6DOF Wind Turbine CFD Simulation

$140.00 $70.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

6DOF Wind Turbine CFD Simulation using ANSYS Fluent

Introduction

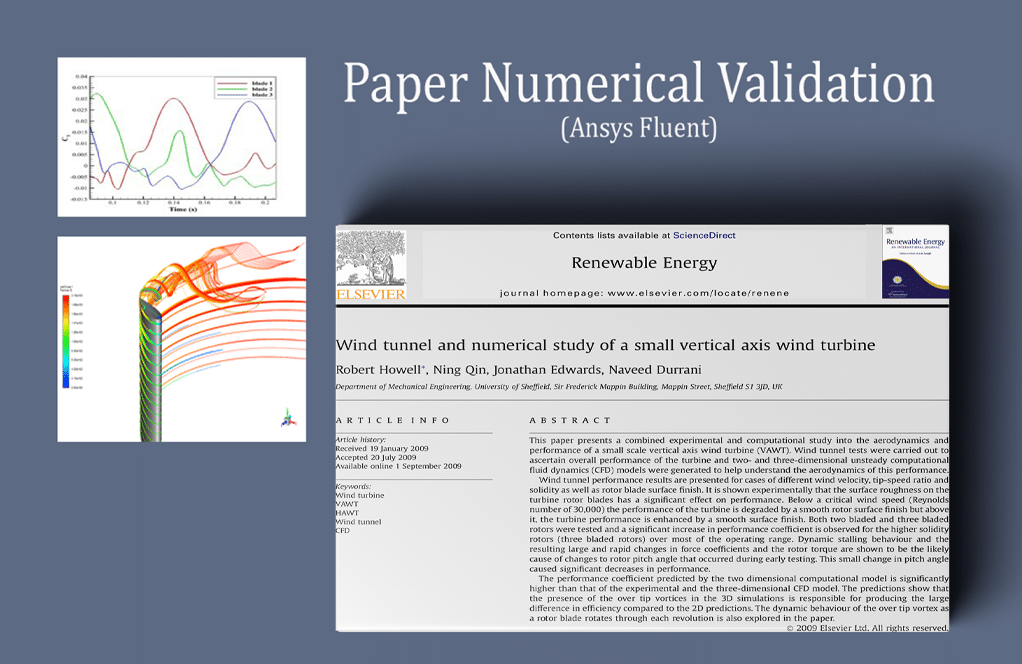

This study investigates the airflow dynamics of a two-dimensional wind turbine using Computational Fluid Dynamics (CFD) analysis. The simulation aims to understand the effects of incoming airflow on the rotation of the turbine and the resulting flow patterns, velocity distributions, and overall system performance. By employing advanced models for turbulence and dynamic meshing, this research provides valuable insights into the complex interplay of fluid dynamics in wind energy systems.

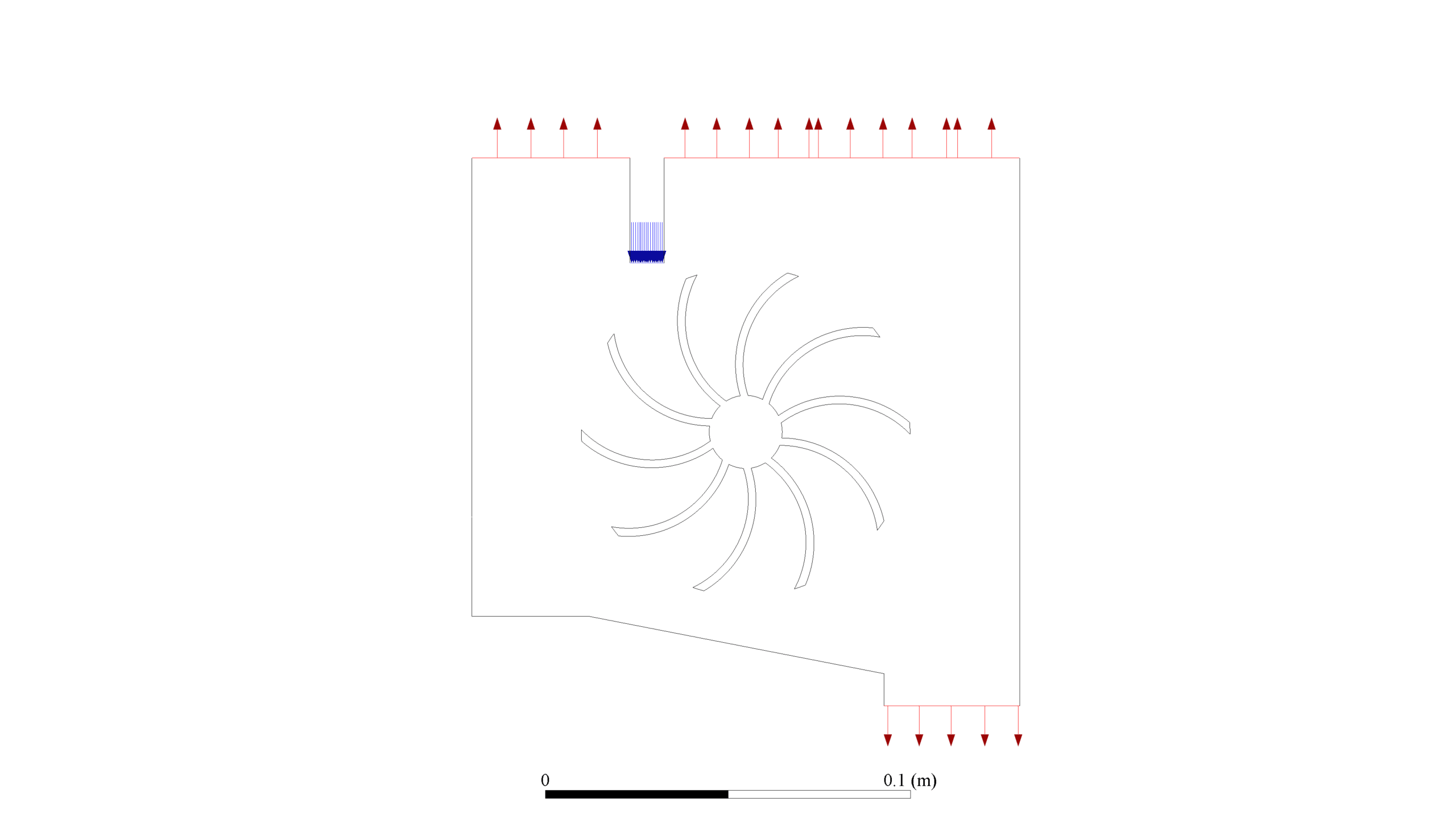

The simulation focuses on a scenario where the incoming airflow drives the rotation of a turbine, represented by a spiral-shaped structure in the center of the domain. This approach allows for the analysis of how the wind’s kinetic energy is converted into rotational motion, which is the fundamental principle behind wind turbine operation.

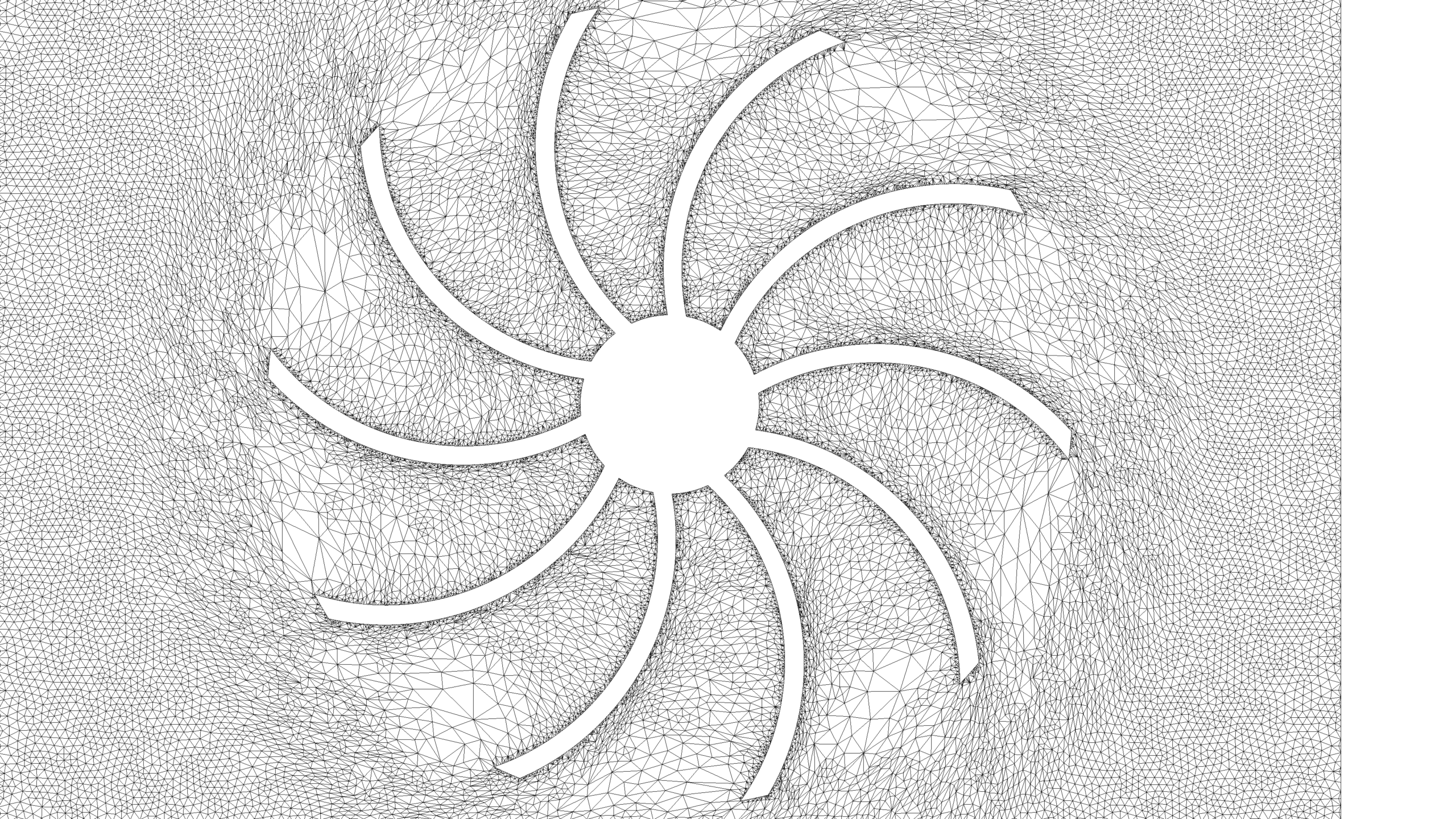

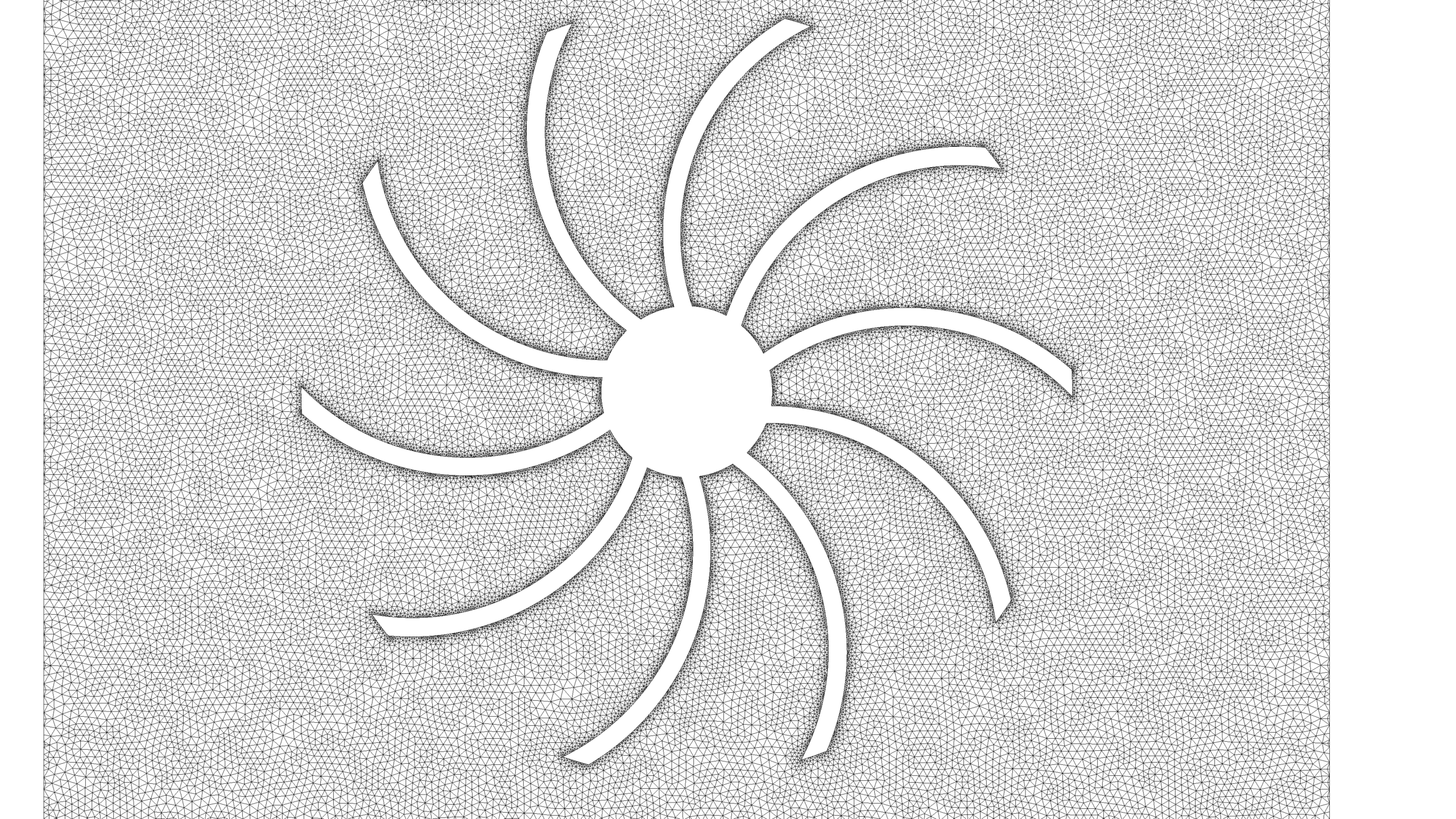

The geometry was designed in ANSYS Design Modeler, representing a 2D wind turbine within a rectangular domain. The mesh was generated in ANSYS Meshing software, consisting of 60,912 tetrahedral elements, chosen for their suitability with the dynamic mesh method in ANSYS Fluent.

Methodology

The simulation was conducted using ANSYS Fluent software, employing a transient, pressure-based solver to capture time-dependent flow characteristics.

The dynamic mesh feature was enabled, utilizing both remeshing and smoothing methods:

Remeshing: Allows for the creation of new mesh elements as the wind turbine rotates, maintaining mesh quality in highly deformed regions.

Smoothing: Adjusts the positions of interior nodes to improve the quality of skewed cells without changing the number of cells.

The Six DOF (Degree of Freedom) option was enabled, with one degree of freedom allocated for rotation in the Z direction.

Results

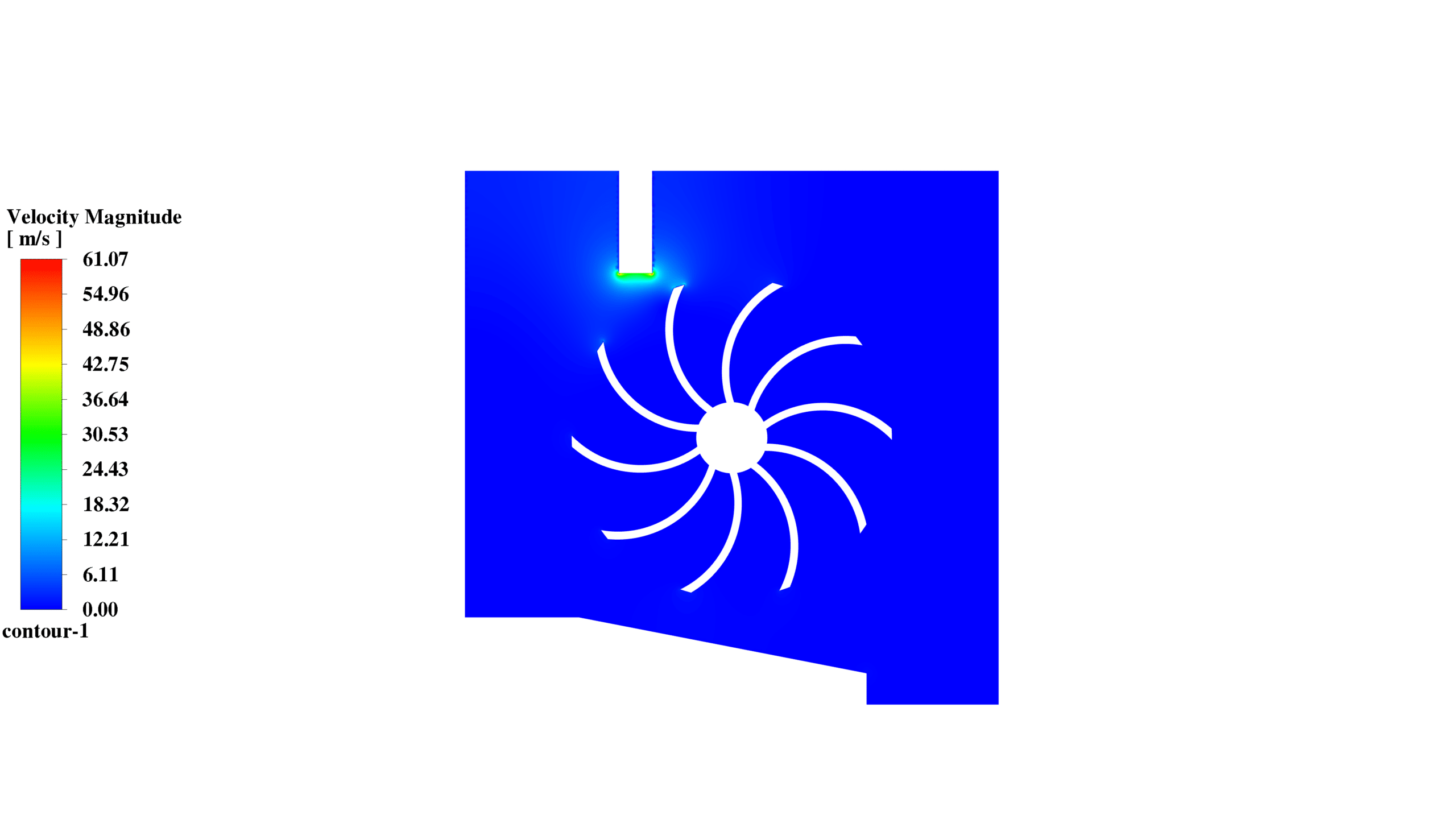

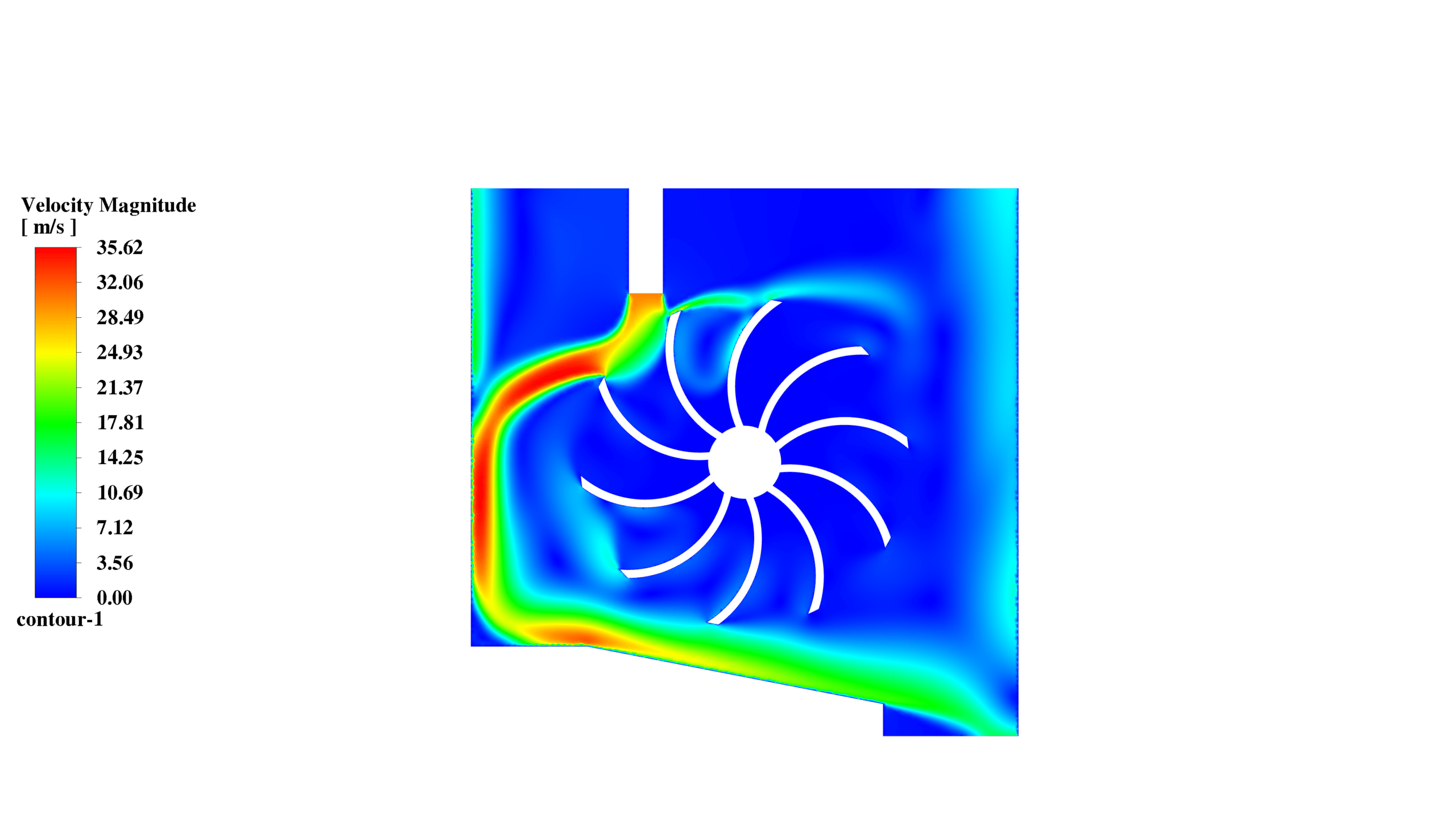

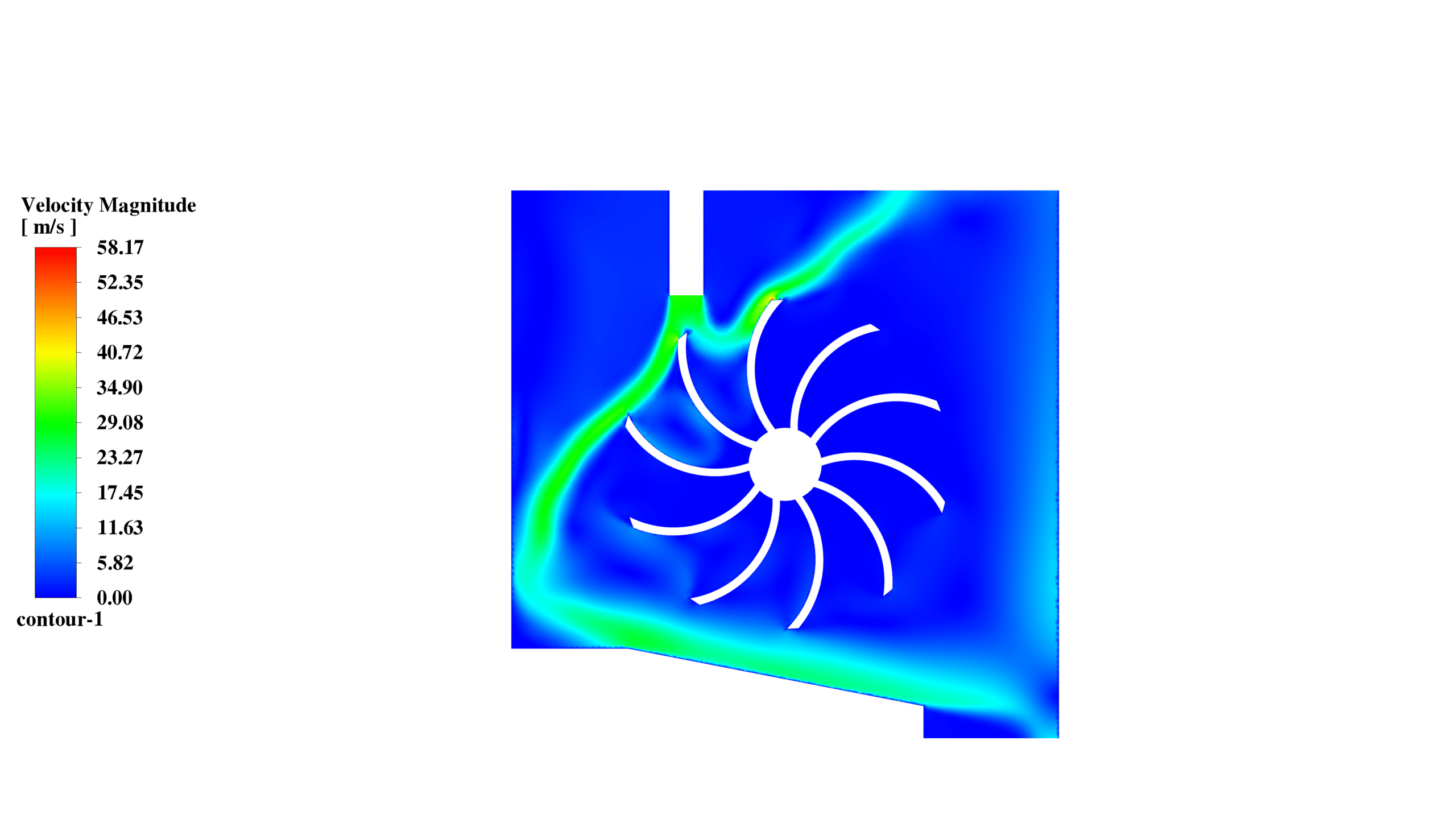

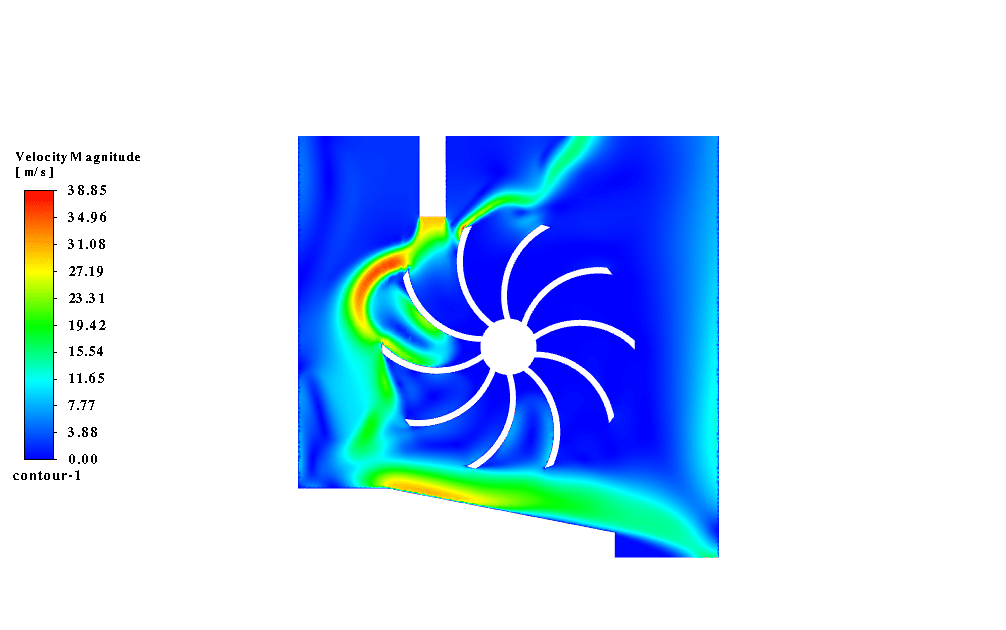

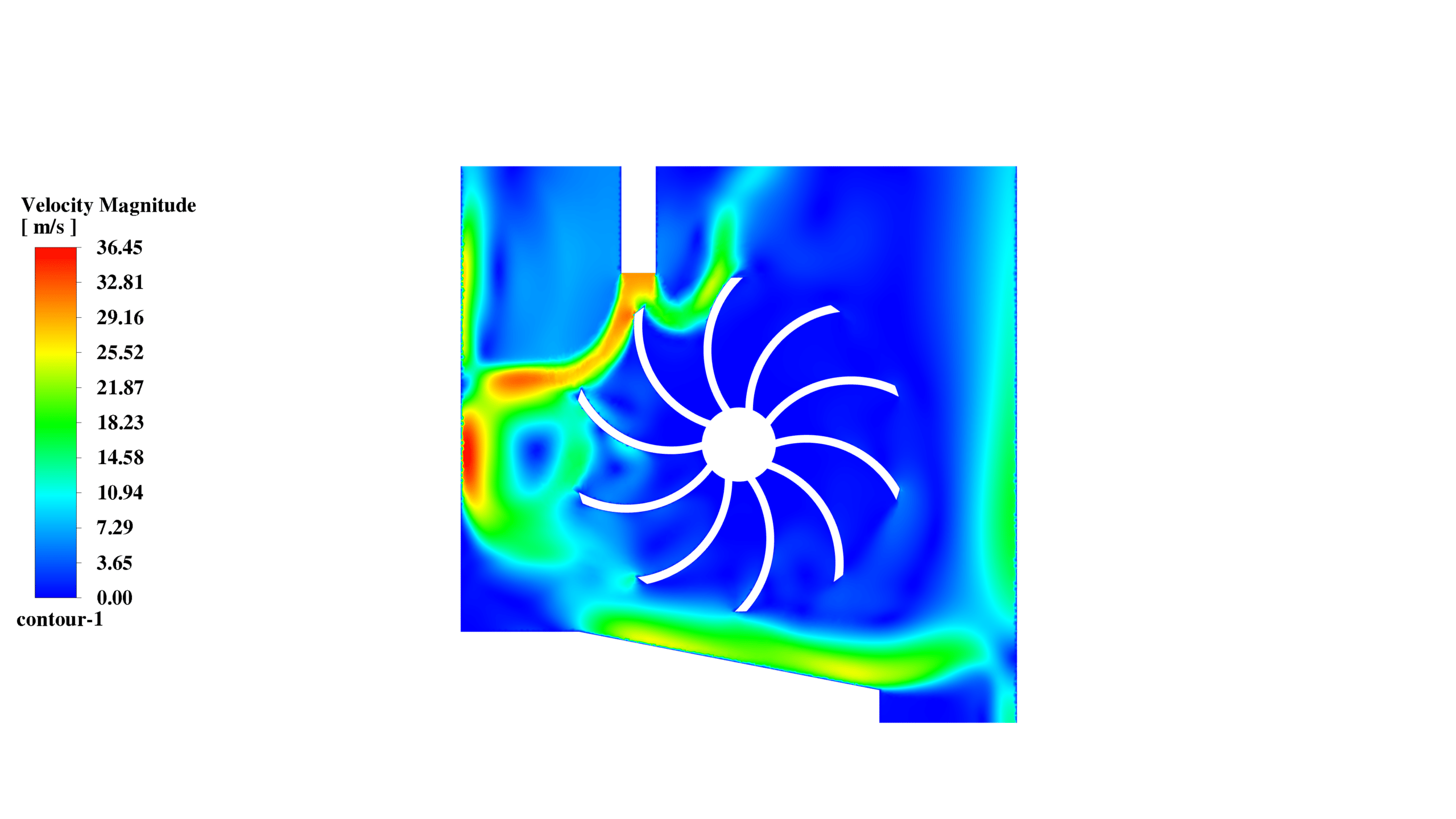

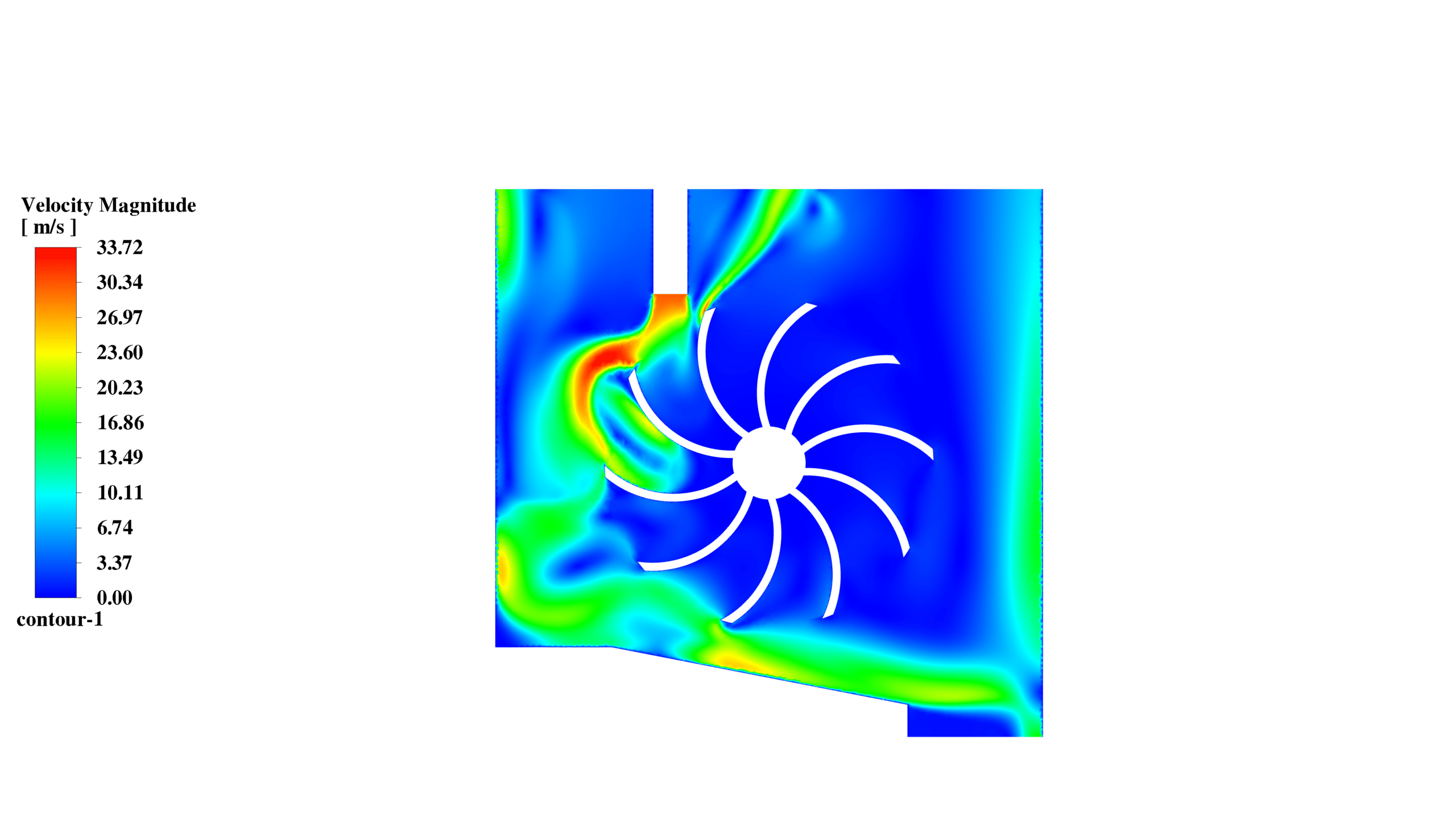

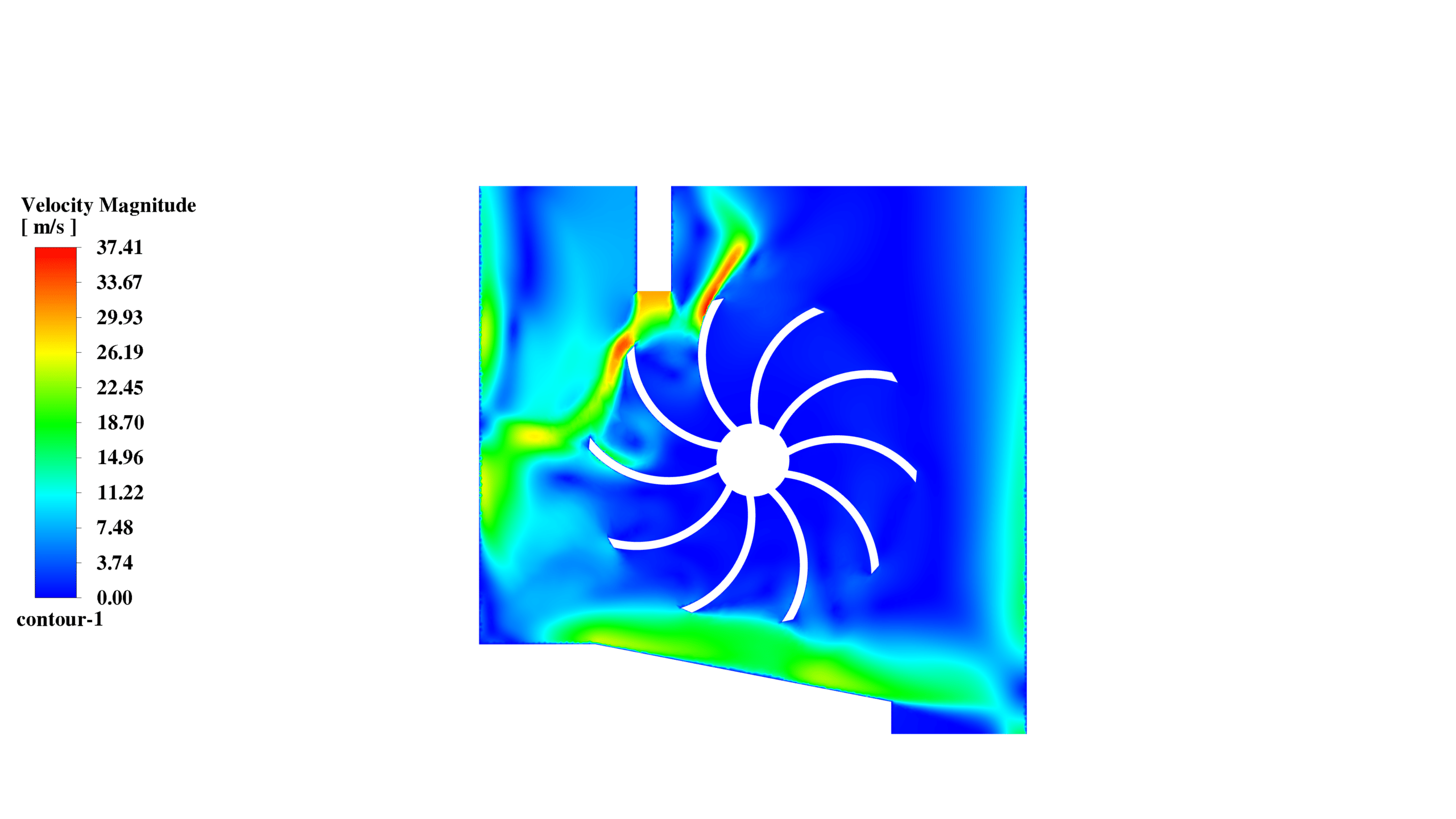

The velocity magnitude contours reveal several key observations:

Maximum velocities range from 33.72 m/s to 61.07 m/s across different time steps, indicating the transient nature of the flow. High-velocity regions are consistently observed near the blades and at the outlet, demonstrating the their effectiveness in accelerating the airflow. The asymmetric velocity distribution around the wind turbine suggests complex flow patterns and potential areas of recirculation.

The airflow enters from the top inlet, interacts with the rotating wind turbine, and exits through the bottom-right outlet. The wind turbine’s rotation creates a swirling motion in the airflow, evident from the curved high-velocity regions in the contour plots. Areas of lower velocity are observed in the corners of the domain, indicating potential dead zones or recirculation regions.

The sequence of velocity contour images shows the evolution of the flow field over time (0.6s):

Initial stages show a developing flow pattern with lower maximum velocities. As the simulation progresses, more complex flow structures develop, and higher velocities are achieved.

The final stages demonstrate a more established flow pattern, with consistent high-velocity regions near the blades and outlet.

This 2D CFD simulation provides valuable insights into the airflow dynamics within the system. The dynamic mesh approach effectively captures the transient behaviour of the rotating wind turbine, demonstrating their ability to accelerate airflow and create complex flow patterns within the domain.

Reviews

There are no reviews yet.