Chemical Engineering Training Package for Beginners, 10 Practical Exercises

$299.00 $149.50 Student Discount

This CFD training package includes 10 practical exercises related to the Chemical Engineering field and devices for BEGINNER Users.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Chemical Engineering CFD Training Package by ANSYS Fluent

Chemical engineers have recently started to use the power of computational fluid dynamics (CFD) simulation to investigate and simulate the combination of fluid flow and chemical processes. For instance, we can also use CFD in the systems with reacting flows, combustion and heat, and mass transfer. Using CFD tools will help a chemical engineer understand physical and chemical processes in more detail, leading to significant process and product improvements in the chemical engineering industry. A combination of the chemical reaction and Computational Fluid Dynamics (CFD) is an exciting area in engineering. Chemical engineers discovered chemical reaction stoichiometric balance for most species in the world a long time ago. They still work on finding new reactions and intermediate reactions for each reactant.

What is more interesting is what will happen to a reaction in different situations of fluid flow in the chemical engineering area. What is the effect of velocity, temperature, and pressure distribution on the reaction procedure? They also predict the impact of these parameters on the rate of the reaction. Especially the effect of temperature on the rate of reaction. However, what will happen in complex geometry? At which point reactants will see each other? The reaction will occur or not. What is the temperature distribution caused by this reaction?

There are lots of Chemical projects that are simulated by ANSYS Fluent software using CFD methods. This CFD training package includes 10 practical exercises related to the Chemical Engineering field and devices for BEGINNER Users.

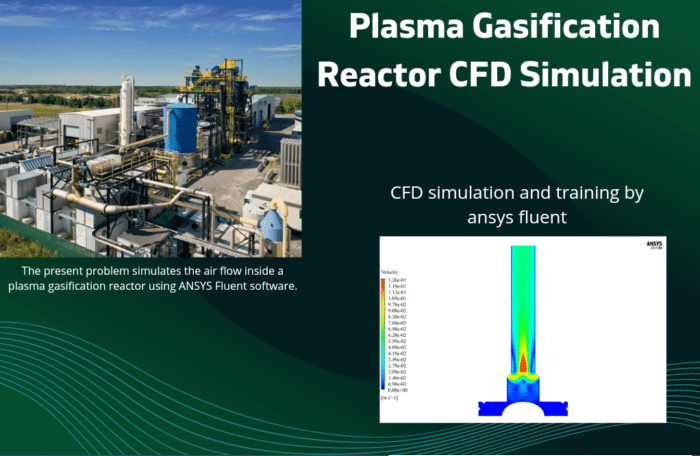

The 1st practical exercise simulates the airflow inside a plasma gasification reactor using ANSYS Fluent software. In general, plasma gasification is a process in which organic matter is converted to synthetic gas with the help of plasma. Arc ignited plasma is used to ionize the gas and catalyze organic matter into synthetic gas and solid waste. These operations are commonly used as a form of waste remediation and for the evaporation of biomass and hydrocarbons such as coal and petroleum sands.

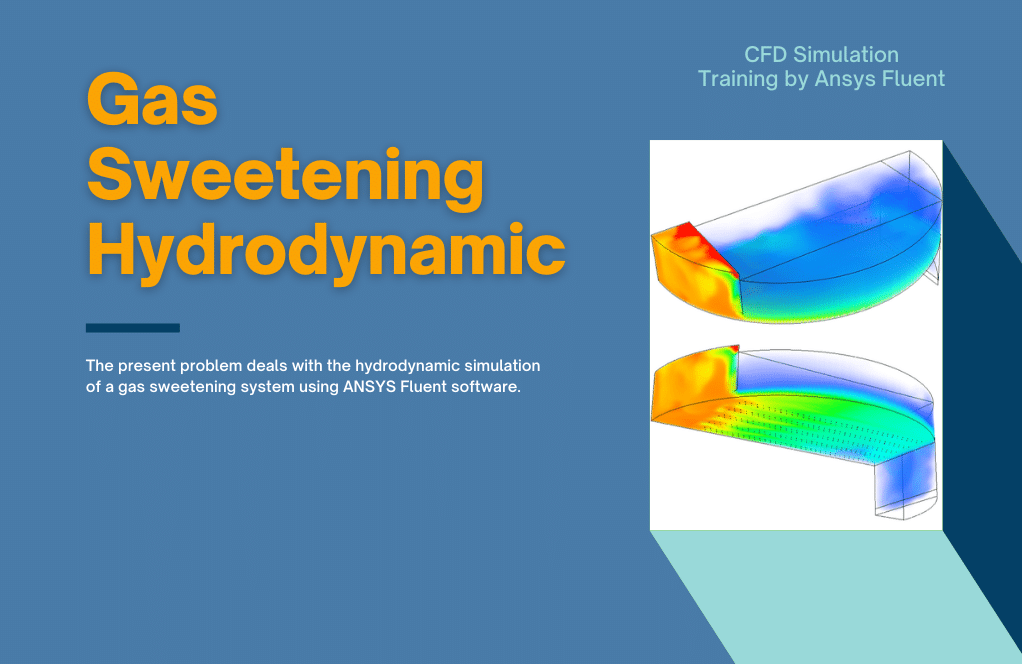

The 2nd practical exercise deals with the hydrodynamic simulation of a gas sweetening system using ANSYS Fluent software. Gas sweetening is generally the process of removing hydrogen sulfide, carbon dioxide, mercaptans, and other impurities from natural gas streams and synthetic gas to make the gas suitable for transportation and use. Sour gas must be sweetened; Because hydrogen sulfide and carbon dioxide have a high corrosive effect on gas pipelines and are also considered a group of toxins for humans.

The 3rd practical exercise simulates gas-solid flow within a Fluid Catalytic Cracking (FCC) system using ANSYS Fluent software. These FCC systems have many applications in chemical process units that are used to optimally convert high-boiling oil ratios to lighter high-value products. Inside FCC reactors, two important separate areas are defined, including a dilute area called the disengager and a dense area called the stripper.

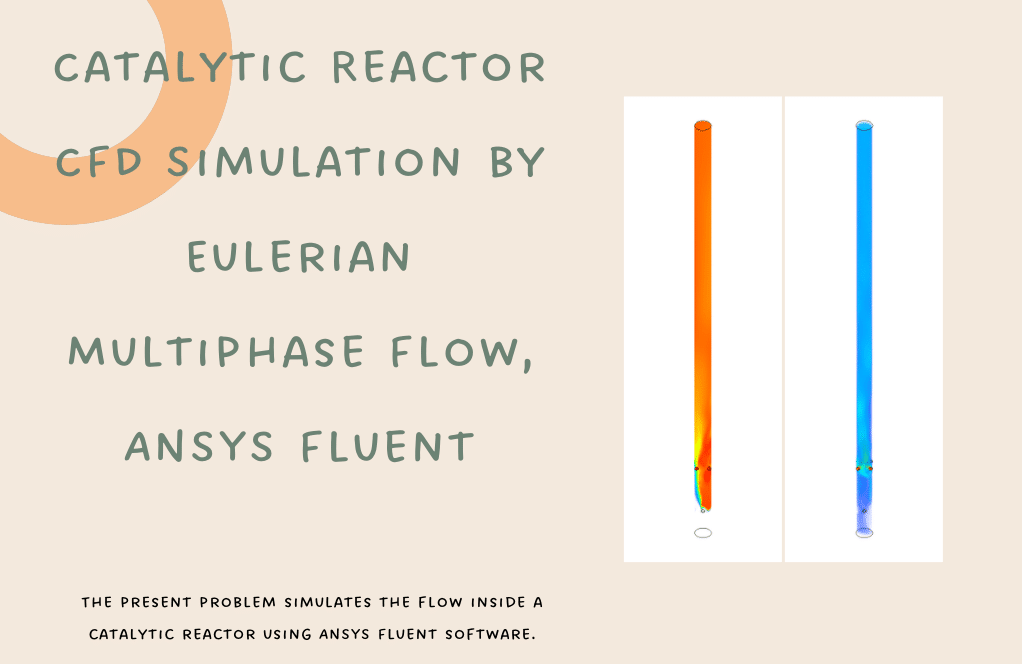

The 4th practical exercise simulates the flow inside a catalytic reactor using ANSYS Fluent software. In the internal structure of this reactor, compressed air is mixed with the fuel spray into the reactor and the catalyst material to cause the reaction to take place. Therefore, in simulating this model, Eulerian multiphase flow is used.

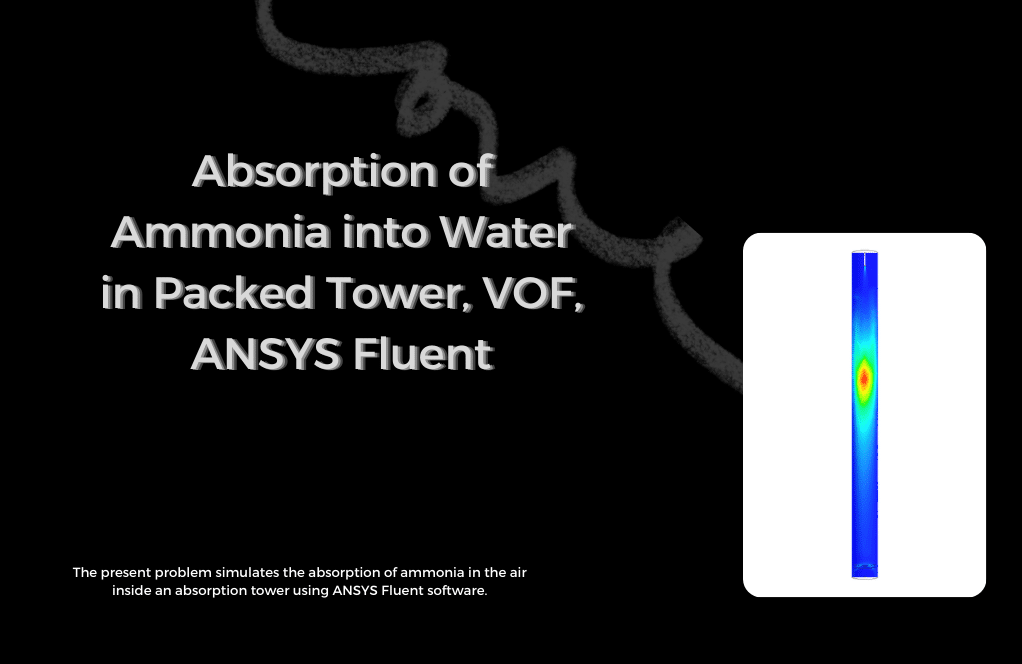

The 5th practical exercise simulates the absorption of ammonia in the air inside an absorption-packed tower using ANSYS Fluent software. The adsorption process is one of the methods of separating the components of a gas mixture placed in the presence of a solvent (liquid phase). The basis of work in this adsorption process is the difference in solubility of the components in the gas phase.

In the 6th practical exercise, numerical simulations of air bubbles under a water column with two different surface tension have been done using Ansys Fluent software. The VOF model has been used to simulate and solve the two-phase flow field equations. The two modes in this project are simulated and compared.

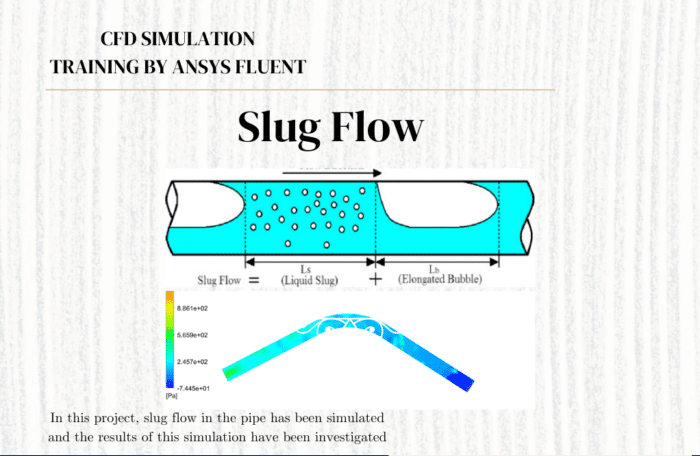

The goal of the 7th practical exercise is to simulate slug flow in a pipe by Ansys Fluent software. There is a multiphase-flow regime in tubes in which most of the lighter fluid is contained in large bubbles dispersed within and pushing along the heavier fluid. The word slug refers typically to the more severe and slower-moving fluid but sometimes to the bubbles of lighter fluid.

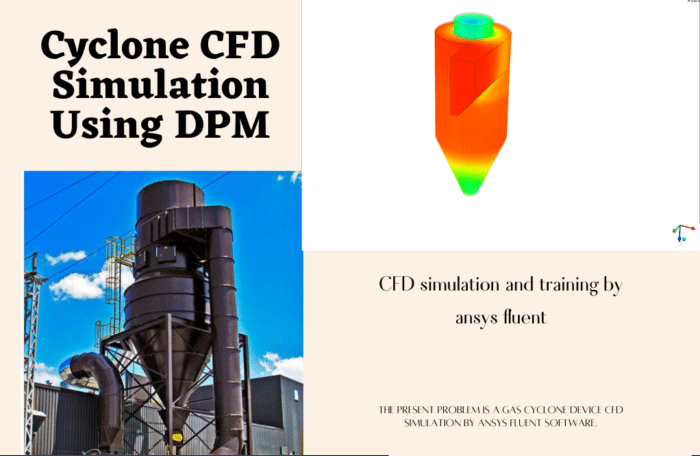

The 8th practical exercise is a gas cyclone device CFD simulation. In this device, the gas flow enters continuously from the top to the inner space between the two cylinders and then the partial cone. Also, the solid particles enter the cyclone from the top as the discrete phase.

The 9th practical exercise simulates the process of water spray into a cubic space by ANSYS Fluent software. The aim of the present study is to investigate the behavior of water flow during the spraying process from a very small circular section to the inner space of an area with a larger volume, which examines the behavior of water flow by tracing every particle. Therefore, to simulate this model, the Lagrangian perspective should be used, which is possible in the form of a Discrete Phase Model (DPM).

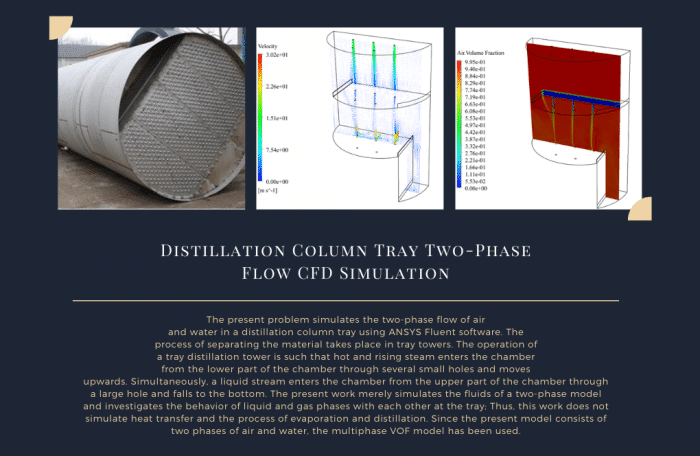

And finally, the 10th practical exercise simulates the two-phase flow of air and water in a distillation column tray using ANSYS Fluent software. In-tray towers, the process of separating the material takes place. The operation of a tray distillation tower is such that hot and rising steam enters the chamber from the lower part of the chamber through several small holes and moves upwards.

Related products

-

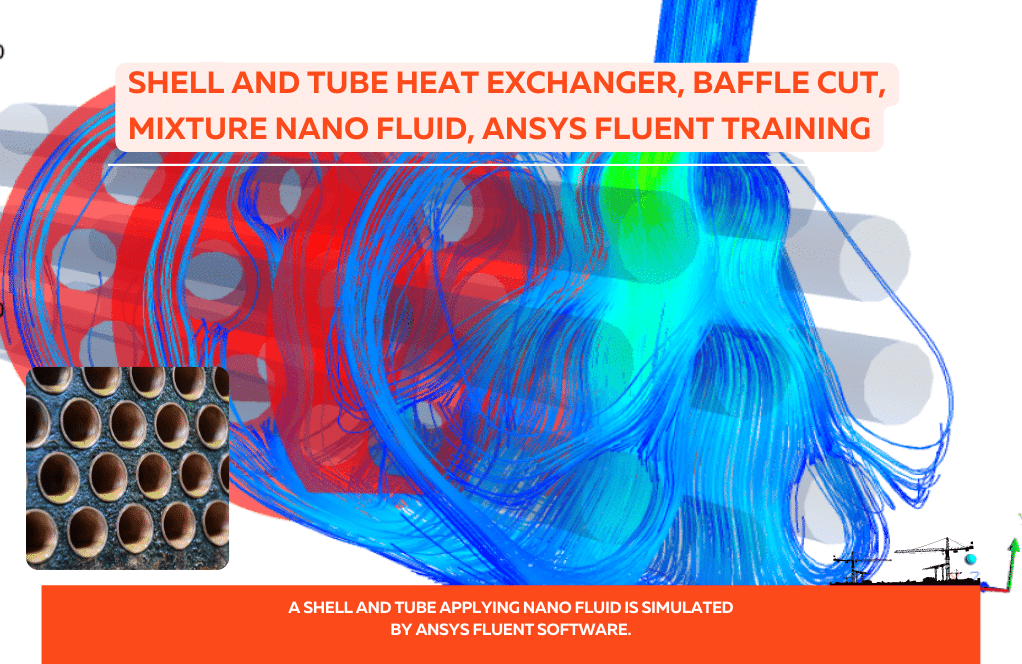

Heat Exchanger with Baffle Cut and Mixture Nano Fluid

Rated 4.67 out of 5$140.00$70.00 Student Discount

Reviews

There are no reviews yet.