Clean Water CFD Simulation Training Package, 7 Learning Products

$499.00 $249.50 Student Discount

In this CFD simulation training package, we have studied various methods for different Clean Water devices. There are 7 CFD projects including HDH, water distiller, solar still, RO, AGMD, and etc.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

This training package includes 7 Clean Water CFD simulation projects using ANSYS Fluent software. MR-CFD suggests this package to those interested in the clean water engineering field. This package introduces you to various clean water systems’ performance principles and how to numerically simulate them. This package presents 7 different clean water systems.

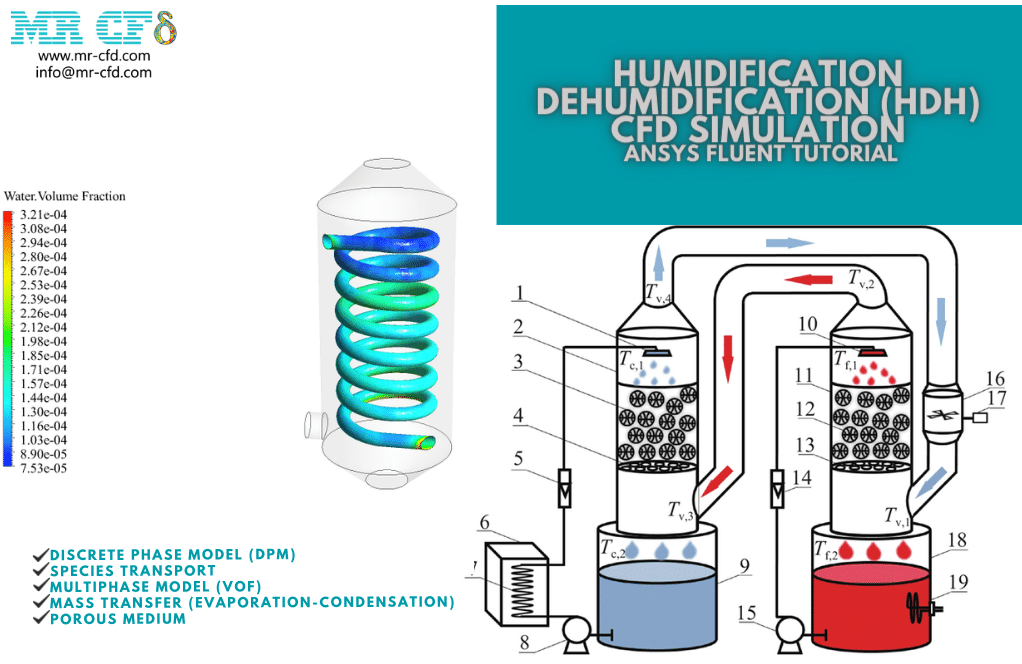

Humidifier-DeHumidifier (HDH)

Water desalination is classified into two general methods, Thermal and Membrane. One of the Thermal methods is humidification and dehumidification systems. Project No. 1 is related to the Humidifier-DeHumidifier (HDH) system. This system consists of two compartments. One of the chambers sprays water on the drying air (humidifier’s system). The other chamber captures the moisture of the wet air due to contact with the cooling pipes (dehumidifier’s system).

So this project consists of two parts. For the humidifier’s system, the DPM Model defines the discrete spraying of water droplets, and the Species Model defines dry air and moist vapor. The VOF Multi-Phase Model defines the vapor and water phases for the dehumidifier system.

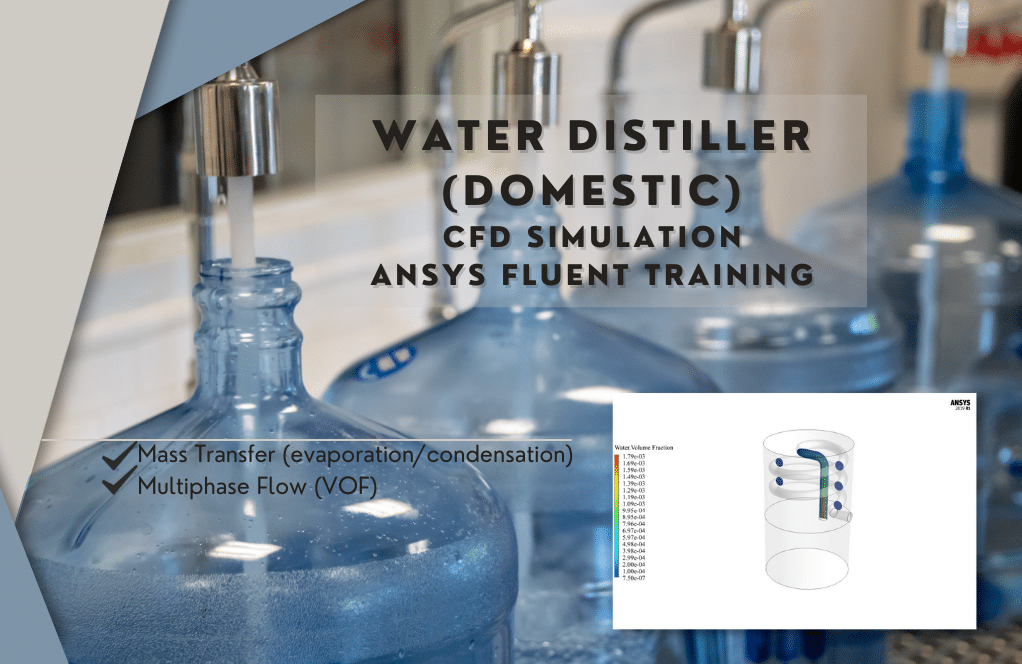

Water Distiller (Domestic Clean Water System)

We design some desalination devices on a small scale and have domestic applications. One of these systems is a water distiller. Project No. 2 simulates a home Water Distiller. The desalination process in this model consists of two stages.

First, impure water evaporates by receiving heat, and then the resulting pure steam condenses due to contact with cold pipes. This project uses the VOF Multi-Phase Model to define water and vapor. Also, we define a mass transfer between water and vapor as evaporation and condensation processes.

Project No. 3 has also presented another small-scale thermal model. This model consists of diagonal plates. First, the water is heated and evaporated by the bottom of the chamber, and then the steam is cooled and condensed by the diagonal cold plate. Therefore, we use the Multiphase VOF Model for this project. A UDF code defines the phase change rate between water and vapor.

Solar Still (Clean Water)

The disadvantage of thermal systems is that they require energy consumption and reduce efficiency. So, using renewable energy such as solar energy can solve this problem. Project No. 4 deals with the simulation of a simple Solar Still.

Inside it, there is water up to a certain level. This solar still consists of sloping glass roofs—the heat of solar radiation transfers to the surface of the water through the glass walls. Water evaporates from the surface to condense after hitting the sloping walls.

Therefore, we use the Multiphase VOF model to define the water and vapor phases. Then, we use a UDF code to define surface evaporation.

Project No. 5 also simulated a solar still with a similar performance mechanism. Also, this solar still has a similar building. However, we use a different method to model it. Instead of defining a multiphase model, we use the Species Transport Model to define a mixture of water and steam.

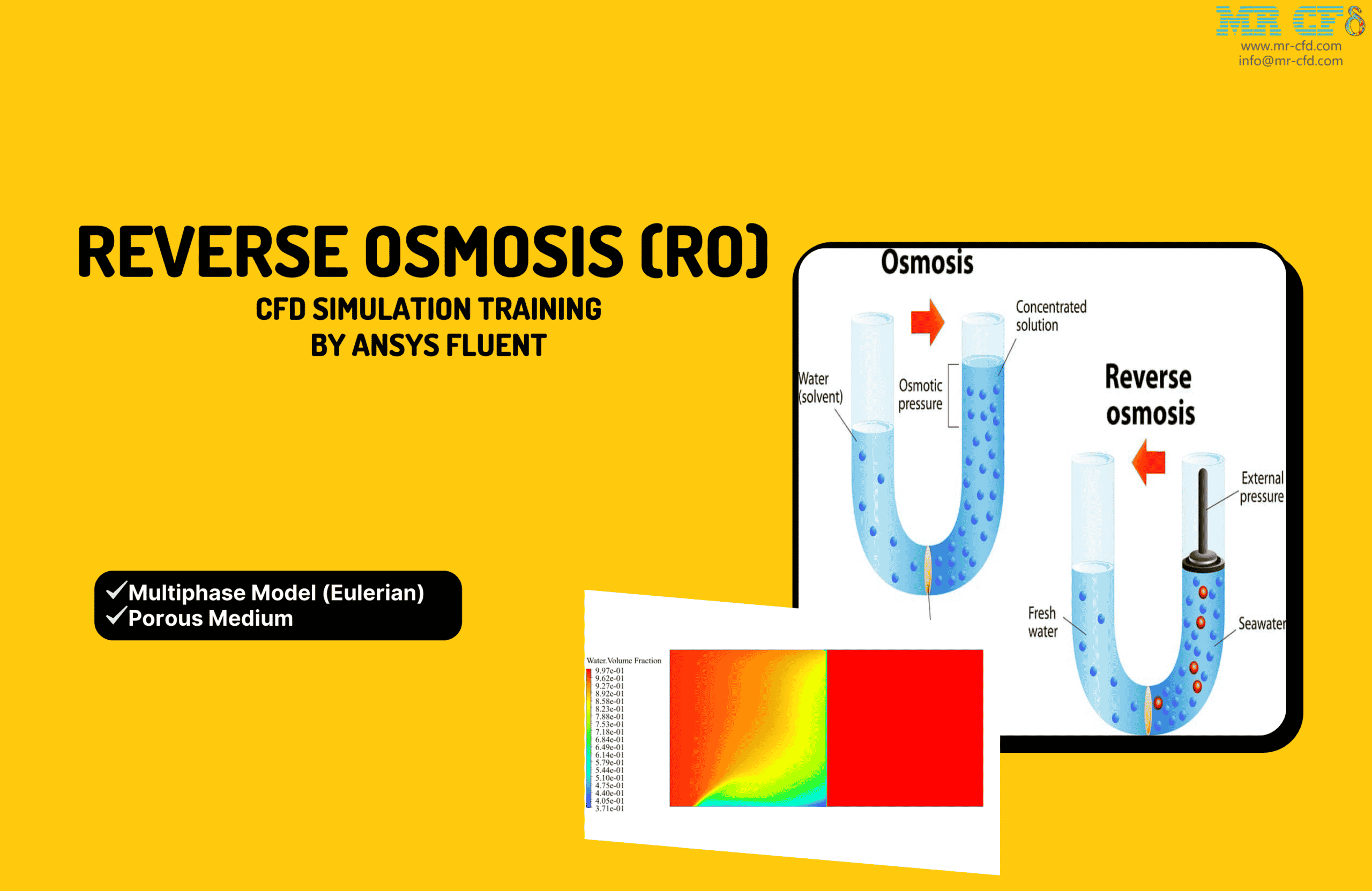

Reverse Osmosis (RO)

Another of the two general methods of water desalination is the Membrane method. The main advantage of this method is to reduce energy consumption. The Reverse Osmosis (RO) method is the most well-known and popular. The reverse osmosis method works against the osmosis pressure approach.

According to the phenomenon of osmosis, fluid always tends to move from lower to higher concentrations. So a pressure difference is created between the two sides, equivalent to osmotic pressure. The mechanism of the reverse osmosis desalination system is opposite to this natural fluid behavior. A filter is placed in the path of the fluid to separate the impurities from the pure fluid after passing through it.

Project No. 6 has simulated a Reverse Osmosis system. We carry out this project in two stages in an unsteady state. First, we investigate the osmosis phenomenon, and then simulate the reverse osmosis desalination system. We use a Porous Medium to define the membrane of the system.

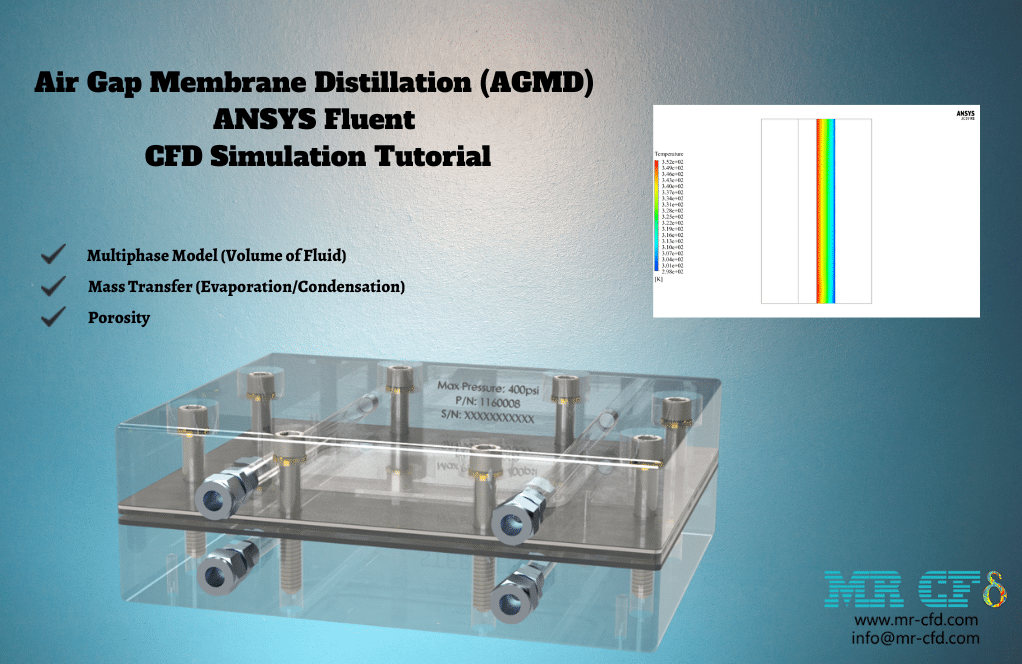

Air Gap Membrane Distillation (AGMD Water Desalination)

Some methods are obtained from the combination of thermal and membrane methods. The Membrane Distillation method is an example of these methods. This method is performed in four different modes. One of them is the Air Gap Membrane Distillation method.

Project No. 7 is related to the AGMD system. Within this system, an air gap is placed between the surface of the cold flow and the membrane connected to the hot flow. This air gap is a special space for condensation to occur. In this space, the steam condenses to produce fresh water.

Emilio Sporer –

I’ve always been curious about small-scale water distillation systems for domestic use. Does Project No. 2 offer insights into how effective these systems are in terms of energy usage and the quality of water produced?

MR CFD Support –

Project No. 2 delves into the simulation of a domestic water distiller, offering comprehensive insights into its efficiency. It addresses energy consumption through the evaporation and condensation processes and evaluates the quality of water produced by simulating the distillation mechanism. The use of VOF Multi-Phase Model assists in accurately depicting these stages, ensuring a realistic representation of the system’s performance.

Mrs. Dina Gibson Sr. –

After reviewing all projects, the whole Clean Water CFD Simulation Training Package provided clear, in-depth knowledge on diverse clean water systems and CFD methodologies to model them using ANSYS Fluent. Especially beneficial were the UDF code explanations which enhanced my understanding of phase change simulations. Kudos to MR-CFD for truly comprehensive and practical CFD learning materials!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Clean Water CFD Simulation Training Package met your learning needs and helped deepen your understanding of ANSYS Fluent simulations. Your recognition of the UDF codes and phase change models is very much appreciated. We strive to provide comprehensive and practical resources for our learners and are glad you find them beneficial. If you need further assistance or have any more questions, don’t hesitate to reach out.

Tamara Mann –

This Clean Water CFD simulation training package is incredibly comprehensive. I learned a lot about various clean water systems and their numerical simulation.

MR CFD Support –

Thank you for your positive feedback on the Clean Water CFD Simulation Training Package. We’re glad that you found the package informative and comprehensive. If you ever need further assistance or have more interest in CFD applications, please don’t hesitate to reach out!

Chet Hayes –

Your training on the Fish Cage Floating on Seawater CFD Simulation by FSI Method via ANSYS Fluent was a game-changer for me! As an engineer looking to specialize in the developments of aquaculture systems, the in-depth explanation of the FSI method combined with hands on guidance for setting up and interpreting the results was invaluable. The complexity of the dynamic mesh and its handling via the software could have been intimidating, but the step-by-step approach made it feel doable and exciting. I now feel much more confident in my simulations. Great job MR CFD Company!

MR CFD Support –

We’re thrilled to hear that the Fish Cage Floating on Seawater CFD Simulation training was so impactful for you! Ensuring engineers like yourself feel confident and have a hands-on understanding of such complex simulations is exactly what we aim for. Thank you for acknowledging the effort we put into making our learning products comprehensive and user-friendly. Your feedback is much appreciated, and we’re excited for the innovations you’ll bring to the aquaculture industry with your new skills!

Dr. Victoria Zemlak –

I am thrilled with this comprehensive package! It offers simulations spanning thermal, membrane, and solar-powered clean water systems—what a holistic approach to understanding desalination technologies.

MR CFD Support –

Thank you so much for the positive feedback! We’re delighted to hear that you found our clean water CFD simulation training package comprehensive and educational. It’s our goal to offer a variety of simulations to cover various technologies comprehensively. We’re glad you appreciate the holistic approach.

Dr. Ned Swaniawski DDS –

Does this package provide both theoretical background and practical application guidance for each type of clean water system CFD simulation?

MR CFD Support –

Yes, this package is comprehensive, offering users both the essential theoretical background and step-by-step practical application methods for conducting CFD simulations in various clean water systems using ANSYS Fluent.

Dr. Lelia Beier –

I’ve learned a lot about different clean water systems from this training package! Every project was detailed and offered in-depth insights into the simulation process.

MR CFD Support –

We’re glad to hear that you found our training package insightful! It’s rewarding to know that our work aids in your understanding of clean water systems. If you have any further questions or need assistance in the future, do not hesitate to get in touch. Thank you for choosing our products.