Cyclone by DPM ANSYS Fluent CFD Simulation Training

$120.00 $60.00 Student Discount

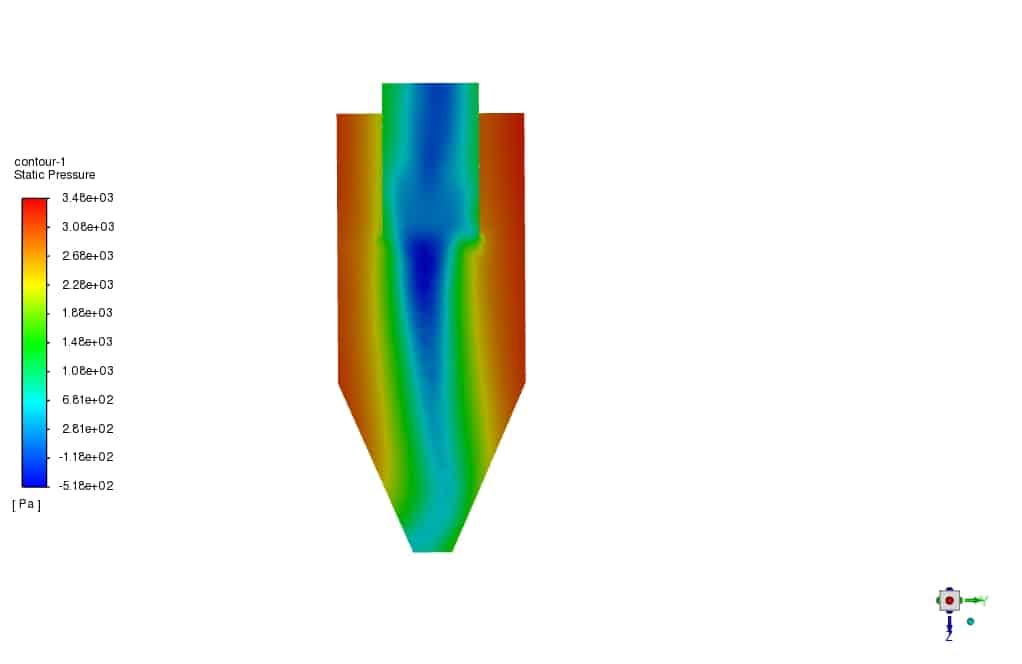

- This product is a gas cyclone device CFD simulation by ANSYS Fluent software.

- Due to the centrifugal force and heavier weight, particles separate from the gas stream and move downward due to gravitational force.

- Design Modeler software models the current 3-D geometry.

- ANSYS Meshing software grid the present model. The element number is 142499.

- the solid particles enter the cyclone interior from the top as the discrete phase, applying the Discrete Phase Model (DPM).

- We also define the discrete phase injection as the INERT of the cyclone inlet.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

This product is about a simulation of Cyclone by DPM via ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis.

Cyclones are one of the most widely used industrial systems in air dewatering, dust disposal, or separating solid particles from the gas flow. In these types of systems, separating solid particles from gas flows is carried out with the help of centrifugal and gravity forces, without filters.

In addition to reducing air pollution, Cyclones are also used to bring solid particles back into the production cycle. These systems commonly produce suspended solid particles in wood, cement, and other industries.

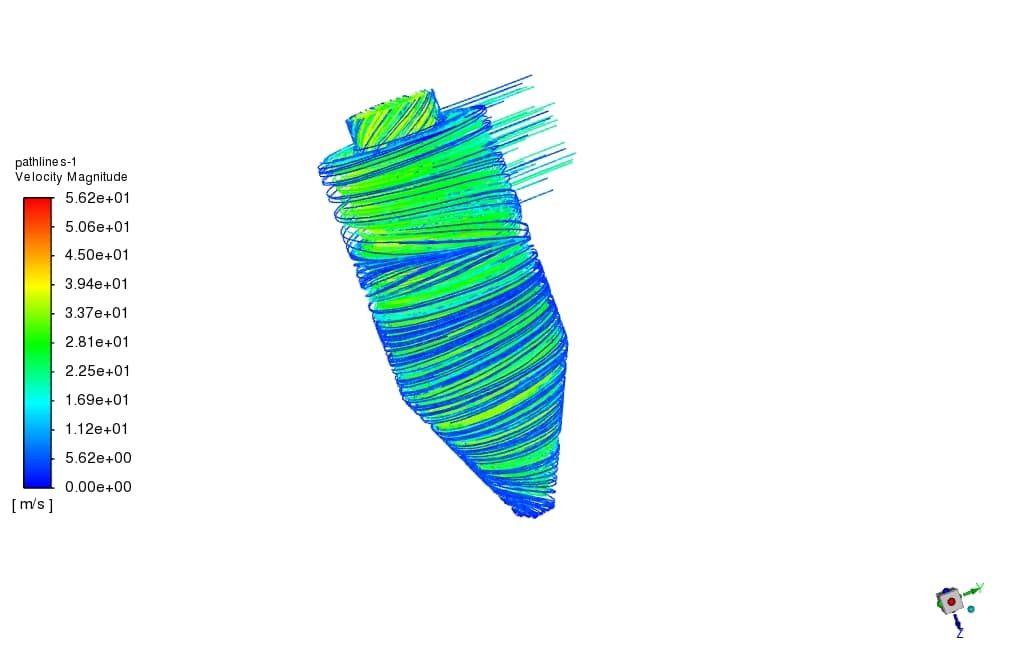

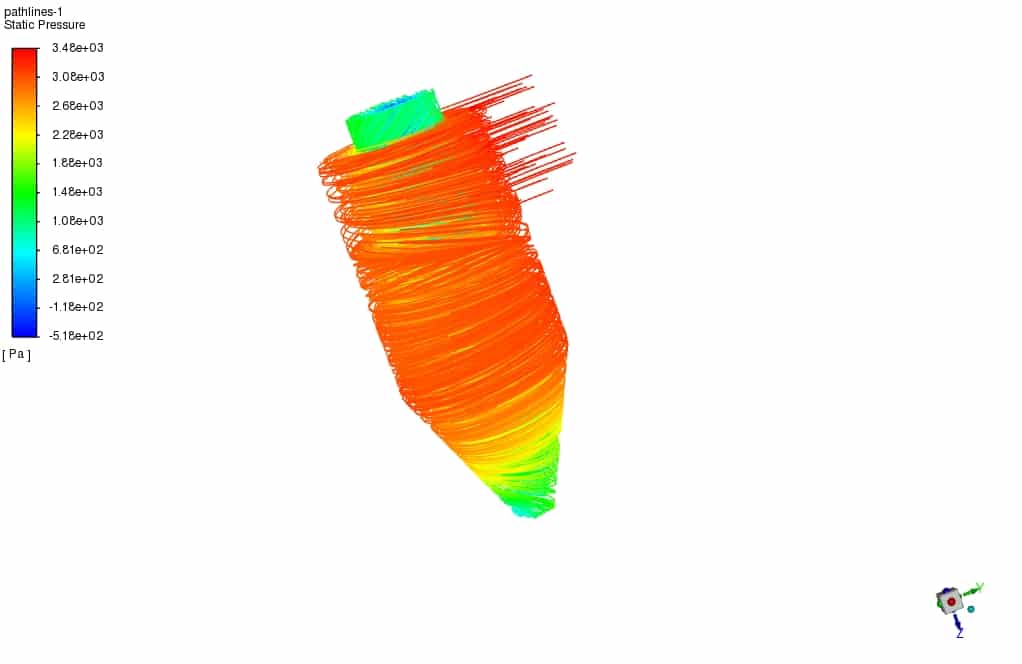

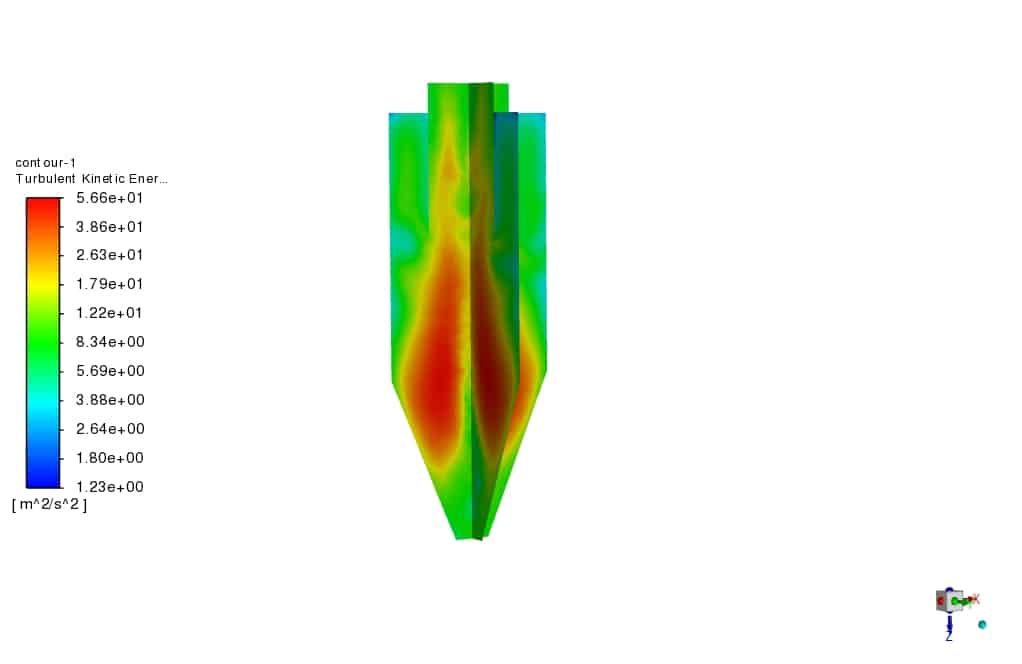

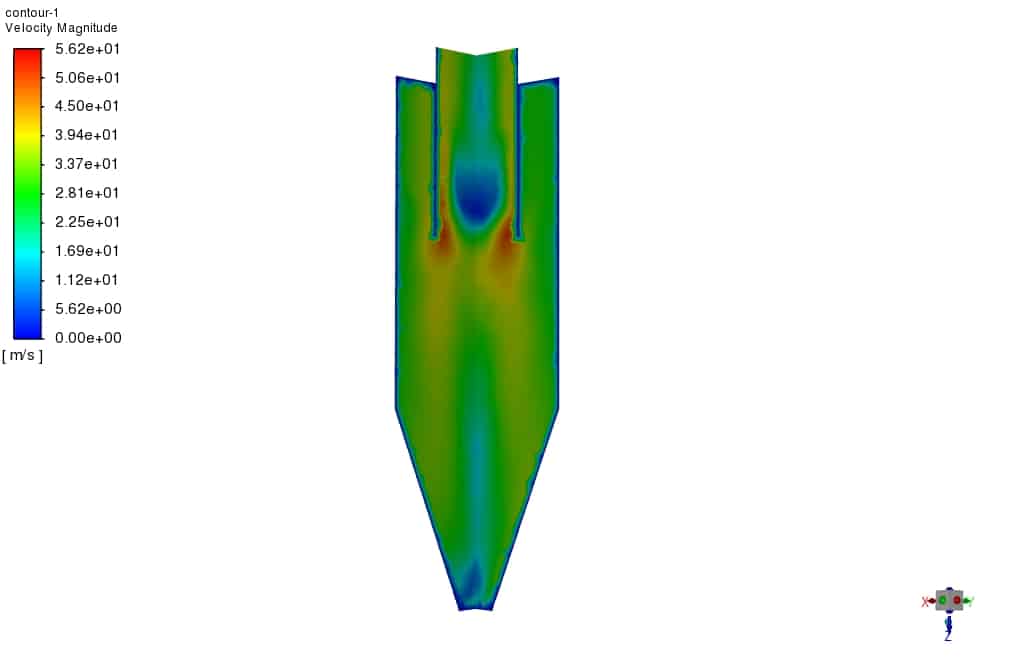

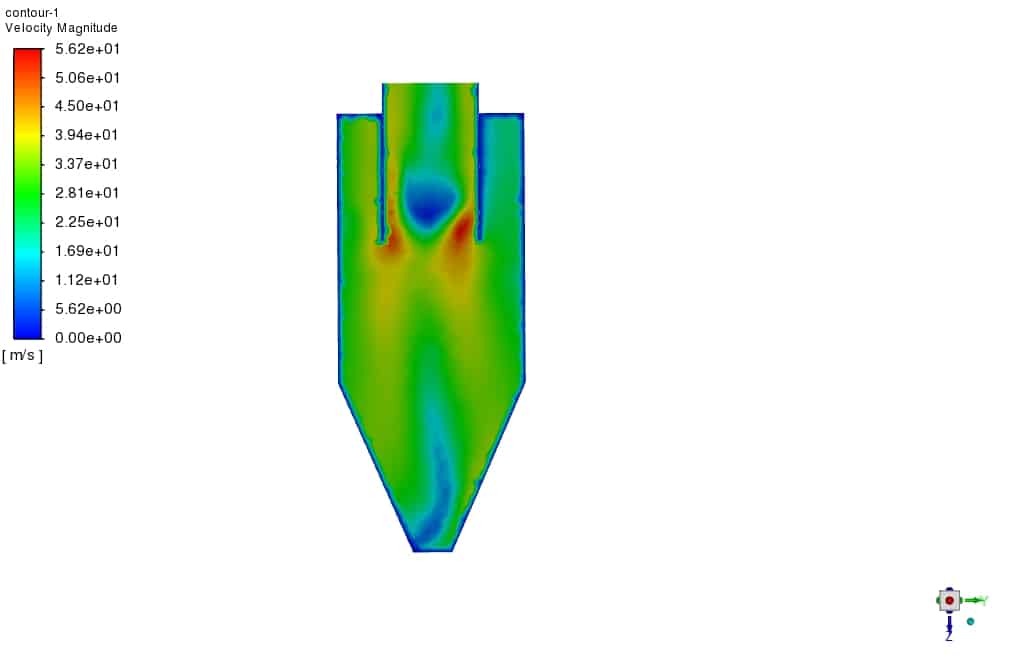

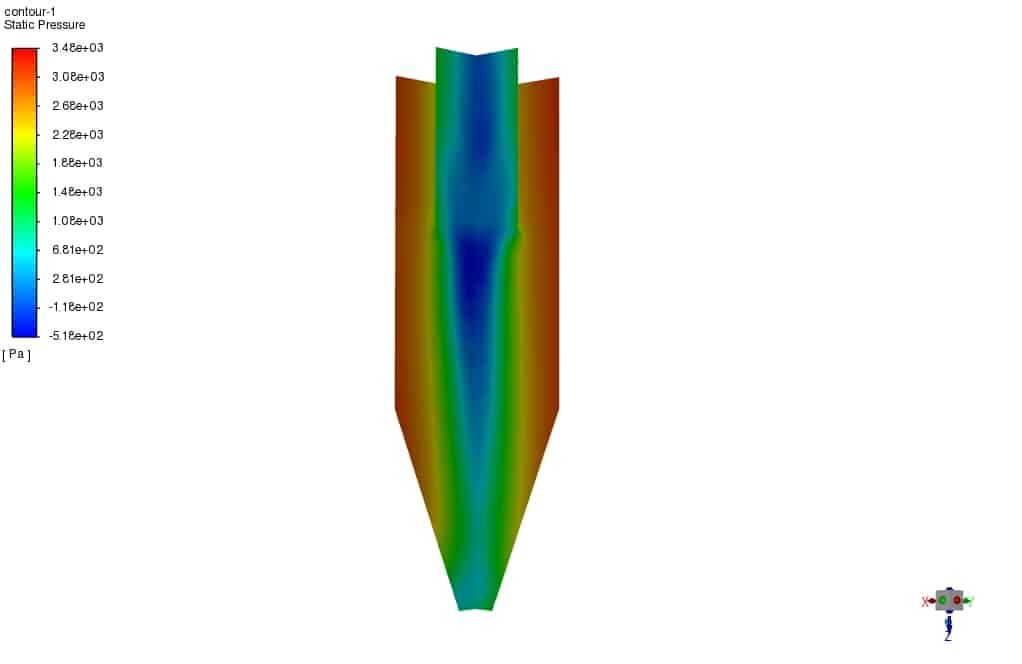

One inlet and two outlets for solid particles and pure air in cyclones. The air-containing particles enter the cyclone from the inlet of the cyclone. It moves in the space between the inner cylinder and the outer cylindrical body in a spiral and vortex manner, such that the solid particles are suspended.

Due to the centrifugal force and heavier weight, particles separate from the gas stream and move downward due to gravitational force. In this way, the solid particles in the air separate from the airflow.

The gaseous flow also flows upward and reaches the upper part of the chamber after reaching the conical region.

Cyclone by DPM Methodology

In this device, the gas flow enters continuously from the top to the inner space between the two cylinders and then the partial cone. Also, the solid particles enter the cyclone interior from the top as the discrete phase.

The contact between these two flows and centrifugal force separates these two phases. In the present simulation, the air is defined as gas flow and ash as discrete phase solid particles. Design Modeler software models the current 3-D geometry.

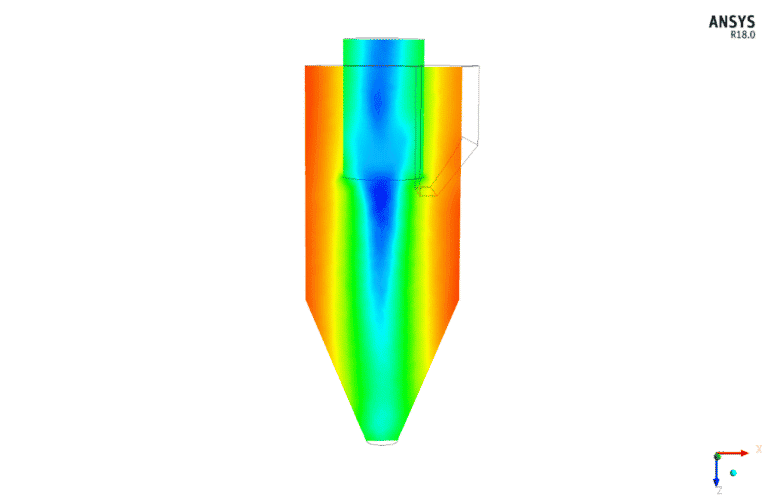

The cyclone structure consists of a cylindrical part and a partially conical part. Above the geometry, a trapezoidal cross-section is designed as the inlet of air impregnated with dust and a circular cross-section as the outlet of pure air.

At the bottom of the geometry, a circular cross-section is designed as a place for dust particles to accumulate. ANSYS Meshing software grid the present model. The mesh was of an unstructured type, and the element number was 142499.

Cyclone by DPM Conclusion

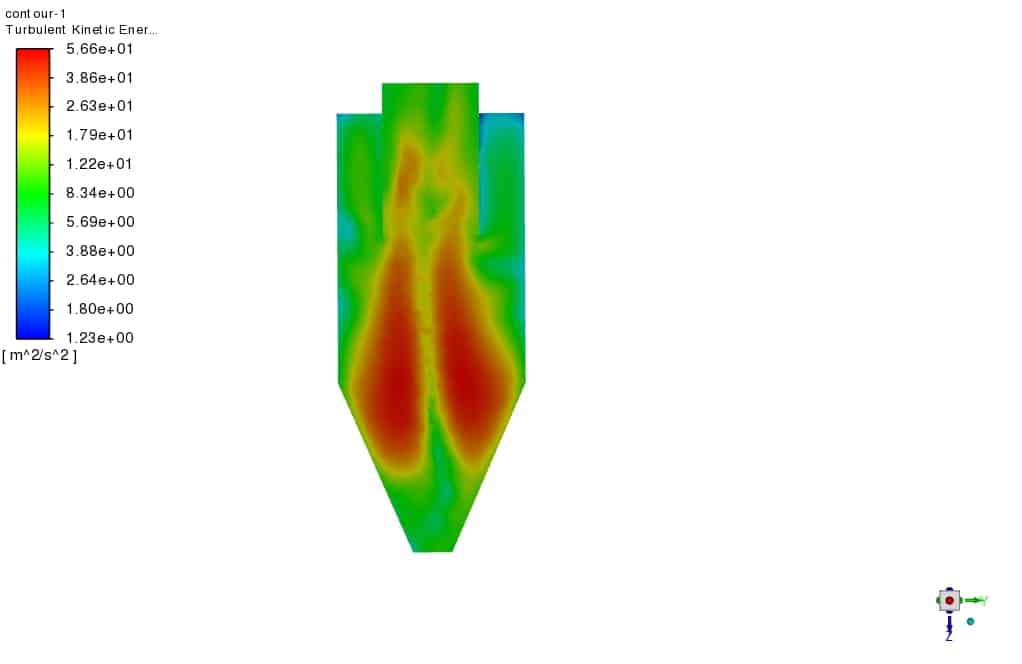

This simulation examines the behavior of a discrete phase from a Lagrangian perspective in the presence of a continuous fluid in the Eulerian perspective. The gas flow as a continuous fluid is under the Eulerian view, while the ash particles are discretized and Lagrangian.

The assumption is that the continuous phase does not affect discrete phase behavior. Therefore, we disable the Interaction With Continuous Phase for the discrete phase setting.

We also define the discrete phase injection as the INERT of the cyclone inlet, meaning that the discrete phase is ineffective and does not exhibit specific behavior. Ash particles can easily be tracked, and the residence time is also achievable. So we can analyze the cyclone performance.

Shanna Boyer –

I appreciate it SO MUCH. MR-CFD, this video has been quite helpful.

Mrs. Chasity Dickens III –

I’m curious about the methodology behind these simulations. How do you ensure the accuracy of the particle tracking in the cyclone?

MR CFD Support –

Great question! We use the Discrete Phase Model (DPM) in ANSYS Fluent, which allows us to accurately simulate the flow of discrete particles in the cyclone. This, combined with our detailed geometry and high-quality mesh, ensures the accuracy of our simulations.

Madaline Hickle –

Could you give me the geometry file? Please

MR CFD Support –

contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +1 (903) 231-3943.

Angie Dach –

I have a specific simulation in mind that I need for my project. Can you accommodate custom simulations?

MR CFD Support –

Yes, we’re open to contributions and can create a simulation tailored to your specific needs. Please get in touch with us to discuss more about your project.

Prof. Salma Deckow IV –

Hello, congratulation

You are the greatest in this sector, and your website is very well.

Norene Schamberger Jr. –

The Cyclone by DPM simulation is impressive. The level of detail is astounding.

MR CFD Support –

Thank you for your encouraging words! We aim to provide detailed and high-quality simulations for our customers.

Cornelius Bauch –

I’m new to CFD simulations. Do you provide any guidance on how to use the Geometry and Mesh File?

MR CFD Support –

Yes, we provide a step-by-step training video with each simulation. The video will guide you on how to use the Geometry and Mesh File. If you have any specific questions or need further assistance, feel free to reach out to us.

Ms. Adah Towne –

I’m interested in the technical aspects of the simulation. Could you explain more about the Discrete Phase Model (DPM) used in this product?

MR CFD Support –

Absolutely! DPM is a powerful tool in ANSYS Fluent that allows us to simulate the flow of discrete particles in a fluid. It’s particularly useful in applications like the cyclone separator, where we’re interested in tracking the path of particles.