Circulating Fluidized Bed (CFB) Boiler CFD simulation, ANSYS Fluent

$220.00 $110.00 Student Discount

- In this project, a Circulating Fluidized Bed(CFB) Boiler is simulated using ANSYS Fluent software.

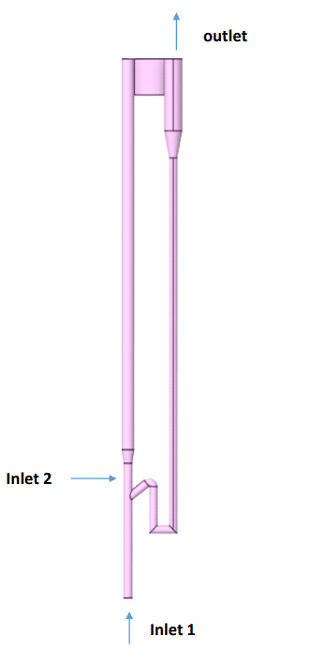

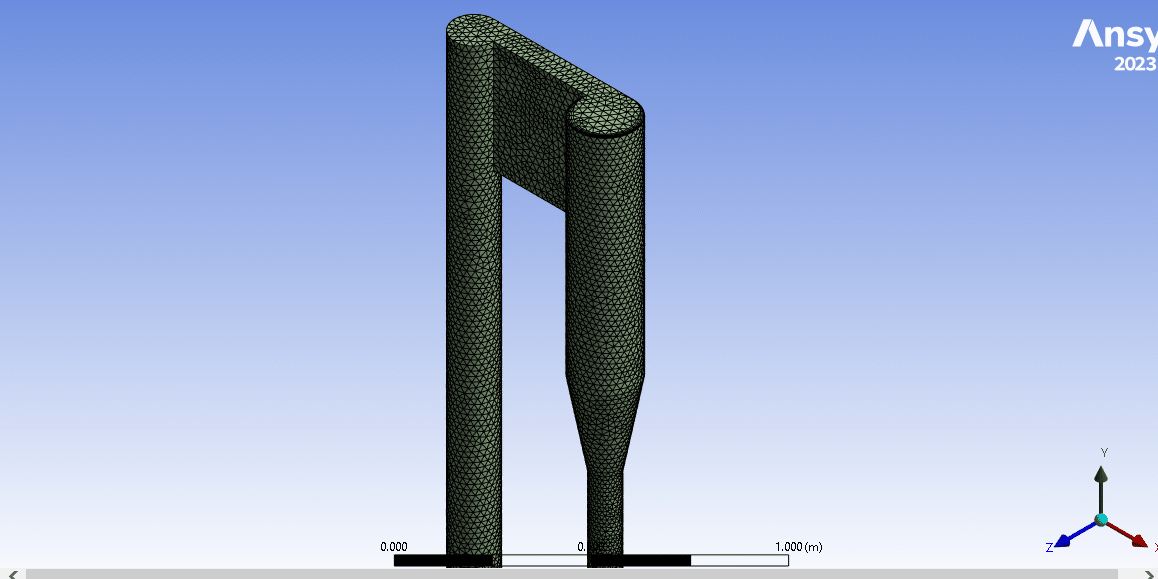

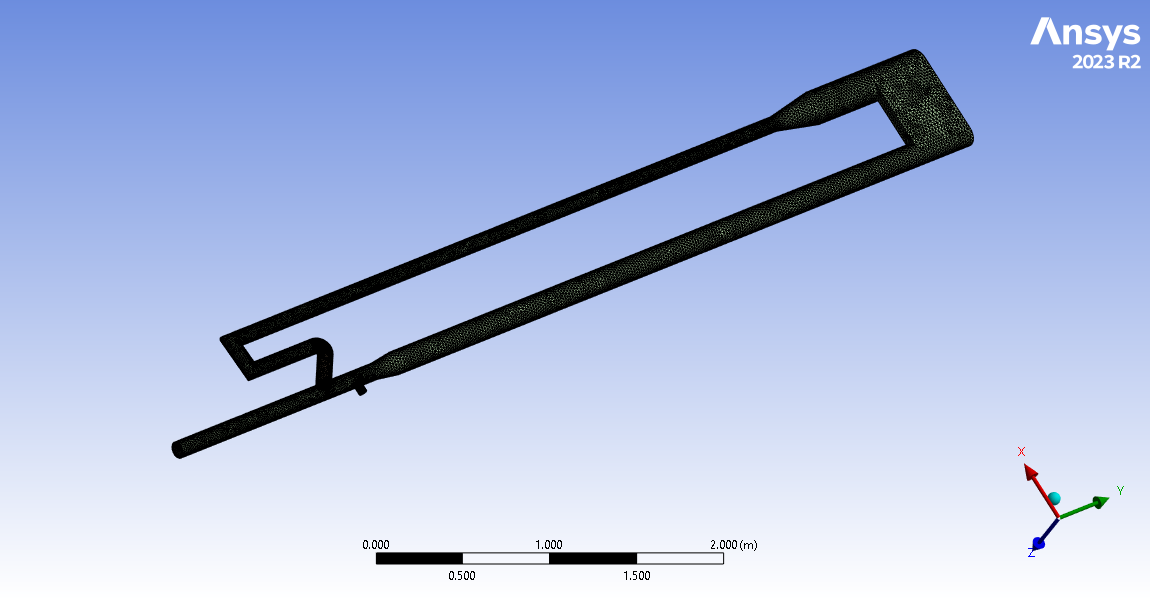

- The 3-D geometry is designed in spaceclaim then meshed in ANSYS Meshing producing 437,472 unstructured cells.

- The species transport including volumetric reactions, is taken into account for modeling combustion.

- The DPM model is used to model the particles.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In CFB combustion method, the fuel is mixed with a large quantity of bed material, forming a fluid-like state (fluidized). The fuel will be combusted in this fluidized state. The advantage of the CFB technology is that it allows for a more efficient and cleaner combustion of coal, compared to traditional methods. It can burn a wide variety of solid fuels, reduce harmful emissions, and it is more flexible in operation. In this project, we aim to simulate a Circulating Fluidized Bed(CFB) Boiler using ANSYS Fluent software and then extract Nox emission from the results after a specific time. Also, the coal specifications and boundary conditions are given by the client.

Methodology

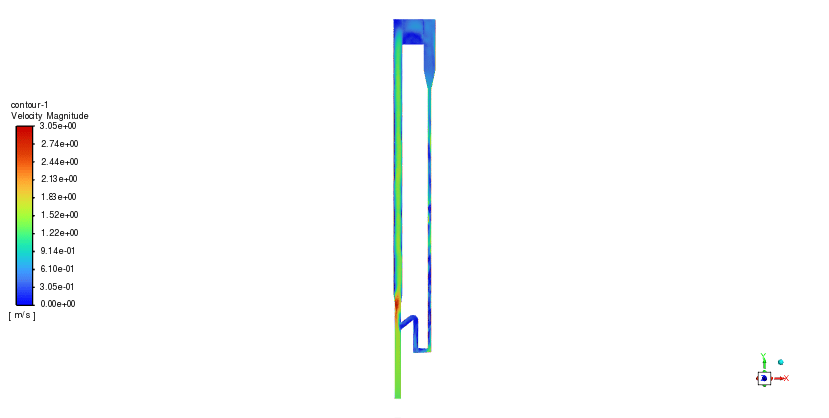

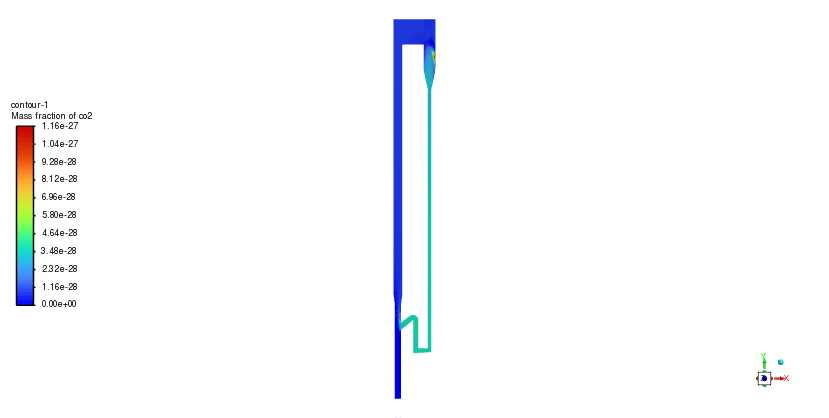

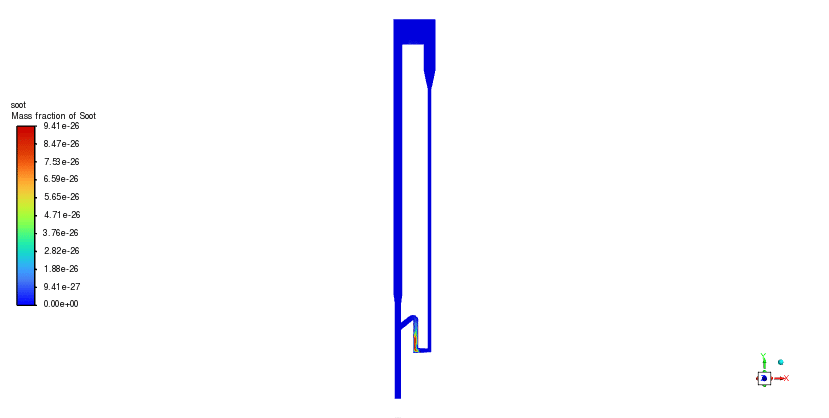

In this simulation the 3-D geometry is designed in spaceclaim then meshed in ANSYS Meshing producing 437,472 unstructured cells. The particles are modeled by using DPM module. Also, the species transport along with volumetric reaction is used to consider combustion. The Nox is also included.

Results

The simulation begins with the injection of Bituminous coal from inlet 2 (fuel feed port). As stated in the confirmation file, the particle`s diameter varies between 0.355 and 0.4mm. It should be noted that the coal is modeled using Discrete phase model (DPM) and after devolatilization, it turns to species. Furthermore, due to the transient nature of the problem, Although the continuous phase was solved in steady-state time mode, the discrete phase was calculated and tracked in unsteady form. After a specific time of injection, the reactions take place based on the governing relations between chemical reactants and products. Next, the simulation continued until it reached a steady state condition. In this state, the reaction rate reaches zero. Also, the coal particle mass in the domain remains constant, which is testimony of steady state condition after 100% of coal combustion. At this time, the Nox mass fraction in the computational domain shows a value between 0.02 and 0.05. It should be added that this is achieved when 0.12kg coal particles are injected. Thus, the mass fraction of Nox could change regarding different injection rates. The typical mass fraction of Nitrogen Oxides (NOx) in a Circulating Fluidized Bed (CFB) boiler can vary depending on several factors, such as the type of fuel used, boiler design, operating conditions, and emission control technologies implemented. However, generally, the mass fraction of NOx in the flue gas of CFB boilers is relatively low compared to other types of boilers due to the lower combustion temperatures used in CFB boilers, which reduce thermal NOx formation.

Related products

-

Bluff-Body Mild Burner CFD Simulation

$200.00$100.00 Student Discount -

Reviews

There are no reviews yet.