Combustion Chamber (Transient) ANSYS Fluent CFD Simulation Tutorial

$140.00 $70.00 Student Discount

- In this project, a combustion chamber is simulated by ANSYS Fluent software applying a Transient and Pressure-based solver, considering the gravity effect.

- The geometry of the present model is 3-D, and Design Modeler software designs it.

- ANSYS Meshing software performs the meshing of the current model. The element number is equal to 694928.

- The Species Transport Model is activated to model the combustion.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Combustion Chamber (Transient) Description

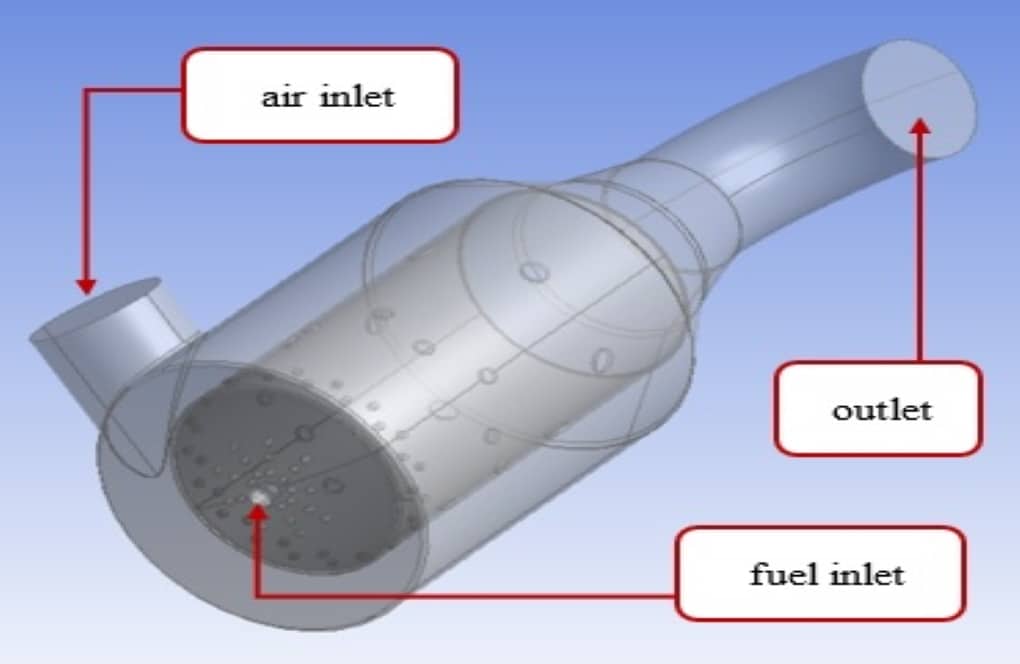

In this project, we simulate a combustion chamber by ANSYS Fluent software applying a Transient and Pressure-based solver, considering the gravity effect. Inside the combustion chamber are three main parts: the air inlet pipe, the burner section, and the outlet pipe.

Inside the chamber is a thin wall with several cavities of varying dimensions. The small primary holes for cooling the chamber wall by layering flow, and the next big ones are to keep the flame in the middle of the chamber. The geometry of the present model is 3-D, and Design Modeler software designs it.

ANSYS Meshing software performs the meshing of the current model. The mesh type is unstructured. We use a triangular grid, and the element number is 694928.

Methodology

We simulate the combustion chamber by applying a Transient and Pressure-based solver, considering the gravity effect. We use the Standard Wall Function and K-epsilon RNG model for the turbulence equation since the flow inside the chamber combustion is relatively complex.

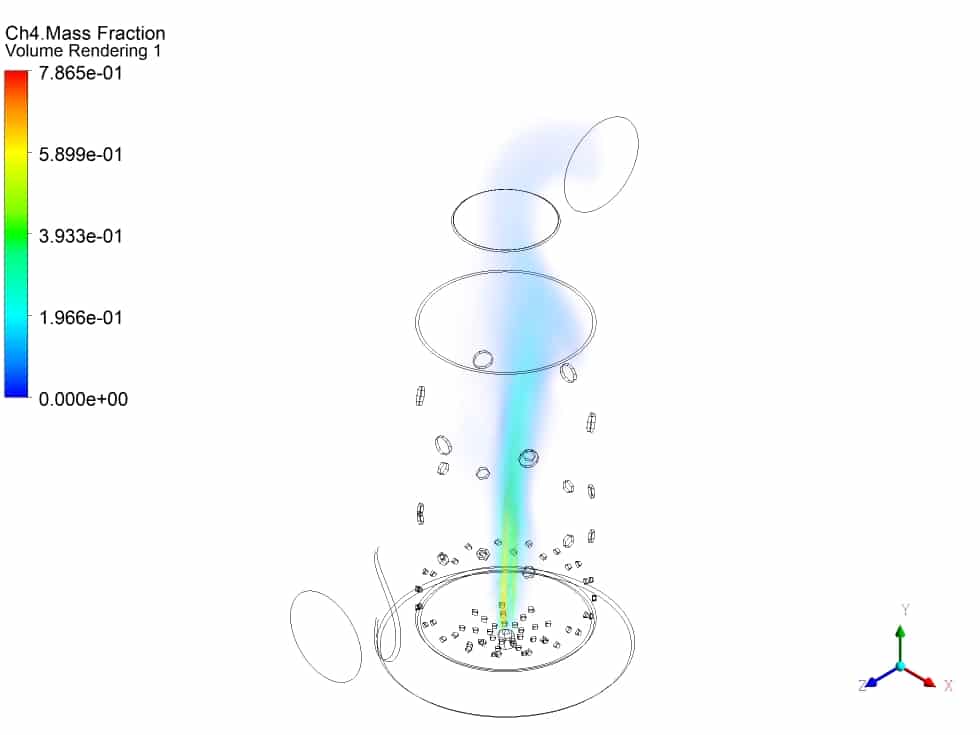

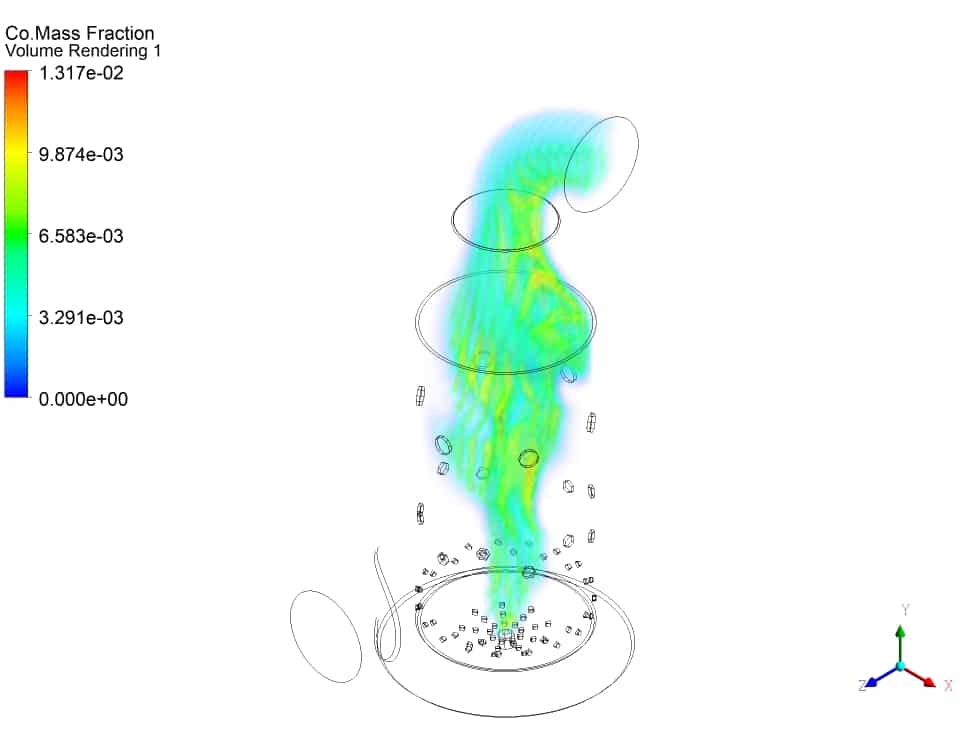

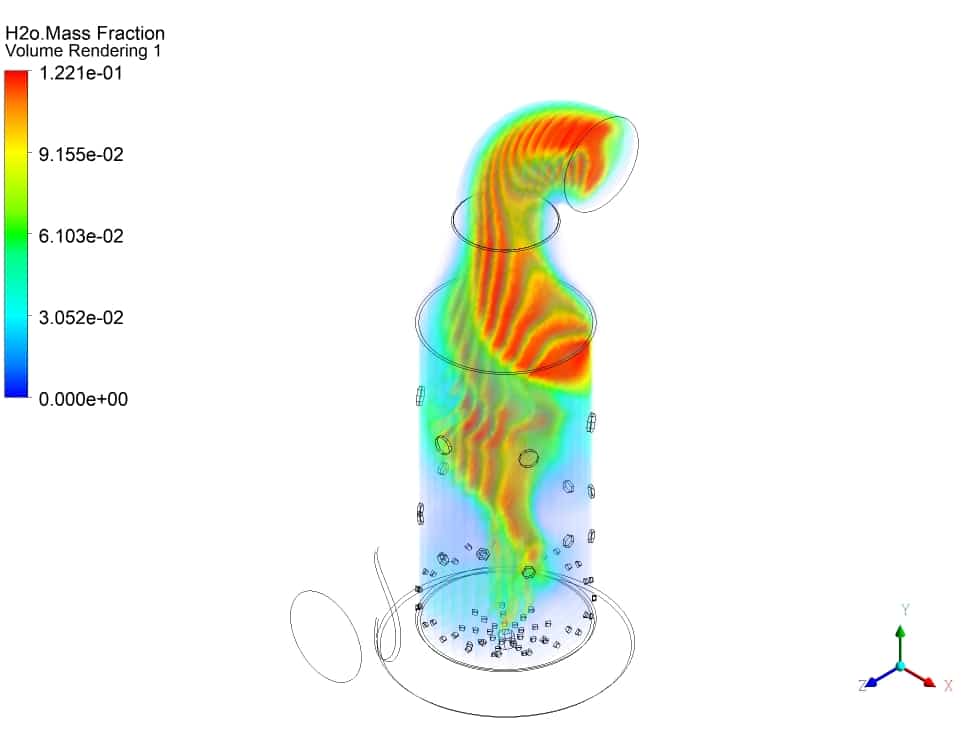

We apply the Species Transport Model to model the combustion. Mass flow rates of the air and the fuel (CH4) equal 0.02 kg.s-1 and 0.0006 m.s-1, respectively, with a temperature of 300k. Also, the chamber’s outer wall is adiabatic. in this case, there are two steps of methane-air combustion, with six species involved in the reaction: methane, Oxygen, nitrogen, water vapor, carbon dioxide, and carbon monoxide.

Mass fractions are .23 and .77 for Oxygen and nitrogen, respectively.

Combustion Chamber (Transient) Conclusion

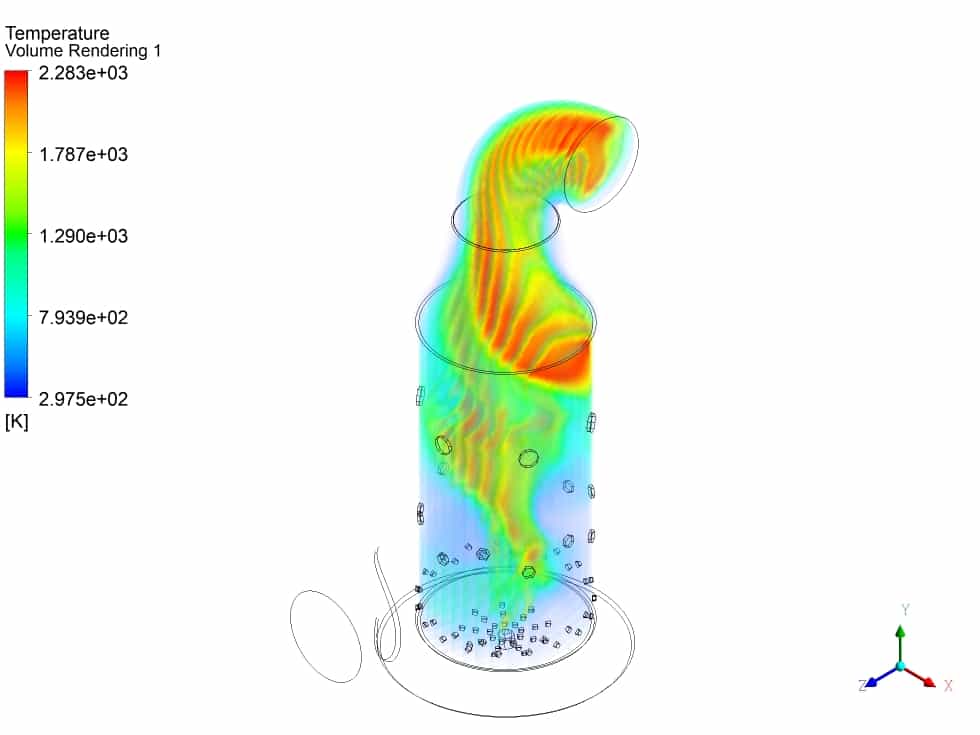

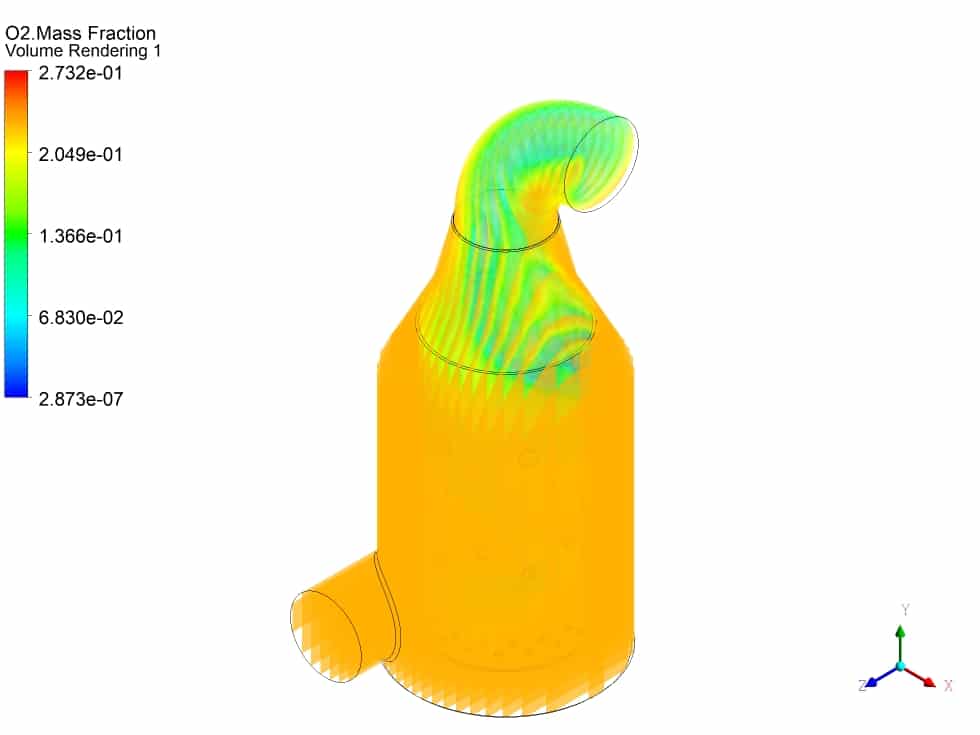

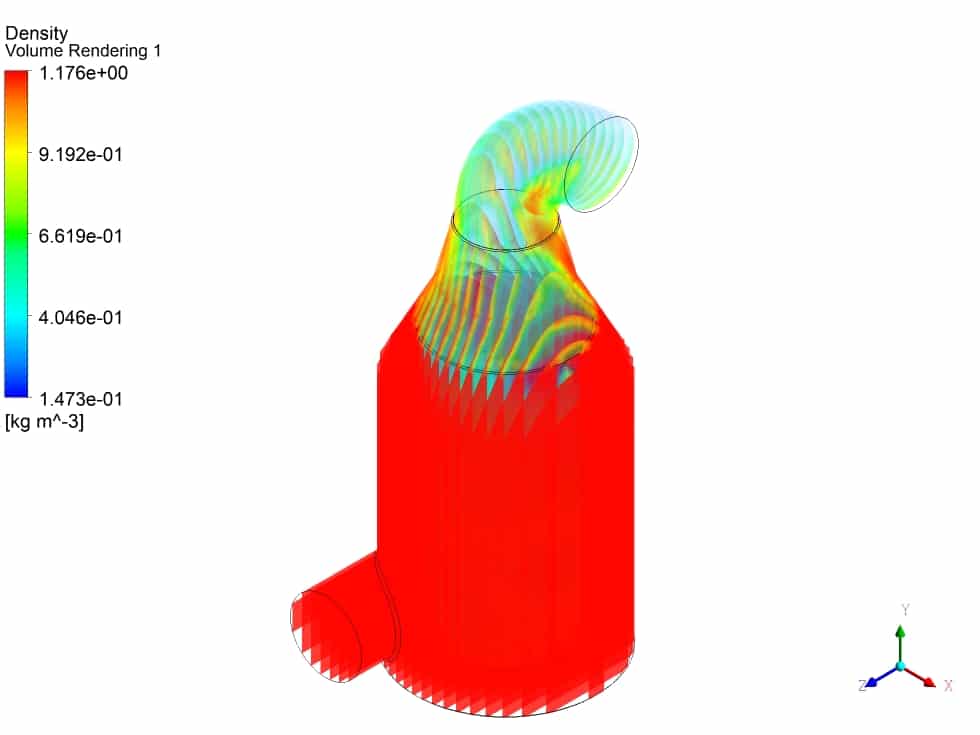

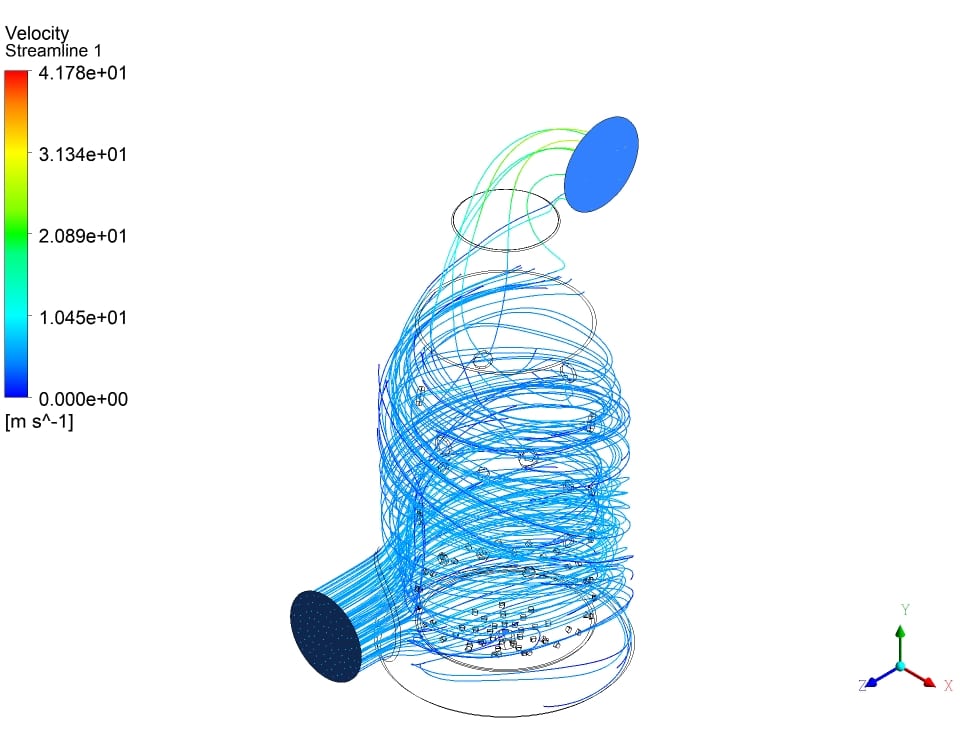

For the current simulation, we present both Volume rendering(3D Contour) and streamlines of velocity, pressure, temperature, density, and mass fraction of components to give much insight into the problem. Briefly, the air and Methane-air enter the domain from the around and bottom surfaces of the geometry, respectively, and make a combustion region.

Temperature and pressure increase and the flow then goes to the outlet at a higher speed, as depicted in the Figures, which is the main challenge of this simulation.

Johathan Dach –

I’m interested in buying this product, but I have a question. Can you customize the simulation parameters according to my specifications? For example, can you change the fuel type, the compression ratio, or the ignition timing?

MR CFD Support –

Yes, we can customize the simulation parameters according to your needs. We have a team of experienced engineers who can modify the simulation setup and run different scenarios for you. You can contact us at info@mr-cfd.com and let us know what kind of simulation you want. We will get back to you with a quote and a delivery time.

Elias Paucek –

I have a suggestion for your product. Can you add some features that allow me to visualize the results in different ways? For example, can you show me the contours of temperature, pressure, velocity, or species mass fraction on different planes or surfaces? Can you also show me some animations or videos of the combustion process?

MR CFD Support –

Thank you for your suggestion. We appreciate your input and we are always looking for ways to improve our product. We already have some features that allow you to visualize the results in different ways using ANSYS Fluent post-processing tools. You can see some examples of these features in our tutorial. However, we are also working on adding more features that will enhance your visualization experience. You can expect to see some updates on our product soon or contact us via info@mr-cfd.com.

Dr. Modesto Gibson PhD –

I really like your product, but I’m not sure if I can afford it. How much does it cost? Do you offer any discounts or payment plans?

MR CFD Support –

Our product is very affordable compared to other CFD solutions in the market. The price of our product depends on the complexity and duration of the simulation, as well as the number of licenses required. You can check our pricing page for more information. We also offer discounts for students, researchers, and bulk orders. You can also pay in installments if you prefer. Please contact us at info@mr-cfd.com and we will be happy to assist you.

Prof. Elbert Kuphal V –

I found the use of different cooling hole sizes for layering flow and flame retention fascinating. Is there a particular reason for the sizes chosen in the design of the cooling holes, or were they determined through trial and error?

MR CFD Support –

The sizes of the cooling holes in the chamber wall were carefully chosen based on theoretical calculations and simulation testing. They are designed to optimize heat transfer and to ensure that the flame is maintained appropriately in the middle of the combustion chamber. The smaller holes are engineered to provide sufficient cooling by layering the flow of combustion gases, while the larger ones are designed to influence the flame position and stability. The exact dimensions are a result of design optimization and computational analysis.

Bell Legros Sr. –

This tutorial sounds very informative. The visual aids provided must make understanding the combustion process much clearer. Great job on compiling such a comprehensive guide.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that our Combustion Chamber tutorial was helpful and provided clear visual insights into the combustion process. We strive to produce informative and practical content to aid in understanding complex CFD simulations. Your feedback is greatly appreciated!

Jada Quigley –

I’m fascinated by the level of detail in the combustion chamber simulation. The use of volume rendering and streamlines must provide a clear image of how these components interact inside the chamber. I commend the thorough approach and beautiful representation of complex combustion processes.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you appreciate the details and visual representations in our Combustion Chamber CFD Simulation Tutorial. It is our aim to provide insightful and rich educational content to assist our customers in understanding complex phenomena. Your enjoyment of the tutorial is very encouraging to our team!

Kathryne Cruickshank –

I was entirely satisfied with your Combustion Chamber tutorial. The explanations were clear, illustrating every step, which made understanding the combustion process much easier. Great job on addressing the application of the Species Transport Model and the transient analysis—it added so much depth.

MR CFD Support –

Thank you for your positive review of our Combustion Chamber tutorial! We are delighted to know that our explanations and the details provided on Species Transport Model application and transient analysis were helpful and enhanced your understanding of the combustion process. We aim to deliver comprehensive tutorials that make complex concepts easier to grasp. If you have any more questions or need further assistance, don’t hesitate to reach out!

Alverta Kuhn –

Just wanted to share how impressed I am with the level of detail and insight provided in this tutorial on simulating a combustion chamber using ANSYS Fluent. Particularly, the explanation of the methodology and the species transport model for tackling the combustion process was top-notch. Watching the streamlines of velocity, pressure, temperature, density, and mass fraction of components really helped me understand the behavior within the chamber. Superb work!

MR CFD Support –

Thank you so much for your kind words and for taking the time to leave such a positive review of the Combustion Chamber (Transient) ANSYS Fluent CFD Simulation Tutorial. We are thrilled to hear that you found the tutorial detailed and insightful. Understanding the behavior of various species within a combustion chamber is critical, and we’re glad our simulations could visually demonstrate these complex processes for you. Your feedback is greatly appreciated, and it encourages us to keep providing high-quality learning materials. Thanks again for your support!

Darby Marks Jr. –

perfect

Ansley Lakin –

It looks like a comprehensive learning tool for combustion chamber simulation. I genuinely appreciated learning about the species transport model for combustion and how the different variables were rendered. I found the included figures particularly helpful for understanding the flow dynamics within the chamber.

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our tutorial on the Combustion Chamber using ANSYS Fluent was helpful to you. Understanding the flow dynamics and the effects of combustion is crucial in such simulations, and we’re glad that our materials, especially the figures, facilitated your learning. If you have any further questions or require more materials to deepen your knowledge, please feel free to reach out!

Enid Reichert –

What model is used for turbulent chemistry interaction?

MR CFD Support –

In this project, it is assumed that the speed of the chemical reaction after mixing fuel and air is infinite and occurs as soon as the chemical reaction is mixed; for this purpose, the eddy dissipation model is used.

Precious Watsica –

Wow, this is amazing! I love how you simulated the combustion process in such a realistic way. How did you do it?

MR CFD Support –

Thank you for your kind words. We used ANSYS Fluent software to model the combustion chamber as a transient problem. We applied the species transport model and the eddy dissipation concept to account for the chemical reactions and the turbulence effects. You can find more details about our simulation setup and results in our tutorial.

Lionel Gleason MD –

I followed the combustion chamber tutorial for an education project, and I’m blown away by the detail level! One quick question: how does the cooling of the chamber wall through those small primary holes affect combustion stability?

MR CFD Support –

The cooling of the chamber wall through the small primary holes helps to maintain a lower temperature on the wall itself, which serves to protect the structural integrity of the chamber over time. This cooling layer of air additionally ensures that the combustion flames are kept centered within the combustion chamber, away from the walls, contributing to the stability and efficiency of the combustion process. By preventing the flame from touching the walls, these holes help avoid hot spots that could lead to material failure or unintended ignition points.

Verona Weissnat –

Is radiation considered in this combustion chamber simulation and how do you account for different materials sensitivity to temperature?

MR CFD Support –

For this simulation, there’s no specific mention of radiation being considered, but it’s commonly included in combustion simulations because it can significantly affect temperature distribution and emissions. Material sensitivity to temperature is typically accounted for by setting temperature-dependent material properties within the simulation software, such as specific heat capacity, thermal conductivity, and emissivity values.

Prof. Pedro Hackett II –

Do you provide specific details about the reaction mechanisms used for the methane-air combustion in the simulation, like the reaction rates and stoichiometric coefficients?

MR CFD Support –

We cover important parameters related to combustion, like mass flow rates and mass fractions; however, for detailed reaction mechanisms, reaction rates, and stoichiometric coefficients, those are often defined in the setup of the simulation depending on the model’s specificity in ANSYS Fluent. If needed, I recommend checking the product’s documentation or contacting MR CFD for in-depth details on the combustion reaction used in the tutorial.

Francesca Wyman –

Great job on the combustion chamber simulation tutorial. It provided a remarkable visualization of complex combustion processes. The attention to detail in explaining the setup and the practical examples helped grasp the concepts efficiently. Keep up the excellent work!

MR CFD Support –

Thank you for your kind feedback! We appreciate the time you’ve taken to compliment our work. It’s wonderful to hear that our Combustion Chamber tutorial was helpful for you. We strive to provide thorough and clear explanations and visualizations to make complex CFD concepts easier to understand. If you have any more questions or need further assistance, please don’t hesitate to ask.

Cordia Ledner –

I’m puzzled about something in the combustion chamber simulation. What exactly do the small primary holes do for cooling? Do they allow for some cooling medium to flow in, or is it just the air doing the cooling?

MR CFD Support –

The small primary holes in the combustion chamber wall serve as passageways for cool air to flow through. This layered airflow acts as a protective blanket over the wall, shielding it from the intense heat generated by the combustion process. This flow of air effectively cools the chamber wall and helps to maintain the structural integrity and temperature of the wall within safe operational limits.

Odie Hartmann –

Can we adjust the mass flow rates to simulate different intensities of combustion within the chamber?

MR CFD Support –

Yes, it is possible to adjust the mass flow rates of air and fuel (CH4) in the simulation to study different combustion intensities within the chamber.

Marlee Hoppe –

The tutorial that taught me to simulate a combustion chamber was very informative. Being able to account for gravity effects and using Species Transport Model advanced my understanding of combustion processes significantly.

MR CFD Support –

Thank you for your review! We’re delighted to hear that our Combustion Chamber ANSYS Fluent CFD Simulation Tutorial was helpful to you. It’s great to know you’ve gained valuable insights into combustion modeling and species transport. If you have any more feedback or need further assistance, don’t hesitate to reach out to us!

Madison Anderson –

I was impressed by the level of detail in the combustion chamber CFD simulation tutorial. Would this tutorial be suitable for beginners or is it intended for more advanced users of ANSYS Fluent?

MR CFD Support –

The combustion chamber CFD simulation tutorial is designed for users with an intermediate to advanced level of understanding of ANSYS Fluent, due to the complexity of processes like combustion modeling and transient analysis. However, beginners with a solid grounding in the basics might find it educational if they are willing to take up the challenge and have support materials or guidance as they learn.

Omari Rohan –

The tutorial sounds really in-depth! The 3D contours and streamlines of velocity and pressure must provide excellent visual insights into the combustion process. How well does it cover the part about setting up combustion reactions?

MR CFD Support –

Thank you for your positive feedback! The tutorial thoroughly covers setting up combustion reactions within the ANSYS Fluent environment. It goes into detail about defining reaction mechanisms for methane-air combustion, explaining steps to input mass fractions and temperatures for fuel and oxidizer, and configuring the Species Transport Model for accurate reaction simulation. Additionally, the tutorial explains how to monitor the reaction progress through simulation to ensure accuracy and convergence.

Mrs. Marjolaine Rohan –

The tutorial was excellent in walking through each step of the process. The visualization of the flame position through volume rendering was particularly helpful. Could you elaborate on how the software handles the reaction rates for the combustion process?

MR CFD Support –

In the tutorial for the combustion chamber simulation using ANSYS Fluent, the software applies the Species Transport Model to tackle the combustion process. Specifically, reaction rates are computed based on predefined reaction mechanisms and their corresponding rate equations, which depend on factors such as temperature, pressure, and reactant concentrations. Adaptive time-stepping might be used to capture the transient nature of the combustion accurately. ANSYS Fluent provides detailed options for setting up the kinetics of the reactions, allowing the accurate prediction of species production, consumption, and the resultant temperature fields within the chamber.

Dell Boyle –

I’m impressed with the capability to simulate combustion in a transient state with ANSYS Fluent. How does the solver ensure accuracy during these transient simulations?

MR CFD Support –

MR CFD’s admin is happy to elaborate! The solver ensures accuracy in transient combustion simulations through refined mesh settings, robust numerical models like the Species Transport Model, and detailed initial conditions for turbulence, fluid flow, and chemical species. Time-step management and convergence criteria are also suitably selected to capture the fast transient phenomena accurately within the combustion chamber.

Mr. Carroll Rodriguez PhD –

This simulation pack was particularly insightful! Will there be advanced tutorials that delve into the optimization of combustion chamber designs?

MR CFD Support –

Thank you for your positive feedback on the Combustion Chamber (Transient) simulation tutorial! Currently, we offer a range of guides and tutorials focused on CFD simulations in various applications. We always consider the interests of our users. We suggest regularly checking our website for updates or subscribing to our newsletter for announcements on any new advanced optimization tutorials for combustion chamber designs.