Bubble Dynamics in a Boiling Chamber CFD Simulation

$240.00 Student Discount

- This study investigates bubble dynamics in a 2D boiling chamber using CFD analysis in ANSYS Fluent.

- The 2D geometry was created in ANSYS Design Modeler and meshed using ANSYS Meshing, resulting in a structured mesh.

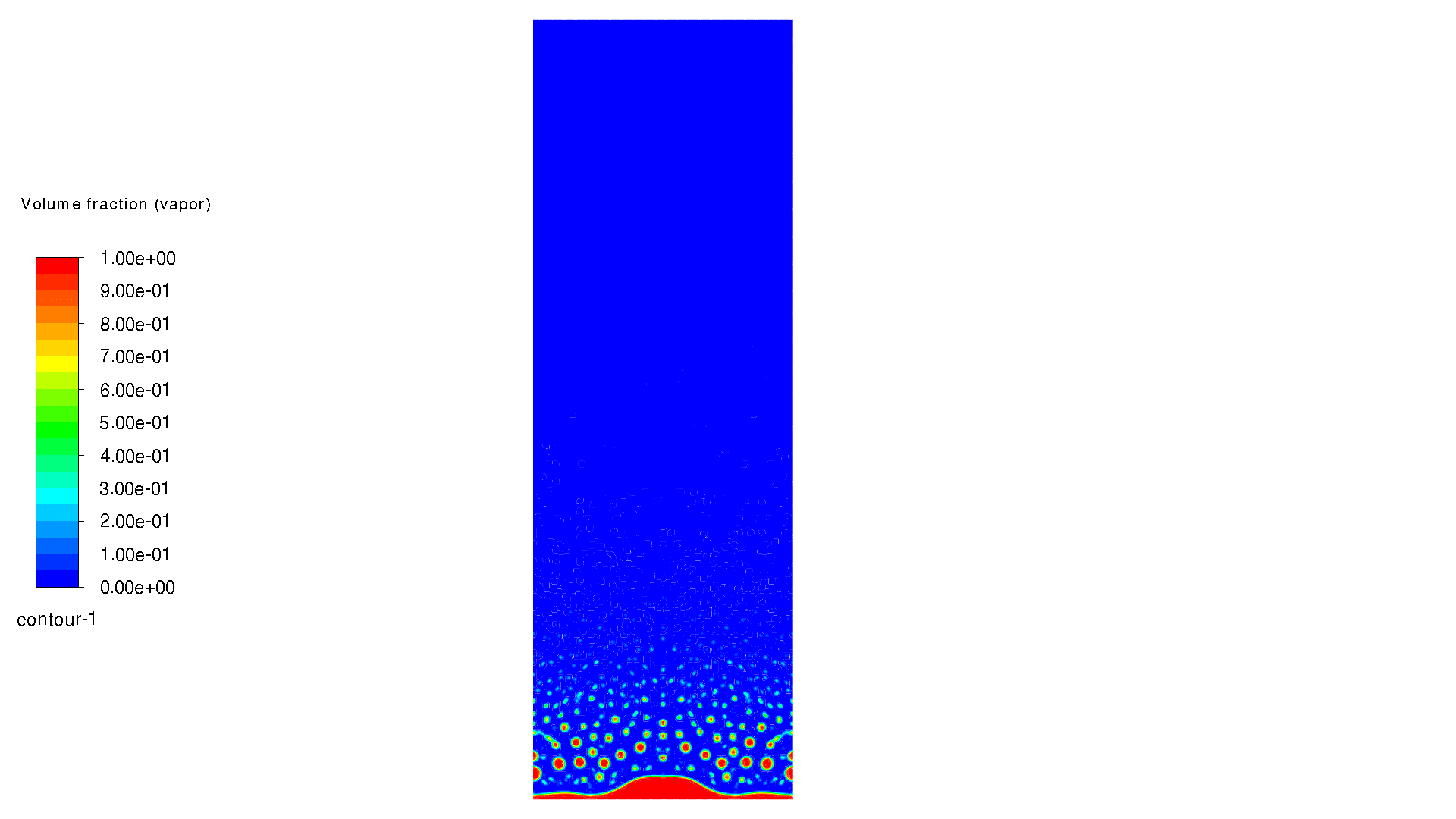

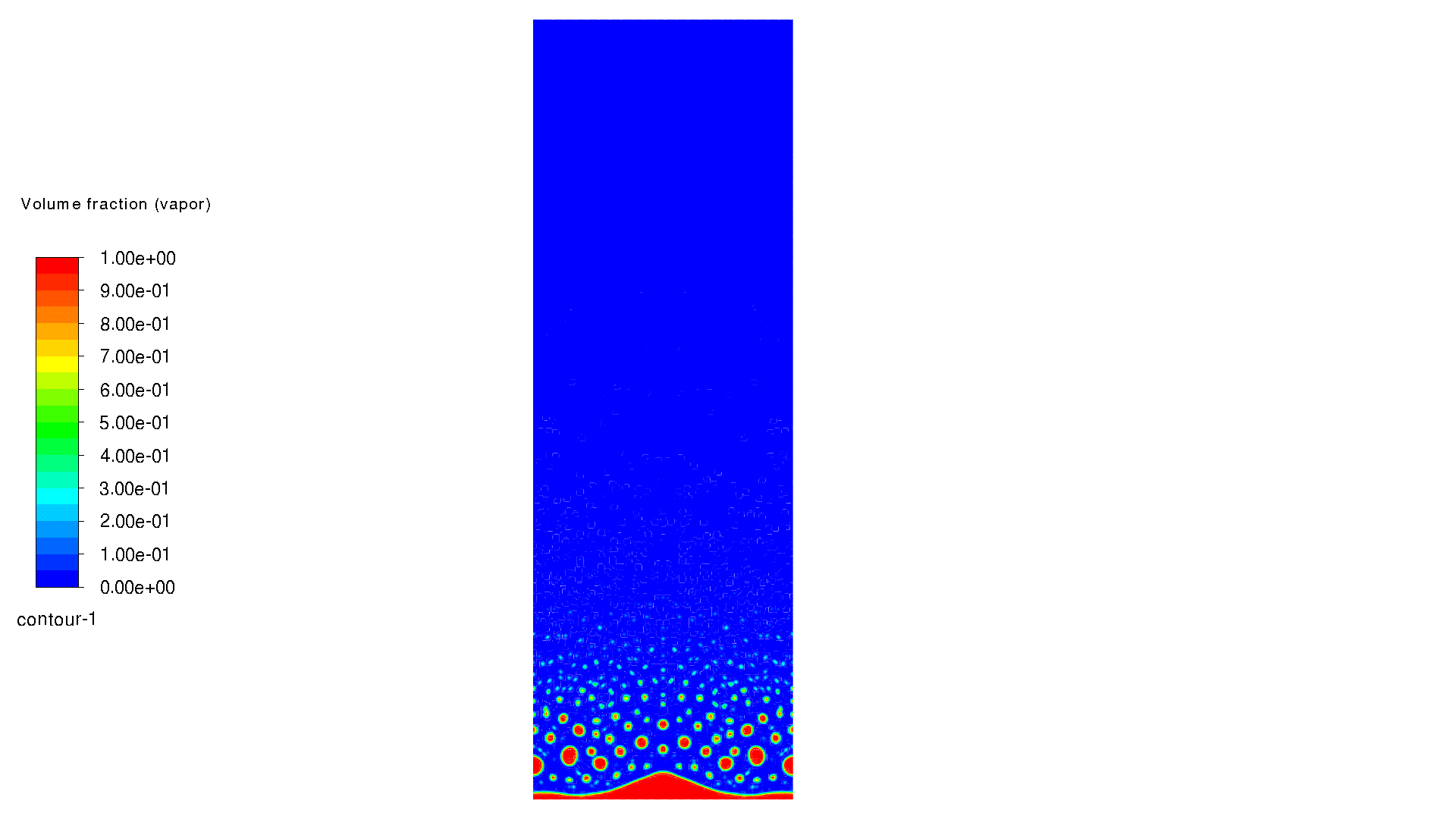

- The simulation utilizes the Volume of Fluid (VOF) multiphase model coupled with an evaporation-condensation model for phase change.

- A User-Defined Function (UDF) initializes a sinusoidal air layer at the chamber bottom.

- The transient simulation examines bubble formation, growth, rise, and detachment over multiple time steps, visualized through volume fraction contours.

To Order Your Project or benefit from a CFD consultation, contact our experts via email ([email protected]), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via [email protected] after you buy the product.

Description

Bubble Dynamics in a Boiling Chamber CFD Simulation, ANSYS Fluent Training

Introduction

This study investigates the boiling process in a 2D chamber using Computational Fluid Dynamics (CFD) analysis. The simulation aims to understand the complex phase-change process involving heat, mass, and fluid dynamics. By employing advanced models for multiphase flow and phase change, this research provides valuable insights into the behavior of boiling fluids under different conditions.

The CFD simulations were conducted using ANSYS Fluent software. The geometry, which is designed in ANSYS Design Modeler, represents a 2-dimensional chamber configuration, with the mesh generated in ANSYS Meshing.

The mesh is structured with higher precision in regions with anticipated temperature and pressure gradients, providing a high-quality representation of the chamber geometry.

Methodology

For multiphase modeling, the Volume of Fluid (VOF) model is utilized, coupled with the evaporation-condensation model, to capture the phase change at the interface.

A User-Defined Function (UDF) is employed to establish a thin sinusoidal layer of air at the bottom of the chamber.

The bottom wall is subjected to a constant heat flux, simulating the heating source for the boiling process. The side walls are treated as symmetric to focus the boiling process at the bottom of the chamber.

The simulation is run over multiple time steps to reflect the transient behavior of the boiling process.

Results

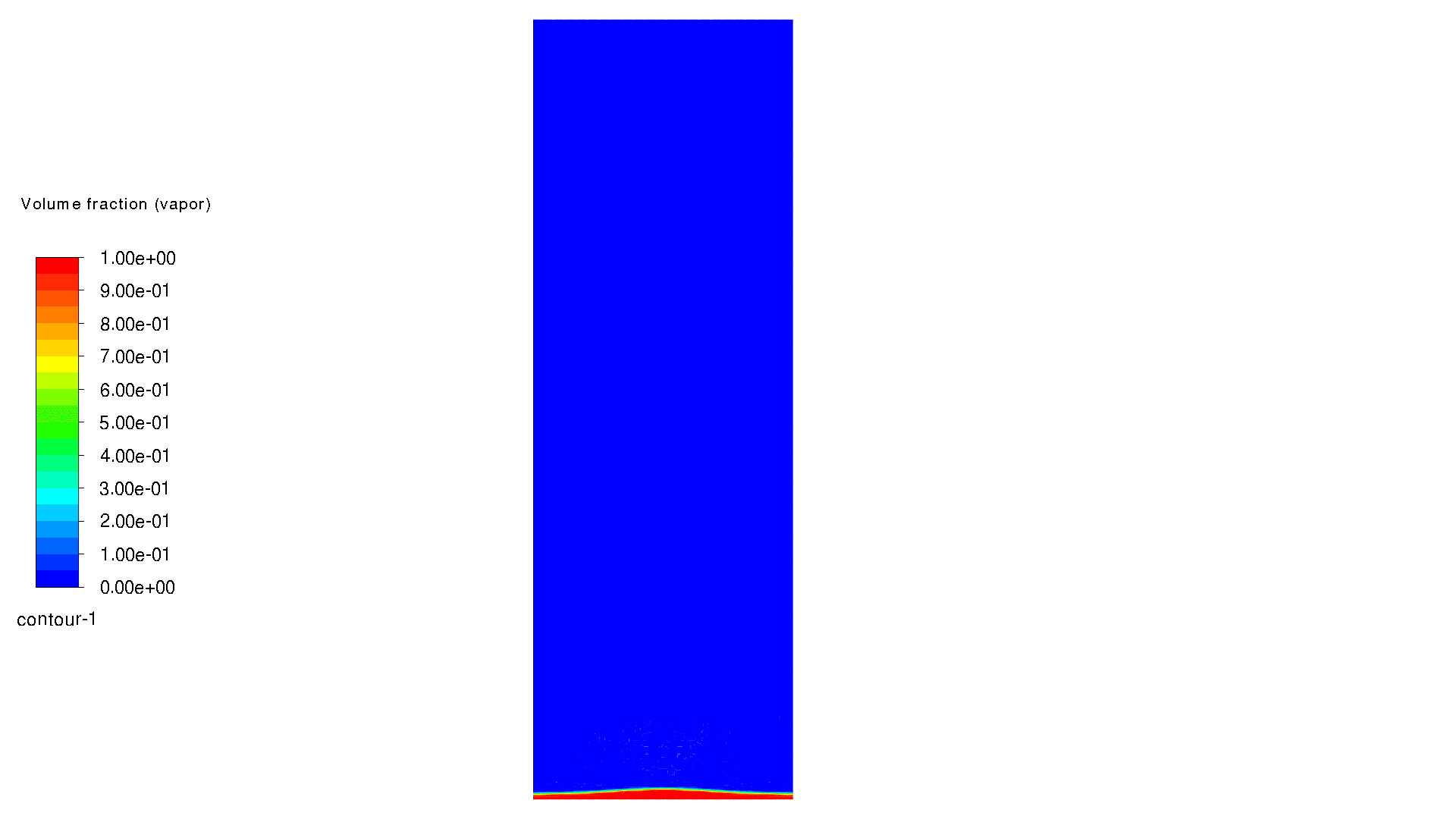

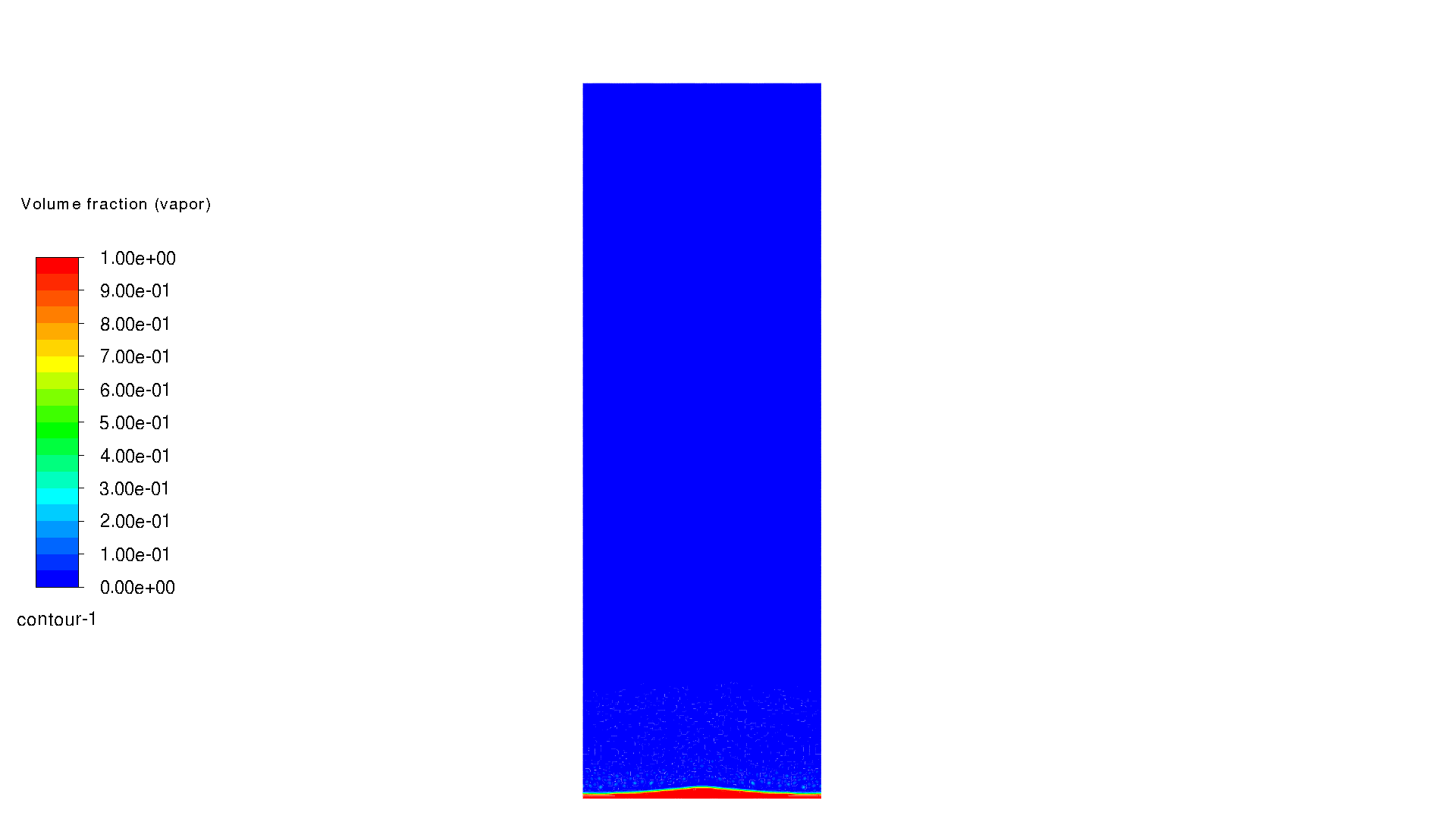

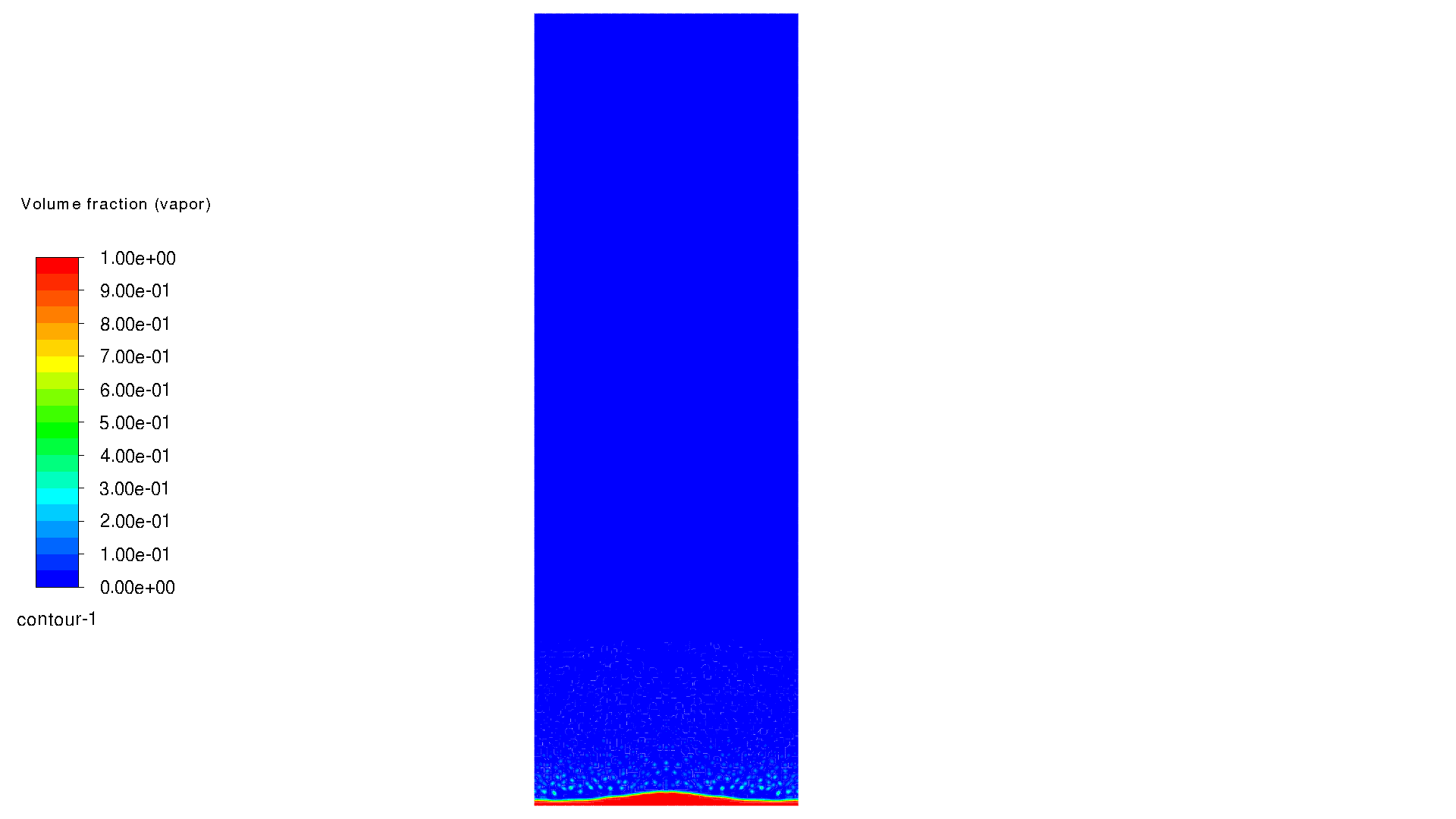

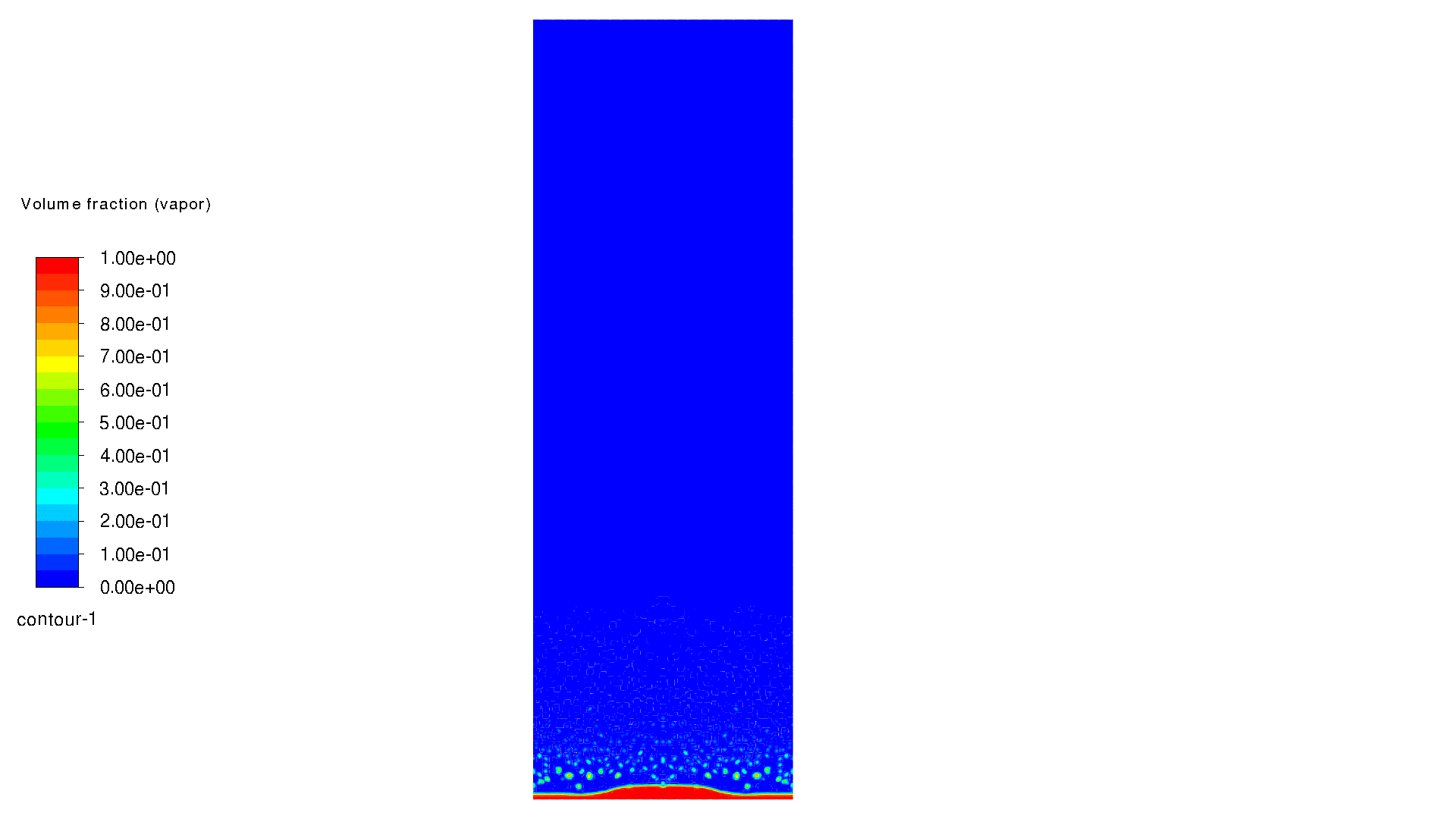

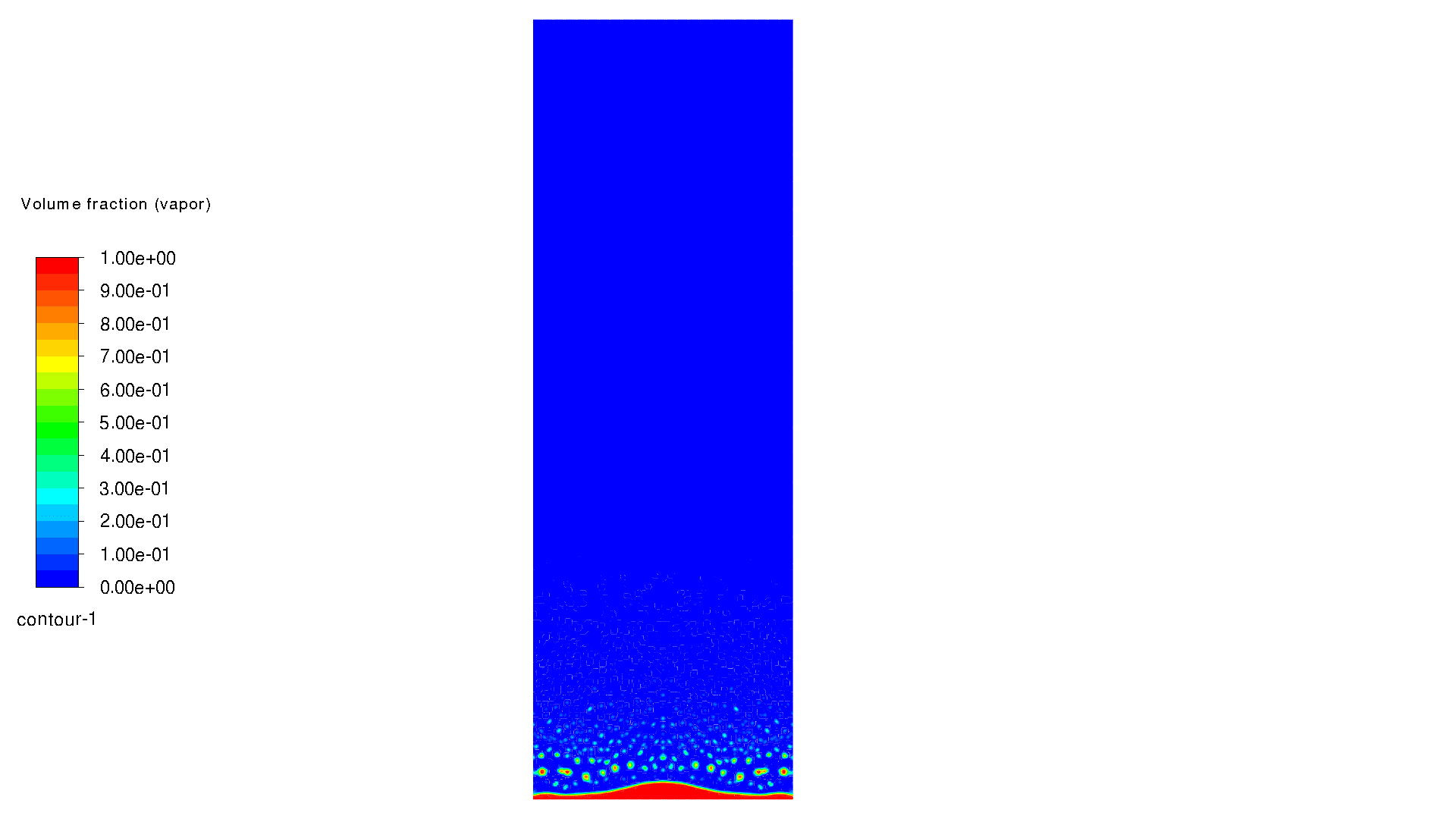

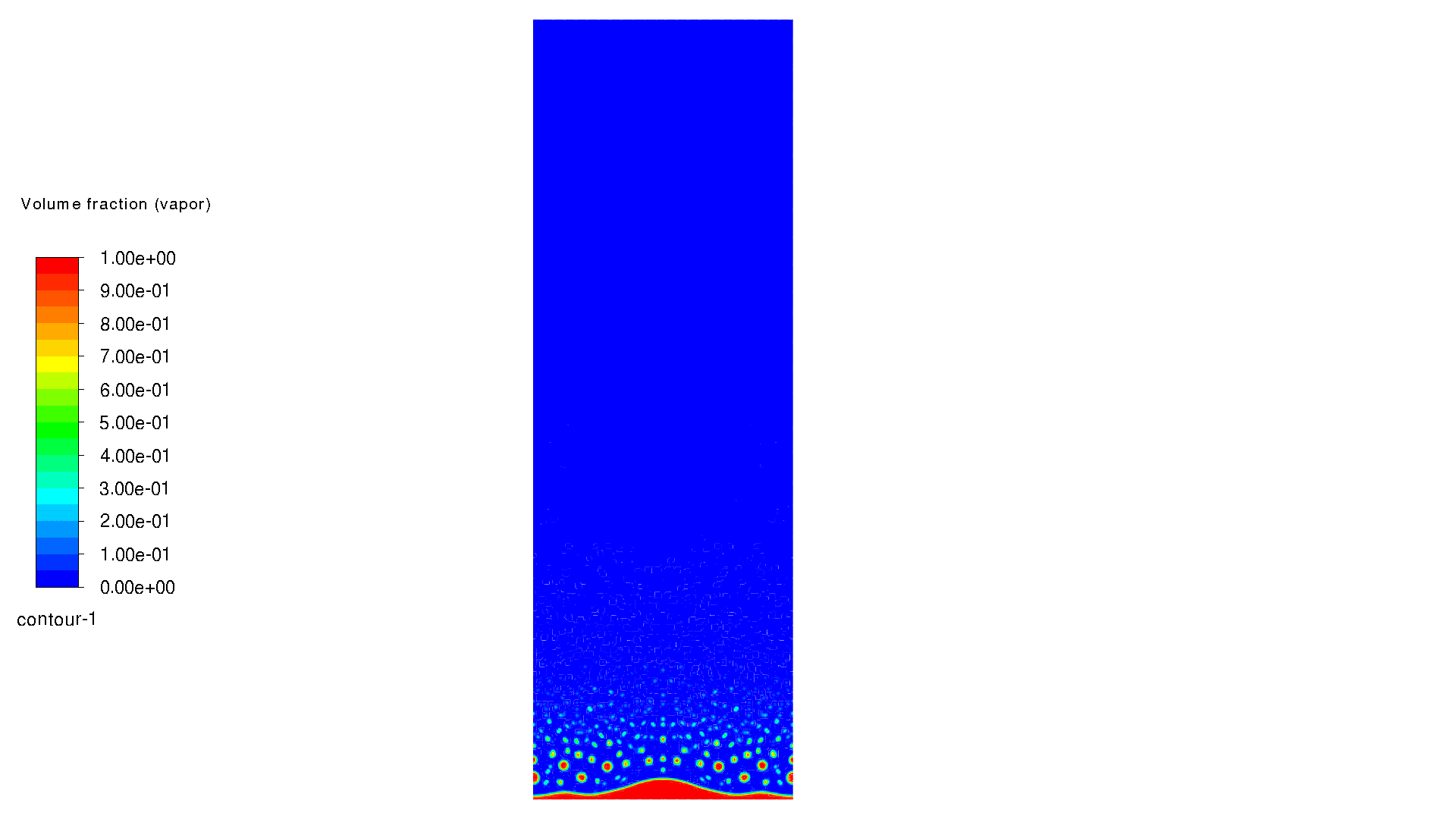

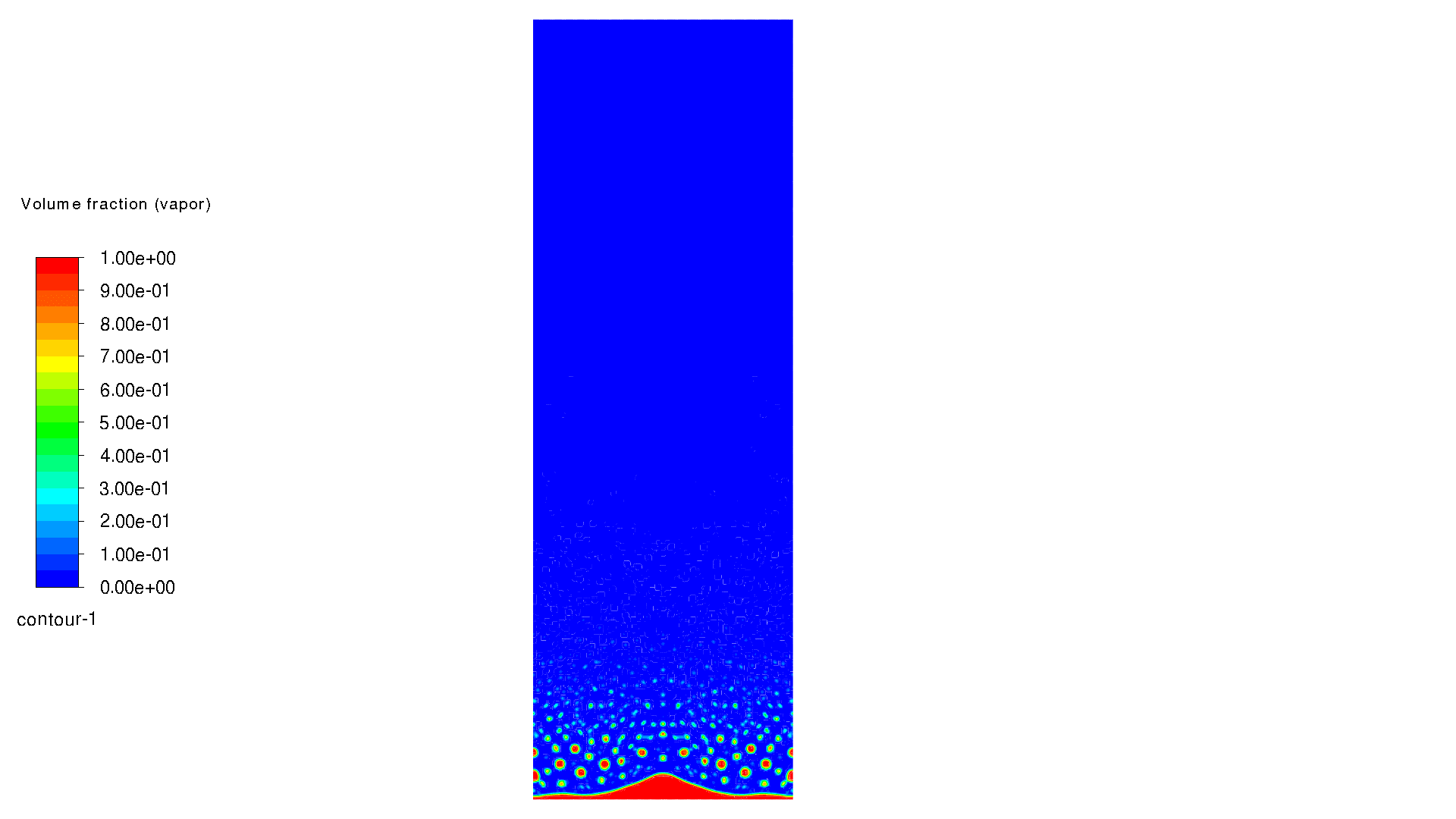

The simulation results demonstrate the intricate dynamics of the boiling process within the 2D chamber. The contours of the volume fraction are used to visualize the bubble formation and movement within the chamber.

As the chamber’s bottom layer heats up, bubbles form at the air-water interface due to evaporation. These bubbles rise due to buoyancy, and their growth and detachment are recorded at different time steps.

The contours produced at various time intervals offer important insights into the dynamics of the boiling process, including:

Bubble nucleation

Bubble growth

Bubble rise

Bubble detachment

These visualizations provide a comprehensive understanding of the boiling fluid behavior, which is crucial for optimizing the design and operating parameters of boiling equipment such as boilers and heat exchangers.

The simulation effectively demonstrates the fundamentals of bubble production and growth during boiling, offering a valuable tool for engineers and researchers interested in simulating boiling events.

Reviews

There are no reviews yet.