Bubble Columns Reactor CFD Simulation using the VOF Model, ANSYS Fluent

$120.00 $60.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

Bubble columns find extensive applications in the chemical, biochemical, and petrochemical sectors as multiphase contactors and reactors. High heat and mass transfer rates, compactness, and low operating and maintenance costs are just a few of the benefits they offer. In reaction engineering, where a catalyst is used, and in biochemical applications, where microorganisms are employed as solid suspensions to produce bioproducts with significant industrial value, three-phase bubble column reactors are frequently utilized. A deeper understanding of the hydrodynamic features, heat and mass transfer processes, and flow regime characteristics presented during operation has resulted from investigations into design parameters describing the operation and transport phenomena of bubble columns. Additionally, mathematical models and computational fluid dynamics (CFD) simulations are used to supplement experimental research to better explain the phenomena occurring in a bubble column reactor.

Ansys Fluent software provides the Volume of Fluid (VOF) model, which is a homogeneous model, for two- or multi-phase flows where all phases are continuous and have a defined interface. The main goal of this model is to find this specific interface. The VoF model uses a special discretization to discretize the volume fraction equation, which makes the interface between the phases well-modeled. To use this model, it must be ensured that the mesh size is very small in the places where we have an interface.

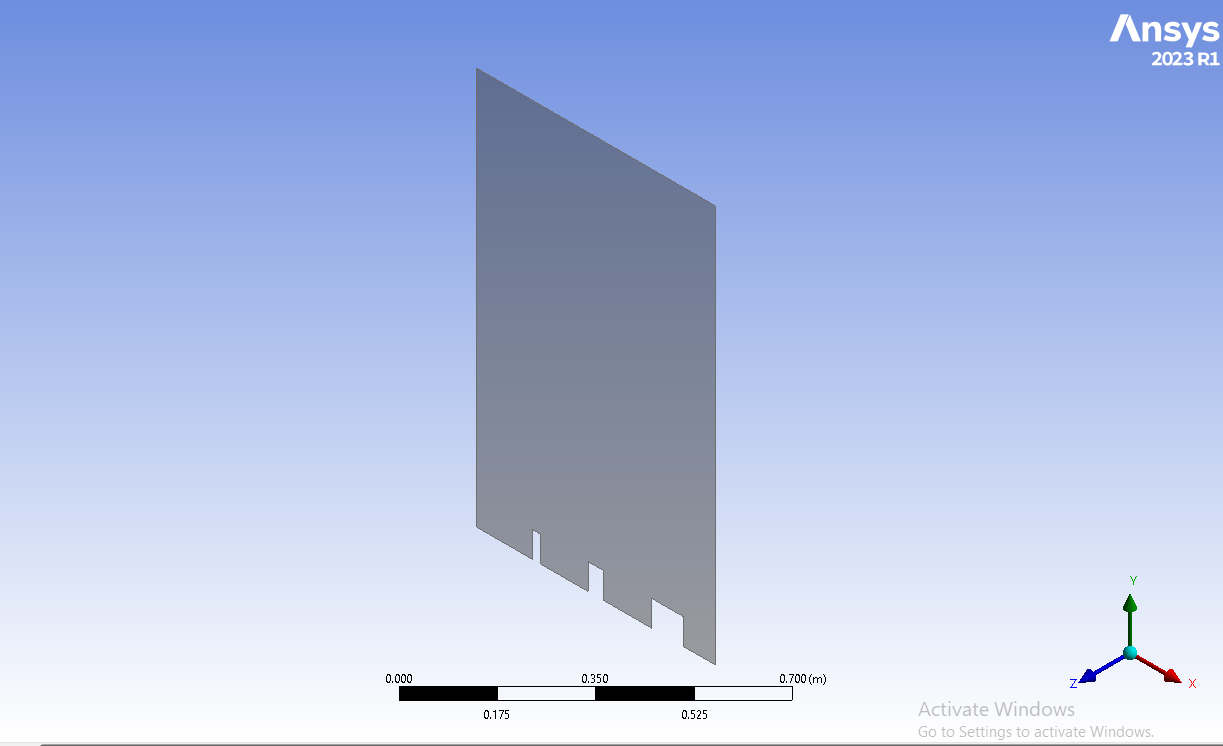

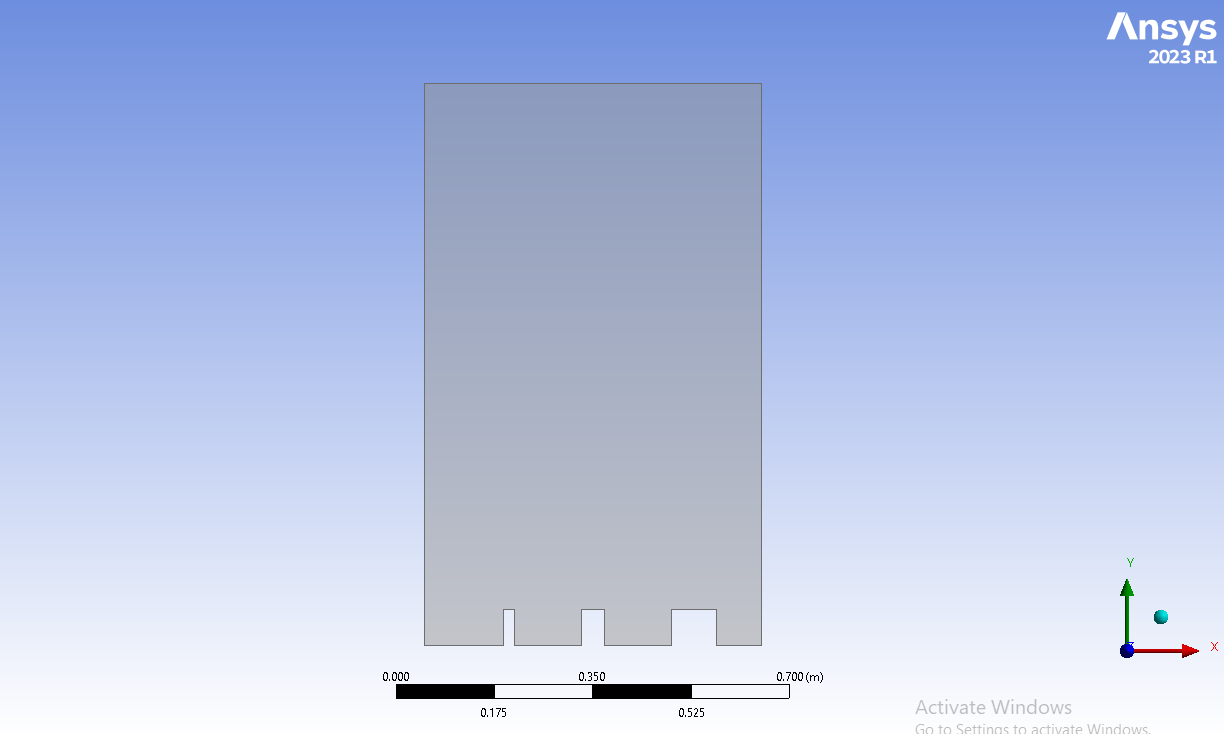

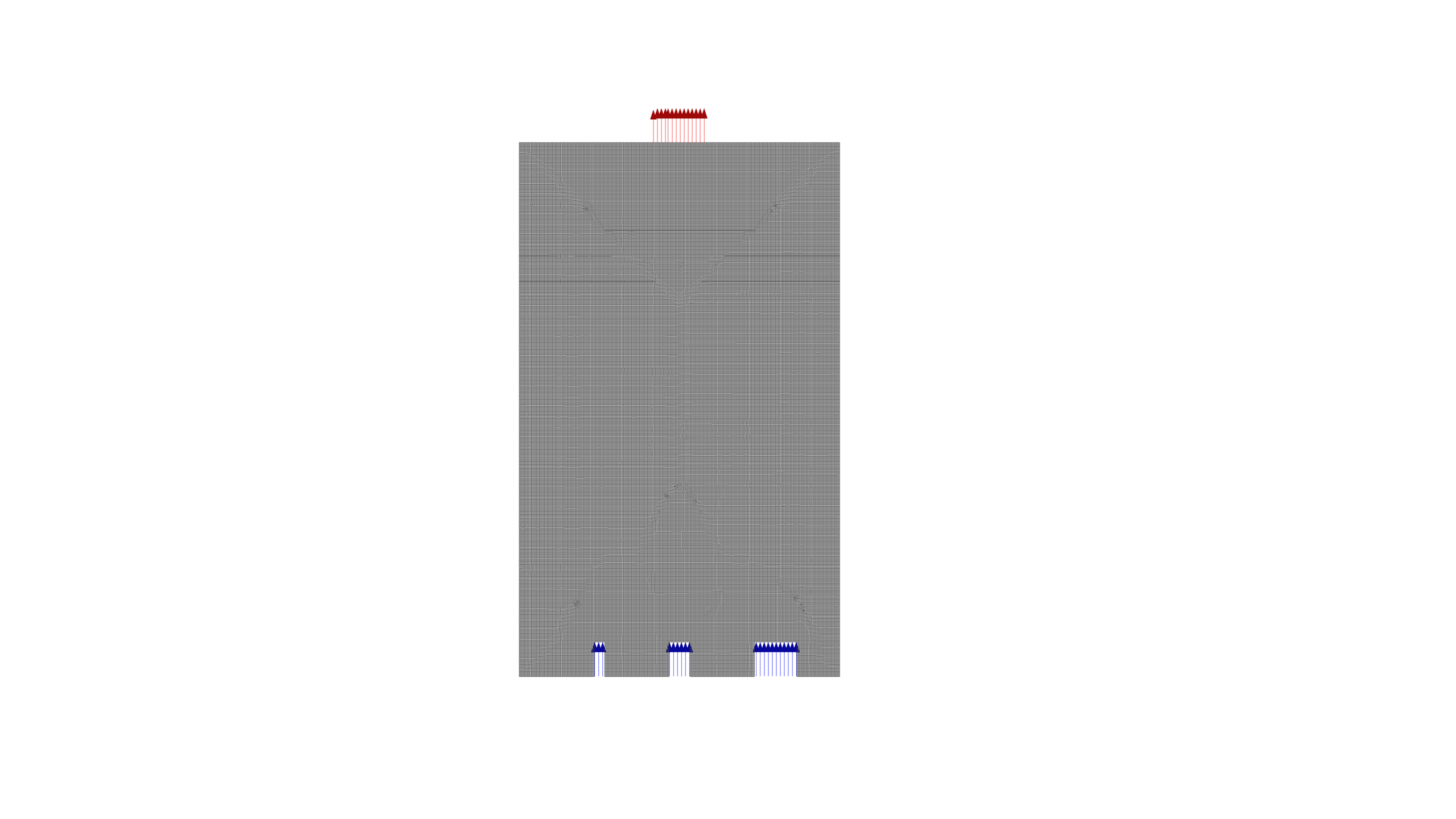

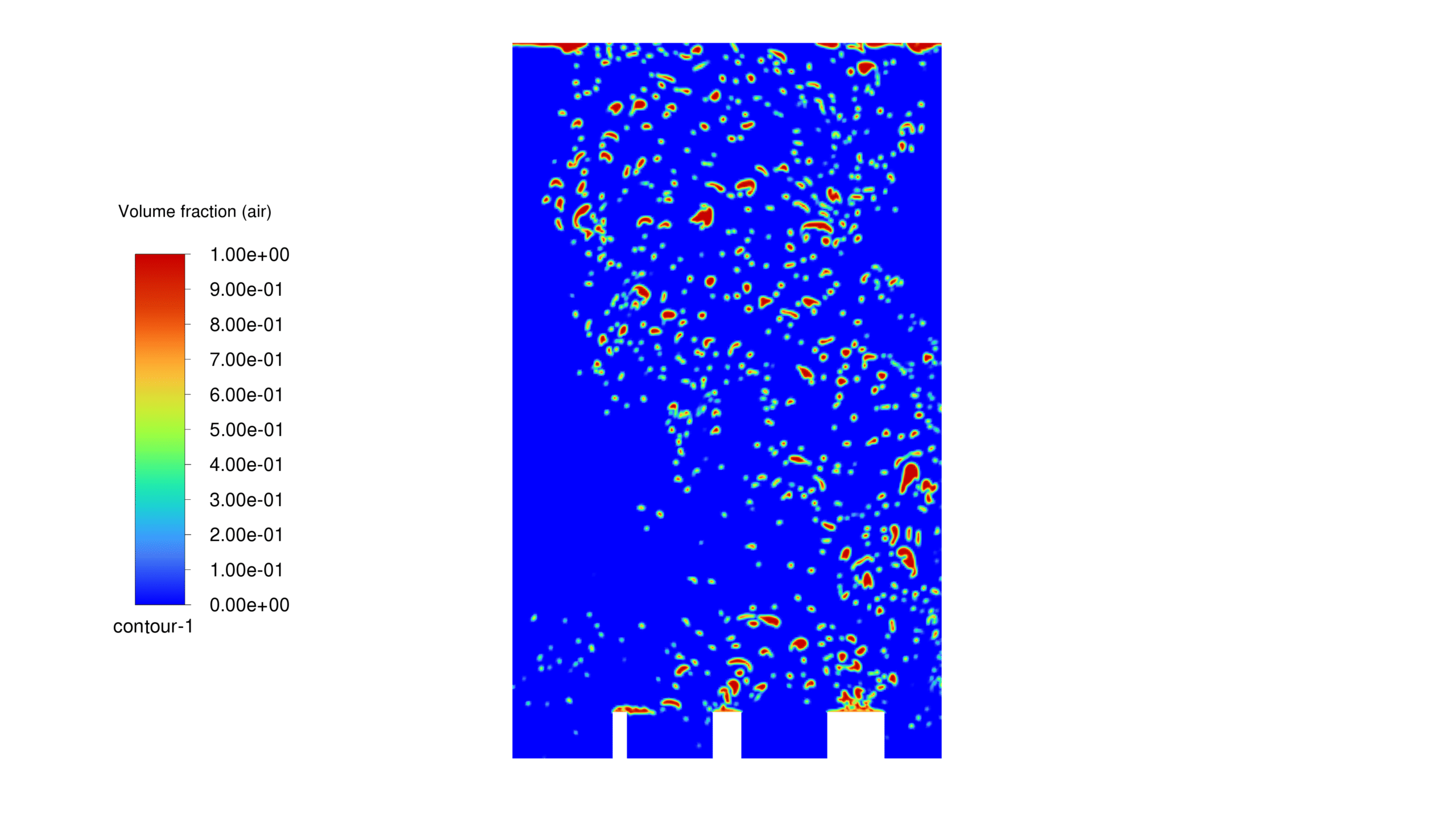

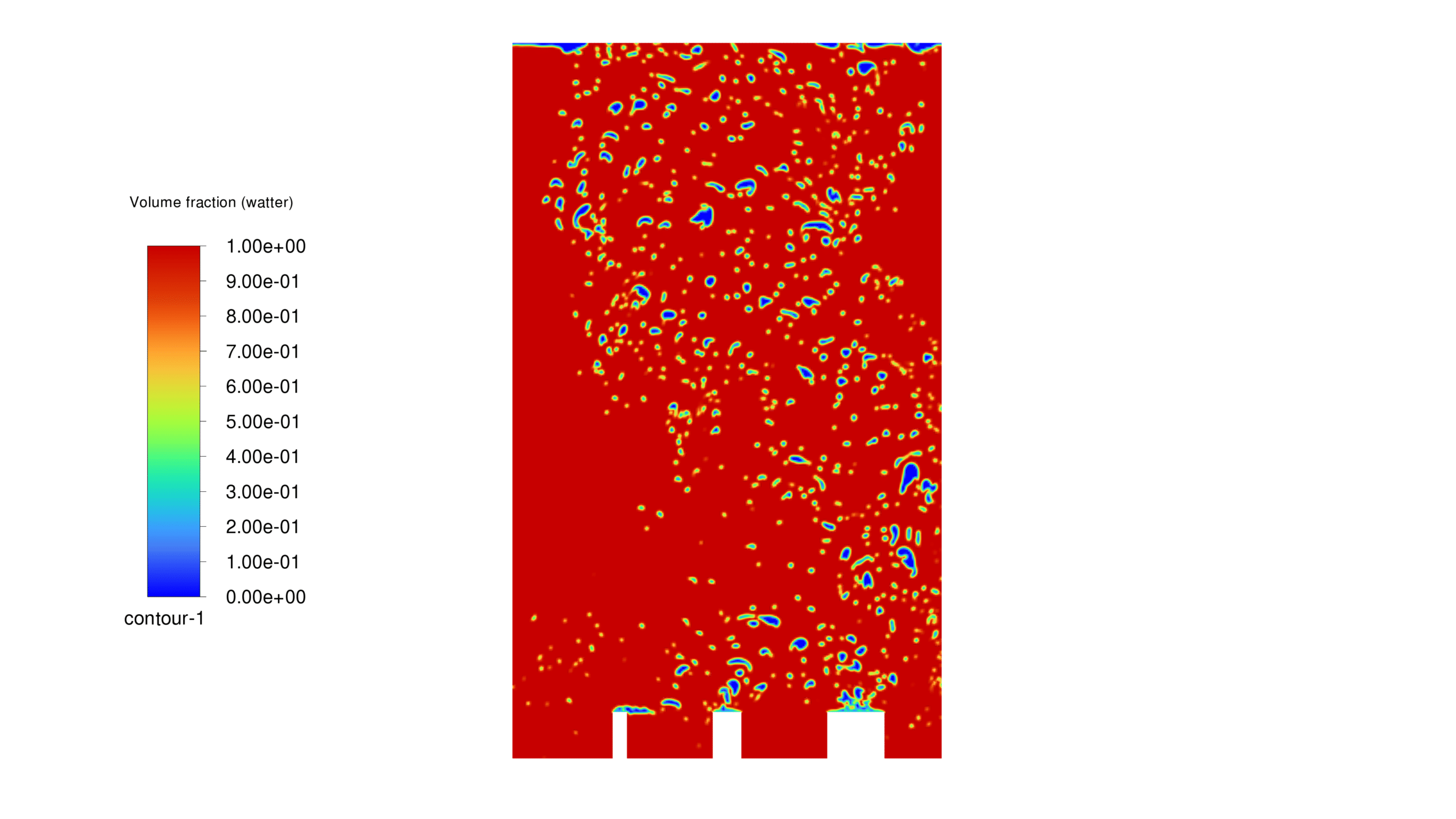

In this project, the entry and flow of air bubbles into an environment containing water are well modeled. Three inlets with different sizes are considered for the entry of air bubbles. In the first one, which is the smallest, the two-phase inlet flow speed is 0.15 m/s, and the volume fraction of air is 0.75. In the other two, the flow speed is 0.1 meters per second, and the air volume fraction is 0.7. An outlet is also considered in the middle of the upper border. This boundary condition ensures that the mass conservation equation is satisfied under the conditions of the current project.

CFD Simulation Methodology

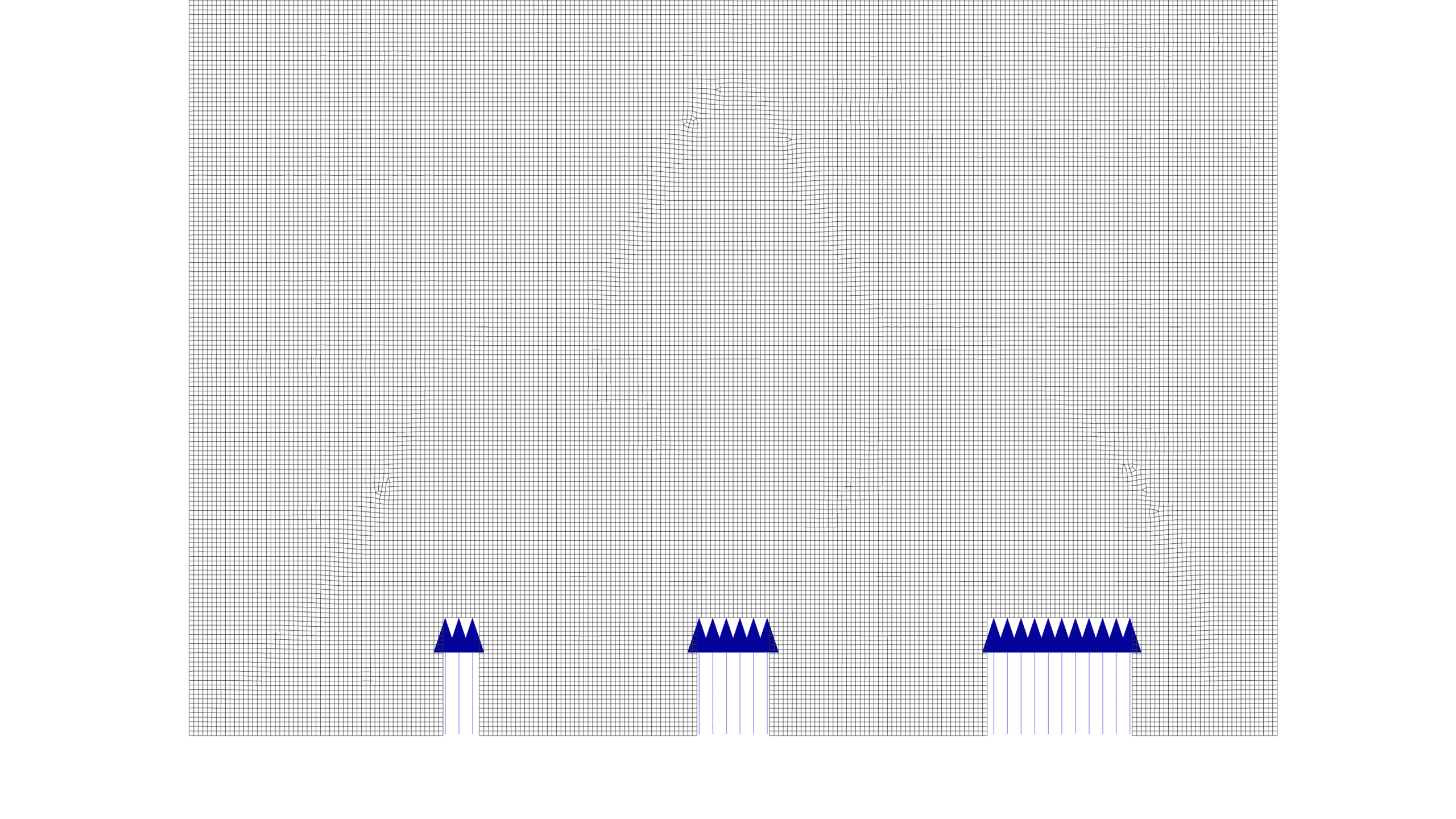

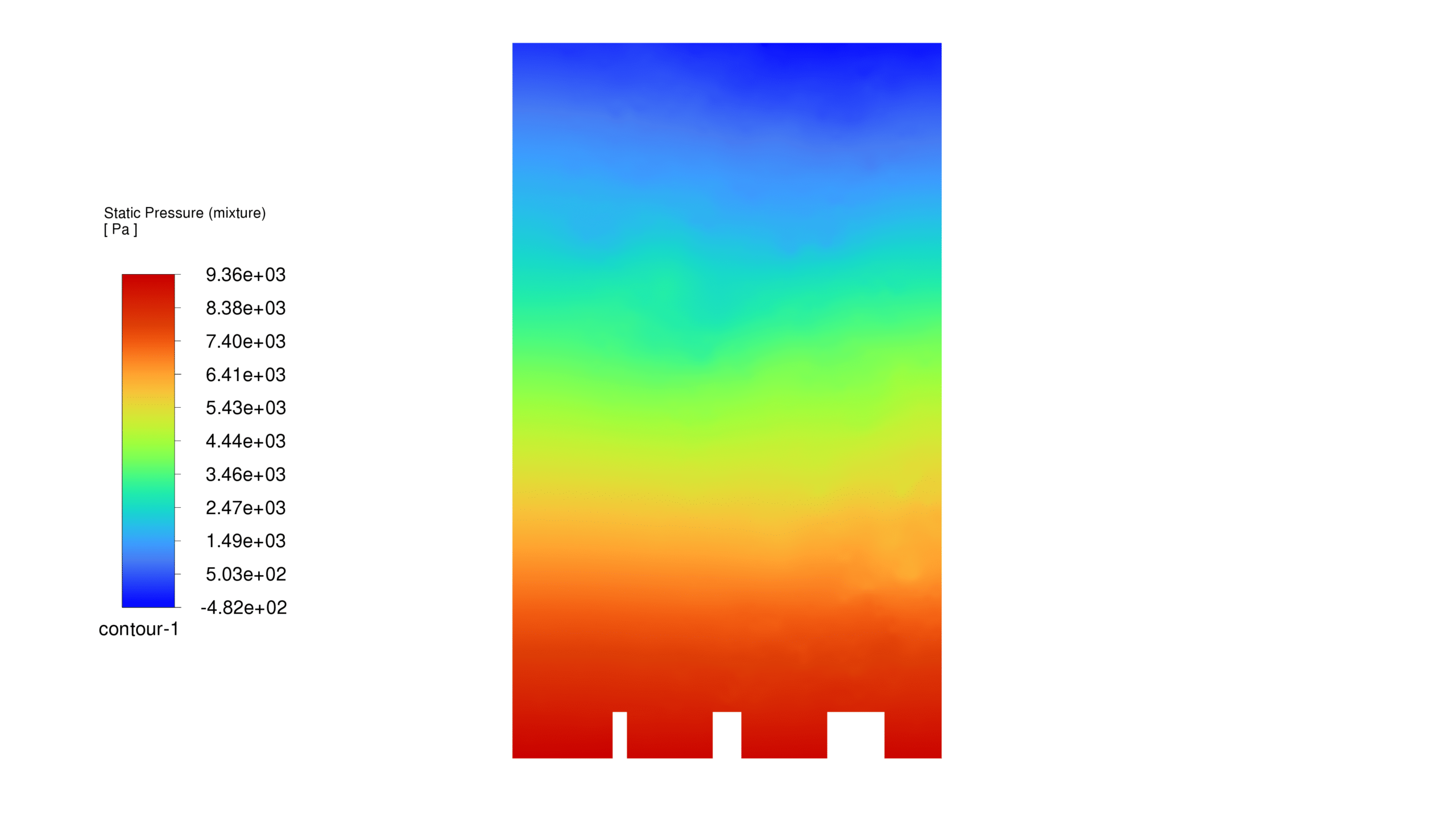

In this project, the 2-D geometry is generated in Design Modeler with three positions to enter the bubbles and meshed in ANSYS Meshing with 93,687 elements. The VOF multiphase model has been used to simulate the two phases, including air and water. The initial conditions are considered such that air is collected in the top 5% of the domain, and there is water in the rest of the domain. It should be noted that the simulation is done transiently. And due to the low velocities in this problem and its simple geometry, the flow is considered laminar.

Conclusion

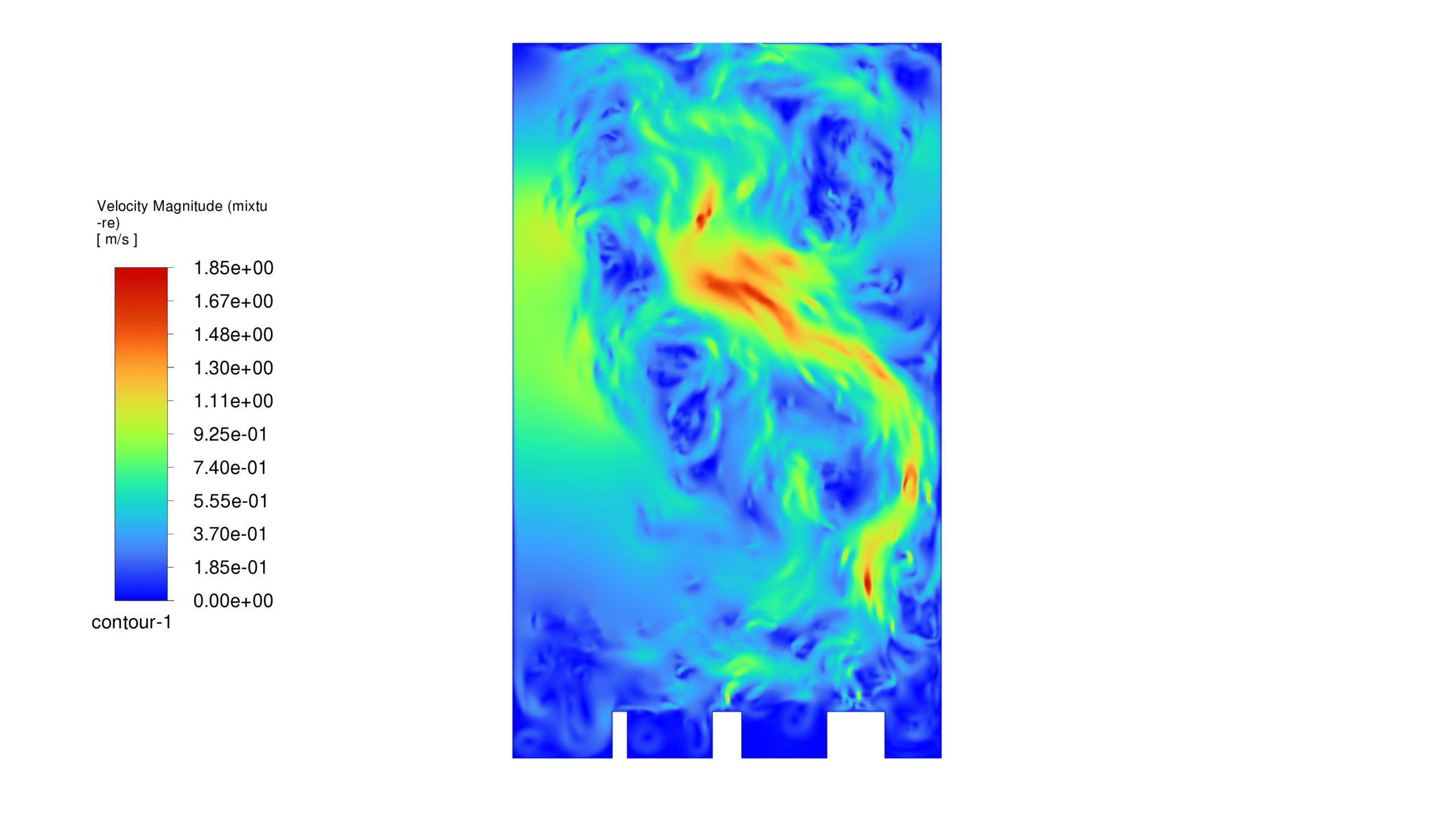

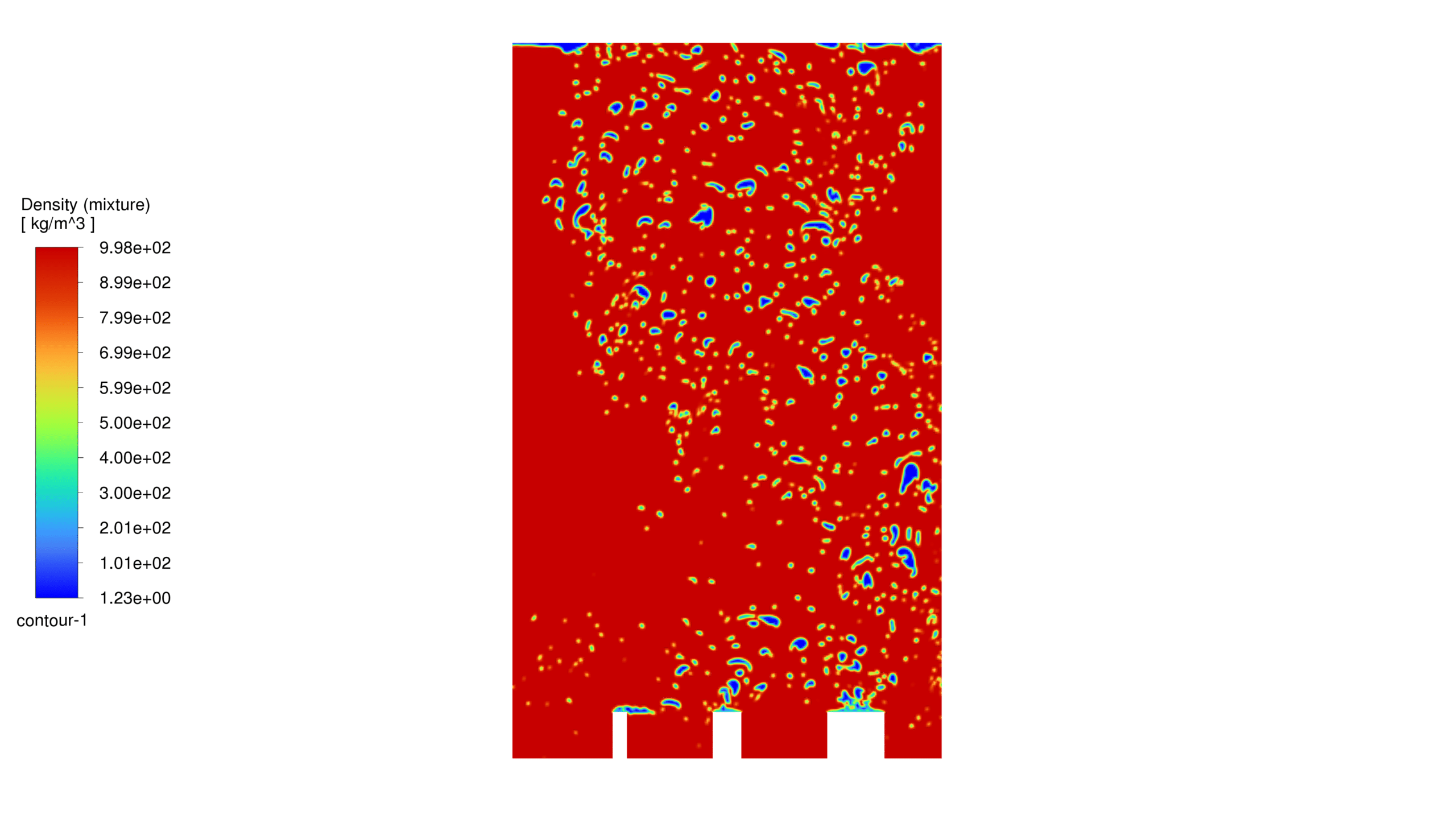

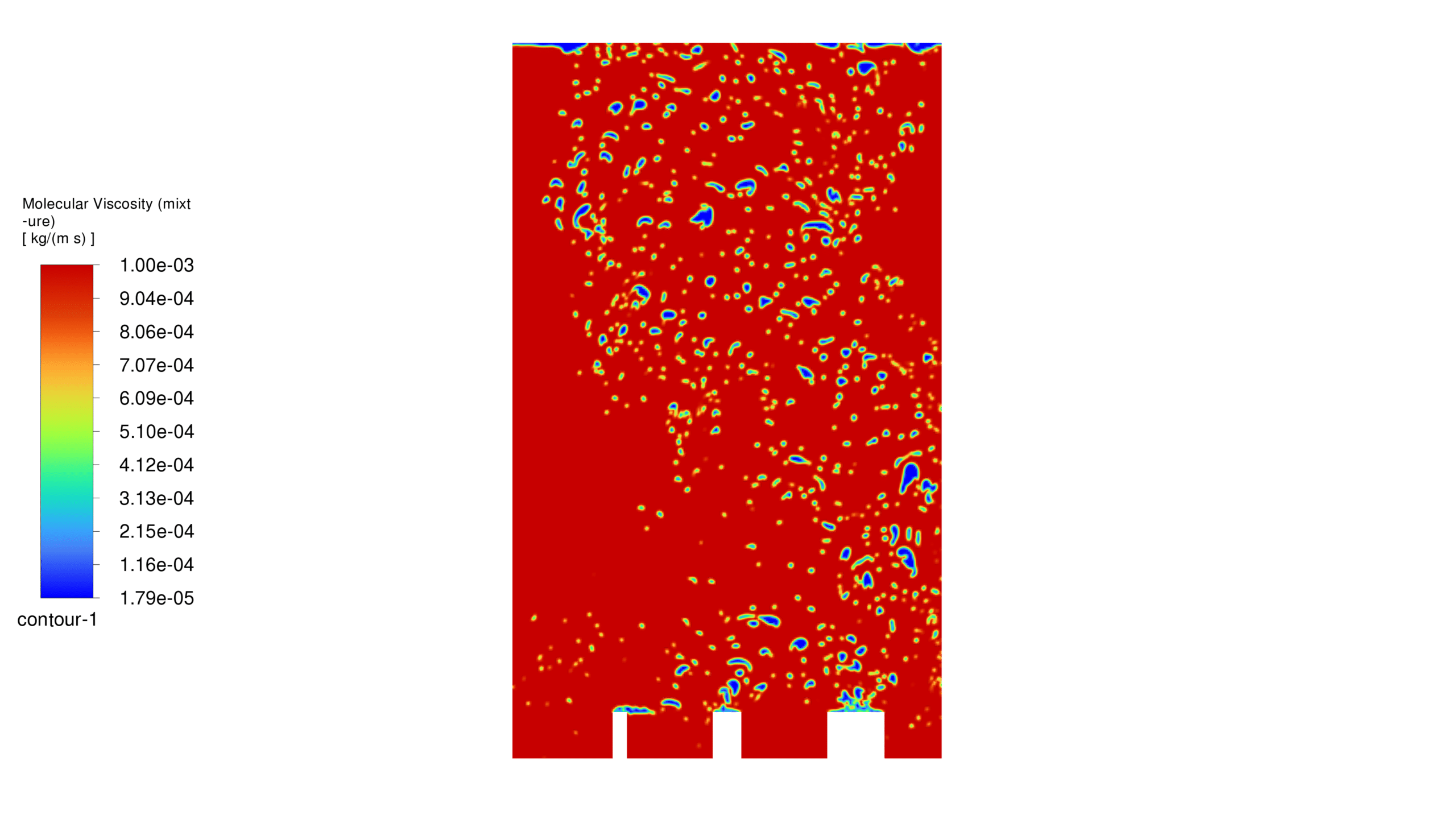

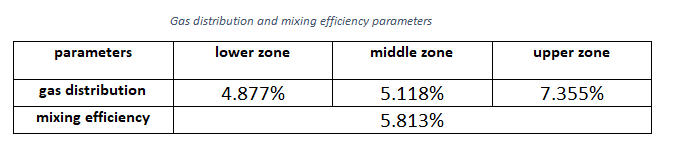

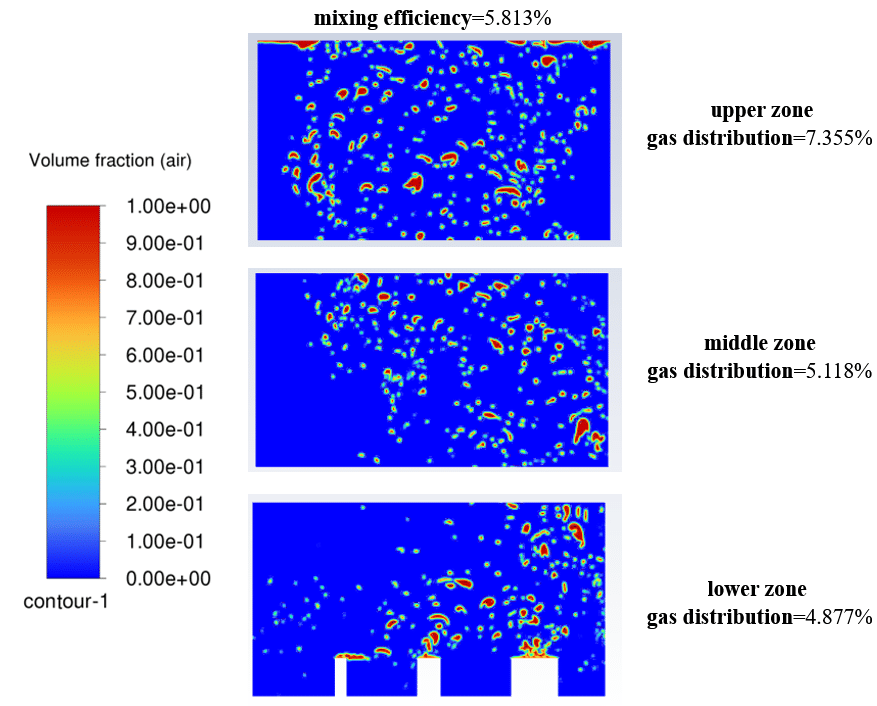

At the end of the solution process, two-dimensional contours related to pressure, velocity, viscosity, density, water volume fraction, and air volume fraction were obtained. Then, the volume fractions of air in 3 subsections of the main zone were investigated to determine the amount of air bubble distribution in different areas of the domain. These local volume fractions are defined as gas distribution parameters in each zone. Similarly, the air volume fraction in the entire domain after the relatively stable state of the system is considered as the mixing efficiency parameter. This parameter shows how much air and water are in the system after a certain time. These parameters are listed and shown in the table and figure below for better understanding. Finally, an animation of the movement of the bubbles has been prepared to observe the effect of the size of the inlet on the movement of the bubbles and to understand the physics of the flow better.

Related products

-

Shell and Tube Heat Exchanger with a spiral Baffle

Rated 5.00 out of 5$80.00$40.00 Student Discount

Reviews

There are no reviews yet.