Coal Gasification in Bubbling Fluidized Bed (BFB) Gasifier CFD Simulation

$120.00 $60.00 Student Discount

- In this project, we are simulating the bubbling fluidized bed (BFB), a type of fluidized bed reactor where solid particles are suspended and agitated by the upward flow of gas

- The design and operation of BFBs allow for better control of temperature and reaction conditions, leading to improved efficiency and product quality in industrial processes

- The 2D geometry of the BFB is designed using Design Modeler software. Then, it is meshed in ANSYS Meshing. In total 26800 cells are generated.

- To model BFB, two Eulerian phases are defined by the Eulerian multiphase model.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Project Description

A bubbling fluidized bed (BFB) is a type of fluidized bed reactor where solid particles are suspended and agitated by the upward flow of gas, creating a dynamic and homogeneous mixture. In this system, the gas velocity is sufficient to lift the solid particles, resulting in a bed that exhibits fluid-like behavior, characterized by the formation of bubbles that rise through the bed. This bubbling action enhances heat and mass transfer, making bubbling fluidized beds particularly effective for various applications, including chemical reactions, combustion processes, and biomass conversion. The design and operation of BFBs allow for better control of temperature and reaction conditions, leading to improved efficiency and product quality in industrial processes. In this project, we are simulating the bubbling fluidized bed.

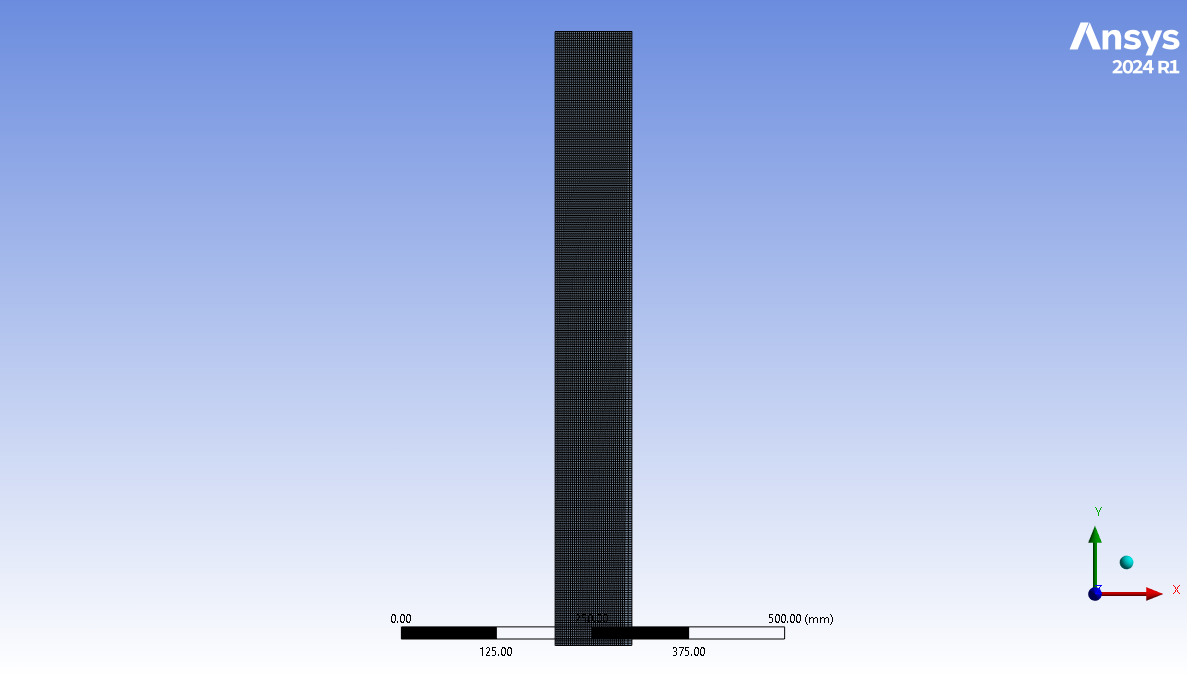

The 2D geometry of the BFB is designed using Design Modeler software. Then, it is meshed in ANSYS Meshing. In total 26800 cells are generated.

Methodology

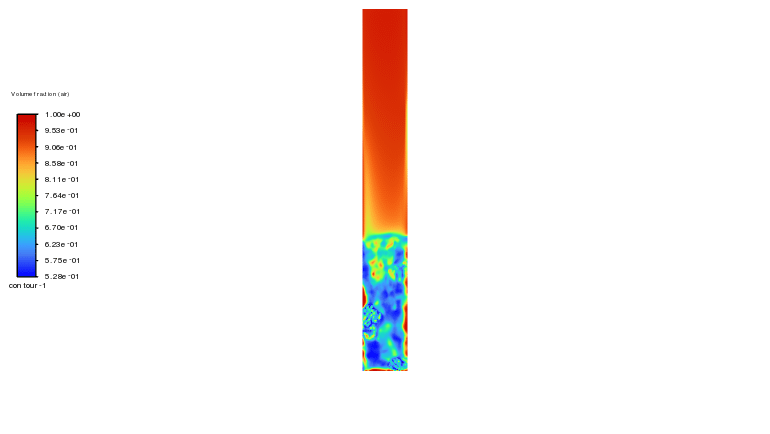

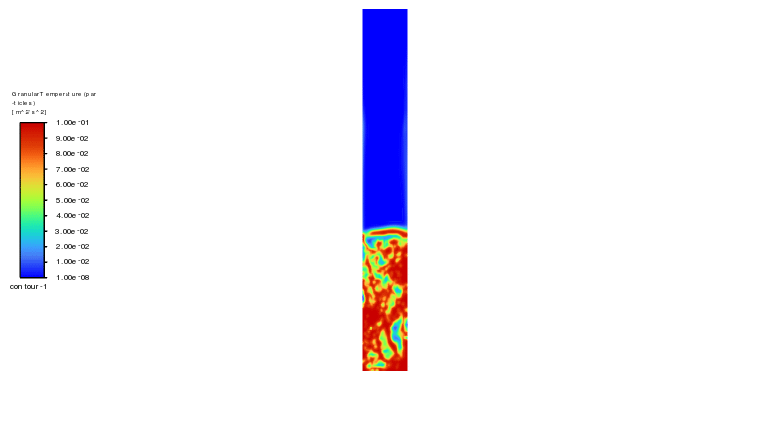

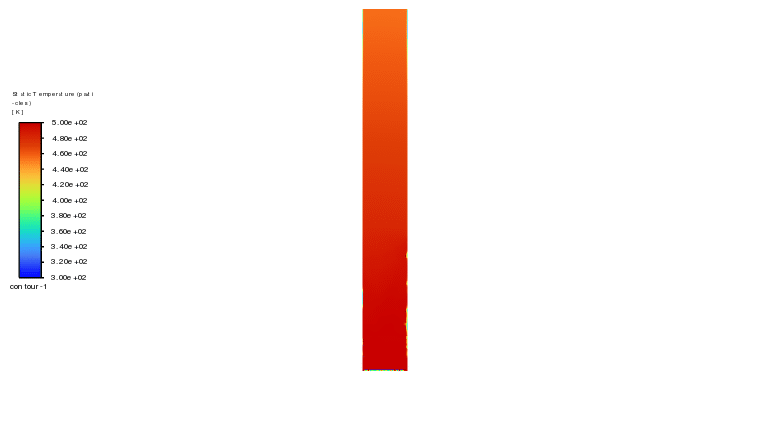

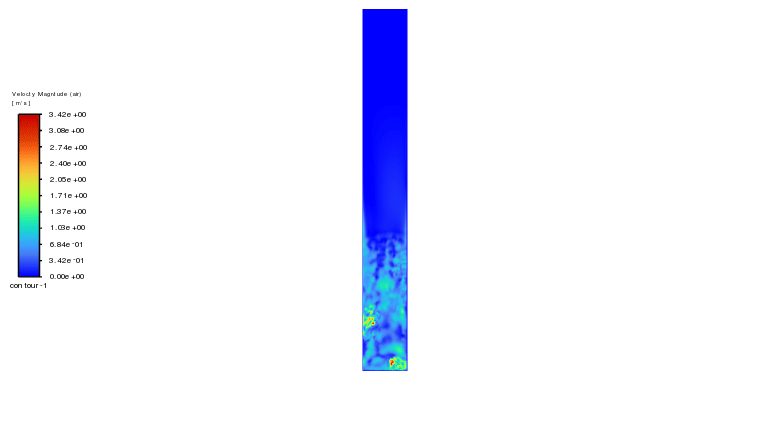

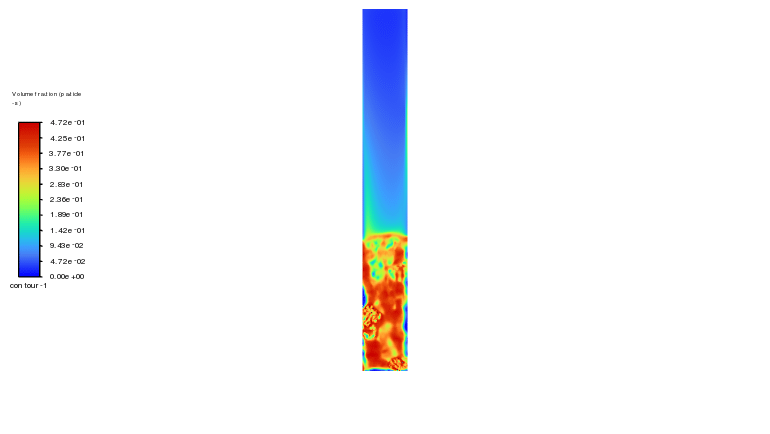

In this research, there are two fluids. One is the air that is injecting from the bottom, and the other is the hot particles that are settled. To model these phases, two Eulerian phases are defined by the Eulerian multiphase model. The secondary phase is granular. Air is injecting from thin inlets on the bottom wall of BFB at 0.4m/s. It has 300K, while the particles are 500 K. The other walls are isolated.

Results

The simulation of the bubbling fluidized bed (BFB) reveals distinct patterns in velocity and temperature distribution within the reactor. The velocity contours indicate a dynamic flow regime, with higher velocities observed at the bottom where gas injection occurs, creating a well-mixed region. This suggests effective fluidization of particles, as evidenced by the turbulent motion and formation of bubbles that facilitate enhanced mixing and interaction between phases. The velocity decreases as the height increases, indicating a transition from a dense bubbling zone to a more dispersed phase. The temperature contours highlight the thermal behavior within the bed. The lower region exhibits higher temperatures due to increased particle-gas contact and heat transfer, which is essential for processes such as combustion or chemical reactions. As the gas ascends, the temperature gradient becomes more uniform, suggesting efficient energy distribution across the bed. These results underscore the effectiveness of BFBs in achieving homogeneous mixing and temperature profiles, crucial for optimizing reaction conditions and improving process efficiency.

Reviews

There are no reviews yet.