Combustion Chamber Steady-State CFD Simulation

$140.00 $70.00 Student Discount

- The problem numerically simulates the Combustion Chamber using ANSYS Fluent software.

- We design the 3-D model by the SpaceClaim software.

- We Mesh the model by ANSYS Meshing software, and the element number equals 2626307.

- We use the Species Transport model to define a combustion reaction.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Combustion Chamber Steady-State, Ansys Fluent CFD Simulation Training

In this project, a Combustion Chamber Steady-State CFD Simulation using ANSYS Fluent is carried out. We perform this CFD project and investigate it by CFD analysis.

The current model is designed in three dimensions using the SpaceClaim software. The model is a cylindrical combustion chamber.

Four inlet sections for airflow are radially around the combustion chamber, and four inlet sections for fuel flow are axially at the top of the chamber. One outlet section for combustion reaction products is determined at the bottom of the combustion chamber.

The meshing of this project has been done with ANSYS Meshing software. The element number is 2626307.

Combustion Chamber Methodology

The combustion chamber is one of the most widely used devices in the industry. Therefore, experts are working to improve the performance of the combustion chamber. In this project, a combustion chamber is simulated using Ansys Fluent software. The present combustion chamber has two air inlets.

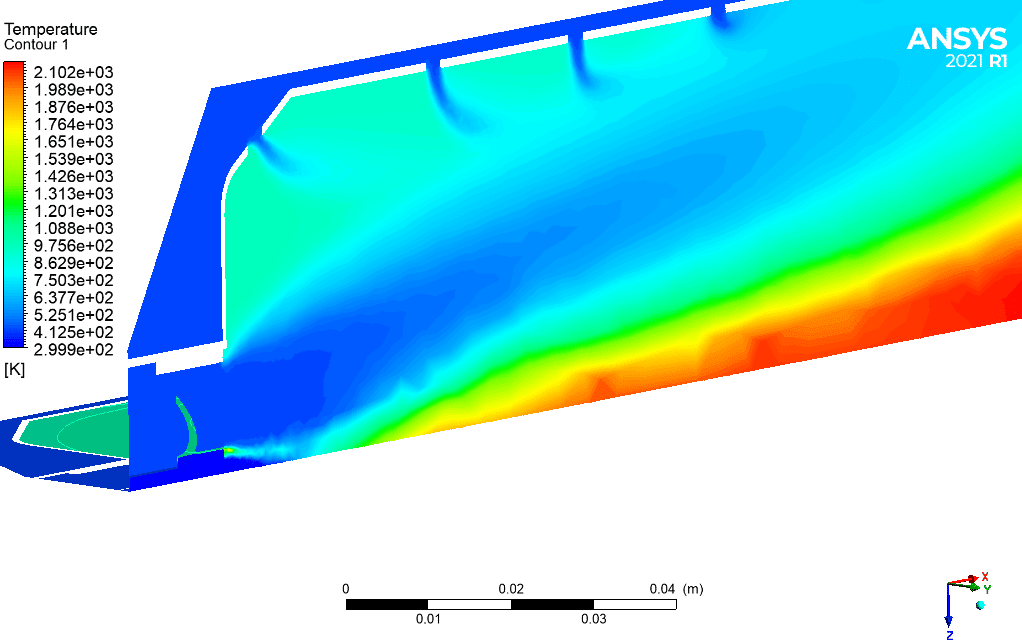

The air of the first inlet hits several blades (to circular the flow) and then enters the chamber; To create a better flame, the air from the second inlet does not enter the combustion chamber at first, instead of entering through the perforations in the combustion chamber. The fuel used in this combustion chamber is methane.

The species transport model has been used to define the chemical reaction between air and methane. This chemical reaction consists of five species, including O2, N2, CH4, CO2, and H2O.

The airflow consists of 0.21 oxygen with a flow rate of 0.005 kg/s and a temperature of 430 K entering the combustion chamber, and the fuel flow enters the combustion chamber with a flow rate of 0.0001kg.s-1 and a temperature of 300 K at the same time.

It is also assumed that the outer wall of the combustion is adiabatic and has a heat flux of 0W/m2. Moreover, the RNG k-epsilon model and energy equation are enabled to solve the turbulent fluid equations and calculate temperature distribution inside the domain.

Combustion Chamber Conclusion

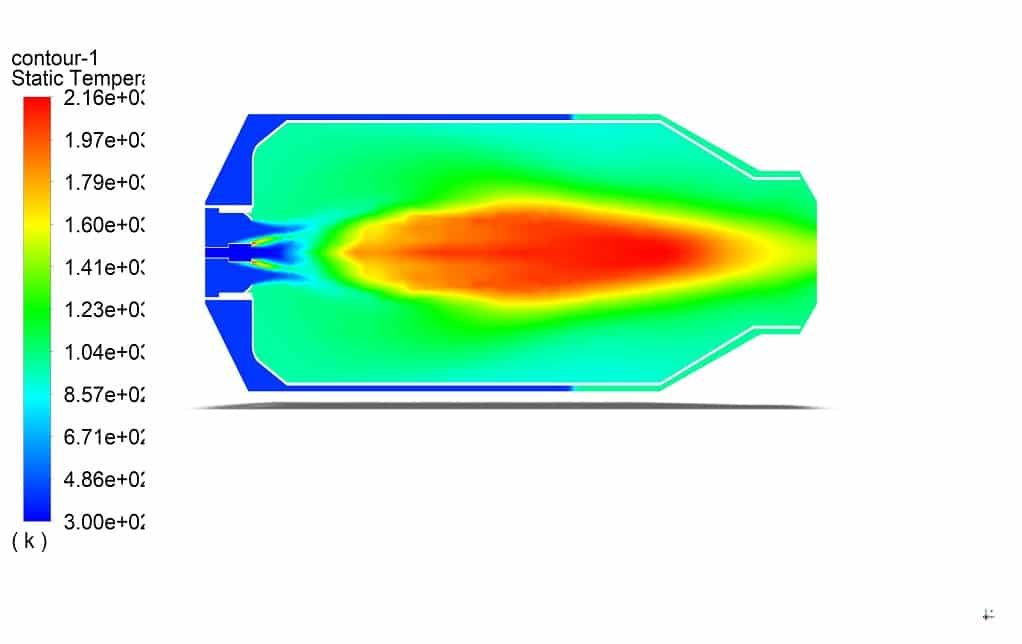

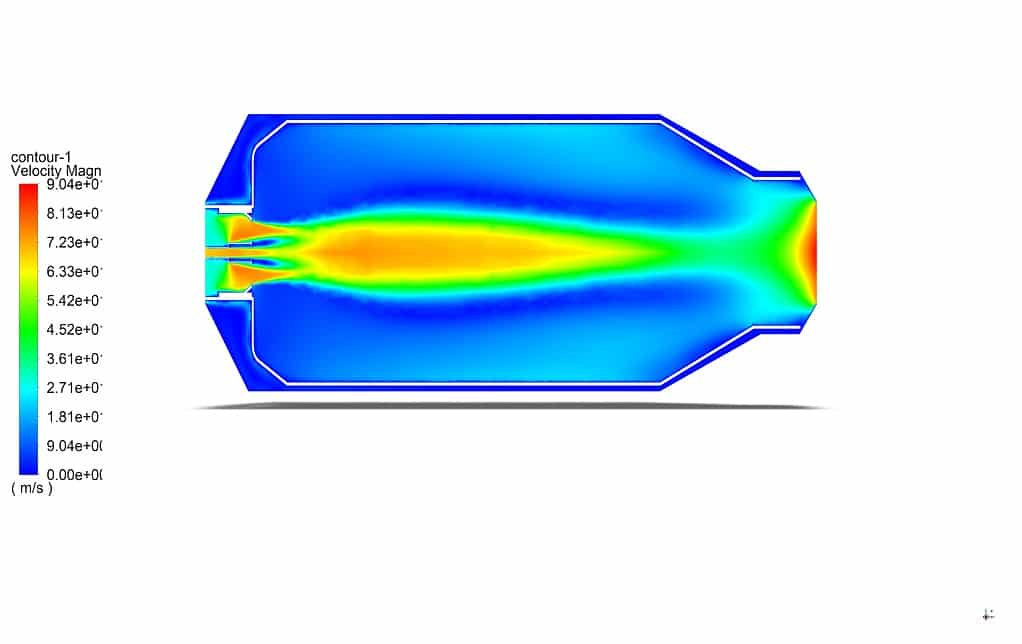

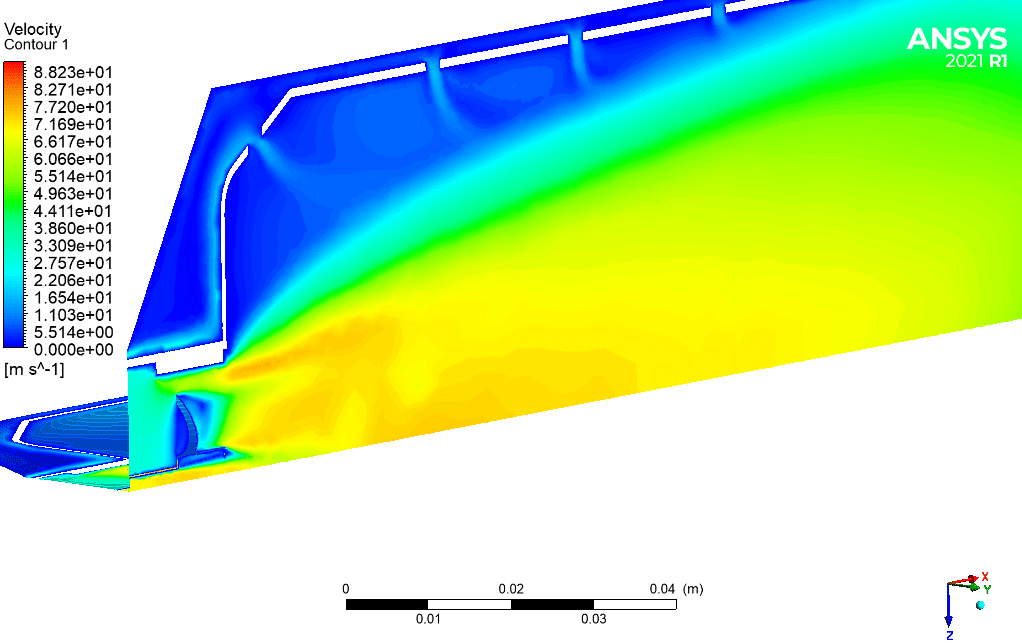

At the end of the solution process, two-dimensional contours related to temperature and velocity are obtained. According to the results, it is observed that good combustion took place in the chamber, and the average temperature of the chamber reached 1006.5k.

Prof. Shakira Schiller –

The training material for the Combustion Chamber Steady-State CFD Simulation by MR CFD is thorough and detail-oriented. The incorporation of the species transport model and the consideration of real gas properties provide an in-depth analysis suitable for both learners and professionals. Thank you for such a comprehensive and practical learning tool.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our Combustion Chamber Steady-State CFD Simulation training material has met your expectations and provided valuable knowledge. Your feedback motivates us to continue delivering high-quality learning experiences. If there’s anything else you wish to learn or any further assistance we can provide, feel free to reach out.

Prof. Ernest Marquardt –

What types of numerical methods are used to ensure stability and convergence in this type of steady-state combustion simulation?

MR CFD Support –

In this steady-state combustion simulation, to ensure stability and convergence, the numerical methods used include the RNG k-epsilon model to handle turbulence, the Species Transport model for chemistry, discretization schemes optimized for the stiffness of reactions, and potentially advanced solution controls such as under-relaxation factors and gradual ramp-up of boundary conditions.

Letha Rippin V –

I was impressed by the simulation setup for efficient combustion in the chamber. Well done!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you’re impressed with the combustion chamber simulation setup. Our team works hard to ensure the highest quality and accuracy in our simulations, and it’s great to see that the effort is appreciated. If you have any more feedback or need further assistance, don’t hesitate to reach out!

Prof. Bruce Morissette –

I am really impressed by the level of detail and professional setup for the Combustion Chamber CFD simulation. The use of species transport model and careful temperature setup reflects a precise scenario. Kudos on ensuring a comprehensive representation.

MR CFD Support –

Thank you for your review! We’re delighted to hear that you appreciate the detail level and setup of our Combustion Chamber CFD simulation. Ensuring our simulations reflect real-world scenarios as closely as possible is crucial for us. If you have any further questions or need more assistance, don’t hesitate to reach out!

Yvonne Jacobs –

This simulation seems to offer impressive and detailed insights. I’m amazed by the level of detail and realism in the temperature and velocity contours. Great job on creating such an extensive model that effectively simulates the complex processes inside a combustion chamber!

MR CFD Support –

Thank you for your positive feedback! It’s great to hear that you appreciate the level of detail put into the Combustion Chamber Steady-State CFD Simulation. Our goal is to provide realistic and comprehensive simulations to assist experts and enthusiasts in better understanding these complex processes. If you have any further questions or need more information, don’t hesitate to ask. We’re always here to help!

Cleveland Stoltenberg –

This training product sounds insightful! The methodology used especially in having air enter through perforations intrigues me. Does the simulation study highlight how that particular approach to airflow improves the combustion efficiency compared to a typical direct-flow setup?

MR CFD Support –

Absolutely, glad you found it intriguing! The simulation indeed showcases that introducing air through perforations in the combustion chamber helps create better mixing between the fuel and the air, which subsequently leads to more efficient combustion. This method also helps to stabilize the flame and reduces the likelihood of creating hot spots, which improves the overall longevity and performance of the combustion chamber.