Battery Module Pack, Pack Builder, ANSYS Fluent CFD Simulation

$210.00 $105.00 Student Discount

- This product numerically simulates the Battery Module Pack using ANSYS Fluent software.

- We design the 3-D model in parallel and serial connection with the Design Modeler software.

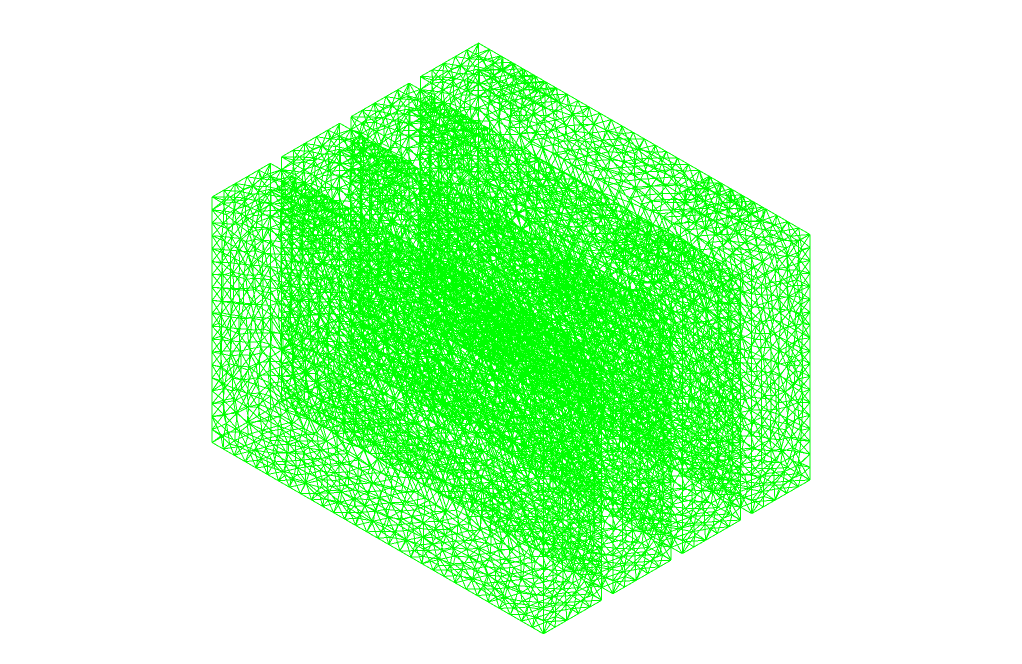

- We mesh the model with ANSYS Meshing software; the element numbers are 269562.

- We use the Circuit Network Battery model to define the charge/discharge.

- We use the ECM (Equivalent Circuit Model) sub-model to determine the electrochemical computations.

- We use the Pack Builder to define the battery module pack.

- The run calculation is in an unsteady state (transient).

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

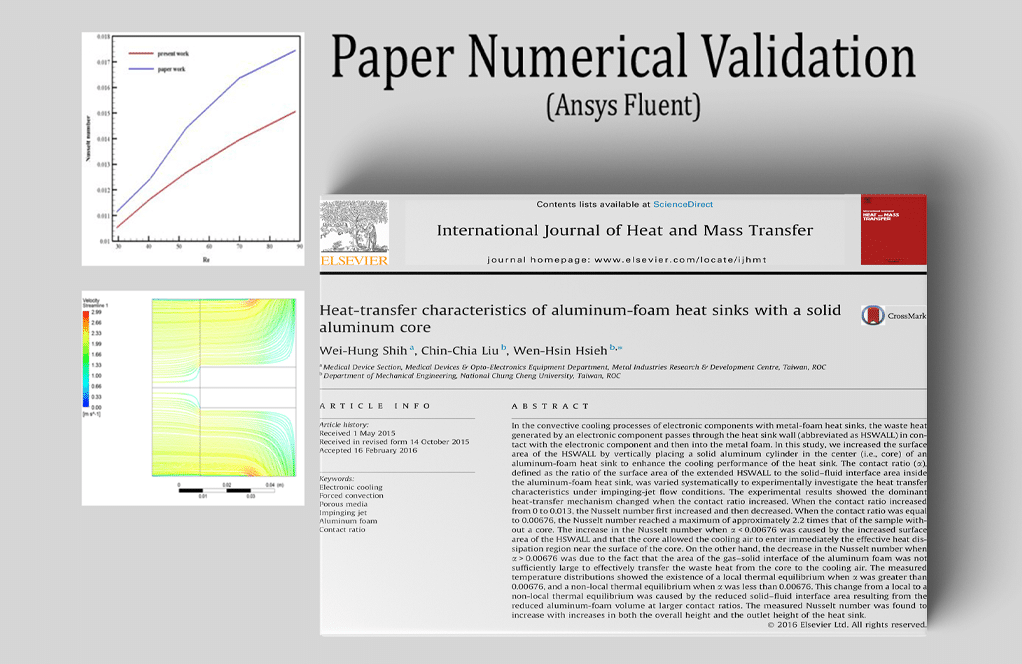

In this project, we present the CFD simulation of the battery module pack using ANSYS Fluent software.

A battery is a device that converts chemical energy into electric energy through chemical reactions if needed. The main zone of a battery is the active cell, where electrochemical reactions occur. The passive zones include a battery’s positive and negative tabs (terminals) for electric conductivity.

In Fluent, we can model a single battery, a battery module, and a battery pack. Sometimes, several battery cells are connected to build a battery module. Then, combining several stages of the battery modules builds a battery pack.

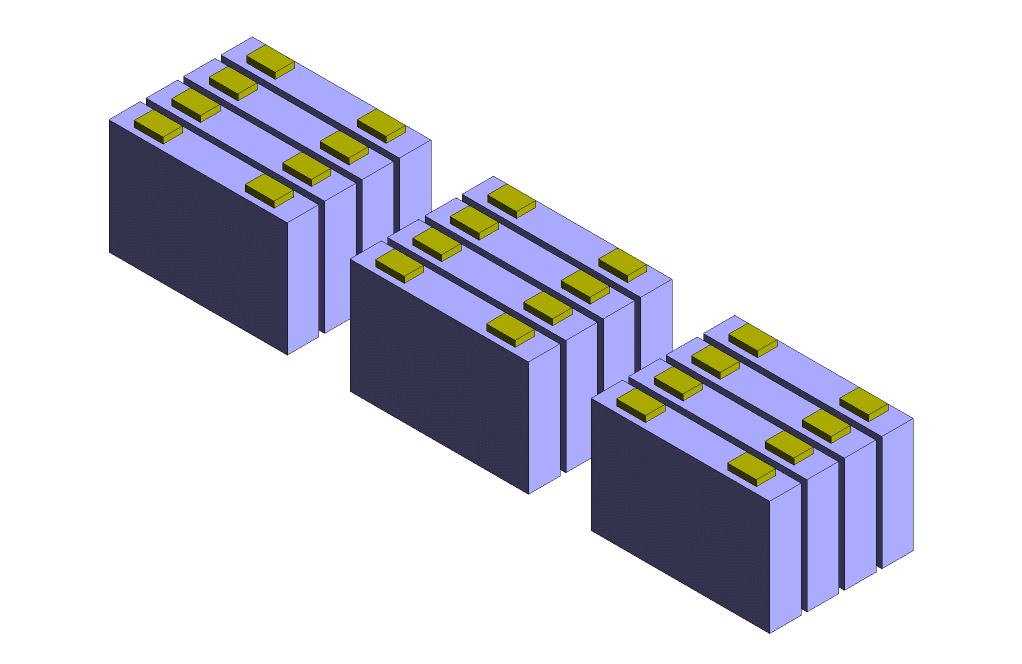

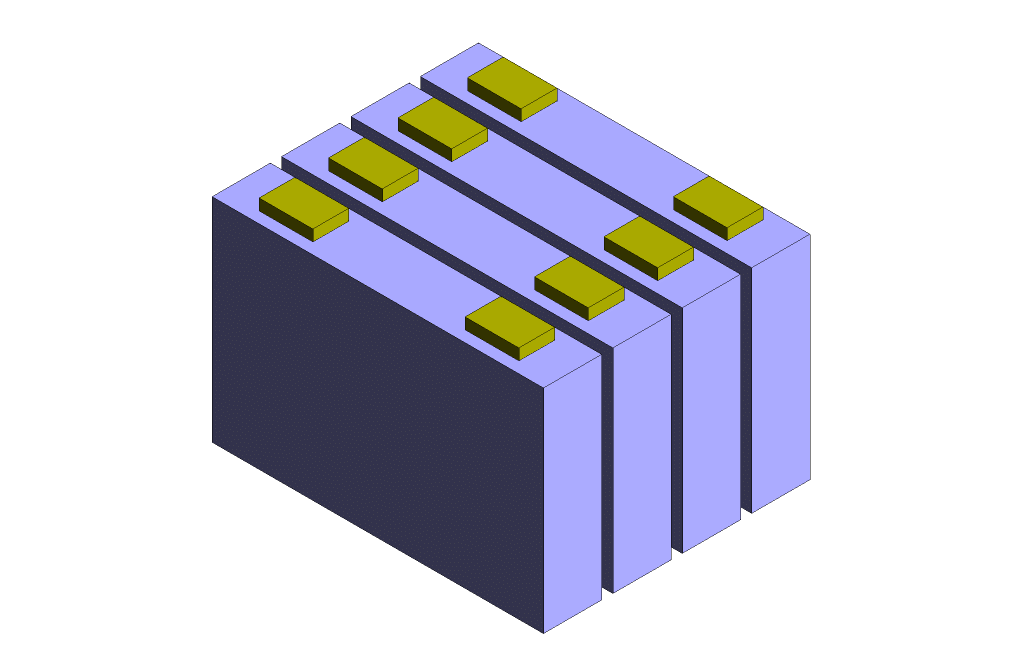

In this project, we use the Pack Builder tool to simulate a battery module pack. It means we only model a battery module containing 4 prismatic batteries with parallel connections. Then, by using the pack builder tool, this only battery module is patterned into three battery stages in a serial configuration.

Methodology

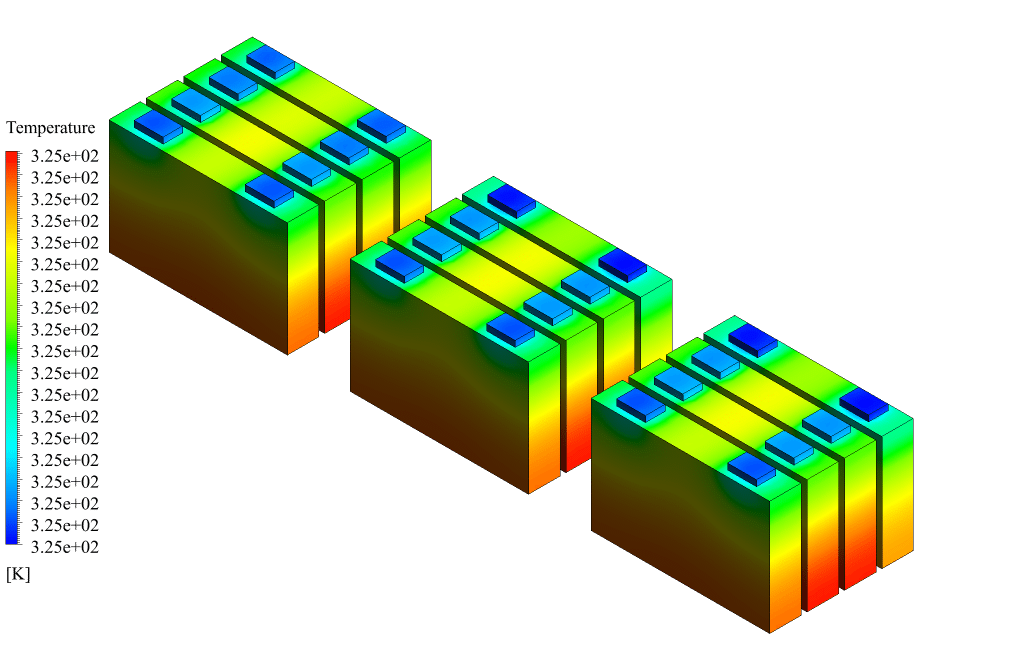

First, we modeled the battery pack geometry in Design Modeler software. Each prismatic battery consists of a cell zone with positive and negative tab zones.

Then, we meshed the model using ANSYS Meshing software, and 269562 elements were generated.

Finally, we simulated this battery pack using the Battery model in ANSYS Fluent software.

In this project, we used the Circuit Network model for battery modeling. Then, we used the ECM (Equivalent Circuit Model) sub-model to specify the electrochemical computations. The ECM model is considered a semi-empirical method for electrochemical formulation.

In this project, we intend to discharge the battery pack at a 10 C rate. For every single battery, we assume the nominal capacity is 14.6 A.h and the voltage range is 3 v to 4.3 v.

Since the charging/discharging process in the battery system occurs over time, we run the calculation in an unsteady state (transient).

Conclusion

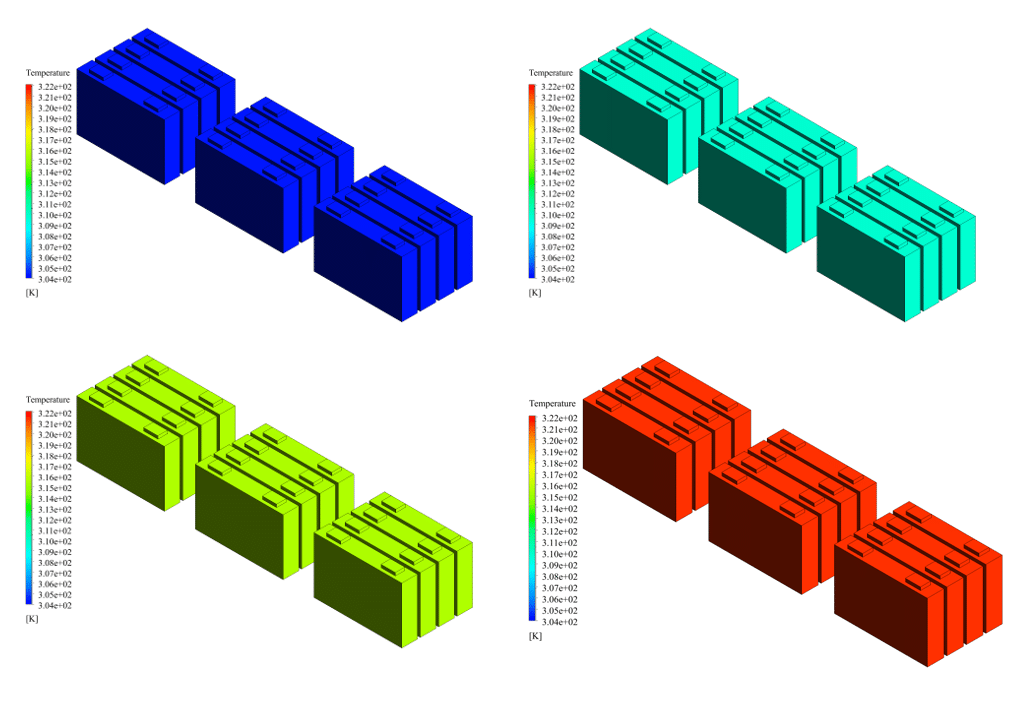

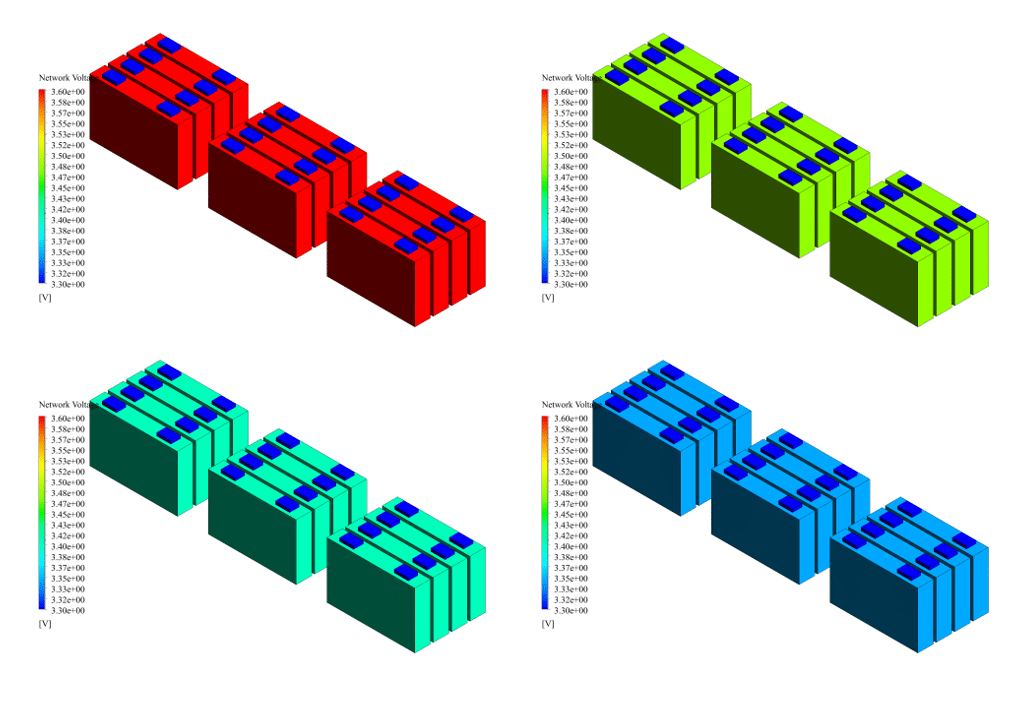

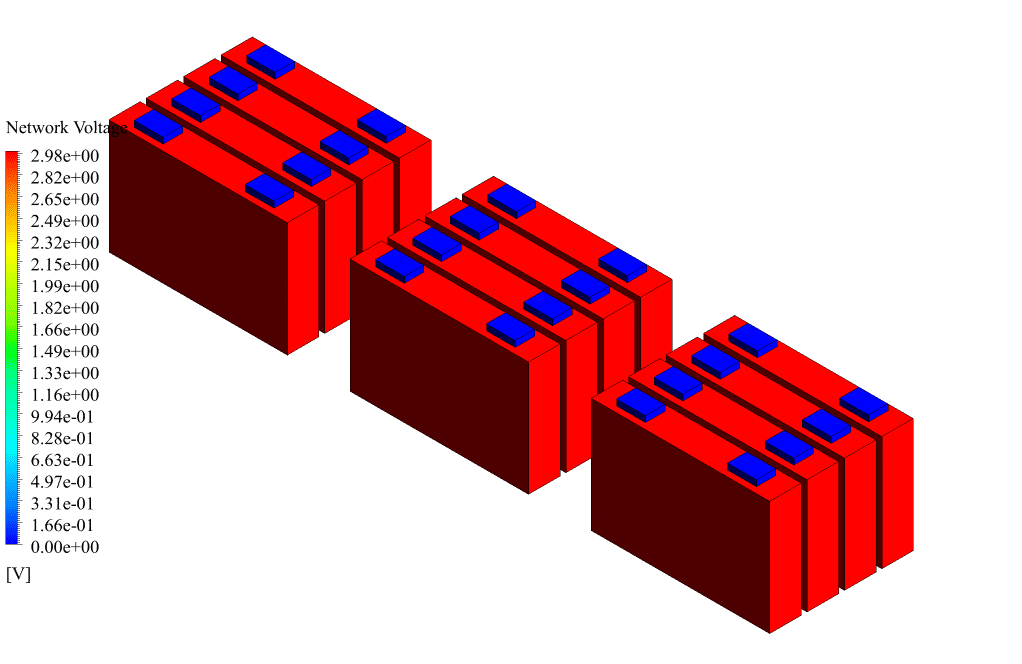

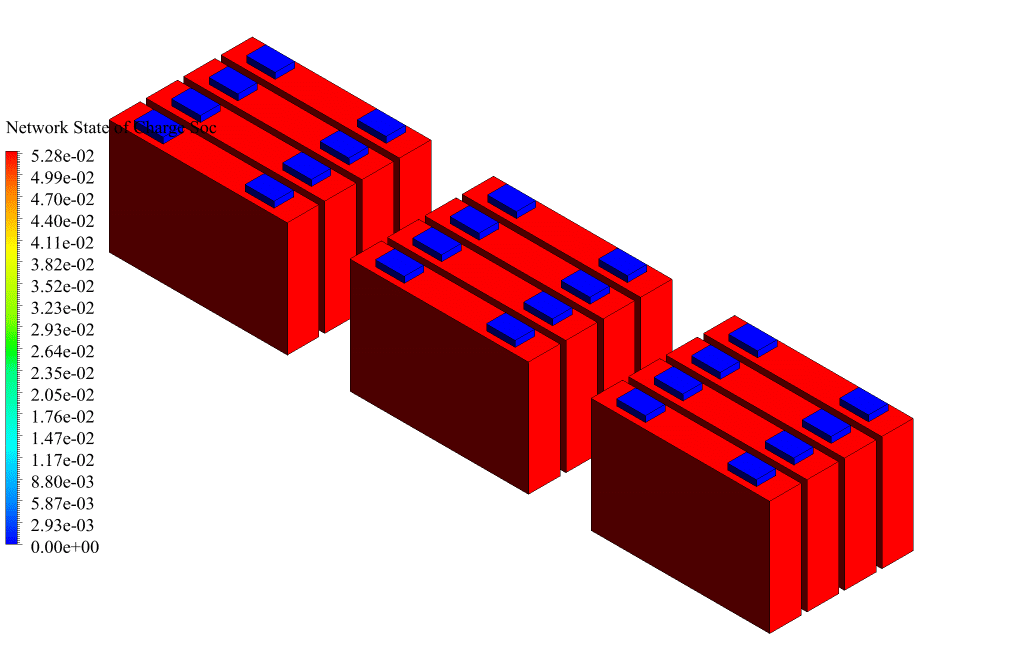

We intend to analyze the battery module pack behavior during the discharging process. Therefore, we obtained the contours of temperature, potential (voltage), current, and SOC (state of charge).

In addition, we obtained the contours of temperature and voltage at different times. The results show that when the battery pack is discharging, its overall voltage decreases. On the other hand, due to the battery pack operation, heat is generated and the surface temperature of individual batteries increases.

Note that we only modeled the geometry of a battery module in a parallel configuration. However, after using the pack builder, all the contours are presented in the form of a battery pack containing three stages of battery modules.

Reviews

There are no reviews yet.