Air Compressor Acoustics Analysis, ANSYS Fluent CFD Simulation Training

$120.00 $60.00 Student Discount

- The present problem simulates the aeroacoustics and sound generation by an airflow inside a four-row multistage compressor (axial flow compressor) using ANSYS Fluent software.

- We have designed the geometry using ANSYS Design modeler software and created the mesh on this geometry using ANSYS meshing software. The mesh type is unstructured with 972354 cells.

- we use the periodic boundary condition in this project.

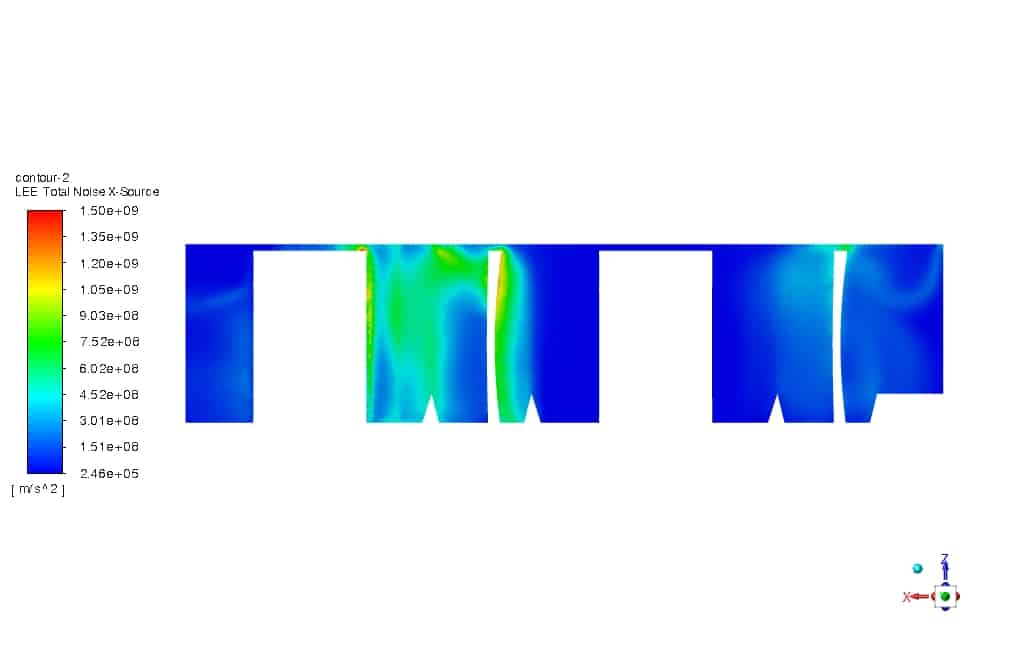

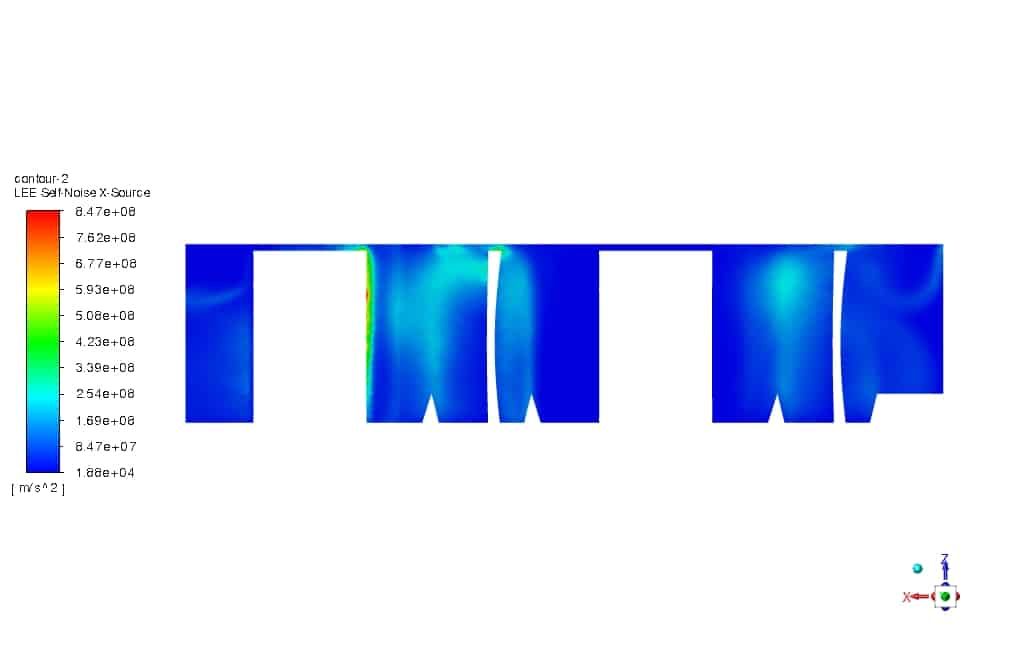

- The Broadband Noise Sources model is also used to define the acoustic model.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

description

In this project, we simulate the Air Compressor Acoustics Analysis in ANSYS Fluent software. Also the present problem simulates the aeroacoustics and sound generation by an airflow inside a four-row multistage compressor (axial flow compressor) using ANSYS Fluent software.

Today, engine manufacturers are trying to reduce the sound pollution caused by engines, and they use various techniques. The first step in this way is to know the amount of sound produced by each part of the engine components.

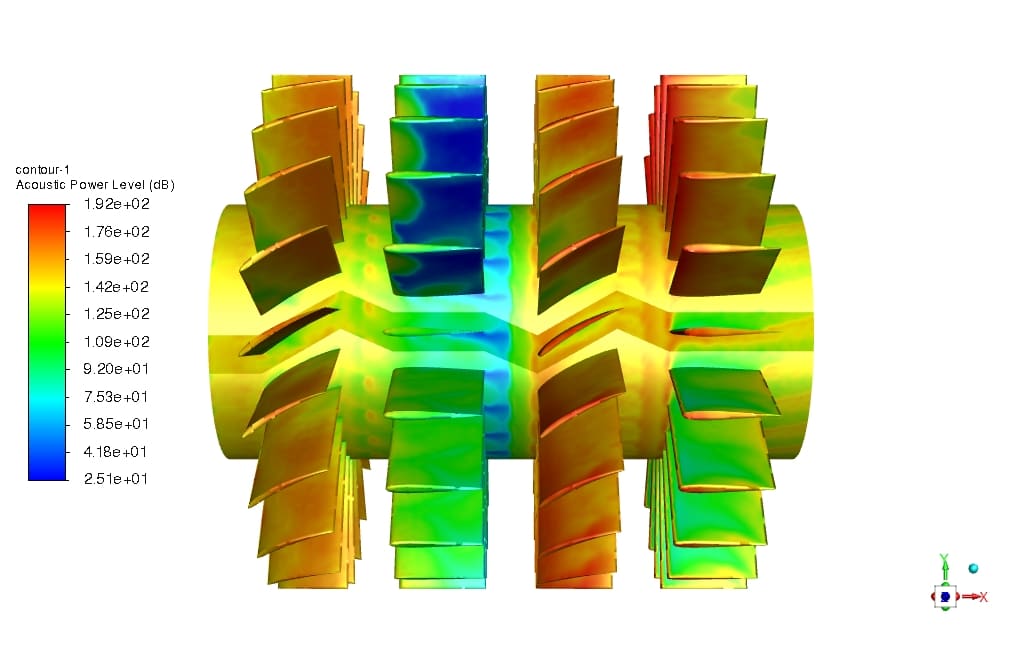

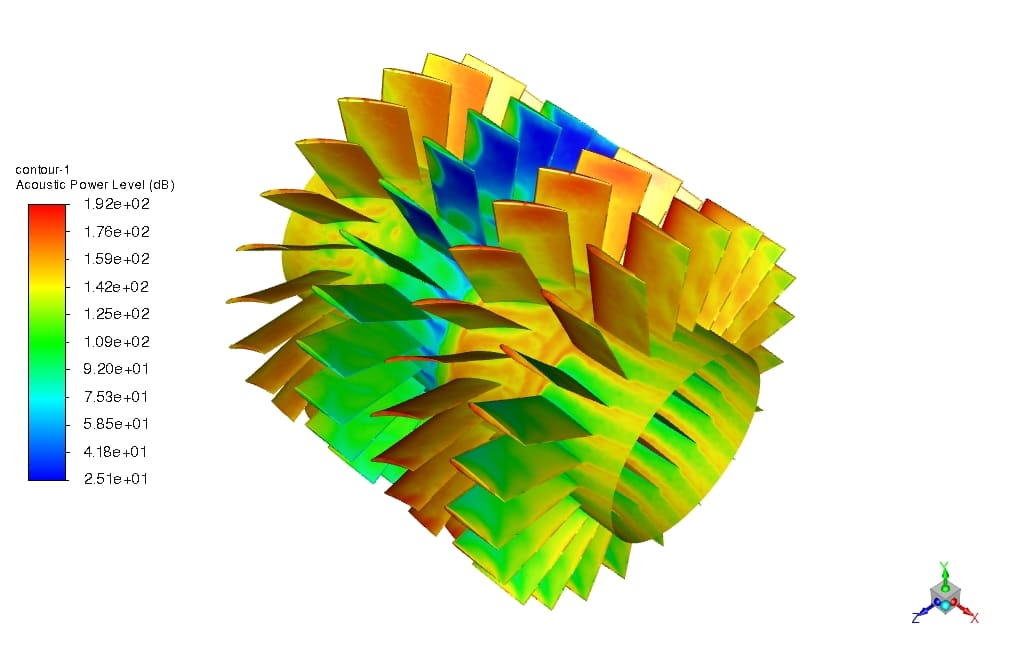

The present model is designed in three dimensions using Design Modeler software. The model includes two rows of the rotor and two rows of the stator. Each row of stator or rotor consists of 22 blades with an airfoil cross-section. The rotor blades have deflection, but the stator blades are horizontal and without deflection.

Due to the perfectly symmetrical structure of this geometry and to reduce the computational cost, we only design one blade of each row of stator and rotor , and we use the periodic boundary condition for its lateral surfaces.

We carry out the model’s meshing using ANSYS Meshing software, and the mesh type is unstructured. The element number is 972354.

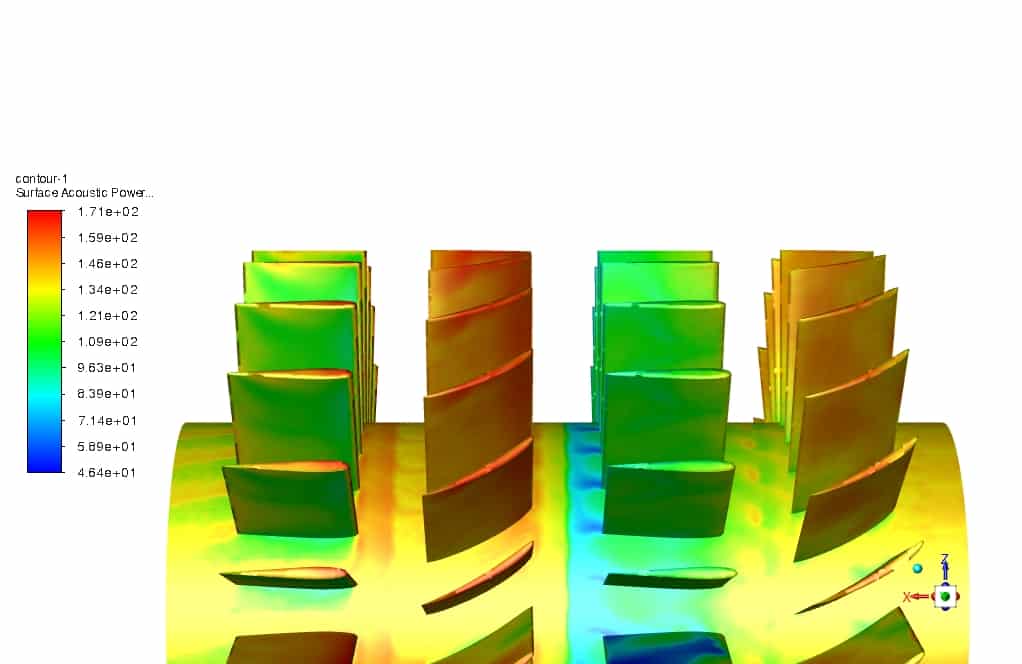

Definitive density is equivalent to air density, i.e. 1.225 kg.m-3, and sound speed is equivalent to sound speed in air, i.e. 340 m.s-1, and reference acoustic power is equal to 1e-12.

Methodology: Air Compressor Acoustics Analysis

We use the periodic boundary condition in this project and the Broadband Noise Sources model is used to define the acoustic model.

Conclusion

Since we investigate the issue of the turbomachine in this case already. This acoustic review continues on the same settings.

Observations show that the rotors have a greater share of the components that create sound and show more acoustic power in the related contour. Contour linear Euler’s equations show how fast the sound propagates in the space between the rotor and the stator.

Reviews

There are no reviews yet.