Compressor CFD Simulation Training Package: 7 Projects by ANSYS Fluent

$299.00 $149.50 Student Discount

- Axial Compressor Projects: NASA 37 Rotor simulation, Multi-Stage Axial design, and 2 Rotors/2 Stators configuration analysis

- Centrifugal Systems: Complete centrifugal compressor modeling from geometry to performance mapping

- Specialized Applications: Innovative Rampressor technology and detailed acoustic analysis techniques

- Advanced Optimization: MOGA optimization with BBD DOE & GA RSM for cascade performance enhancement

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Comprehensive Compressor Simulation Training: From Fundamentals to Advanced Applications

Are you looking to master compressor CFD simulation using ANSYS Fluent? This comprehensive training package offers seven carefully curated projects that take you from basic compressor modeling to advanced optimization techniques. Whether you’re an engineer, researcher, or student, these hands-on projects will equip you with the skills needed to tackle real-world compressor design challenges.

Axial Compressor Simulation Projects

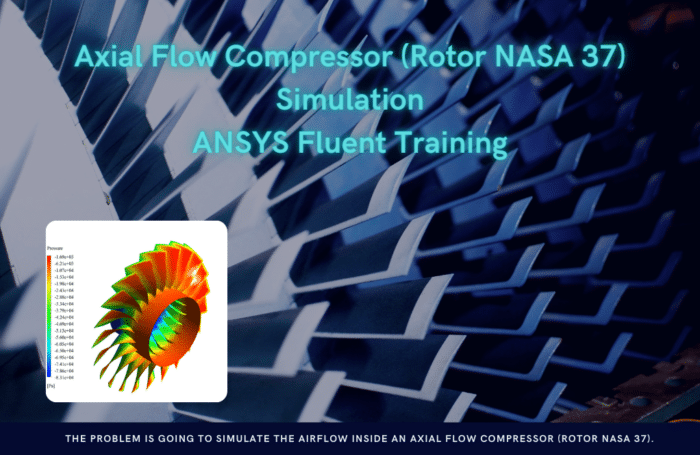

Axial Flow Compressor (Rotor NASA 37) Simulation

Begin your journey with the industry-standard NASA 37 rotor benchmark case. This project introduces fundamental concepts of axial compressor simulation including:

- Setting up proper boundary conditions for rotating machinery

- Implementing turbulence models optimized for compressor flows

- Analyzing performance parameters like pressure ratio and efficiency

- Validating results against experimental data

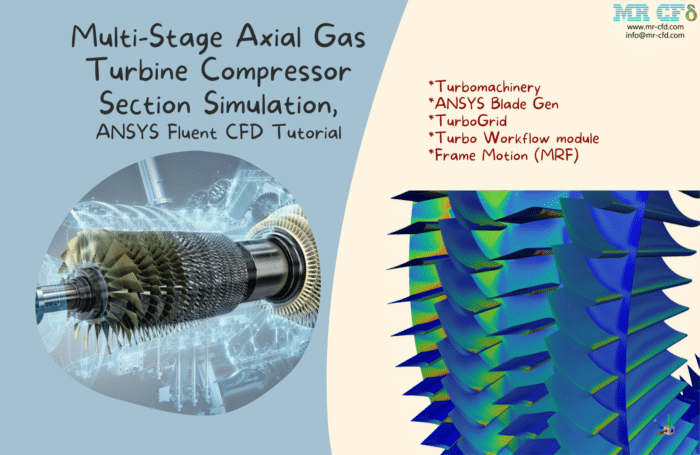

Multi-Stage Axial Compressor CFD Simulation

Take your skills to the next level with this comprehensive multi-stage axial compressor project:

- Learn stage-stacking techniques for complex compressor geometries

- Master interface modeling between rotating and stationary components

- Analyze stage-by-stage performance characteristics

- Investigate flow phenomena including wake interactions and secondary flows

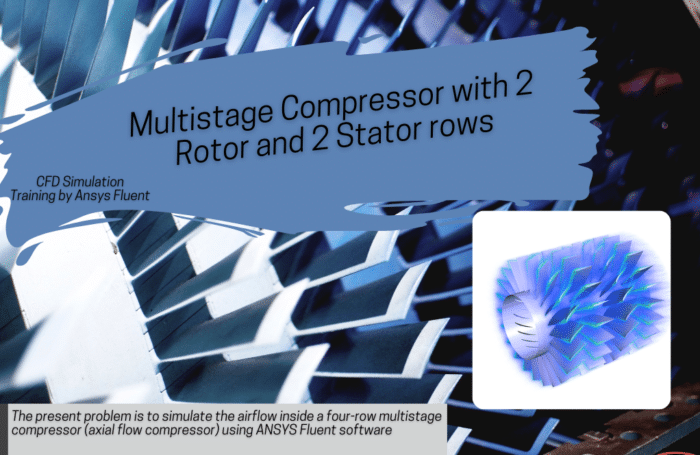

Multistage Compressor with 2 Rotors and 2 Stators Rows

This advanced project focuses on the complex interactions in multistage configurations:

- Set up multi-reference frame models for multiple rotating components

- Analyze interstage flow phenomena and their impact on performance

- Investigate blade row interactions and their effect on overall efficiency

- Optimize blade designs based on simulation results

Centrifugal Compressor Simulation

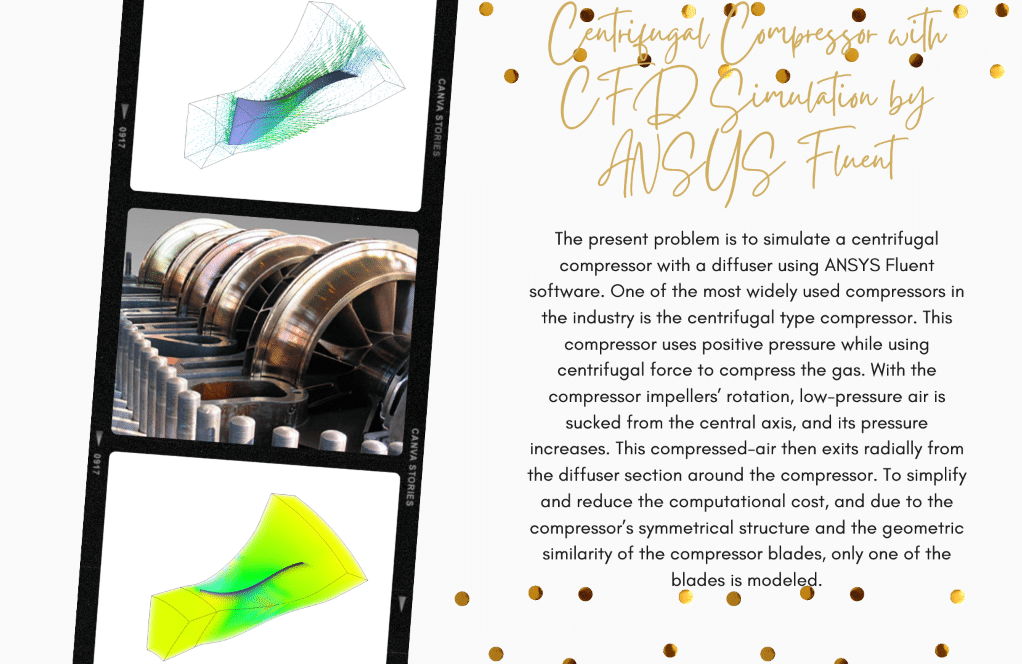

Centrifugal Compressor ANSYS Fluent CFD Simulation

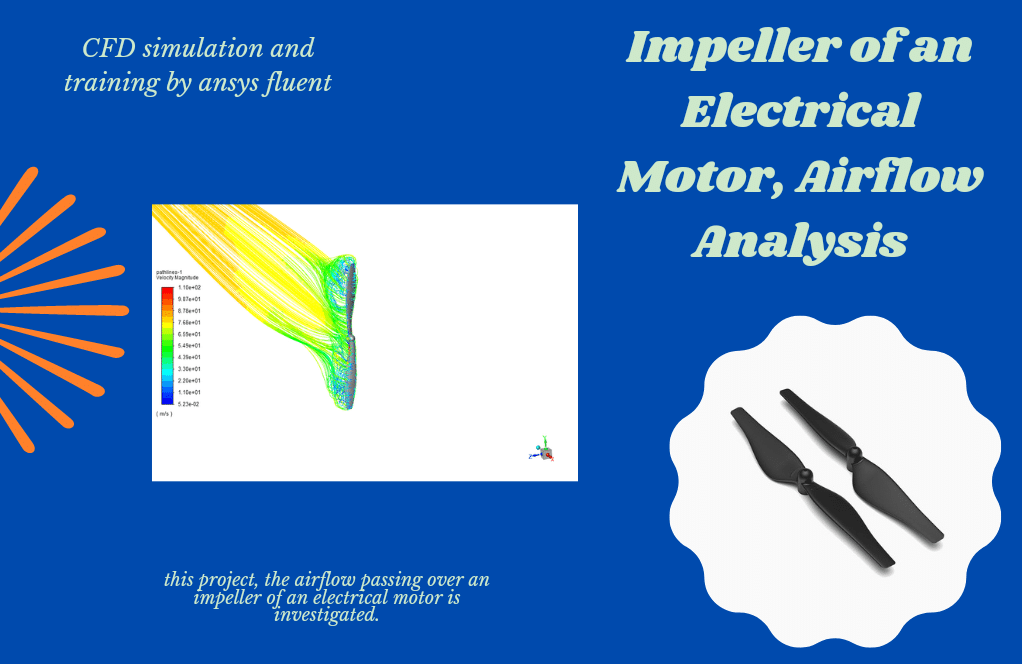

Expand your expertise to radial flow machines with this detailed centrifugal compressor project:

- Model complex 3D impeller geometries and volutes

- Analyze flow patterns including jet-wake structures and secondary flows

- Predict performance maps across various operating conditions

- Identify and mitigate potential design issues like flow separation and recirculation

Specialized Compressor Applications

Rampressor, ANSYS Fluent CFD Simulation Training

Explore cutting-edge compressor technology with this innovative rampressor simulation:

- Model shock wave compression mechanisms in supersonic flows

- Analyze complex geometries with integrated inlet and compression surfaces

- Evaluate performance metrics for this novel compression approach

- Compare advantages against conventional compressor designs

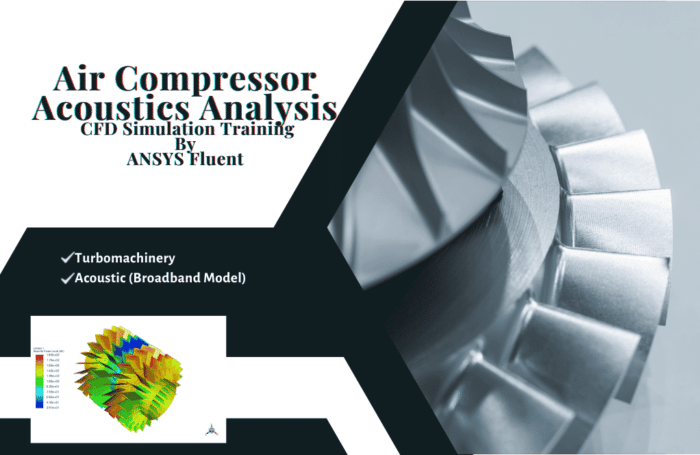

Air Compressor Acoustics Analysis, ANSYS Fluent CFD Simulation Training

Delve into the critical area of compressor noise prediction and mitigation:

- Set up acoustic models using ANSYS Fluent’s aeroacoustic capabilities

- Identify noise sources and propagation patterns

- Implement and evaluate noise reduction strategies

- Perform frequency analysis of acoustic signatures

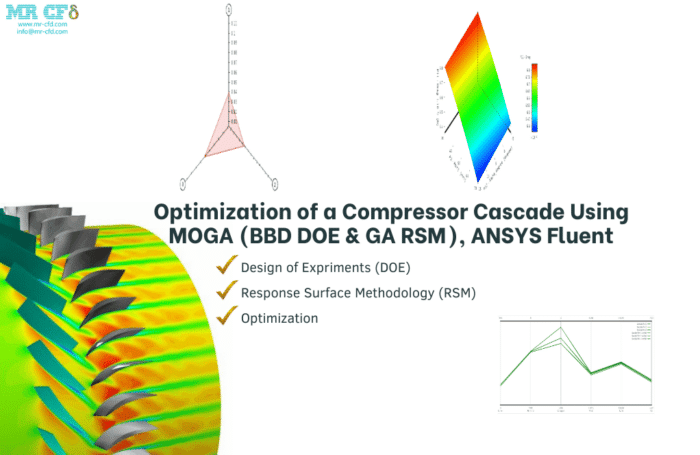

Advanced Optimization Techniques

Optimization of a Compressor Cascade Using MOGA (BBD DOE & GA RSM), ANSYS Fluent

Cap your training with cutting-edge optimization methodologies:

- Implement Design of Experiments (DOE) using Box-Behnken Design

- Develop Response Surface Models (RSM) for efficient optimization

- Apply Multi-Objective Genetic Algorithms (MOGA) to identify optimal designs

- Balance competing objectives like efficiency, pressure ratio, and operating range

What You’ll Learn

This comprehensive package will equip you with:

- Proficiency in setting up complex compressor simulations in ANSYS Fluent

- Deep understanding of flow physics in both axial and centrifugal compressors

- Advanced post-processing and analysis techniques for performance evaluation

- Optimization strategies to enhance compressor designs

- Practical experience applicable to industrial compressor development

Who Should Enroll

- Mechanical and aerospace engineers focused on turbomachinery design

- CFD analysts seeking specialized training in compressor simulation

- Graduate students conducting research in turbomachinery

- Industry professionals looking to enhance their simulation capabilities

Take your compressor design and analysis skills to the next level with this comprehensive training package. Each project includes detailed instructions, ready-to-use simulation files, and expert guidance to ensure your success.

Reviews

There are no reviews yet.