Airplane Washing Using Water Jet, CFD Simulation ANSYS Fluent Training

$140.00 $70.00 Student Discount

This project was performed to simulate aircraft washing using a water jet by ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Airplane washing Introduction

Airplane fuselages become contaminated over time due to high-velocity motion, including insect carcasses and bird droppings that combine with engine exhaust to create a carcinogenic layer of contaminant on the fuselage. This Airplane washing is done several times during the year. Airplane windows are also sensitive parts that can be easily scratched, and it is best to cover these parts before starting the washing process.

Problem Description

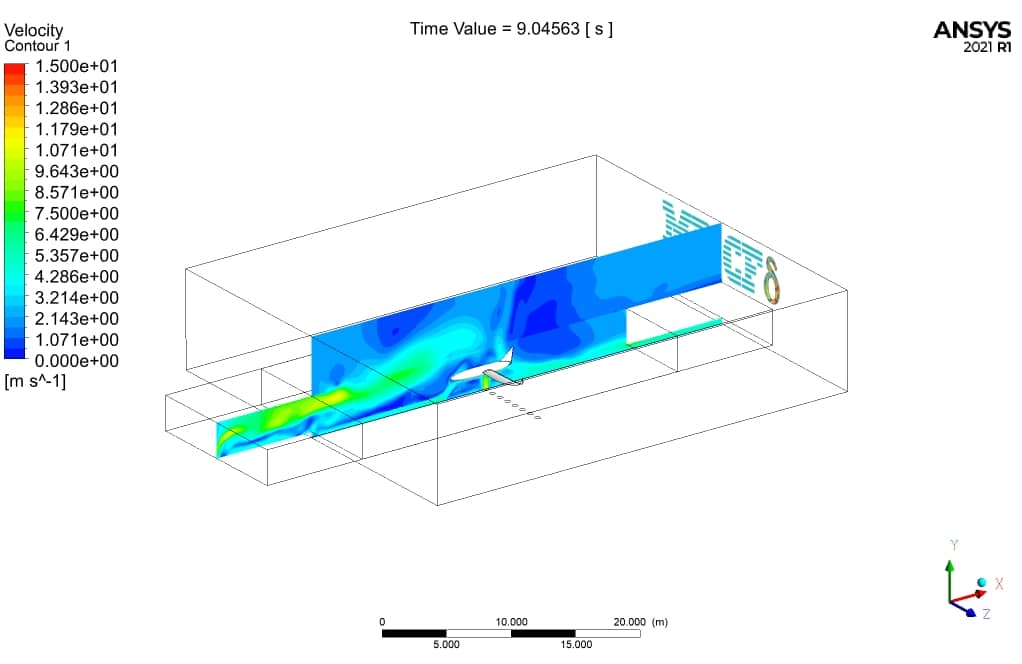

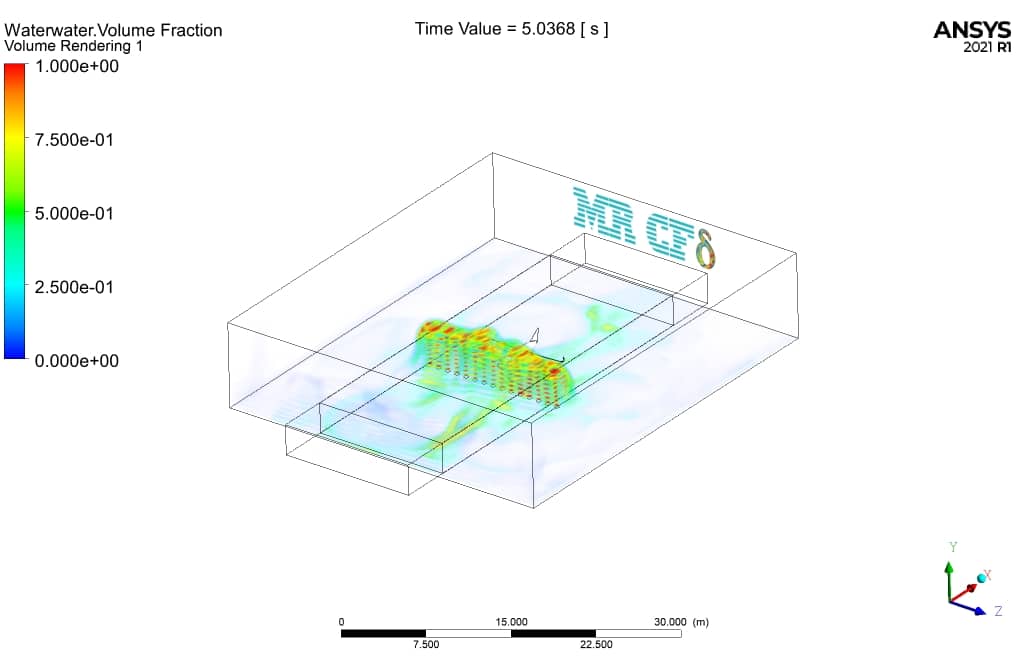

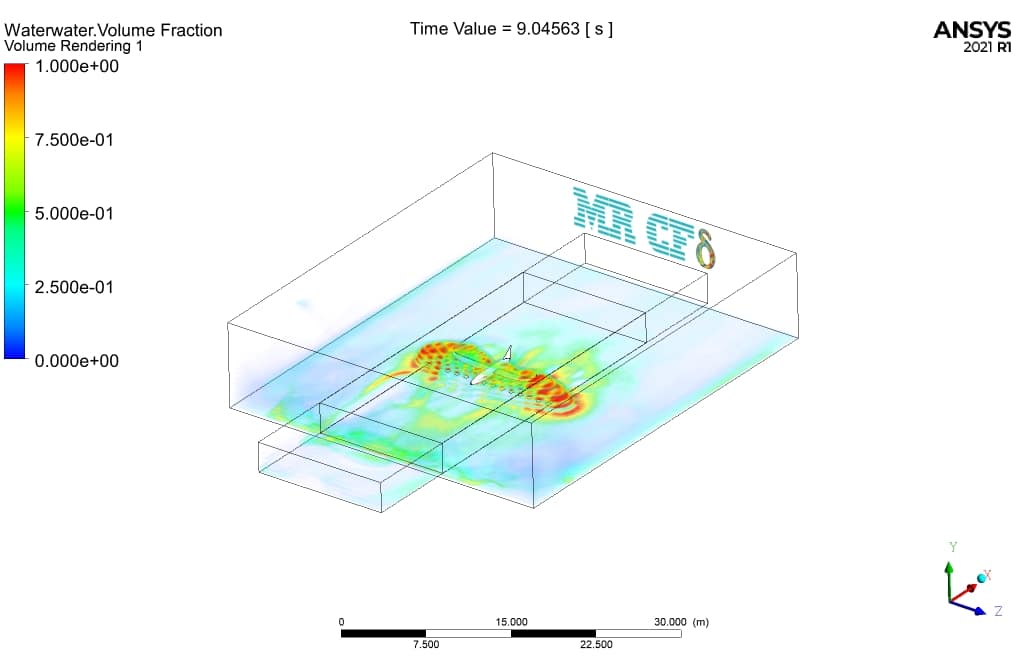

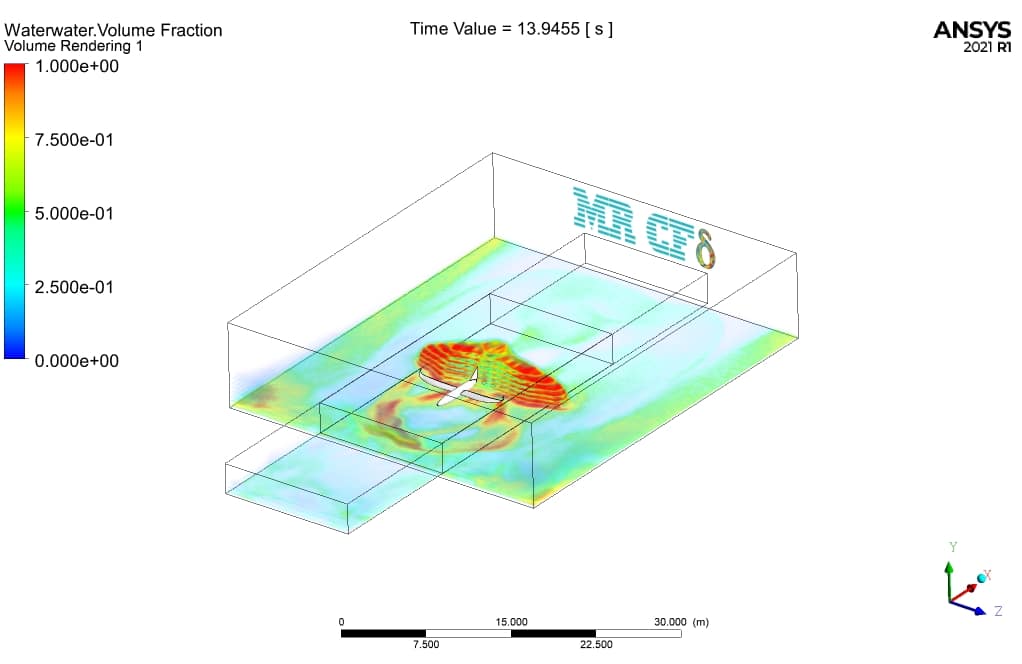

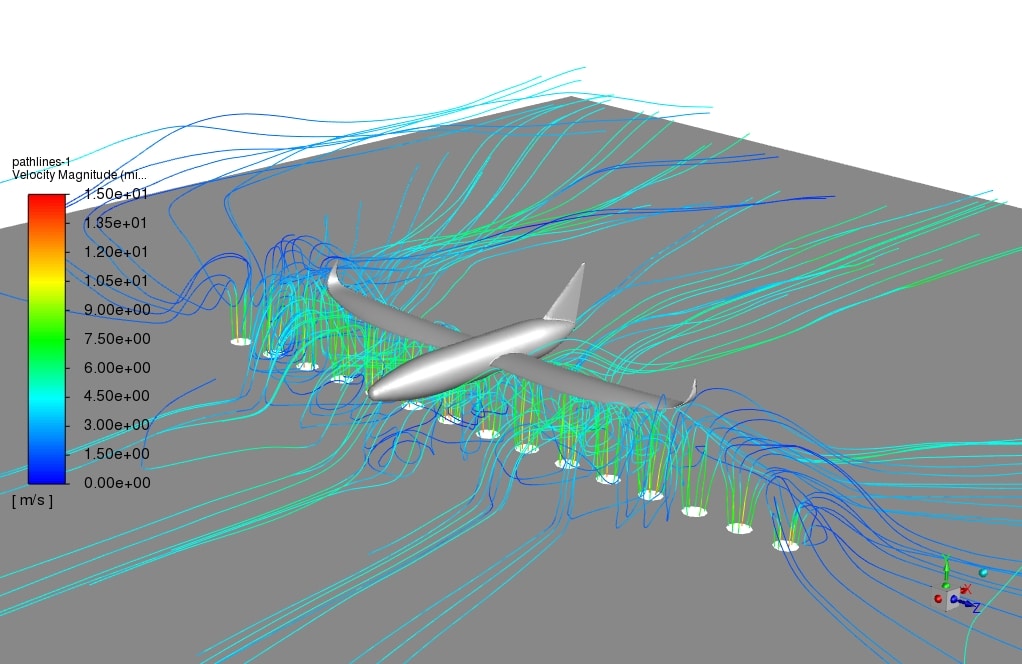

This project was performed to simulate aircraft washing using ANSYS Fluent software. The computational domain of a cube with dimensions of 46 x 8.5 x 17, in which a separate part is provided to move the sub-domain of the aircraft using the sliding mesh model. Water enters the computational domain through holes in the bottom of the slope at a speed of 15 meters per second and air in the opposite direction of the plane at a speed of 2 meters per second from the opposite side to model more realistic conditions.

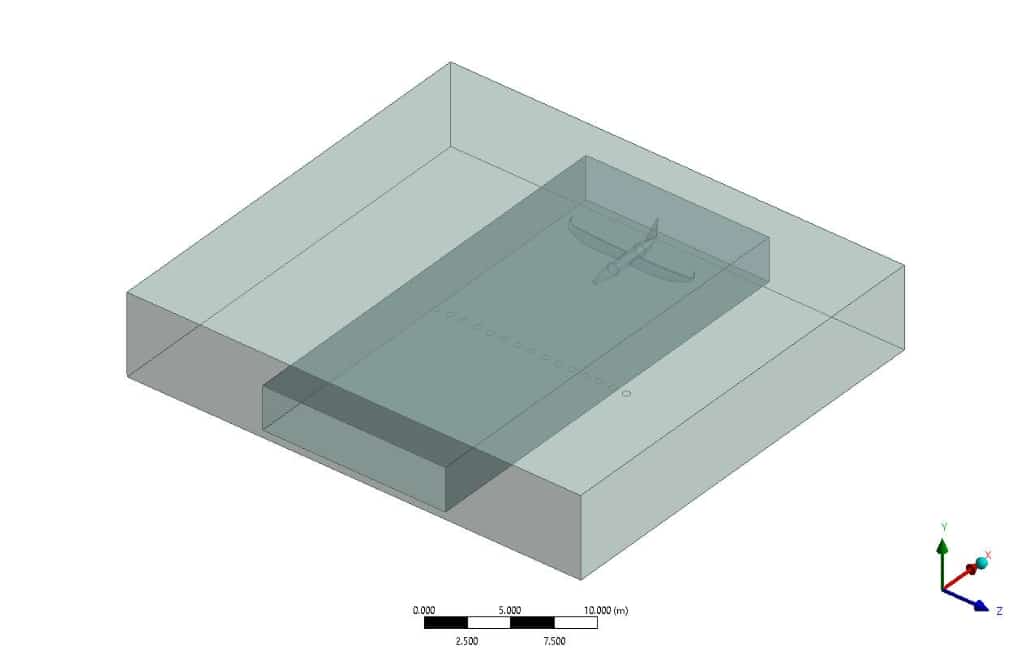

Geometry & Mesh

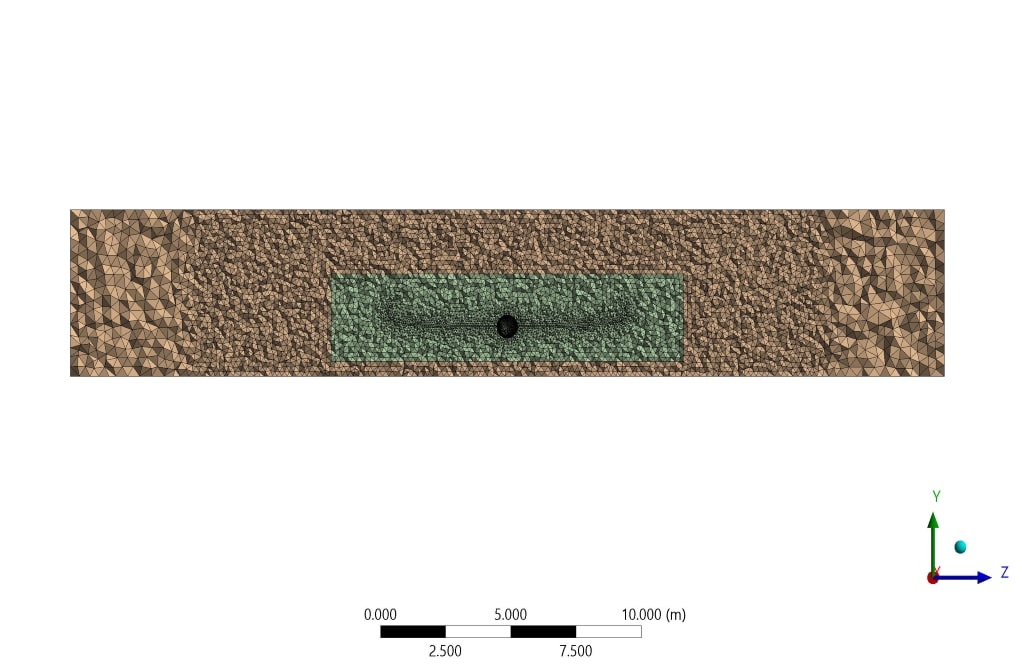

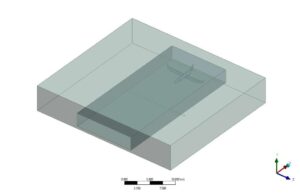

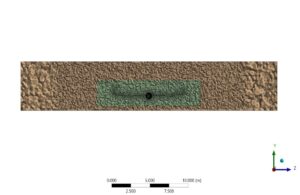

The computational domain was designed using Design Modeler software. The computational domain includes a 46 x 8.5 x 17 m cube. The domain in which the plane was located and moving a cube with a cross-section of 13.5 x 3 meters.

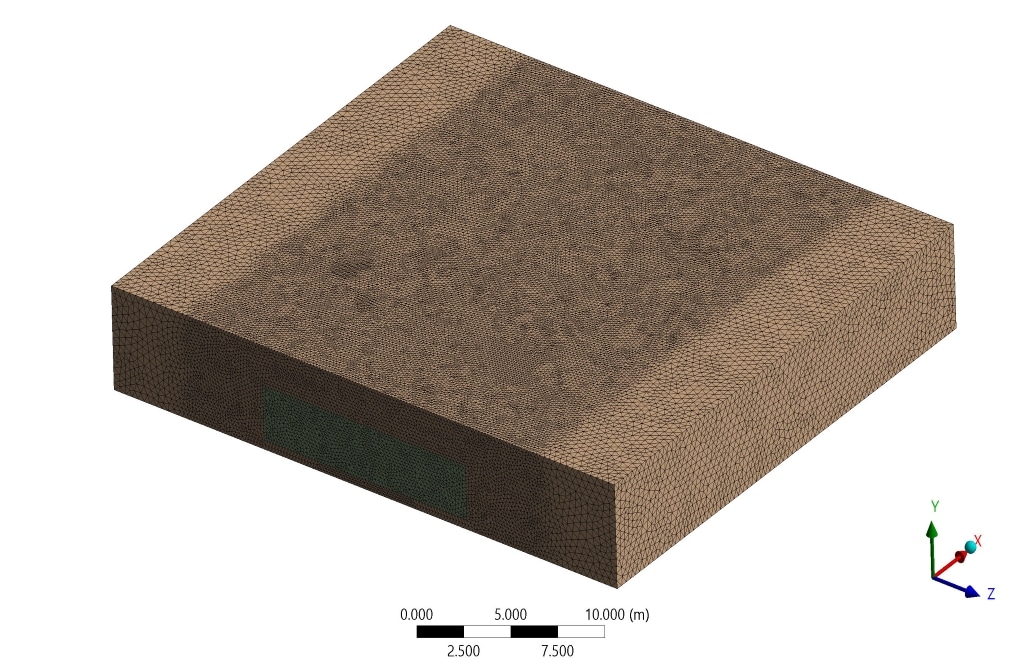

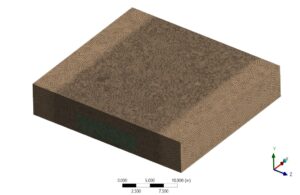

ANSYS Meshing software was used for grid generation, and the type of problem elements was unstructured. Also, the total number of elements was about 4560000.

Solver Setting

In this simulation, the following hypotheses are established:

- A pressure solver was used.

- The problem was solved transient.

- The gravitational effect was considered.

Also, the table below shows the characteristics and values of boundary conditions, along with the models and hypotheses.

| Material Properties | |

| Water | |

| Amount | Fluid properties |

| 998.2 | Density (kg/m3) |

| Air | |

| Amount | Fluid properties |

| 1.225 | Density (kg/m3) |

| Multiphase | |

| Homogeneous model | VOF (volume of fluid) |

| Number of Eulerian phases | 2 (water-air) |

| Interface modeling | sharp |

| Formulation | Explicit |

| Air-water surface tension coefficient | 0.072 N/m |

| Boundary Condition | |

| Type | Velocity inlet |

| Water inlet | 15 m/s |

| Air inlet | 2 m/s |

| Type | Outlet |

| Outlet | Gauge pressure zero |

| Cell zone condition | |

| Fluid | mixture |

| Mesh motion | |

| Moving zone | Translational velocity = 1 m/s |

| Turbulence models | |

| K-e | viscous model |

| Realizable | K-e model |

| Standard wall function | Wall function |

| Solution methods | |

| Simple | pressure velocity coupling |

| Spatial discretization | |

| PRESTO | pressure |

| Second-order upwind | momentum |

| Modified HRIC | Volume fraction |

| First-order upwind | turbulent kinetic energy |

| First-order upwind | turbulent dissipation rate |

| Initialization (Hybrid) | |

Results

In this section, volume fraction and velocity counters are placed in a longitudinal section of the computational range. Observing these images, it is clear that the amount of air injection into the domain increases over time, and when the aircraft reaches that part, the washing process is performed.

Reviews

There are no reviews yet.