CFD Project Outsourcing

Outsource your CFD project to the MR CFD simulation engineering team. Our experts are ready to carry out every CFD project in all related engineering fields. Our services include industrial and academic purposes, considering the ANSYS Fluent software's wide range of CFD simulations. By outsourcing your project, you can benefit from MR CFD's primary services, including CFD Consultant, CFD Training, and CFD Simulation.

The project freelancing procedure is as follows:

An official contract will be set based on your project description and details.

As we start your project, you will have access to our Portal to track its progress.

You will receive the project's resource files after you confirm the final report.

Finally, you will receive a comprehensive training video and technical support.

What is the NanoFluid?

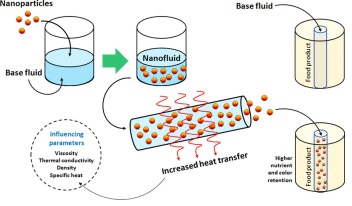

Nanofluid is a fluid containing nanometer-sized particles called nanoparticles. These fluids are engineered colloidal suspensions of nanoparticles in a base fluid. The nanoparticles used in nanofluids are typically made of metals, oxides, carbides, or carbon nanotubes. Common base fluids include water, ethylene glycol, and oil. Nanofluids have novel properties that make them potentially useful in many applications in heat transfer, including microelectronics, fuel cells, pharmaceutical processes, hybrid-powered engines, engine cooling/vehicle thermal management, domestic refrigerators, chiller, heat exchangers, nuclear reactor coolants, grinding, machining, in space technology, defense and ships, and in boiler flue gas temperature reduction. They exhibit enhanced thermal conductivity and the convective heat transfer coefficient compared to the base fluid. Knowledge of the rheological behavior of nanofluids is found to be very critical in deciding their suitability for convective heat transfer applications. In an analysis such as computational fluid dynamics, nanofluids can be assumed to be single-phase fluids. The classical theory of single-phase fluids can be applied, where the physical properties of Nanofluid are taken as a function of the properties of both constituents and their concentrations.

A nanofluid refers to a fluid that comprises particles of dimensions in the nanometer scale, commonly referred to as nanoparticles. The fluids above are colloidal suspensions of nanoparticles that have been intentionally designed and formulated inside a base fluid. Nanoparticles employed in nanofluids are commonly composed of metals, oxides, carbides, or carbon nanotubes. The commonly utilized base fluids encompass water, ethylene glycol, and oil.

Nanofluids have unique characteristics that render them potentially valuable in a variety of heat transfer applications, such as microelectronics, fuel cells, pharmaceutical processes, and hybrid-powered engines. Additionally, nanofluids have shown promise in areas such as engine cooling, vehicle thermal management, residential refrigeration, chillers, and heat exchangers. The observed characteristics include an increase in thermal conductivity and convective heat transfer coefficient when compared to the original fluid.

– Augmented thermal conductivity

– Elevated heat transfer coefficient

– Enhanced stability

An experimental study showed that the incorporation of Al2O3 nanoparticles into water, resulting in a nanofluid with a volume fraction of 1%, led to a notable enhancement of heat transfer rate by around 16% when compared to pure water. Nanofluid refers to a colloidal suspension consisting of nanoparticles dispersed in a base.

A colloidal suspension comprising particles with dimensions in the nanometer range, commonly referred to as nanoparticles. Typically, these materials are composed of metals, oxides, carbides, or carbon nanotubes. Nanofluids have superior thermal characteristics in comparison to the underlying base fluid in isolation.

Influence of NanoFluid on Heat Transfer

There are many ways to improve thermal heat transfer. These include creating plates to increase heat transfer surface, vibration, and microchannels. Thermal efficiency can also be increased by increasing the thermal conductivity of the working fluids. Fluids commonly used in industry, such as water, ethylene glycol, motor oil, etc., often have lower conductivity than solids, which is why solids can be used to improve performance in the form of solid particles (nanoparticles) added into the fluid. On the other hand, these particles can also cause scavenging or blockage of the channels or their corrosion, which has some disadvantages and the potential to increase the conductivity coefficient to increase efficiency.

Many materials can be used as nanoparticles. Since the thermal conductivity of materials, whether in the metal or non-metallic state as Al2O3, CuO, TiO2, SiC, TiC, Ag, Au, Cu, and Fe are generally several times higher, even at low concentrations, they have an effective influence on the thermal transfer coefficient. Nanoscale solid particles with dimensional scales in the range of 1–100 nm have been observed with high thermal conductivity, which can significantly increase the effective conductivity of the main fluid and its heat transfer coefficient. Most of these particles are spherical. However, other forms, such as tubular, elongated, and disc-shaped, are also considered.

Nanofluids are a novel category of heat transfer fluids that have been deliberately formulated through the dispersion of nanoparticles inside base fluids, like water, oil, or ethylene glycol. The basic fluids have been seen to have inferior thermal characteristics in comparison to the superior thermal properties exhibited by the materials above.

There are several mechanisms via which nanofluids exert an influence on heat transmission:

– Enhanced Thermal Conductivity: Nanofluids often exhibit enhanced thermal conductivity in comparison to their respective base fluids. This phenomenon can be attributed to the enhanced thermal conductivity of the nanoparticles when dispersed within the fluid medium. As a result, there is an enhancement in the efficiency of heat transfer.

– Increased Convective Heat Transfer Coefficient: The convective heat transfer coefficient of the fluid can be enhanced by the inclusion of nanoparticles. The observed phenomenon can be attributed to the modification of the thermal boundary layer of the fluid caused by the presence of nanoparticles.

Nanofluids, which are solid-liquid mixtures, are better at transferring heat and conducting heat flow than base fluids that don’t have nanoparticles in them. So, nanotechnology can be used to improve the process of heat movement. Increasing heat transfer under free convection depends on the concentration of nanoparticles. This is because many studies have shown that heat transfer is related to the concentration of nanoparticles.

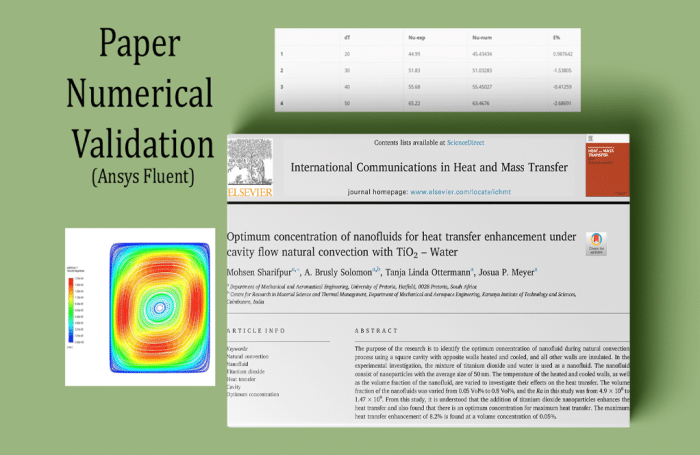

ANSYS Fluent software is used to model the process of mixing water and Nanofluid in a lab chamber for this project. Based on the study “Optimal Concentration of Nanofluids to Increase Heat Transfer under Natural Convection Cavity Flow with TiO2–Water,” this work was done. It is possible to match the results of the quasi-simulation to those of the paper.

A nanofluid is a mixture of titanium dioxide and water that is used in experiments. Nanoparticles that are about 50 nanometers in size make up the Nanofluid. To find out how they affect heat transfer, we change the volume fraction of the Nanofluid and the temperature of the heat and cool walls.

The goal of this study was to find the best nanofluid concentration for free convection in a square room with hot and cold walls on opposite sides and insulated walls on all the other sides. The Nusselt numbers given in the paper match the numbers found in this CFD calculation, so they are correct.

If you look at these numbers next to each other, you can see that they are similar to the theory and experimental results. The Nusselt number is given at different temperature changes between the walls. As the Riley number and concentration of Nanofluid go up, so does the Nusselt number.

The main topic of this work is free convection in a titanium dioxide nanofluid that is based on water. It was looked into what would happen if the temperature changed and the volume concentration changed. There is the best volume concentration that was found when the effect of volume concentration on heat transfer was looked into.

It is clear from this study that adding titanium dioxide nanoparticles makes heat movement better at a volume concentration of 0.05% and a temperature difference of 50 °C. The most heat can be transferred (8.2%). There is also a link between the simulation and the experimental and theoretical results in this work. This study backs up the idea that any nanofluid that conducts heat better than its base fluid may help heat move faster under the same conditions.

ANSYS Fluent software is used to model the forced heat transfer of a non-Newtonian nanofluid in a horizontal tube for this problem. There is a reference article called “Modeling of forced convective heat transfer of a non-Newtonian nanofluid in the horizontal tube under constant heat flux with computational fluid dynamics” that this simulation is based on. The simulation’s results are compared and confirmed with those in the article. In this example, the Nanofluid is made up of water as the base fluid and xanthan and Al2O3 particles as the nanoparticles. When xanthan is present, the fluid changes into a non-Newtonian fluid, and when aluminum oxide particles are present, the base fluid changes into a nanofluid.

In this model, the Nanofluid is not described by the multiphase flow model. Instead, it is described as a new material that has thermophysical qualities similar to a nanofluids. The Herschel-Bulkley model is used to figure out the Nanofluid’s viscosity because it is not a Newtonian fluid and is moving through the tube. Based on the diagram in Figure 3-a of the above piece, this simulation has been proven to work. Because the Reynolds number value changes, this graph shows how the heat transfer coefficient of model (h) changes along with it.

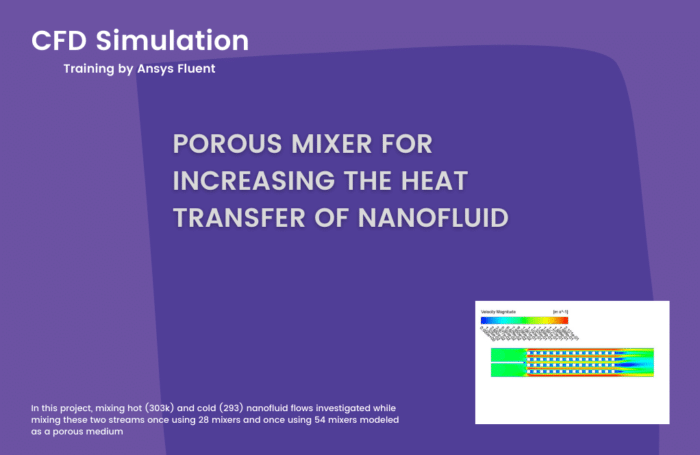

Nanofluid Porous Mixer for Increasing Heat Transfer

This means that even though there are more separation zones in the 4-row case, the gaps between them are bigger in the 2-row case. The pressure gauges also show that the 2-row case has lower pressure. This makes sense, too, if you look at Bernoulli’s equation.

At the very top of the domain, where the temperature is lower than at other points in the domain, the pressure is higher. There is no difference between the two cases when it comes to the highest and lowest temperatures or temperatures. But in the 4-row case, the temperature changes happen more slowly and over a wider range because of the way the geometry is shaped. The temperature diagram is shown in the middle of the shapes.

– Reduced Boundary Layer Thickness: The utilization of nanofluids has the potential to decrease the thickness of the boundary layer, hence leading to an enhancement in the rate of heat transmission.

– Improved Critical Heat Flux: The utilization of nanofluids has been found to have a substantial impact on the critical heat flux during the process of boiling heat transfer. The implementation of this measure can effectively inhibit the development of a vapor layer, which has the potential to act as an insulating barrier on the surface, thus resulting in a significant decline in the rate of heat transmission.

– Enhanced Heat Transmission in Radiators: The utilization of nanofluids in radiators has been found to augment the rate of heat transmission, hence resulting in enhanced performance.

Nevertheless, it is crucial to acknowledge that whereas nanofluids have the potential to improve heat transmission, they can also result in elevated pressure drop and increased pumping power. Hence, it is important to take into account the comprehensive performance of the system when utilizing nanofluids.

Radiator Heat Transfer Simulation by Hot Nanofluid Flow, ANSYS Fluent

ANSYS Fluent software is used to simulate how heat moves through a radiator with nanofluid flow in this case. The way these radiators work is that hot fluid flows through the pipes inside the radiator, and air flows through the pipes, too. In this way, the airflow goes through the pipes holding the hot flow and picks up their heat. The hot air flow is then sent to the outside world. After the problem is solved, two-dimensional and three-dimensional outlines of pressure, speed, and temperature are found.

How can NanoFluid CFD simulation be applied in Engineering?

The utilization of Computational Fluid Dynamics (CFD) simulation for Nanofluid analysis is a versatile technology that finds application in several engineering disciplines. It enables the examination and prediction of nanofluid behavior across diverse environmental circumstances. The following is a concise elucidation of its potential application:

– Thermal Engineering: In the field of thermal engineering, nanofluids have gained recognition for their exceptional thermal characteristics. Engineers can employ CFD simulations to forecast the heat transfer properties of nanofluids inside various systems, such as heat exchangers, cooling systems, and radiators. This contributes to the development of thermal systems with enhanced efficiency.

The following is a basic markdown example that serves to demonstrate the practical implementation within the field of thermal engineering. The utilization of computational fluid dynamics (CFD) simulation for nanofluid applications in the field of thermal engineering.

The utilization of nanofluids, which possess enhanced thermal characteristics, has the potential to augment the efficiency of thermal systems. A computational fluid dynamics (CFD) simulation can be employed to examine the characteristics and performance of nanofluids across different environmental and operational scenarios.

In the context of a heat exchanger system, the simulation of nanofluid flow and heat transfer can be achieved through the utilization of Computational Fluid Dynamics (CFD). The utilization of simulation techniques can yield significant insights pertaining to the functioning of a given system, including the analysis of temperature distribution and heat transfer rate. Based on the findings above, there is potential for optimizing the system to enhance its overall performance.

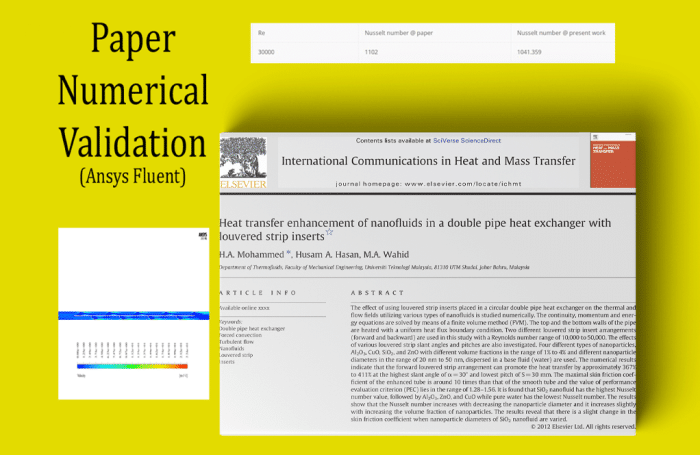

ANSYS Fluent software is used to model the flow of heat inside a double-pipe heat exchanger with a Louver strip. The simulation is based on the information in the reference article [Heat transfer increase of nanofluids in a double pipe heat exchanger with louvered strip inserts]. The results are checked against the results in the story to make sure they are correct. The model is based on a heat exchanger with two pipes. Inside the pipe, a strip is put in a louvered pattern and connected to it at certain angles and distances.

The goal of this work is to find out how much Nusselt number is on the outside wall of the heat exchanger’s tubes when the heat flow stays the same. The Nusselt number is found on the outside tube wall of the heat exchanger, which is always transferring heat. This is done at the end of the solution process. Lastly, two-dimensional pathlines and contours that are linked to pressure, temperature, and speed are found.

Nano Fluid Heat Transfer in a Porous Heat Exchanger

ANSYS Fluent software is used to model and study Nanofluid flow heat transfer in a porous medium heat exchanger for this project. Researchers have done much work on fluid flow and heat transfer in porous surfaces in the last few decades. It is possible to make a porous medium so that its volume has holes and pores in it. In business, porous media are used for many things, like making crude oil, making sure buildings are well insulated, making heat exchangers that recover heat, and more.

At the end of the answer, we get the pressure, speed, temperature, streamlines, and velocity vectors. The lines clearly show how the temperature changes. Especially where there is a prosthesis and the direction of the velocity vectors is based on the holes.

Heat Exchanger with Baffle Cut and Mixture Nano Fluid

This program simulates a Shell and tube heat exchanger with a baffle cut that uses a Nanofluid. Power plants, the food and chemical industries, electronics, environmental engineering, manufacturing, ventilation, freezers, the space industry, and many other fields use heat exchangers in many different ways. There are lots of ways to make a heat exchanger better at handling heat. Some of these are using microchannels making plates to improve heat movement and vibration. Increasing the conductivity of the working fluids is another way to boost thermal efficiency. Fluids that are used in industry, like water, ethylene glycol, motor oil, and others, tend to be less conductive than solids. In order to improve efficiency, solids can be added to the fluid in the form of nanoparticles, which create a Nano Fluid. On the other hand, these particles can also scavenge, block, or corrode channels, which can raise the transfer coefficient and make the system work better.

Nanoparticles can be made from a lot of different things. Since materials like Al2O3, CuO, TiO2, SiC, TiC, Ag, Au, Cu, and Fe are thermally more conductive, even at low concentrations, they have an effective heat transfer rate. This is true whether the material is metal or not.

Finally, the Mixture method was used to make a multiphase model of the Nano Fluid. The solid phase is also thought to be flexible in this model. Two-phase fluid will combine in this case to run the numerical model. The results are shown as temperature outlines and fluid path lines (so that the baffles’ effect can be seen) of the heat exchanger.

Shell and Tube Heat Exchanger, Helical Fin, NanoFluid

In this ANSYS Fluent example, a shell and tube heat exchanger with helical fins is being looked at. There are mechanical devices called heat exchanges that move heat from hot to cold areas. There are different kinds of heat exchangers, and they are used in many ways in business. Shell and tube heat exchangers are one of the most popular and widely used types in the business.

There are two cold or hot flows. One goes through the tubes of the heat exchanger, and the other goes through the shell. Now, spiral fins inside the heat exchanger’s shell will make the fluid move more slowly inside the shell, which will increase the chance that it will touch the tubes’ surfaces. This makes the rate of heat transfer inside the heat exchanger faster. In this project, the movement of heat inside the heat exchanger is looked into. Nanofluid made of Al2O3 and water is used inside the heat exchanger instead of pure fluid.

The curves of temperature, speed, and pressure are found after modeling. The findings show that using nanofluids instead of fluid and putting spiral fins inside the flow path of the shell helps move heat more efficiently. It is clear from the temperature curve that heat is moving through the shell part of the heat exchanger.

– Mechanical Engineering: In the field of mechanical engineering, nanofluids have been identified as potential candidates for applications such as coolant or lubricant in various mechanical systems. Computational fluid dynamics (CFD) simulations have the potential to contribute to the optimization of flow and heat transfer characteristics of nanofluids, hence resulting in improved system performance.

– Chemical Engineering: In the field of chemical engineering, the utilization of nanofluids in reactors has been explored as a means to enhance heat transmission during chemical processes. Computational Fluid Dynamics (CFD) simulations have the potential to enhance comprehension of the intricate dynamics exhibited by nanofluids within reactors, hence facilitating the development of more effective process designs.

– Energy Systems: In the context of renewable energy systems, such as solar collectors and thermal storage systems, the utilization of nanofluids has been found to improve energy efficiency significantly. Computational Fluid Dynamics (CFD) simulations can be employed for the purpose of analyzing and optimizing these systems.

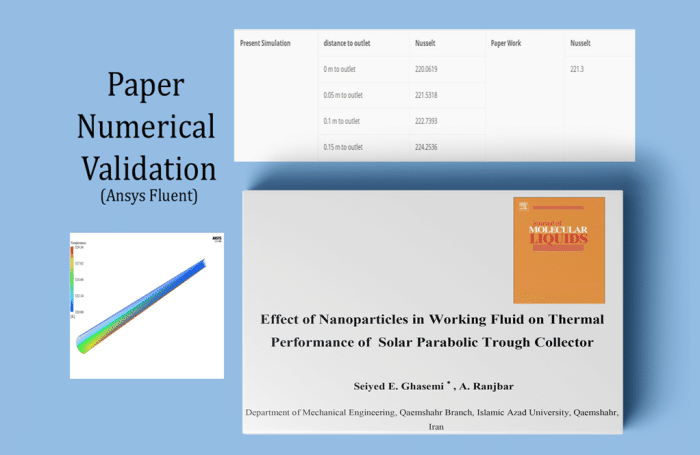

In this case, only the pipe that moves water is modeled. The wall of the pipe is split into two parts: the upper wall and the bottom wall. The water pipe’s wall is also made of metal. The main goal of this exercise is to learn more about the Nusselt number. One last step in the solution process is to find the Nusselt number value and make sure it matches the values given in the reference piece.

When you use the REPORT command, it figures out how much surface Nusselt is at the point where the fluid meets the pipe wall. The paper says that the value of the Nusselt number is found in areas with fully formed flow. This numerical program also looks at the Nusselt number value at the pipe’s end, which is where the flow starts.

When we look at the amount of Nusselt on the surface at different points near the pipe’s end and compare it to the amount of Nusselt in the article, we can see that the solution is more accurate and the simulation is more valid as we get closer to the pipe’s end and the area with the developed flow. You can also get two-dimensional and three-dimensional images of the pressure, speed, and temperature. In the model’s symmetrical cross-section, two-dimensional lines are drawn around the edges.

MR CFD services in the NanoFluid Simulation for Engineering and Industries

With several years of experience simulating various problems in various CFD fields using ANSYS Fluent software, the MR CFD team is ready to offer extensive modeling, meshing, and simulation services. MR CFD is a reputable organization that offers a range of Computational Fluid Dynamics (CFD) services encompassing the specialized field of NanoFluid Simulation. This phenomenon is of particular significance within the engineering and industrial domains, where there is a pressing need to forecast and assess the behavior of nanofluids.

The method of simulating Nanofluid involves the intricate modeling of fluid flow at the nanoscale. This holds special significance in sectors such as:

– Electronics: Electronics are utilized in the context of cooling systems for microelectronic devices and data centers.

– Automotive: The automotive industry seeks to improve heat transfer in automobiles.

– Energy: The purpose of this research is to enhance the efficiency of solar panels and nuclear reactors in terms of energy production.

– Biomedical: The field of biomedical research focuses on the development of medication delivery methods and advancements in cancer treatment.

The services provided by MR CFD encompass:

– 3D Modeling and Meshing: The process of 3D modeling and meshing involves the creation of a three-dimensional representation of a system, followed by the subdivision of this model into smaller cells to facilitate precise simulation.

– CFD Simulation: The present study used computational fluid dynamics (CFD) software to conduct simulations of flow and heat transport phenomena in a system using nanofluids.

– Result Analysis: The examination of the obtained results in order to gain insights into the characteristics and effects of nanofluids on the system.

– Optimization: Optimization involves proposing improvements aimed at enhancing the efficiency and performance of the system.

The specific range of services and capabilities offered by MR CFD may exhibit variability. Therefore, it is advisable to establish direct contact with the company to obtain more precise and up-to-date information.

NanoFluid in ANSYS Fluent

To simulate a NanoFluid using ANSYS Fluent, it is necessary to adhere to the following procedural guidelines:

– Define the fluid properties: The initial stage involves establishing the characteristics of the base fluid and the nanoparticle in question, thereby defining their respective qualities. The material properties in ANSYS Fluent can be defined by accessing the ‘Materials’ tab.

The materials undergo a transformation process, resulting in the creation of a fluent database. This database is characterized by its ability to adapt and change easily. It is a dynamic and flexible system that allows for the efficient storage and retrieval of information. Please choose your base fluid, then proceed to modify or create a new one. Provide a name for the fluid and confirm your selection by clicking “OK.”

– Create a mixture material: To generate a nanofluid, it is necessary first to identify the constituent fluid and nanoparticle, followed by the creation of a composite material.

The process involves selecting materials, specifically a new material, and creating a mixture of materials. This mixture material is then given a name, and the process is confirmed by selecting the “OK” option.

– Define the properties of the Nanofluid: The qualities of a nanofluid are contingent upon the volume fraction of the nanoparticles present within the base fluid. The features above can be formally characterized within the designated section labeled as ‘Mixture Material.’

– Set up the model: To commence the modeling process, it is necessary first to establish the parameters and characteristics of the Nanofluid. Once the Nanofluid has been defined, the subsequent step involves configuring the model. This encompasses the establishment of boundary conditions, configuration of the solver, and initialization of the solution.

– Run the simulation: To proceed with the experiment, it is essential to execute the simulation and subsequently examine the obtained outcomes.

It is important to acknowledge that the precision of the simulation is contingent upon the precision of the characteristics of the foundational fluid, the nanoparticle, and the Nanofluid. The model additionally posits that the nanoparticle exhibits homogeneous distribution within the base fluid and does not experience gravitational settling.

NanoFluid MR CFD Projects

Presented below is a comprehensive framework delineating the potential structure for the project above.

1. Introduction

The present section serves as an introductory segment. This section aims to present a concise description of the project, its objectives, and its significance within the realm of computational fluid dynamics.

1.1 Purpose

The main aim of this study is to replicate the behavior of NanoFluid MR under different settings and gain knowledge about its qualities and potential uses.

1.2 Importance

The results obtained from this study possess considerable potential for practical implementation across diverse sectors, such as the automobile, energy, and aerospace industries.

2. Research Methodology

This section will include a comprehensive account of the methodologies employed in the project.

2.1 Simulation Software

The simulation will be conducted using computational fluid dynamics (CFD) software. The software offers a comprehensive platform for the simulation of fluid flow, heat transfer, and other associated phenomena.

2.2 Model Configuration

The model configuration will encompass the establishment of the geometric design, the determination of fluid properties, and the specification of boundary conditions.

2.3 Simulation

Simulation In this section, we will discuss the concept of simulation and its relevance in academic research. Simulation is a technique used to model and replicate The simulation will be conducted under many situations, and the outcomes will be subjected to analysis.

3. The findings and subsequent analysis

The subsequent part will provide an exposition of the outcomes derived from the simulations and deliberate about their ramifications.

3.1 Findings

In this section, the outcomes of the simulations will be shown. This may encompass visual representations such as figures, graphs, and tables that illustrate the performance of the NanoFluid MR across various situations.

3.2 Discussion

The following section will discuss the findings of the study and their implications. In this discourse, we shall examine the ramifications of the obtained outcomes, juxtapose them with prior investigations, and put up plausible justifications for any unforeseen discoveries.

4. Conclusion

The subsequent section will provide a concise overview of the project’s findings and provide potential avenues for future research.

4.1 Overview of Results

In this section, we shall provide a concise overview of the primary outcomes derived from the study.

4.2 Future Research

Areas for Future Research In this section, we discuss potential areas for future research that could build upon the findings of this study. Based on the findings of this project, we will propose prospective avenues for future research.

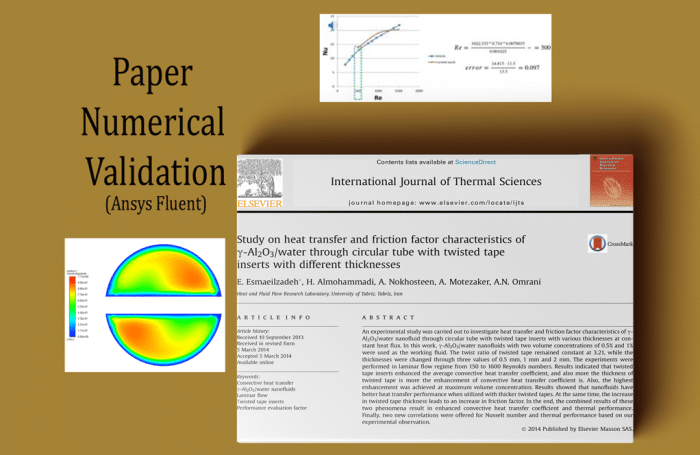

ANSYS Fluent software is used to model the flow of Al2O3 and water inside a round tube with twisted tape inserts. “Study on heat transfer and friction factor characteristics of Al2O3-water through circular tube twisted tape inserts with different thicknesses” is what the simulation is built on.

The article’s findings are compared to its own and found to be correct. The results of this work are compared with the results of the study after simulation. Figure 10 was used as a guide because it shows how the Nu number changes as the Re numbers change. Also, it’s important to state that we’ve checked the results for Re number =500.

The results show that there aren’t many mistakes and that the current exercise is being done right. It is also possible to get the outlines of pressure and speed. The Nanofluid’s pressure drops along the path that goes through the twisted tapes, as shown by the contours. This is because these barriers break the pressure. The temperature of the Nanofluid, on the other hand, also rises. Putting a spiral barrier in the way of the Nanofluid makes it go farther and come into touch with the outside wall more, which increases the heat flow.

Nanofluid Flow Heat Transfer in a Wave Sine Channel

ANSYS Fluent software is used to simulate the wave motion of a nanofluid in a sinusoidal channel for this task. The nanofluid current in the channel is made up of Al2O3 and water. This means that it has 1% nanoparticles by volume. The thermophysical properties of the nanofluid material can be found using the following formulae. The table below shows how much of each thermophysical property there is in the water fluid and nanoparticles. When the Nanofluid flows into the channel, it is at a temperature of 300 K. Because the shape is wavy, the horizontal speed of the input current depends on its vertical direction. The following describes this horizontal flow velocity function, which is built into the program as a UDF.

At the end of the solution process, temperature, pressure, and speed are shown as two-dimensional outlines. It is also possible to get a graph of how pressure and speed change along a made-up horizontal line that runs through the middle of the canal.

Nano Fluid in Heat Source Channel, Mixture Multiphase

ANSYS Fluent software is used to simulate the flow of an Al2O3-water nanofluid into a channel with a heat source in this case. This channel is square, and there are ten obstacles inside it. Each of these hurdles has a cylinder in the middle and two diagonal plane barriers that face each other. Because of this, the direction of the nanofluid flow through the channel is determined by these barriers.

Because of this, two different substances have been used: water as the main fluid and aluminum oxide (Al2O3) as the second fluid. The aluminum oxide nanoparticle may enter the tube at the same speed and temperature as the water. This means that the nanoparticle volume fraction is 0.01.

When the solution process is over, two-dimensional and three-dimensional shapes are made that show the mixing pressure, temperature, and speed of the water and Al2O3 stages. There is a heat source that makes the fluid warmer as it flows to the outlet area. Nanoparticles also raise the temperature because they allow more heat to move through them.

NanoFluid Application in Industrial Companies

Nanofluids are a new class of heat transfer fluids that have been developed for enhancing the thermal performance of existing industrial cooling systems and heat transfer applications. They are engineered by dispersing nanoparticles into a base fluid such as water, oil, and ethylene glycol. Here are some of the applications of nanofluids in industrial companies:

1. Cooling Systems

Nanofluids are used in cooling systems to enhance heat transfer. They provide better cooling performance compared to conventional coolants. This application is particularly useful in industries that require high-performance cooling systems, such as automotive and electronics manufacturing.

2. Energy Sector

In the energy sector, nanofluids are used to improve the efficiency of thermal power plants. They are used in solar collectors and geothermal energy systems to improve heat transfer.

3. Manufacturing Processes

Nanofluids are also used in various manufacturing processes. For example, in metalworking industries, nanofluids are used as coolants in machining processes to enhance tool life and improve the surface finish of the workpiece.

4. Electronics Industry

In the electronics industry, nanofluids are used for cooling electronic components and systems. They are used in thermal interface materials, heat sinks, and microchannel coolers to improve thermal management.

Thermal Management of Battery Using Nano Fluid

Before, an efficient, modular battery simulation model called the MSMD model was released to help with the scaling up of Li-ion material and electrode designs to full cell and pack designs. It did this by capturing the electrochemical interaction with 3-D electronic current pathways and thermal reactions. The design is expandable and flexible, and it connects the physics of how batteries charge and discharge, as well as safety, reliability, and thermal control.

In this simulation, a mixture multiphase model is used, and the role of nanofluid movement in improving heat transfer in the battery is studied. The goal of this work is to find out how well phase change materials work in cooling the battery. At the end of the solution process, we got pressure outlines in two dimensions and temperature contours in three dimensions. This image was shown in 500 seconds. The findings show that adding a Nanofluid flow to the battery’s body will cool it down and slow the rate at which the temperature rises.

Electric Field Effect on Nanofluid Considering Charge Density, CFD Simulation, ANSYS Fluent Training

A nanofluid is a liquid that has nanoparticles, which are particles that are only a few nanometers in size. Nanofluids have unique qualities that could make them useful in many heat transfer situations. Compared to the base fluid, they have better thermal conductivity and convective heat transfer efficiency.

Nanofluids’ rheological behavior is very important for figuring out if they can be used for convective heat transfer. An electric field has made a potential difference between the outside of a tube and a wire inside it. Since the shell has a higher potential and the wire is a negative pole, the particles move in a direction away from the electrodes.

A bent pipe is used to show the cross-section of Cooling System pipes in this case. Electricity is sent through this pipe by putting a thin wire in the middle of it. At the entrance, cool water comes into the pipe. It is 390 Kelvin hot inside the parts of the pipe body that have walls.

The cold water moves heat between the walls and the water, and the rise in temperature at the exit is watched. Aluminum nanoparticles with a Charge Density of 23 were added to the cooling liquid to make it better at transferring heat, and their behavior in an electromagnetic field was studied. The last step was to compare the data from the modes with and without particles.

When we look at the two cases we looked into, we can see that the temperature and speed are spread out more evenly in the case with particles. The average temperature calculated in the range of temperature increase is 0.1 Kelvin higher in the case with particles than in the case without particles, as shown in the table below.

The average temperature at the exit, on the other hand, goes up by 0.5 K in the model with electromagnetic field particles. Also, the velocity curve shows that nanoparticles affect the cooling fluid because of the magnetic field and the way the particles are shaped. The velocity field is also more even.

Electric Field Effect on Nanofluid Heat Transfer (EHD)

ANSYS Fluent software is used to study how nanofluid moves through a tube that is bumpy while an electrical potential is applied. The flow of fluid is steady and is simulated as a single-phase flow. However, the thermophysical features of the Nanofluid are changed. Due to the electrical properties of Nanofluid, the flow mechanics are changed, which leads to more heat movement.

The difference in the temperature of the Nanofluid’s outlet when an electric field is present versus when it is not shown how well the electric field was used in this study. When an electric field is applied, the temperature at the exit rises by 04K, and 54W/m2 of heat is transferred to the Nanofluid.

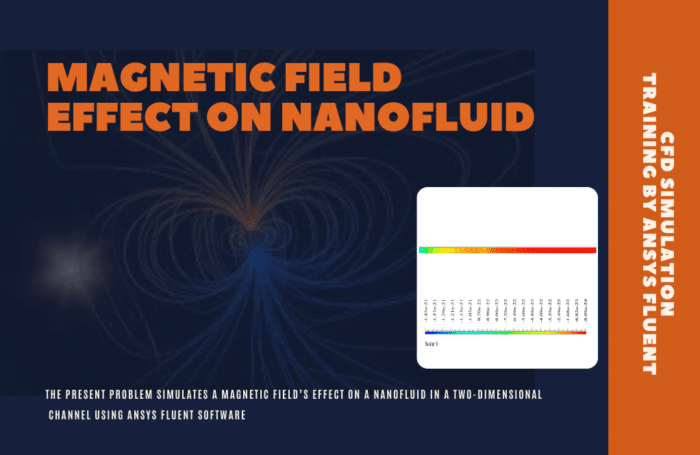

Magnetic Field Effect on Nanofluid, CFD Simulation, ANSYS Fluent Training (2-D)

Magnetic Field Effect on Nanofluid Heat Transfer (MHD)

ANSYS Fluent software is used to simulate how nanofluid moves through a solid aluminum channel when a magnetic field is introduced as part of this project. The average temperature of the nanofluid flow at the entrance is 293.2K, and at the outlet it is 304.175K. The temperature at the exit drops to 303.74K if there is no magnetic field acting on the Nanofluid. Nanofluid has a heat flow of 112102.2 w/m2.

By comparing the temperature of the Nanofluid’s outlet when there is and isn’t a magnetic field, we can see how well the magnetic field works in this study. When a magnetic field is applied, the temperature at the exit rises by 1K, and 200w/m2 of heat is transferred to the Nanofluid.

5. HVAC Systems

Nanofluids are used in Heating, Ventilation, and Air Conditioning (HVAC) systems to enhance heat transfer and improve energy efficiency.

The use of nanofluids in industrial applications is still a growing field, and more research is being done to understand their potential and optimize their use fully.

MR CFD Industrial Experience in the NanoFluid Field

Some examples of NanoFluid industrial projects recently simulated and analyzed by MR CFD in cooperation with related companies are visible on the MR CFD website.

You may find the Learning Products in the NanoFluid CFD simulation category in the Training Shop. You can also benefit from the NanoFluid Training Package, which is appropriate for Beginner and Advanced users of ANSYS Fluent. Also, MR CFD is presenting the most comprehensive NanoFluid Training Course for all ANSYS Fluent users from Beginner to Experts.

Our services are not limited to the mentioned subjects. The MR CFD is ready to undertake different and challenging projects in the NanoFluid modeling field ordered by our customers. We even carry out CFD simulations for any abstract or concept Design you have to turn them into reality and even help you reach the best strategy for what you may have imagined. You can benefit from MR CFD expert Consultation for free and then Outsource your Industrial and Academic CFD project to be simulated and trained.

By outsourcing your Project to MR CFD as a CFD simulation consultant, you will not only receive the related Project’s resource files (Geometry, Mesh, Case, and Data, etc.), but you will also be provided with an extensive tutorial video demonstrating how you can create the geometry, mesh, and define the needed settings (preprocessing, processing, and postprocessing) in the ANSYS Fluent software. Additionally, post-technical support is available to clarify issues and ambiguities.