Battery, MSMD, P2D Model, ANSYS Fluent CFD Simulation

$120.00 $60.00 Student Discount

- This product numerically simulates the Pouch Battery Discharge using ANSYS Fluent software.

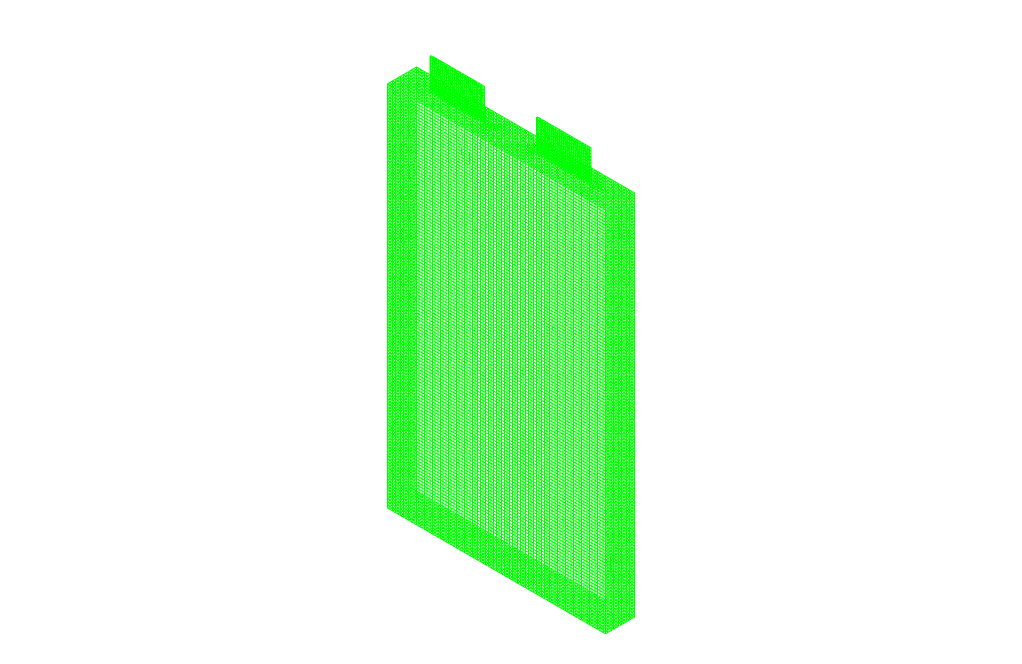

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 125401.

- We use the MSMD (Multi-Scale Multi-Domain) Battery model to define the charge/discharge.

- We use Newman’s P2D (Pseudo 2-D) sub-model to determine the electrochemical computations.

- The run calculation is in an unsteady state (transient).

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this CFD project, we present the numerical simulation of a battery discharge by the Newman P2D model in ANSYS Fluent software.

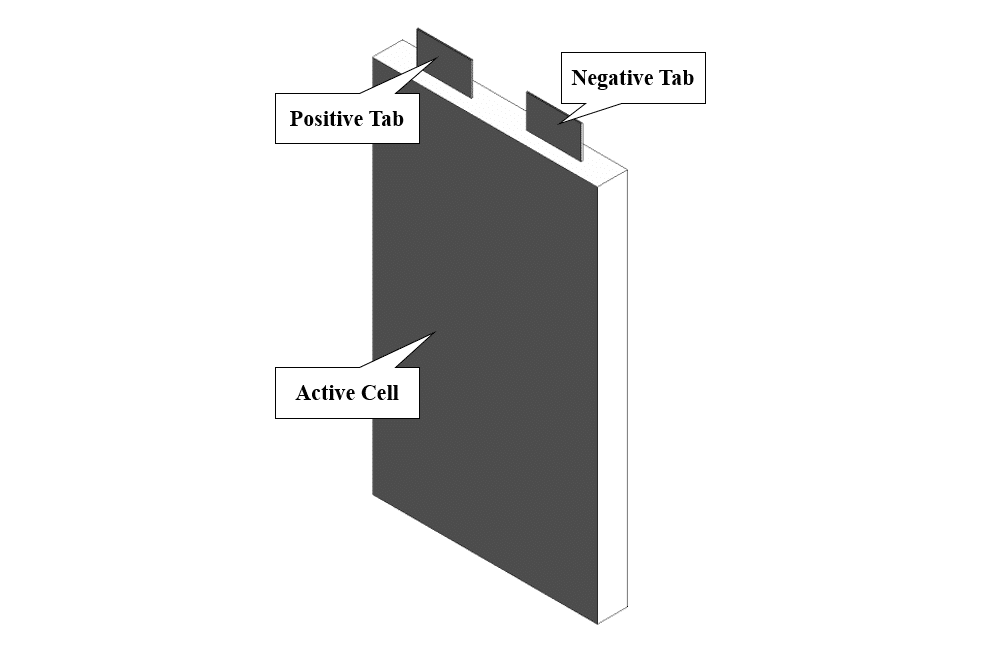

A battery is a device that converts chemical energy into electric energy through chemical reactions if needed. The main zone of a battery is the active cell, where electrochemical reactions occur. The passive zones include a battery’s positive and negative tabs (terminals), only for electric conductivity.

Batteries are exposed to charge and discharge during operation. During charging, electrons are transferred from the negative to the positive electrode through an external circuit, and consequently, the electric current is supplied by an electric source. However, during discharging, electrons are transferred from the positive to the negative electrode through the external circuit, and consequently, the electric current is consumed by an electric load.

In this project, we analyzed a pouch battery. Pouch batteries are a type of lithium-ion battery with a flexible, flat, and pouch-shaped design. These batteries are widely used in various applications, including automotive, consumer electronics, and energy storage.

Methodology

First, we modeled the battery geometry using Design Modeler software. The battery construction consists of a cell zone with positive and negative tab zones.

Then, we meshed the model using ANSYS Meshing software, and 125401 elements were generated.

Finally, we simulated the battery system using the Battery model in Ansys Fluent software.

In this project, we used the Multi-Scale Multi-Domain (MSMD) model for battery modeling. The MSMD is a comprehensive method for modeling lithium-ion batteries; because it involves a multi-scale and multi-physic nature.

Then, we used Newman’s P2D (Pseudo Two-Dimensions) sub-model to specify the electrochemical computations. The P2D model is considered a physics-based method for electrochemical formulation.

So, a set of relations based on battery physics is used to estimate the current transfer rate and the heat production rate due to electrochemical reactions.

Therefore, we define the LiMnO2 material for the positive electrode and the Carbon material for the negative electrode. Then, we determine the parameters of the corresponding relations such as thickness, for positive electrode, negative electrode, and separator.

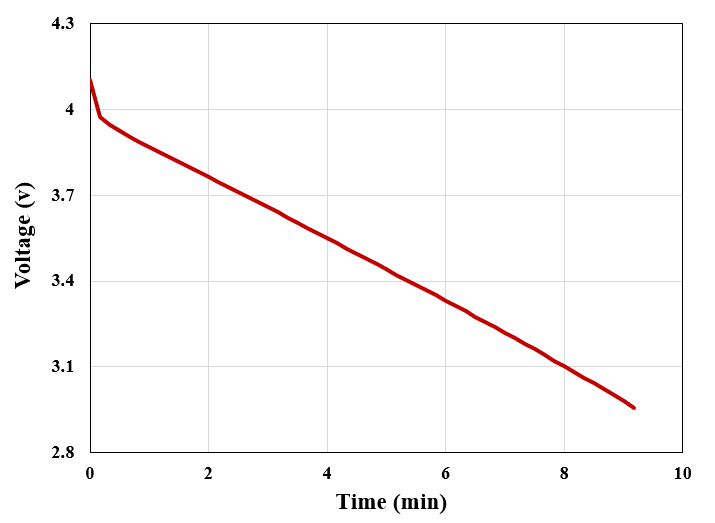

We defined the discharge process in the voltage range from 3 to 4.3 volts with a nominal capacity of 14.6 A.h and a 1 C-rate.

Since the charging/discharging process in the battery system occurs over time, we run the calculation in an unsteady state (transient).

Conclusion

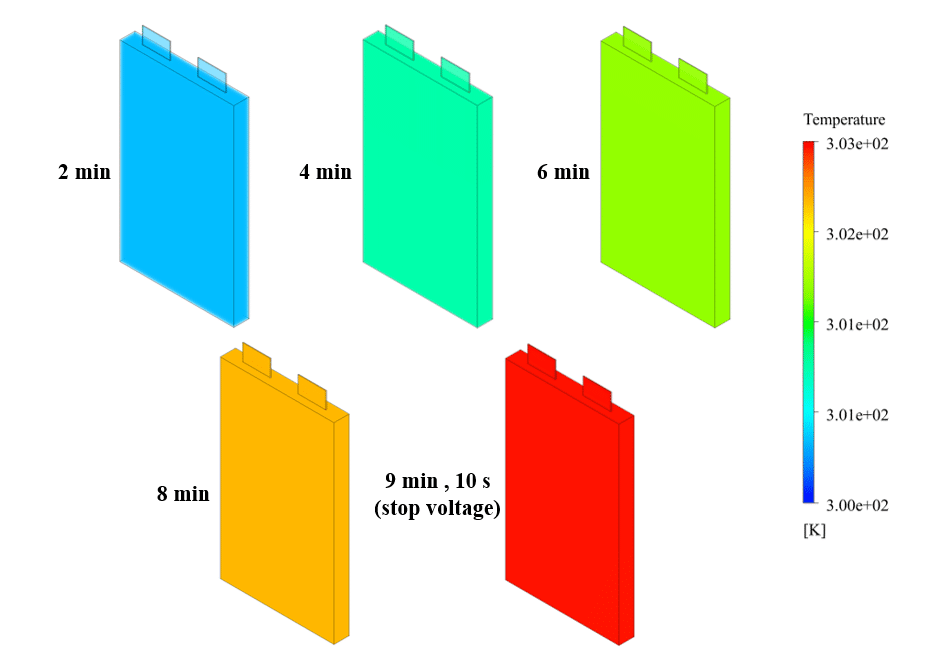

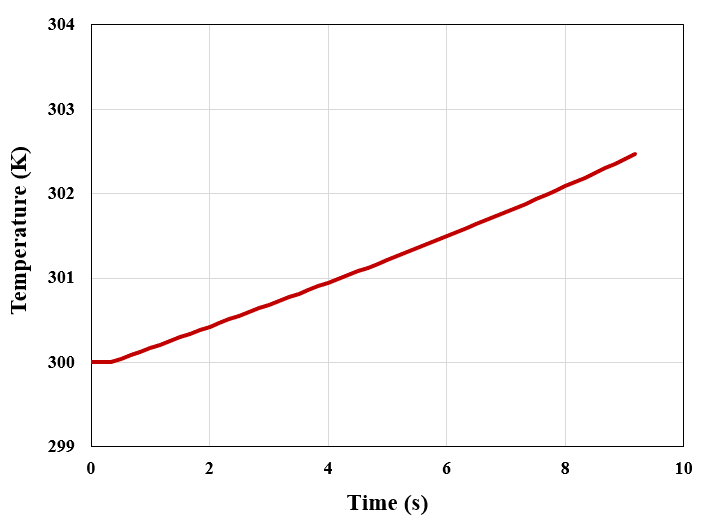

We intend to analyze the battery discharge process and the resulting heat rise. Therefore, we obtained plots of the potential (voltage) variation and the maximum temperature over time.

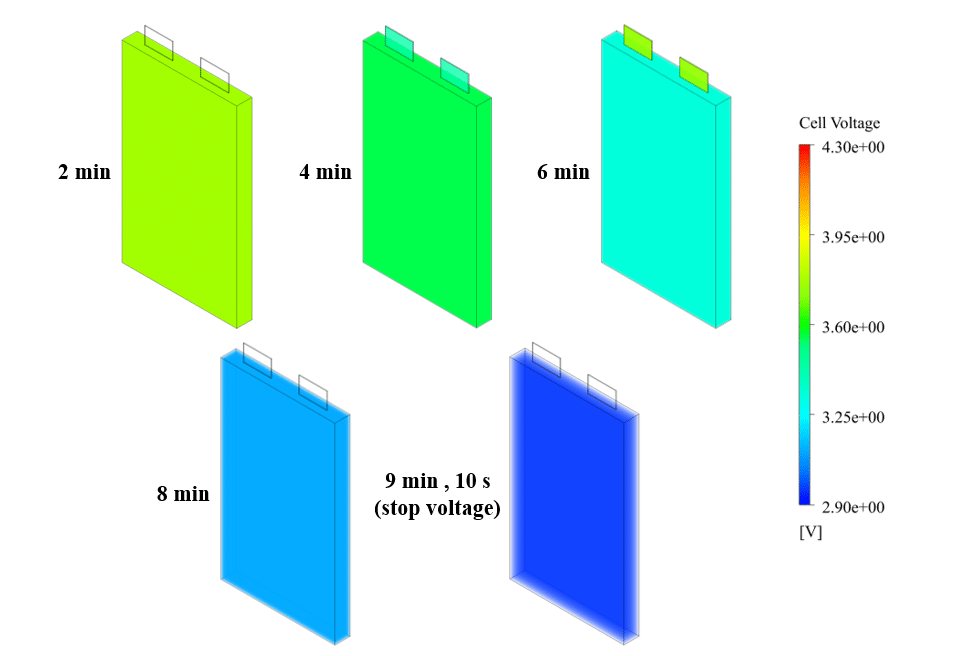

Then, we obtained the contours of the cell voltage and temperature at different times. The results show a decrease in voltage and an increase in temperature during discharge. Results represent that voltage decreases to reach the minimum battery voltage during discharge. On the other hand, the battery temperature increases during battery operation.

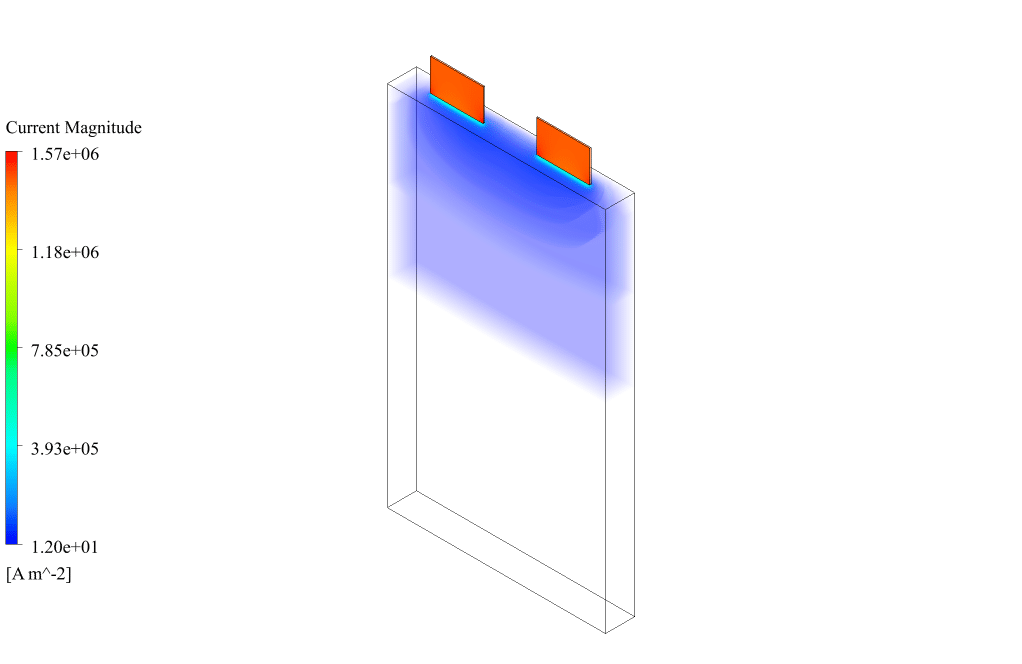

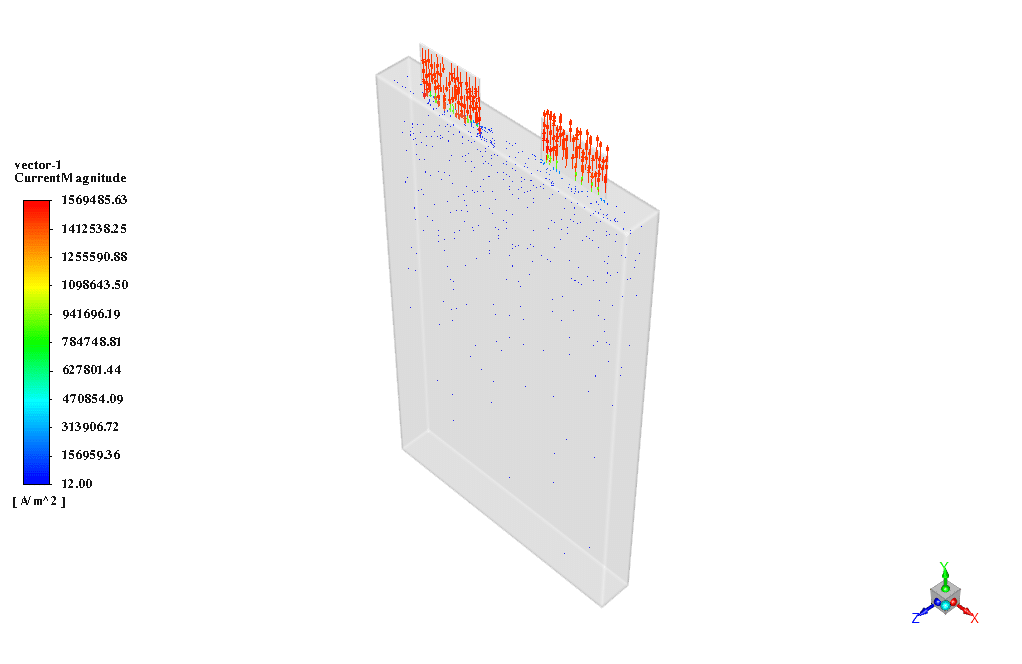

In addition, we obtained the contour and vector of the current magnitude inside the battery cell. The vectors confirm that the current leaves the positive tab and enters the negative tab during the battery discharge.

Reviews

There are no reviews yet.