Bulb Turbine, Sand erosion study CFD Simulation

$160.00 $80.00 Student Discount

- The current CFD Analysis models the Bulb Turbine via ANSYS Fluent software.

- We have designed the geometry using ANSYS Design Modeler software and generated the mesh on this geometry using ANSYS Meshing software.

- The Frame Motion technique is utilized to model the rotation of the turbine.

- The Discrete Phase Model (DPM) account for the presence of sand particles.

- The Erosion on the turbine, due to particle collision is investigated.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Bulb Turbine, Sand Erosion Study CFD Simulation, ANSYS Fluent

Description

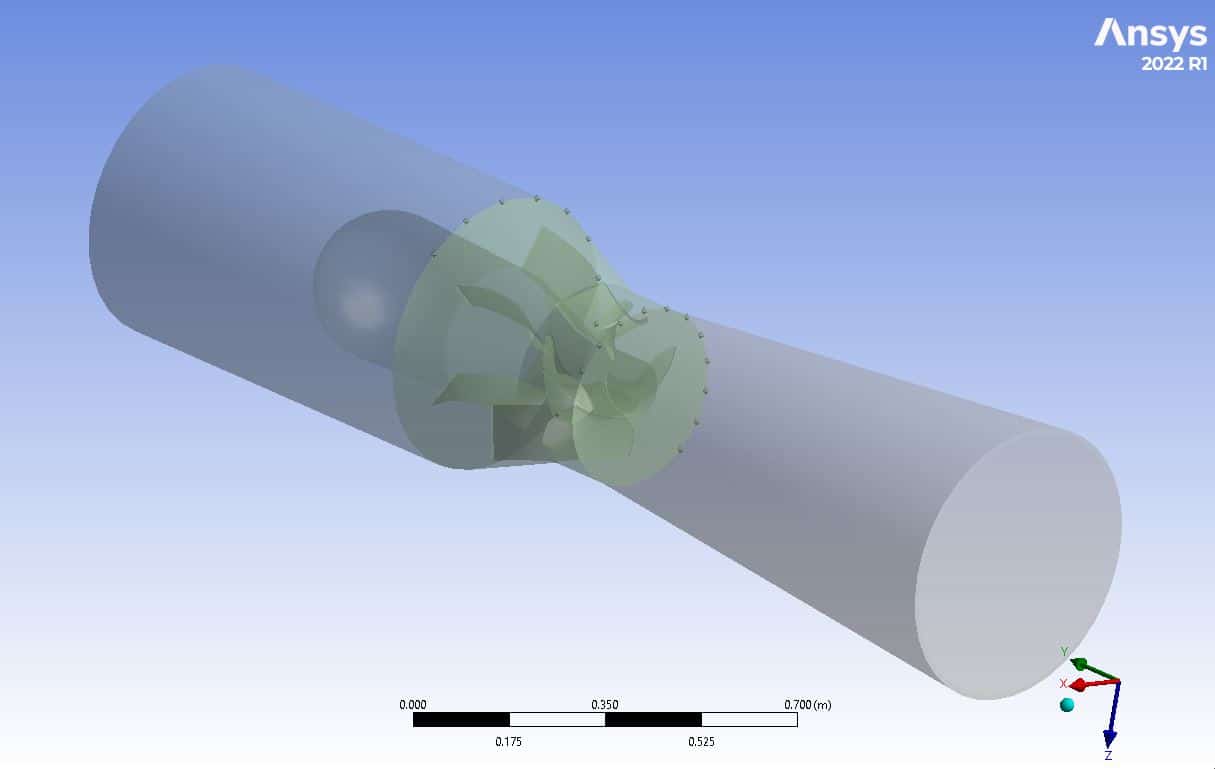

The current project aims to simulate the operation of a Bulb Turbine using ANSYS Fluent software. The Bulb Turbine is a type of hydraulic turbine that is widely used in hydroelectric power plants. It consists of a rotor with several curved blades, which are positioned around the central axis of the turbine.

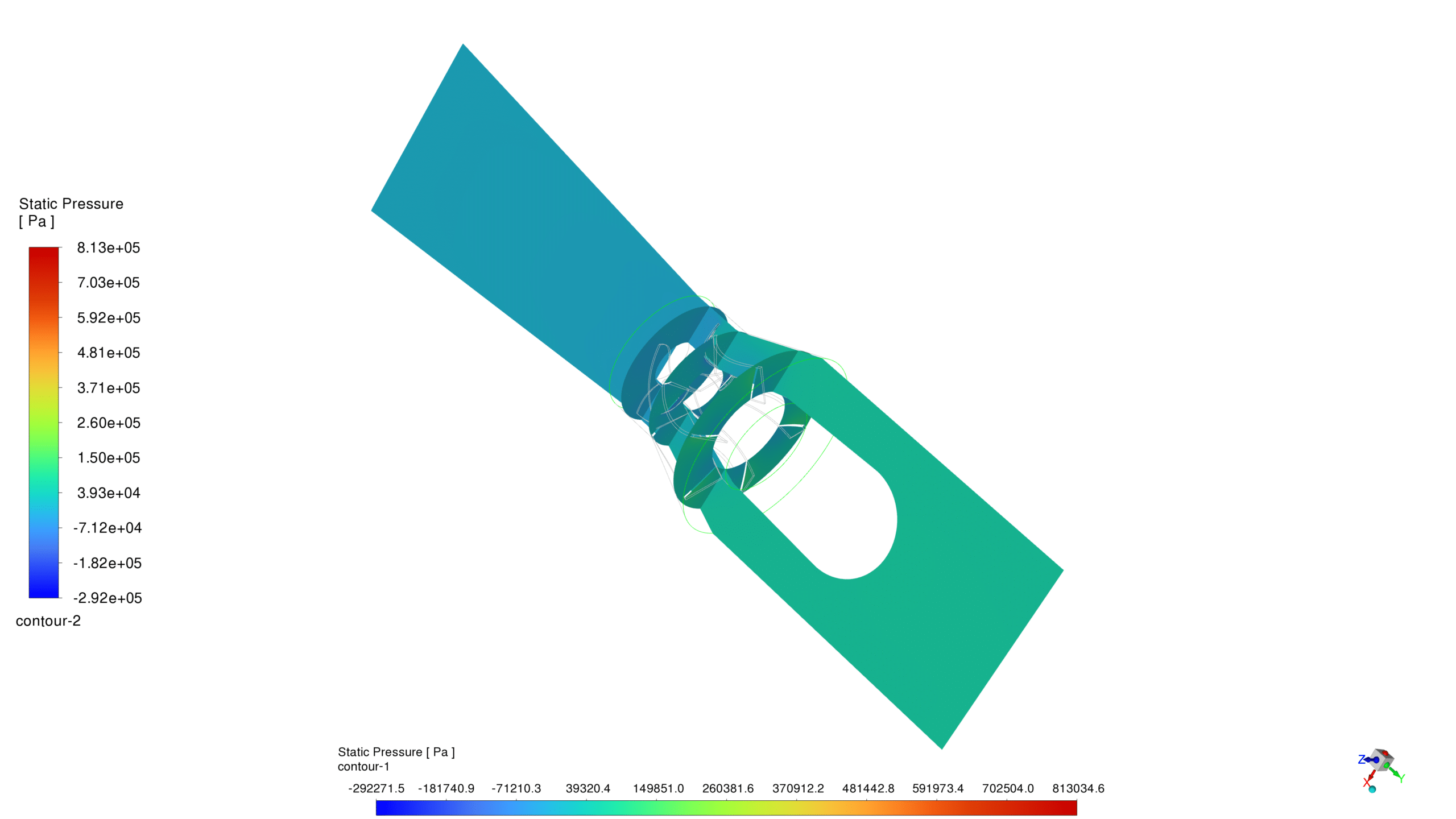

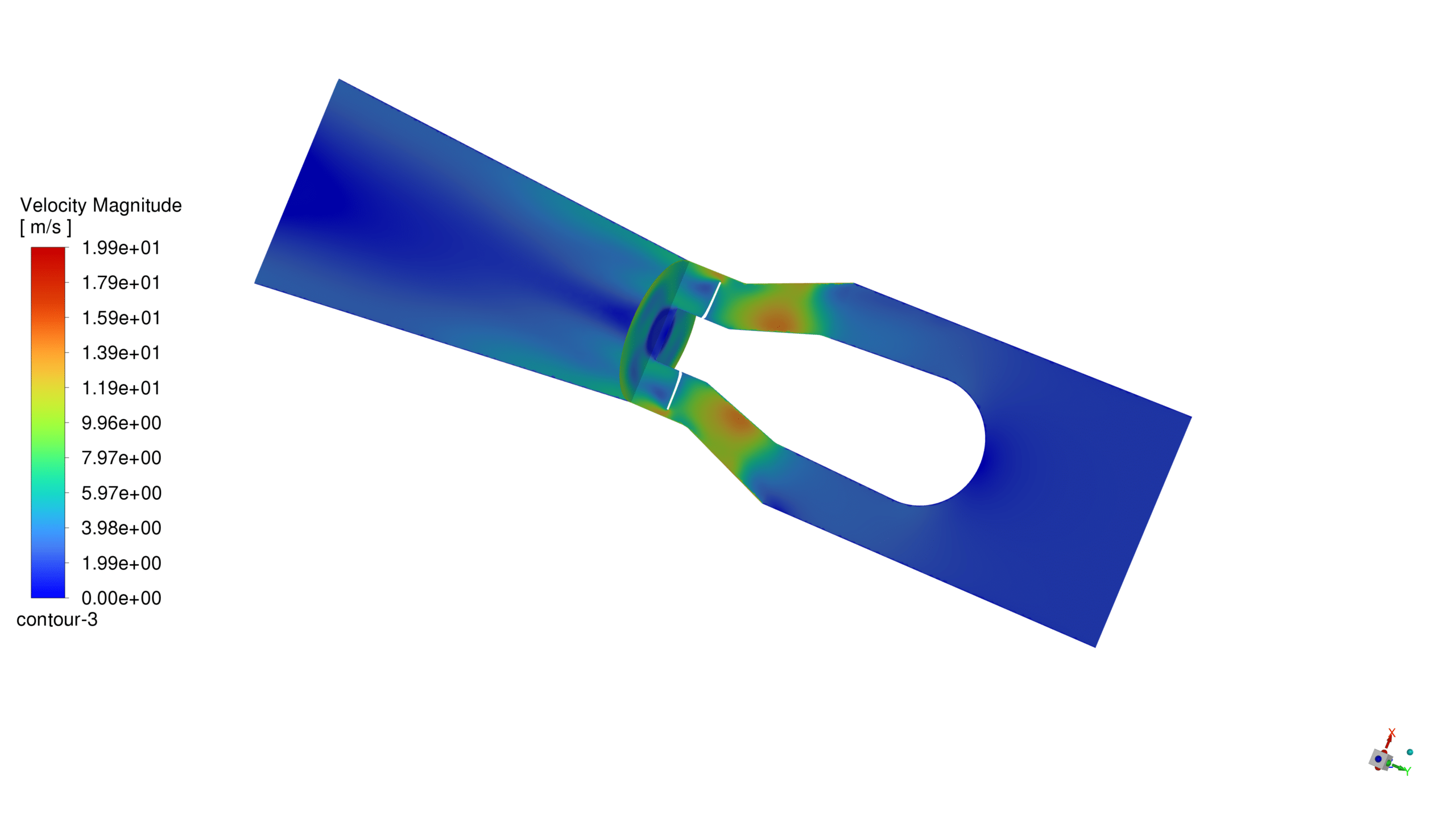

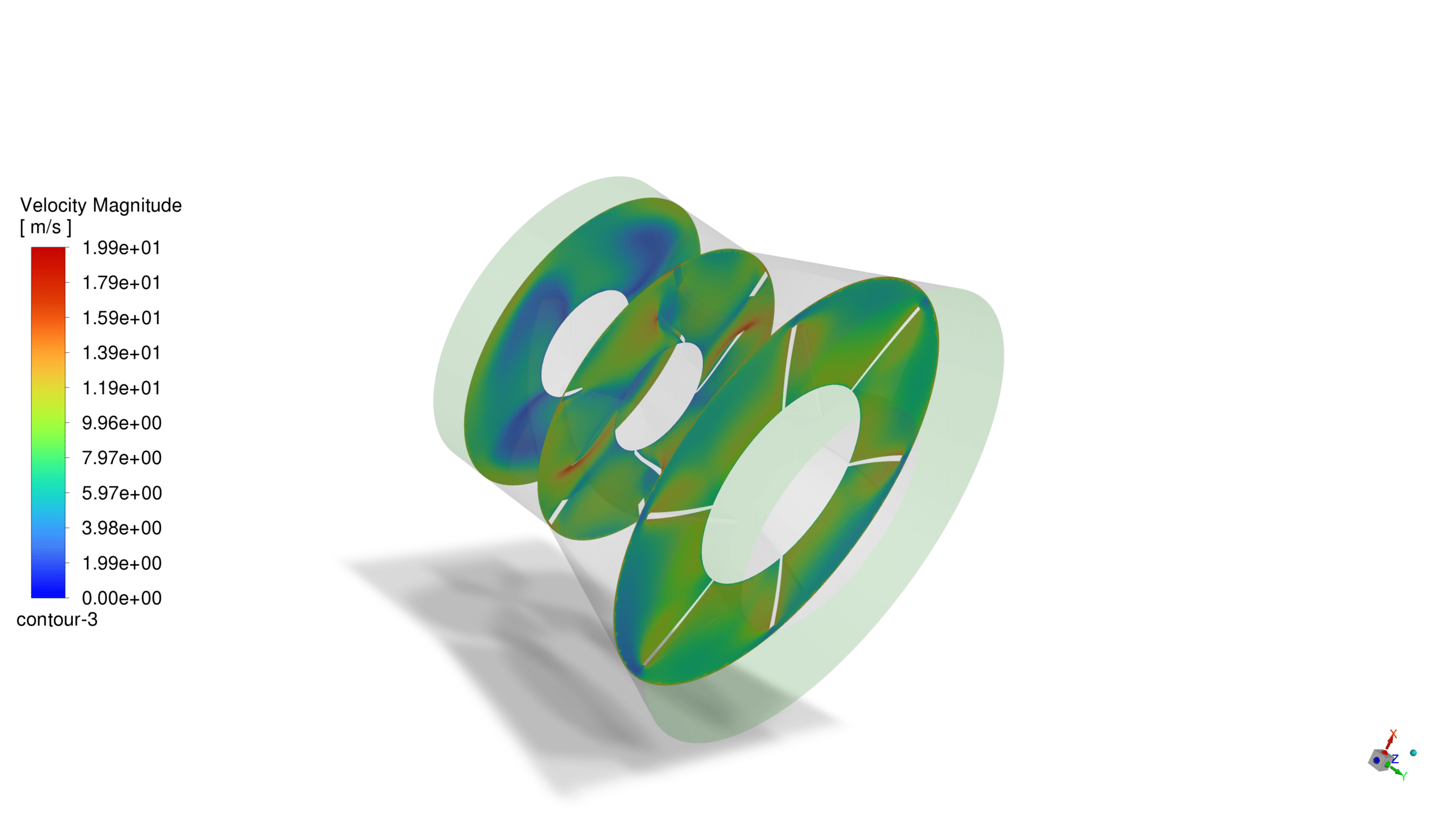

In this project, we consider a water flow with 2 m/s velocity, which passes through the turbine. The model is designed in three dimensions, taking into account the intricate details of the Bulb Turbine. The blades are first designed in SOLIDWORKS software, where their dimensions, angles, and distances from the central axis are carefully determined. Then, the blade design is imported into the Design Modeler software to construct the integrated blade model. To create a circulating water flow around the blades, a special cylinder is placed in the space around the turbine blades.

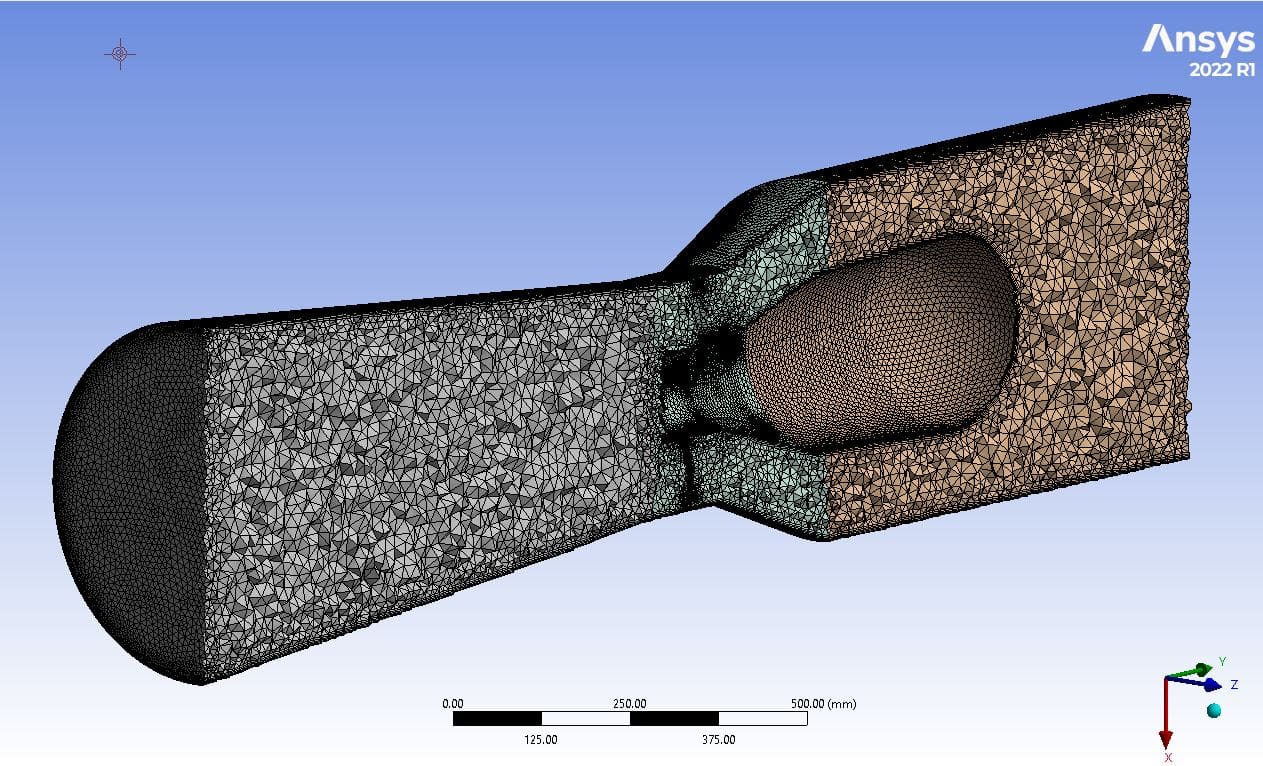

The meshing of the model is carried out using ANSYS Meshing software with an unstructured mesh type. To ensure high accuracy, the element number is set to 2,792,060. This helps to capture the intricate flow patterns and turbulence effects that occur around the blades during the operation of the turbine. Overall, this project provides a detailed and accurate simulation of the Bulb Turbine, which is essential for optimizing its performance and efficiency in hydroelectric power plants.

Methodology

In order to accurately simulate the rotation of the turbine blades, the Frame Motion technique is utilized. Specifically, for the cylindrical section, a mesh mode is defined by establishing a rotational speed of 572 revolutions per minute around the central horizontal axis of the turbine.

Additionally, the simulation involves the use of the Discrete Phase Model (DPM) module to account for the presence of sand particles and erosion/accretion effects. It is important to note that due to the nature of the Erosion/Accretion phenomena, a steady-state solver is employed.

Further, the Realizable-K-Epsilon model is selected to capture the turbulence characteristics of fluid flow accurately. Moreover, the simulation takes into account the effects of gravity in the Z direction, with a magnitude of -9.81 meters per second squared.

Conclusion

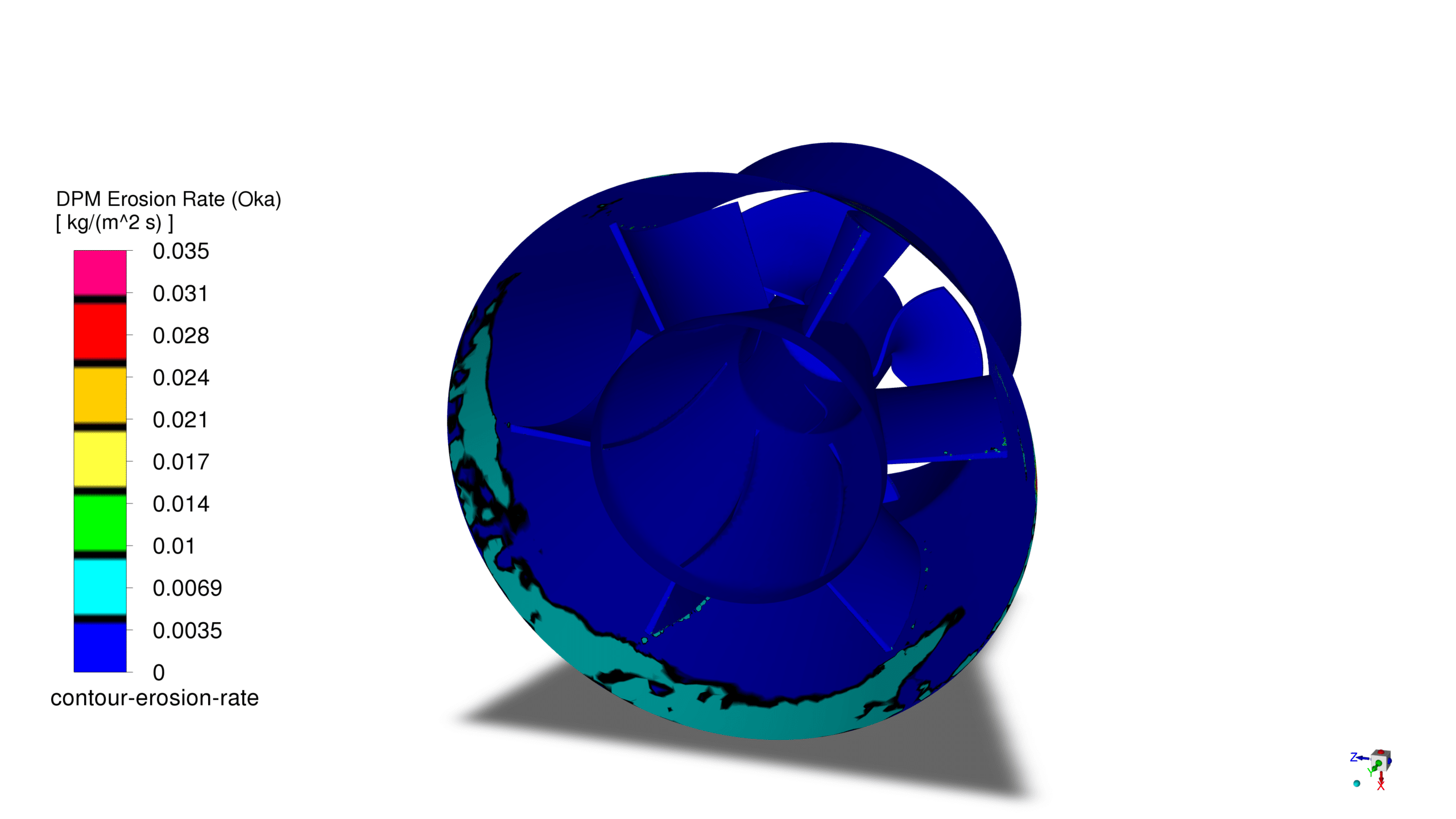

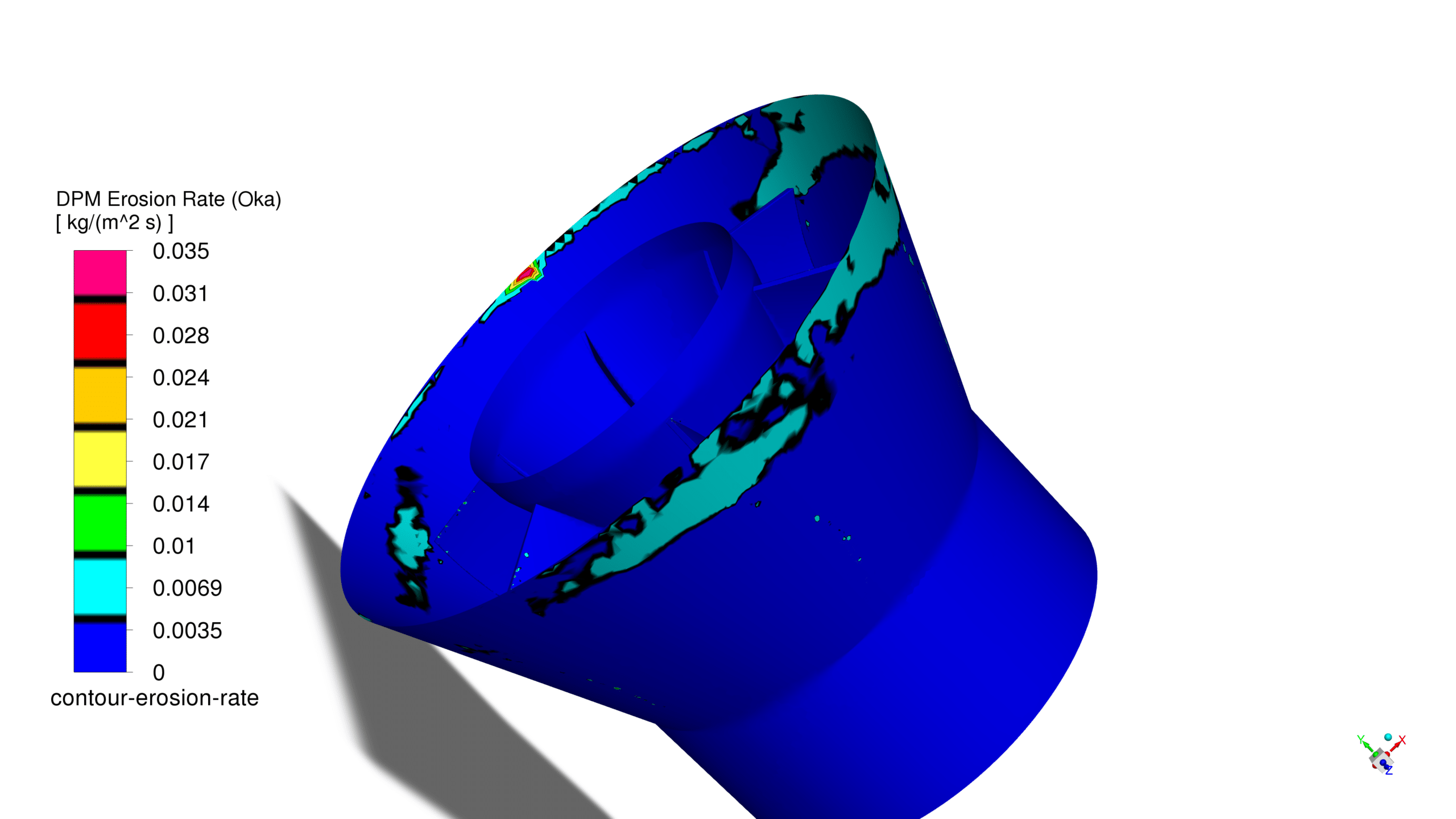

Upon concluding the solution process of the fluid dynamics simulation, a wealth of valuable data was obtained in the form of two-dimensional and three-dimensional contours, providing insight into various parameters such as pressure, velocity contours, and. The results revealed that the maximum velocity occurred near the rotating blades, which is a crucial finding in the field of fluid mechanics. Furthermore, the three-dimensional contours clearly depicted the effect of sand particles.

However, these results also highlighted the issue of erosion, which was evident over time, particularly over the blades. These findings are visible in erosion/accretion contours such as Oka, Mclaury, Finnie, etc.

Cleveland McClure –

Is the project accounting for different sizes or densities of sand for the erosion study, and how does this impact the erosion rate on the bulb turbine blades?

MR CFD Support –

In this simulation project, the Discrete Phase Model (DPM) is employed which allows for tracking the movement and impact of sand particles within the flow. While the description does not specify varying sizes or densities of sand, the DPM module in ANSYS Fluent does have the capability to simulate particles of different sizes and densities. The impact on erosion rate would depend on these variables; generally, larger or denser sand particles might cause more significant erosion due to greater momentum upon impact with the blades.

Aiden Bahringer –

Is it possible to adjust the real-world scaling of the sand particles in the simulation, and can we simulate different grades of sand to see their impact on erosion?

MR CFD Support –

Yes, ANSYS Fluent allows you to specify the size distribution and material properties of sand particles within the Discrete Phase Model (DPM), enabling the simulation of various grades of sand and their consequent impact on the turbine erosion.

Marcus Fay –

This project showcases the advances in CFD capabilities. Well done!

MR CFD Support –

Thank you for your positive feedback! We are glad to hear you found the Bulb Turbine sand erosion study insightful and up to date with the latest CFD technology. It’s great to know our efforts in providing detailed simulations are appreciated. If you have any further inquiries or need more information on similar projects, do not hesitate to reach out to us.

Arne Hills –

What specific results do erosion/accretion contours, like Oka, Mclaury, and Finnie, provide in this bulb turbine simulation and how do they help in assessing the turbine’s performance?

MR CFD Support –

Erosion\/accretion contours like Oka, Mclaury, and Finnie provide localized details about the wear to which the turbine is subjected due to sand particle impacts. By showing areas of high erosion, these models allow us to assess which parts of the turbine might face faster material degradation, thus influencing maintenance schedules and life-cycle assessments for the turbine. Analyzing these results helps us optimize the bulb turbine’s design to reduce wear and enhance its performance and longevity.

Alvera Torp –

Can you explain how the sand erosion is modelled in this simulation and its impact on the turbine over time?

MR CFD Support –

In this simulation, sand erosion is modeled using the Discrete Phase Model (DPM) coupled with erosion models like Oka, Mclaury, Finnie, and others. As the sand particles carried by the water interact with the turbine blades, these erosion models help determine the wear on the blades over time. The impact of sand erosion can lead to reduced efficiency and potential damage to the turbine, requiring maintenance or design alterations to mitigate the erosion effects.

Hertha Jakubowski DVM –

What specific challenges are faced during the DPM simulation for sand erosion, and how is it addressed in the study?

MR CFD Support –

In the DPM simulation for sand erosion, challenges typically include accurately predicting the trajectory of sand particles within the turbulent flow and ensuring that the simulation realistically captures erosion rates on the turbine blades. This study may address these challenges by carefully choosing an appropriate particle size distribution, material properties for the sand particles as well as for the turbine material, and suitable erosion models like Oka, Mclaury, Finnie to predict erosion on the blades. These parameters aid in delivering a more precise indication of wear patterns due to sand erosion on the turbine blades under operational conditions.

Joany Torphy –

After this simulation, which erosion model predicted the highest rate of erosion on the turbine blades?

MR CFD Support –

The project description doesn’t specify which particular erosion model predicted the highest rate of erosion. Erosion is determined using models like Oka, Mclaury, and Finnie as mentioned, but further analysis of the simulation data would be required to determine the most aggressive erosion prediction among the models used.

Frida Conroy –

I learned a lot about Bulb Turbine erosion from this study and the detailed simulation approach. Brilliant work on capturing the intricate effects of sand particles on the blades.

MR CFD Support –

Thank you for the positive feedback! We’re pleased to hear that you found the simulation informative and that it provided a comprehensive understanding of sand erosion effects on Bulb Turbine blades. Your recognition of the detailed simulation approach is greatly appreciated, and we are glad that our efforts have contributed to your learning experience. If you have any further questions or need more information, feel free to reach out to us.

Gregoria Dare –

I’m really impressed with how the simulation captures the effect of sand erosion on the turbine blades! Could you provide some details on how the Discrete Phase Model was set up to analyze this specific aspect?

MR CFD Support –

Thank you for your praise! In the simulation, the Discrete Phase Model (DPM) is set up to introduce sand particles into the water flow at a prescribed injection point. The properties of the sand particles, including diameter, density, and mass flow rate, are defined to model the erosion effects accurately. The interaction of these particles with the turbine blades is calculated to determine the erosion rate, which can be visualized in the erosion/accretion contours resulting from different erosion models like Oka, Mclaury, and Finnie.

Ozella Sauer –

The Bulb Turbine simulation seems very comprehensive. Can you explain how the sand particle distribution was initialized in the simulation?

MR CFD Support –

In the simulation, sand particle distribution was initiated using the Discrete Phase Model (DPM) in ANSYS Fluent. Sand particles were initialized with specific size range and material properties and were injected at specified boundary conditions to examine their trajectory, impact velocity, and erosion effects on the Bulb Turbine blades over time.

Reba Flatley –

What is the significance of incorporating the effects of erosion in the simulation of the bulb turbine, and how does it impact the overall understanding of bulb turbine performance?

MR CFD Support –

Incorporating erosion effects in the simulation of a Bulb Turbine is crucial for predicting the longevity and durability of the turbine blades. Consequently, understanding the impact of erosion leads to more effective maintenance scheduling and material selection, increasing the turbine’s operational lifespan.

Rasheed Swift –

What measures are taken in the simulation to account for sand particle erosion on the Bulb Turbine’s blades?

MR CFD Support –

In the simulation, the Discrete Phase Model (DPM) module is utilized to track the trajectory of sand particles and analyze erosion effects on the turbine blades. Furthermore, various erosion models like Oka, Mclaury, and Finnie are used to predict erosion rates, capturing the impact sand particles have on the turbine blades over time.

Haven Dickinson DDS –

How does the simulation handle the computation of sand erosion on the turbine blades, and could you use this simulation to predict maintenance schedules for the Bulb Turbine based on erosion data?

MR CFD Support –

The simulation utilizes the Discrete Phase Model (DPM) which allows sand particles to interact with the rotating blades. Erosion rates on the blades are computed based on various erosion models like Oka, Mclaury, Finnie, et cetera. These models calculate material wear as a result of the impact of sand particles. By analyzing erosion patterns and rates, one could potentially predict the lifespan of critical components and schedule maintenance accordingly to ensure optimal operation of the Bulb Turbine.

Kaylah Herzog DDS –

The Bulb Turbine simulation sounds impressive! The methodology to model erosion is interesting. Could you give more insight into how the erosion rates were quantified, and what parameters influenced these rates the most?

MR CFD Support –

In the simulation of the Bulb Turbine, erosion rates are quantified by using the Discrete Phase Model (DPM) alongside erosion models such as Oka, Mclaury, Finnie, and others within ANSYS Fluent. The key parameters influencing erosion rates typically include the velocity of sand particles, particle concentration, impact angle, hardness of the blade material, and particle size and shape. The software calculates the wear on the turbine blades based on the flow dynamics and interactions of sand particles, providing insights into which areas are most susceptible to erosion.

Angelica Tillman –

What are the key factors affecting the erosion prediction in the DPM module of this simulation and do these factors vary with different erosion models like Oka, Mclaury, Finnie, etc.?

MR CFD Support –

In the DPM module of the simulation, key factors affecting erosion prediction include particle size, density, velocity, impact angle, material properties of the blade, and cohesive forces of the particles. Yes, these factors can vary with different erosion models like Oka, Mclaury, Finnie, etc., as each model may have unique constants and equations that respond differently to these parameters when predicting erosion rates.

Dr. Micheal Bergnaum Jr. –

I’m amazed at how detailed the study on sand erosion within the Bulb Turbine is! It must have been challenging to capture the interaction between the sand particles and blade surface. Your team did an excellent job.

MR CFD Support –

Thank you for your kind words! Capturing the intricate details of the interactions is one of our priorities to provide an accurate analysis of erosion. We’re glad to hear that our efforts are appreciated!

Sienna Jacobson –

Is it possible to observe real-time erosion with this product, or are the erosion results predicted over an estimated time frame based on the simulation data?

MR CFD Support –

The erosion results are predicted based on the simulation data over an estimated time frame rather than observed in real-time. The outcome highlights where erosion is more likely to happen on the turbine blades due to the presence of sand in the flowing water.

Sasha Blick –

The simulation results mention different erosion models like Oka, Mclaury, Finnie, etc., could you please explain the differences this makes, particularly how each model affects the study of erosion on the Bulb Turbine?

MR CFD Support –

Each erosion model, such as Oka, Mclaury, and Finnie, represents a different approach for predicting the erosion rate based on the material properties, particle impact angle, velocity, and flow characteristics. Differences in these models can lead to variations in the predicted erosion patterns and rates on the Bulb Turbine’s blades, which is critical for understanding and mitigating wear-and-tear in the long term.

Amara Mosciski MD –

In the study of sand erosion on the Bulb Turbine, what specific method is utilized to calculate the erosion on the turbine blades?

MR CFD Support –

For the calculation of erosion on the Bulb Turbine’s blades in this simulation, the model employs the Discrete Phase Model (DPM) along with various erosion models such as the Oka, Mclaury, and Finnie models to capture the effect of sand particles impacting the turbine’s surfaces. These models provide a detailed assessment of how the impinging sand particles contribute to the erosion of the blade material over time.

Giovanni Bergstrom DVM –

Can the sand erosion results be used to predict the lifespan of the turbine blades?

MR CFD Support –

Yes, the sand erosion results obtained from the CFD simulation can provide valuable information for predicting the lifespan of the turbine blades by analyzing the erosion patterns and rates over time. By understanding the wear on the blades, engineers can estimate when maintenance or replacement might be necessary.

Abbey Rice –

I was incredibly impressed with the depth of analysis on the Bulb Turbine simulation regarding the erosion patterns. The use of the DPM module for sand particulate modeling sounds extensive. Are the erosion models like Oka, Mclaury, and Finnie customizable within ANSYS Fluent to fit specific material properties or do they come with predetermined parameters for certain materials?

MR CFD Support –

Thank you for your compliments! The erosion models within ANSYS Fluent like Oka, Mclaury, and Finnie are indeed customizable. Users have the flexibility to input material properties and operational conditions specific to their simulation needs which allows for a more precise prediction of erosion based on real-life scenarios.

River Bechtelar –

Does the model accounted for possible deformation of the turbine blades due to erosion, and was this deformation considered dynamically during the simulation or as a post-processing effect?

MR CFD Support –

The simulation primarily focused on assessing the erosion effect of sand particles on the turbine blades, where erosion contours like Oka, Mclaury, and Finnie show the stress on the blades. However, it appears the deformation due to erosion was analyzed as a critical outcome rather than integrated dynamically during the operation simulation. For a dynamic deformation assessment, a Fluid-Structure Interaction (FSI) approach would be necessitated, which isn’t referenced in the provided data.

Rebeca Balistreri –

I’m interested to know if the study includes the analysis of erosion on different parts of the turbine, like the blades and the housing.

MR CFD Support –

In this complex CFD study, erosion analysis is indeed conducted on different components of the Bulb Turbine, including the blades. Using the Discrete Phase Model (DPM), which incorporates several erosion models like Oka, Mclaury, and Finnie, the simulation estimates the wear and tear due to sand particles on the turbine material. The results display erosion accretion contours distinctly illustrating the areas of maximum erosion.

Ms. Sallie Romaguera V –

Are the erosion patterns on the turbine blades visualized using erosion models, and if so, which ones are applied in this simulation?

MR CFD Support –

Yes, the erosion patterns on the turbine blades are visualized using erosion models. In this simulation, erosion models such as Oka, Mclaury, and Finnie are applied to describe and visualize the erosion effects due to sand particles on the blades.