Capillary Action (wicking), Water flows in porous media, Ansys Fluent Simulation Training

$140.00 $70.00 Student Discount

- The problem numerically simulates Water flow in porous media and capillary action using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 178325.

- The Eulerian multiphase model is used, applying the Brooks-Corey model to simulate air and water phases.

- We use porous media to investigate pressure loss.

- Applying Transient solver.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this project, Water flow in porous media and capillary action has been simulated using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

Capillary action is the process of a liquid flowing in a narrow space without the assistance of, or even in opposition to, any external forces like gravity.

The present model is designed in three dimensions using the Design Modeler software. The geometry consists three-section, the lower section is resident water, and the upper section contains resident air; the pipe in the middle is considered a porous zone.

The meshing of the model was done using ANSYS Meshing software. The element number is equal to 178325.

Capillary Methodology

In this project, we simulated the water flows in porous media. This simulation aims to model a simple porous and capillary action through vertical pipe-like Plant vessels in Ansys Fluent Software.

The porous media model can be used for a wide variety of single-phase and multiphase problems, including flow through packed beds, filter papers, perforated plates, flow distributors, and tube banks.

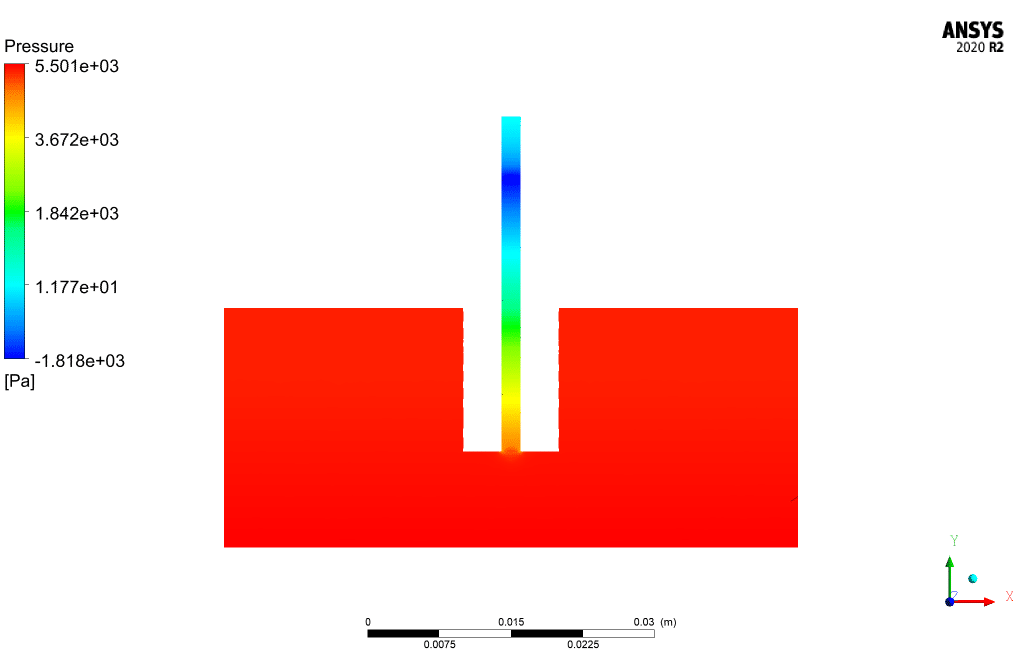

When using this model, a cell zone in which the porous media model is applied and the pressure loss in the flow should be determined. The porous media model incorporates an empirically determined flow resistance in a region of the model defined as “porous.”

The porous media model is nothing more than an added momentum sink in the governing momentum equations.

The Eulerian multiphase model has been used applying the Brooks-Corey model to simulate air and water phases. Gravity is considered as -9.81 m/s2 on the y-axis.

Capillary Conclusion

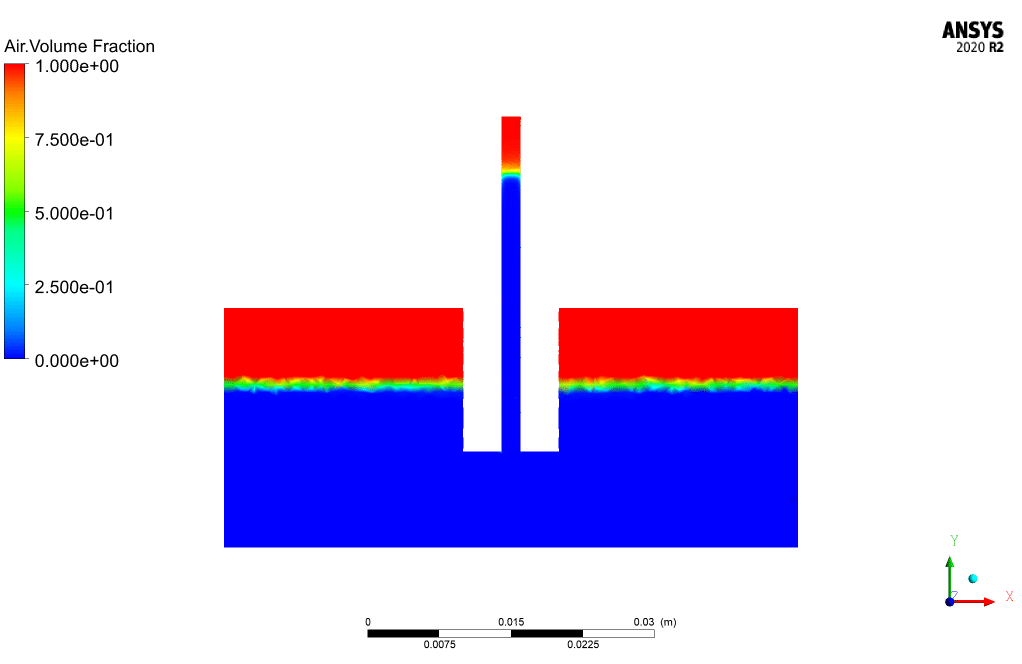

At the end of the solution process, three-dimensional velocity, air and water volume fraction, and animation are obtained. The result shows that the resident water starts to flow upward through a vessel to reach the top of the vessel due to the capillary effect.

Brock Lindgren V –

I’m intrigued by how the Brooks-Corey model is applied in the capillary simulation. Could you please explain this more?

MR CFD Support –

Certainly! In the simulation of capillary action using ANSYS Fluent, the Brooks-Corey model is an empirical approach applied within the Eulerian multiphase model. This model helps describe the relationship between capillary pressure and saturation within the porous medium, distinguishing how the interacting phases—water and air in this case—will distribute within the porous structure. It contributes significantly in determining how the water wicks up through the medium against gravity, representing the effects of surface tension and the differential pressure rise that characterizes the capillary action. This approach is critical in predicting the flow pattern and the distribution of fluid phases in porous structures, such as the vertical pipe similar to plant vessels considered in our analysis.

Mr. Gideon Barrows I –

I enjoyed learning about capillary action through this CFD simulation. The complex phenomenon of water wicking in porous media was compelling and made easy to understand with the guidance provided. It was exceptionally enlightening to visualize how capillary action works in plant vessels. Thank you for such an informative course!

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that you found the simulation informative and that it enhanced your understanding of capillary action in porous media. We strive to provide clear and comprehensive learning materials, and it’s rewarding to know we’ve succeeded. If you have any further questions or need assistance in the future, don’t hesitate to reach out.

Jerry Hayes –

After watching the simulation results presented, the visual explanation of the capillary action is fascinating. Thank you for such an insightful training module!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that you found the training on capillary action and the simulation results insightful. If you have any further questions or need more information, please feel free to reach out.

Augustus D’Amore –

I found the water flow in porous media and the capillary action simulation very insightful. I could clearly see the effect of capillary action on the water movement within the simulation. Great job on providing clear results and animation.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation on capillary action was informative and that the results and animation provided clarity on the subject. Your appreciation is highly valued and motivates us to keep providing high-quality simulations. If you have any further questions or need more insights, please don’t hesitate to ask.

Ova Medhurst Jr. –

What physics interfaces are used to simulate the capillary action, and can the results predict the rate at which water travels through different porous materials?

MR CFD Support –

In this simulation, the porous media model and the Eulerian multiphase model, with the Brooks-Corey model, are used to simulate the capillary action. The results can predict the rate at which water travels through the particular porous medium simulated, under the specified conditions.

Hettie Hermiston –

I really appreciated the clear explanations of the capillary action simulation. The visual results helped me understand how water moves through a porous medium, like a plant’s vessels. Well done!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that you found our explanation and visual aids effective in understanding the capillary action simulation. If there’s anything more you’d like to learn about this or related topics, please don’t hesitate to reach out.

Dr. Santos Prosacco PhD –

Is ANSYS Fluent capable of simulating other porous media flow phenomena, such as in heat sinks or oil reservoirs, in addition to capillary action?

MR CFD Support –

Yes, ANSYS Fluent is capable of simulating a wide range of porous media flow applications, including but not limited to heat sinks, oil reservoirs, and packed bed reactors, using its comprehensive porous media model features.

Ellis Weissnat Sr. –

Does the simulation take into account the effects of gravity on capillary action, and how is it implemented in ANSYS Fluent?

MR CFD Support –

Yes, the simulation takes into account the effects of gravity on capillary action. In ANSYS Fluent, gravity is typically specified in the operating conditions as an acceleration vector. In this case, gravity is set as -9.81 m/s2 on the y-axis, opposing the capillary rise. This helps in accurately simulating the capillary effect as it occurs when considering gravitational pull.

Joanie Torphy –

Did this simulation take into account different pore sizes within the porous media, or was the media considered homogeneous throughout?

MR CFD Support –

In this simulation, the porous media is typically modeled as a homogeneous medium to simplify the analysis. The physical properties such as porosity and permeability are assigned uniformly to the entire porous zone. If capturing the effects of varying pore sizes is paramount, additional models or finer resolution mesh might be necessary.

Ida Fadel Sr. –

Could the results from this capillary action simulation be applied to help understand fluid dynamics in natural scenarios like water transport in plants?

MR CFD Support –

Absolutely, the capillary action simulation can provide valuable insights into the fluid dynamics experienced in natural phenomena such as water transport in plant vessels. By understanding the capillary effects within a controlled environment, researchers can extrapolate findings to more complex natural systems.

Donna Hill II –

I saw that the Brooks-Corey model was used for the simulation – could you explain why this model is suitable for depicting the capillary action in this context?

MR CFD Support –

The Brooks-Corey model is appropriate for simulating capillary action because it provides a method to relate the porous media’s properties like permeability and porosity to the capillary pressure and saturation of the fluids within the media. This model effectively describes how water moves through the porous matrix of the pipe against gravity due to capillary forces, making it suitable to predict the wicking action observed in this project.

Dr. Edison Casper Sr. –

What exactly does the Brooks-Corey model used in this simulation do?

MR CFD Support –

The Brooks-Corey model in ANSYS Fluent is a capillary pressure model that describes the relationship between capillary pressure and saturation in a porous medium. It is particularly useful in simulating multiphase fluid flows where capillarity plays an important role, such as in the wicking process simulated in this project. It helps predict how water travels through the porous medium and reaches the top of the vessel due to capillary action.

Mossie Rice –

Was concept of contact angle and how it affects wicking incorporated in the simulation specifics?

MR CFD Support –

In the provided simulation of capillary action, contact angle effects are critical in defining the capillarity and thus could be included in the ANSYS Fluent model using wall adhesion properties. It defines how the liquid interfaces with the solid porous medium. If explained in the product’s learning material, it would highlight how variations in contact angle would alter the capillary rise observable in the simulation results.

Yasmin Nader –

I really appreciated how this project captured the nuances of capillary action in a way analogous to a plant’s vessels! It was amazing to see the detailed simulation of water traveling against gravity. Can I visualize the actual path of the capillary flow in three dimensions with the provided results?

MR CFD Support –

Yes, within the provided results of this simulation, there should be three-dimensional velocity and volume fraction data. These results would allow you to visualize the water’s flow path as it moves upward through the porous medium, reflecting the capillary action in three dimensions.

Zelda Ullrich –

The training course on capillary action simulation in Ansys Fluent was perfect. It helped me understand the principles of wicking and water flow in porous media. The provided results and animations made the concept really clear.

MR CFD Support –

Thank you for your positive feedback on our Capillary Action (wicking) simulation training course! We are thrilled to hear that the course was helpful and that the visual materials clarified the complex concepts for you. If you ever have more questions or need further assistance, please don’t hesitate to reach out.

Eugenia Zemlak DDS –

I used the training for capillary action in porous media, but I’m not sure how gravity is factored into the simulation model. Could you please clarify this for me?

MR CFD Support –

In the capillary action simulation, gravity has been considered as a downward force (-9.81 m/s2 on the y-axis). Even though the process of capillary action typically acts against gravitational forces, gravity is included in the model to accurately simulate the overall interaction of forces acting on the water, ensuring that the capillary rise due to intermolecular forces within the porous media is accurately depicted in opposition to gravity.

Gay Sipes –

I appreciate the detailed explanation of the capillary action simulation! How does the Brooks-Corey model enhance the simulation of the multiphase flow in this scenario?

MR CFD Support –

The Brooks-Corey model is a useful approach to characterizing the capillary pressure and relative permeability within a porous medium when dealing with earth materials. It helps simulate the multiphase flow more accurately by taking into account the wetting properties of the media as well as the pore size distribution, providing a more precise representation of the capillary effects and fluid behaviors. This ensures that the capillary rise and subsequent distribution of water through the porous pipe in the simulation realistically mirrors physical phenomena.

Dr. Troy Botsford MD –

The project sounds fascinating! Was surface tension between water and air taken into account in this simulation?

MR CFD Support –

Yes, the surface tension effect between water and air is a critical factor in capillary action studies. This effect has been considered in the simulation to authentically represent the physics dictating the capillary rise in the porous media.