solved. Calculating the flow around a rigid airplane wing and transferring the pressure loads to address structural deformation would illustrate this. The structural deformation would be returned to the CFD simulation to compute the flow again.

FSI is the dynamic interaction between fluids and solid structures. It links the fluid and solid by exchanging forces, momentum, and energy. The fluid and solid domains interact in FSI simulations. This is especially important when fluid behavior impacts solid structural response or vice versa.

Engineering, physics, and biology use FSI. FSI applications include:

– Aerospace: Airflow impacts structural deformation and vibrations in aircraft wings, making FSI essential.

– Civil Engineering: Fluid flow can cause structural vibrations and wear in bridges, dams, and offshore structures, making FSI relevant.

– Biomechanics: FSI helps comprehend arterial blood flow, respiratory airflow, and fluid-soft tissue interaction.

– Marine and Ocean Engineering: FSI helps analyze ships, offshore platforms, and ocean waves.

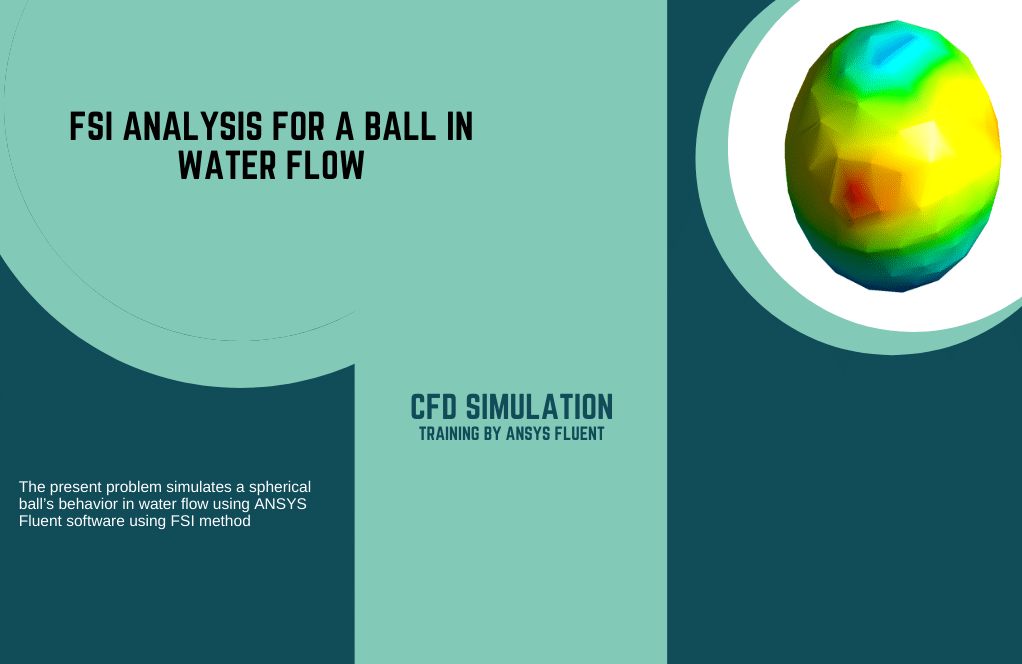

ANSYS Fluent models a spherical ball in water flow using the FSI approach. After solving, two-dimensional contours of the pressure and shear stress on the spherical body’s surface and the speed and pressure around it in the tube’s middle plate are generated. These contours represent the final simulation second. The structural analysis yields deformation and elastic strain contours.

CFD and FEA are used to simulate FSI. These approaches simultaneously solve fluid flow and structural mechanics governing equations, considering fluid-solid interactions. To handle complicated interactions, FSI simulations require accurate fluid and solid property modeling, boundary conditions, and powerful numerical techniques.

How can FSI CFD simulation be applied in Engineering and Industries?

Engineering and industry use FSI CFD simulations. Some examples:

– Aerospace Industry: FSI CFD models study airflow-aircraft structure interactions. This aids in understanding the wing, control surface, other component aerodynamics, structural integrity, and flutter.

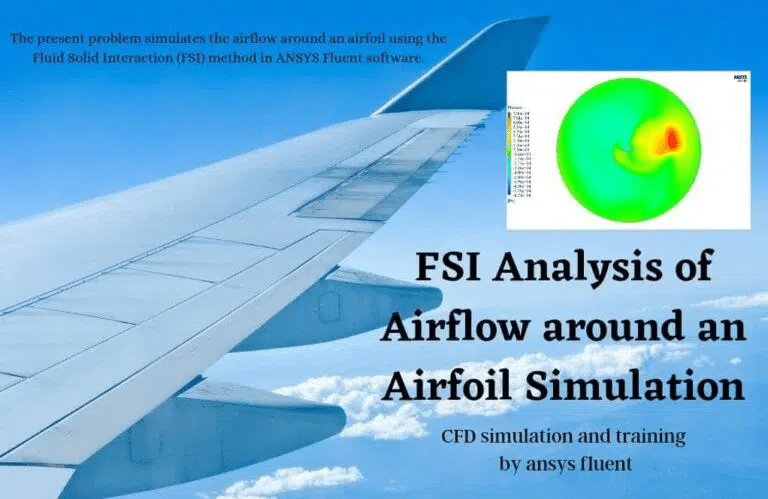

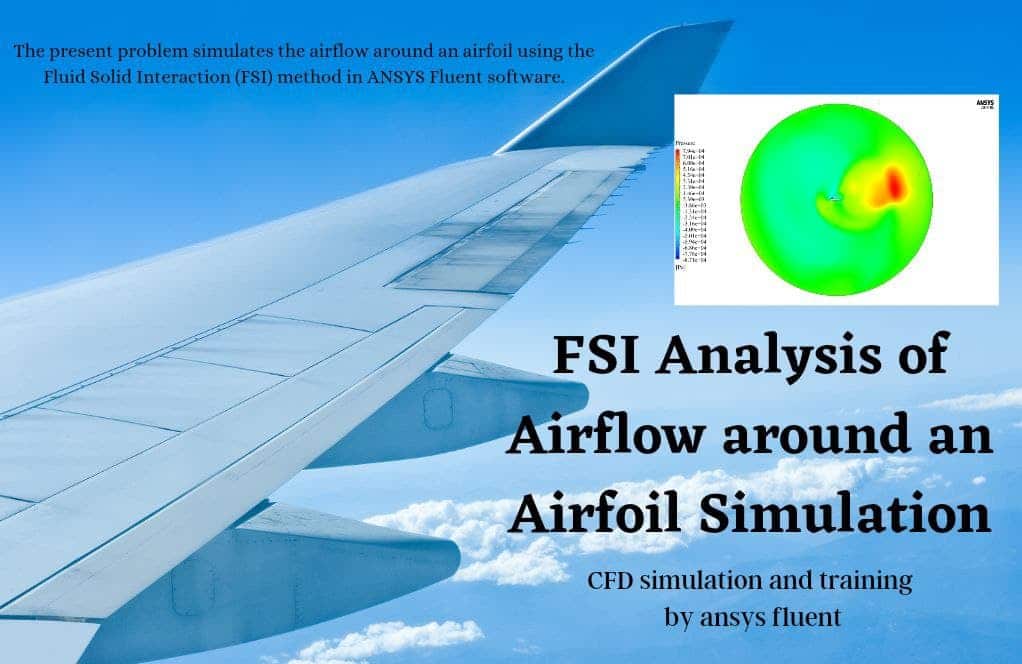

ANSYS Fluent Fluid Solid Interaction (FSI) analysis of airflow over an airfoil is the current problem. This simulation creates a circular airflow computational domain to place an airfoil. Since this airfoil travels fast, airflow collides with its body, creating a force. This model distinguishes a circular hole inside the airfoil from establishing the inner surface boundary surrounding this circle as fixed support. This barrier or surface is constantly influenced by fluid flow but does not deform.

The fluid flow colliding with the airfoil body displaces the two sides. Hence these limits must be described as displacement. We must define a data transfer from fluent software’s model wall to Force’s transient structural software’s model wall. The airfoil wall is hit by fluid flow around it.

Data transfer from transient structural software to Fluent software should be defined as displacement. The wall alters fluid flow. In this simulation, a circular computational domain defines the airflow’s inlet border. We get Fluent and Transient Structural findings after solving. Transient structural software shows airfoil deformation, strain, and stress contours.

These contours represent the simulation’s final 0.32 s. In fluent software, we exhibit two-dimensional velocity, pressure, and temperature contours on the symmetrical computational area around the airfoil. These contours match the simulation’s final second (0.32 s). In 0.32 s, we show airfoil drag and lift coefficient variations.

– Automotive Industry: FSI CFD simulations investigate fluid flow and vehicle components. Airflow impacts vehicle aerodynamics, cooling systems, and flexible structures like tires.

– Energy Sector: FSI CFD simulations create and optimize energy systems. They can be used to study wind turbines in turbulent winds, heat exchangers in power plants, and undersea turbines in tidal energy generation.

ANSYS Fluent unstable CFD simulation evaluates water flow around a vertical water turbine. In this situation, the fluid flowing through the turbine blades impedes forces on the turbine body, deleting or resizing the blades. Thus, the FSI approach and coupling between fluid flow and Transient Structural are adopted since the problem simultaneously has two fluid and solid solutions.

– Civil Engineering: Bridges, dams, and offshore platforms are analyzed using FSI CFD models. They explain how fluid forces like wind and water currents affect structural integrity and stability.

– Biomedical Engineering: FSI CFD models explore arterial blood flow, respiratory airflow, and medical devices like heart valves and stents. They help optimize medical devices and comprehend biological fluid-structure interactions.

Blood Vessel with the Pulse Velocity

Ansys Fluent software simulates a blood artery with a wall and its displacement. UDF defines pulse velocity, and ambient pressure is the output. Fluent FSI simulation. After the simulation, we can see the vessel’s velocity, pressure, and blood force-induced strains and displacements.

– Marine and Offshore Engineering: FSI CFD models evaluate ships, offshore structures, and ocean waves. They assist in comprehending how fluid forces like waves or currents affect these systems’ performance, safety, and structural integrity.

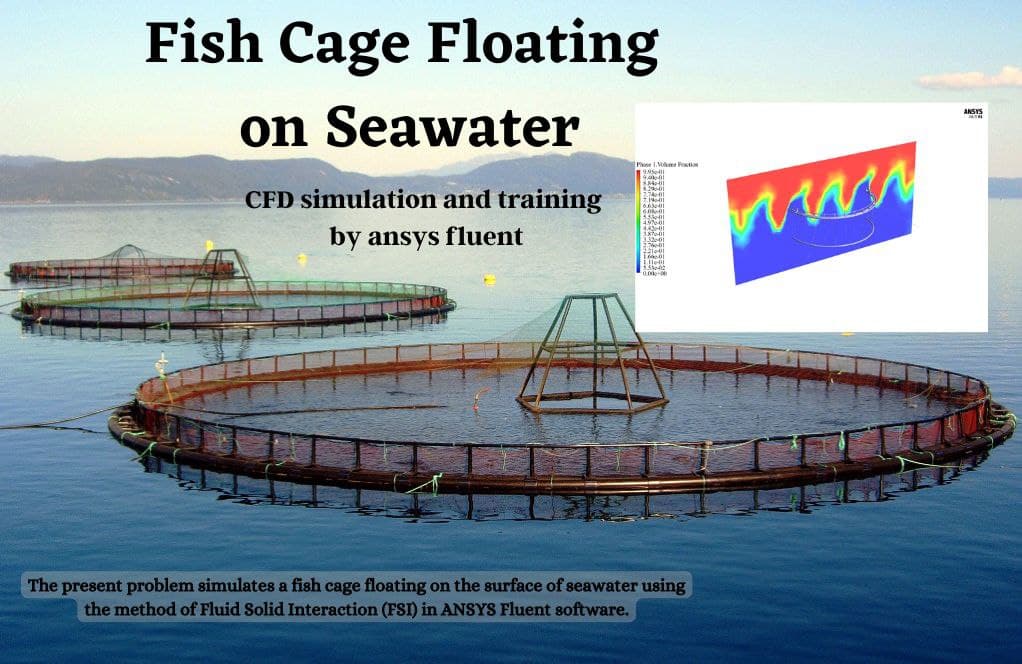

Fish Cage Floating on Seawater

The ANSYS Fluent Fluid Solid Interaction (FSI) approach mimics a fish cage floating on seawater. We analyze this CFD project. We get Fluent and Transient Structural findings after solving. The simulation’s final second (0.05 s) determines all results. In transient structural software, we calculate fish breeding cage body surface deformation, strain, and stress contours.

Fluent software generates two-dimensional velocity, pressure, water, and air volume fraction contours on the center plate (the symmetry plate). We also show the fish breeding cage’s pressure contour. It has also been attempted to get the seawater wave surface and depict two-dimensional pressure, velocity, and velocity vector contours.

Volume fraction outlines show open channel wave BC waves. The narrow bars connecting the top and bottom holders deform the most. FSI CFD simulations help engineers and industrialists understand complicated fluid-structure interactions. They improve designs, performance, cost, safety, and dependability.

MR CFD services in the FSI Engineering and Industries

One of the most essential applications of ANSYS software is simultaneously analyzing fluids and solids. This software allows us to use fluid-structure interactions to establish the relationship between fluid and solid analysis and investigate how the structure and fluid interact. The mentioned process above is done by coupling ANSYS Fluent software with transient structural using the system coupling option in ANSYS.

- Simulation of stress and strain analysis of blood vessels in variable blood velocity

- Predicting final deflection and fluctuation of high altitude and skyscraper

- Human heart stress analysis while pumping blood in a human vessel

- Generating power from sea waves on the beach using a flexible structure

- Stress and stress analysis of tidal turbine in submerged and submerged situation

- Airplane wing fluttering in turbulence fluid flow

- The fluctuation of structure in the vortex-shedding region

- …

CFD modeling helps engineers and industrialists analyze and comprehend fluid-structure interactions (FSI). FSI engineering and industry CFD simulation highlights:

Fluid Flow Analysis: CFD simulation allows engineers to properly simulate and analyze fluid flow behavior around and within structures. It helps understand complex flow patterns, pressure distributions, and velocity profiles, revealing how fluids interact with solid components.

Structural Analysis: CFD simulation can analyze the reaction and deformation of solid structures to fluid forces. This helps evaluate structural integrity, detect failure areas, and optimize design for performance and safety.

Fluid-Structure Interaction Modeling: CFD simulation can describe fluid-structure interactions, where fluid and solid components interact. It accounts for fluid forces on the structure and vice versa due to dynamic coupling. Understanding the mutual influence and optimizing design for performance helps.

Optimization and Design Improvement: CFD simulation in FSI engineering and industries helps design optimization by revealing fluid-structure interactions. Engineers can evaluate design modifications’ effects on fluid flow and structural reaction to optimize system performance.

Performance Evaluation: CFD simulation allows performance evaluation under different operating conditions. It forecasts drag, lift, heat transfer, pressure decrease, and fluid-induced vibrations. Optimization, energy reduction, and operational reliability depend on this data.

Virtual Prototyping and Testing: CFD simulation lets engineers visually prototype and test designs before prototyping. It saves time and costs by giving a complete understanding of fluid-structure dynamics, allowing design changes and performance enhancements early in the development process.

CFD simulation in FSI engineering and industries helps understand, analyze, and optimize fluid flow and structural behavior. It helps engineers make informed design decisions, increase system performance, and ensure system dependability and safety across industries.

How to Model FSI inside ANSYS Fluent

With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, the MR-CFD team is ready to offer extensive modeling, meshing, and simulation services.

Steps to model Fluid-Structure Interaction (FSI) in ANSYS Fluent:

Preprocessing

– Create the fluid domain: Define the fluid domain geometry and mesh it using ANSYS Meshing or any compatible meshing tool.

– Create the solid domain: Mesh the solid structural geometry and ensure compliance with the fluid mesh.

– Set boundary conditions: Inlet velocity, outlet pressure, and wall conditions are fluid boundary conditions. Define fixed support or prescribed displacement solid border conditions.

– Define FSI interface: Find the fluid-solid interface where interaction happens. This interface will transfer data between fluid and structural solvers.

FSI Analysis Set Up

– Define the FSI coupling method: ANSYS Fluent offers segregated and fully coupled approaches. Select a method depending on issue needs and computational resources.

– FSI solver settings: Configure FSI solver convergence criteria, time step size, and coupling method-specific parameters.

– Fluid solver setup: Set turbulence models, discretization schemes, and solver controls in ANSYS Fluent.

– Configure the structural solver: Material properties, boundary conditions, and solver controls.

FSI Analysis

– Convergence: Track fluid and structural solver convergence. Make that the solution is stable and meets both domain convergence conditions.

– Post-process the results: After the simulation, examine fluid flow dynamics, structural reaction, and fluid-structure interaction effects. Visualize and analyze simulation results with ANSYS Fluent post-processing tools.

Note that ANSYS Fluent versions differ in steps and choices. Thus, consult the documentation and tutorials for detailed instructions on modeling FSI simulations in ANSYS Fluent.

FSI MR CFD Projects

FSI CFD simulation projects:

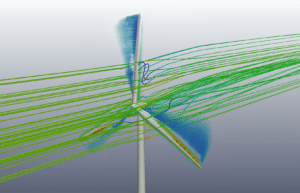

– Fluid-Structure Interaction Analysis of a Wind Turbine Blade: Simulate the interaction between fluid flow and structural response to evaluate wind turbine blade performance, fatigue life, and structural integrity under different wind conditions.

This study analyzes fluid-structure interaction over a HAWT turbine. This simulation warms the turbine with a 25 m/s flow at 12 RPM. The one-way FSI technique investigated fluid effects on the structure. The blade tips deformed 0.2 m. Bending stress and strain were also examined. We calculated turbine deformation, strain, and stress using domain pressure and structure section speed.

– Blood Flow Analysis in Intracranial Aneurysms: Model blood flow in cerebral aneurysms to determine how fluid dynamics affect rupture risk and find therapeutic options.

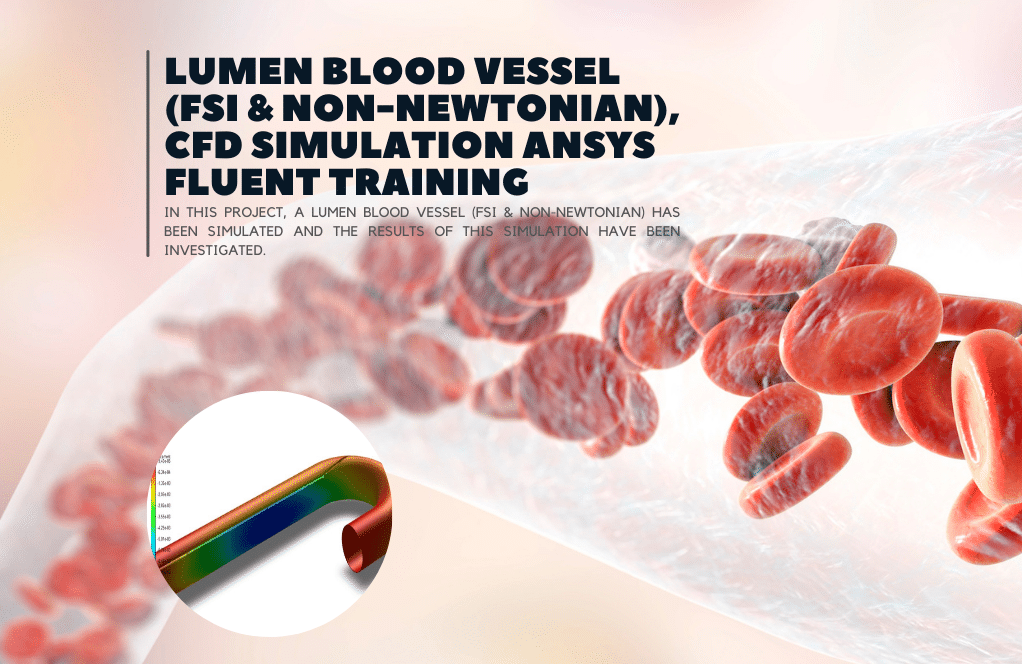

Lumen Non-Newtonian Blood Vessel

This Project used ANSYS Fluent to simulate and analyze a Lumen Blood Vessel (FSI & Non-Newtonian). We analyze this CFD project. Three-dimensional contours of wall displacements and von Mises stresses are obtained after solving. As seen, blood flow stresses channel walls.

– FSI Simulation of Aircraft Wing Flutter: Assess flutter instability and optimize wing design for safety and performance by studying the aeroelastic behavior of an aircraft wing under different flying situations.

– Fluid-Structure Interaction in Heart Valve Function: Study blood flow and heart valve leaflets to determine regurgitation and stenosis risks and optimize valve designs.

– FSI Analysis of Flexible Pipes in Subsea Oil and Gas Systems: Simulate flexible pipes’ structural reaction and fatigue life under diverse flow and environmental conditions.

– Fluid-Structure Interaction in Fish Swimming: Study fish swimming fluid dynamics and structural deformation to understand fish locomotion and optimize biomimetic swimming robots.

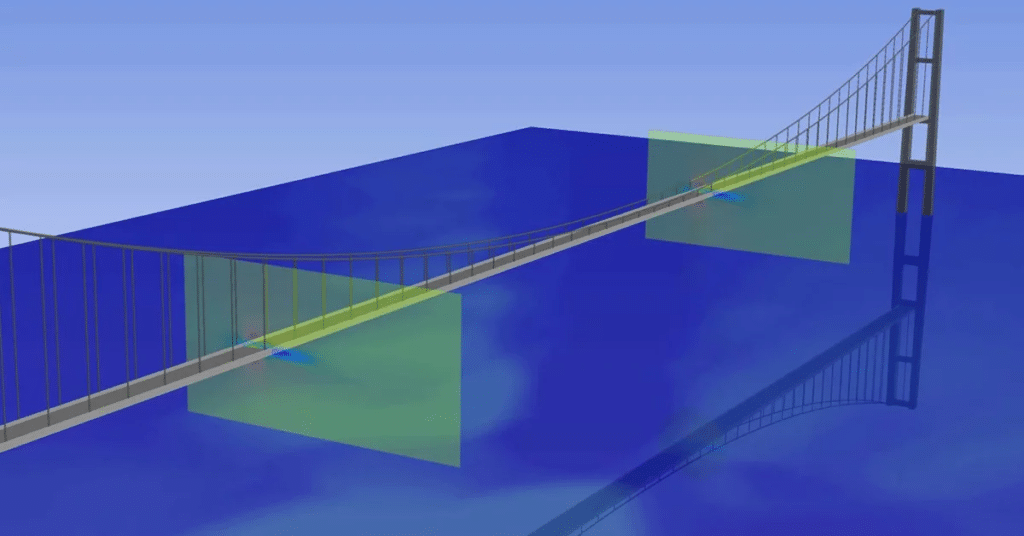

– FSI Simulation of a Bridge under Wind Loading: Analyze a bridge structure’s reaction to wind-induced vibrations and test aerodynamic improvements to reduce structural damage.

– Fluid-Structure Interaction in Microfluidic Systems: Optimize microfluidic devices for lab-on-a-chip, drug delivery, and microscale mixing by modeling their fluid flow and structural reaction.

– FSI Analysis of Wind Effects on High-Rise Buildings: Simulate wind flow and tall building structures to assess wind-induced vibrations, evaluate structural integrity, and optimize building designs for safety.

– Fluid-Structure Interaction in Artificial Heart Assist Devices: Optimize design, blood flow characteristics, and patient outcomes by studying fluid dynamics and structural response.

These versatile project themes can be customized to research or industry needs. When choosing a project topic, consider resources, expertise, and time.

FSI in Industrial Companies

Industrial businesses across sectors are using Fluid-Structure Interaction (FSI) simulations. Industrial FSI examples:

– Aerospace Industry: FSI simulations help develop and analyze aircraft parts, including wings, control surfaces, and engines. These simulations evaluate the aircraft’s structural integrity, aerodynamic performance, and aeroelastic behavior under different operating situations.

– Automotive Industry: FSI simulations optimize vehicle design, including fluid flow and flexible components like spoilers, mirrors, and tires. These simulations improve aerodynamics, drag, stability, and fuel efficiency.

– Oil and gas: Risers, pipelines, and subsea equipment are analyzed using FSI simulations. These simulations evaluate how fluid flow, waves, and currents affect offshore installation structural integrity, fatigue life, and performance.

– Biomedical Engineering: Stents, heart valves, and drug delivery systems are developed and analyzed using FSI simulations. These simulations optimize device performance, analyze blood flow properties, and assess fluid flow-tissue interactions.

– Chemical and Process Industry: Chemical reactors, mixing vessels, and heat exchangers are designed and analyzed using FSI simulations. These simulations increase process efficiency, forecast fluid-structure interactions, and evaluate how fluid flow affects equipment performance.

– Civil engineering: FSI models analyze bridges, buildings, and dams subjected to fluid forces, including wind and water movement. These models examine structural stability, anticipate natural frequencies, and optimize fluid load designs.

These are some industrial uses of FSI simulations. Industry, problem description, and outcomes determine applications. FSI simulations improve industrial safety, performance, cost, and design.

MR CFD Industrial Experience in the FSI Field

Some examples of an FSI industrial project were recently simulated and analyzed by MR CFD in cooperation with related companies on the MR CFD website.

You may find the Learning Products in the FSI CFD simulation category in Training Shop. You can also benefit from the FSI Training Package, which is appropriate for Beginner, Intermediate, Advanced, and Expert users of ANSYS Fluent. Also, MR CFD is presenting the most comprehensive FSI Training Course for all ANSYS Fluent users from Beginner to Experts.

Our services are not limited to the mentioned subjects. The MR CFD is ready to undertake different and challenging projects in the Combustion modeling field ordered by our customers. We even carry out CFD simulations for any abstract or concept Design you have to turn them into reality and even help you reach the best strategy for what you may have imagined. You can benefit from MR CFD expert Consultation for free and then Outsource your Industrial and Academic CFD project to be simulated and trained.

By outsourcing your Project to MR CFD as a CFD simulation consultant, you will not only receive the related Project’s resource files (Geometry, Mesh, Case & Data, …), but also you will be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings (preprocessing, processing, and post-processing) in the ANSYS Fluent software. Additionally, post-technical support is available to clarify issues and ambiguities.