Diesel-Air Mixture Flow with Fuel Droplet Evaporation

$160.00 $80.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Diesel-Air Mixture Flow with Fuel Droplet Evaporation CFD Training

Introduction

This report presents the results of a Computational Fluid Dynamics (CFD) simulation of a diesel-air mixture flow with fuel droplet evaporation conducted using ANSYS Fluent software. The simulation aims to investigate the complex dynamics of the mixture, including the interaction between the dispersed fuel droplets and the continuous air phase, as well as the impact of droplet evaporation on the flow field. This analysis is relevant to applications such as engine combustion and fuel spray characterization.

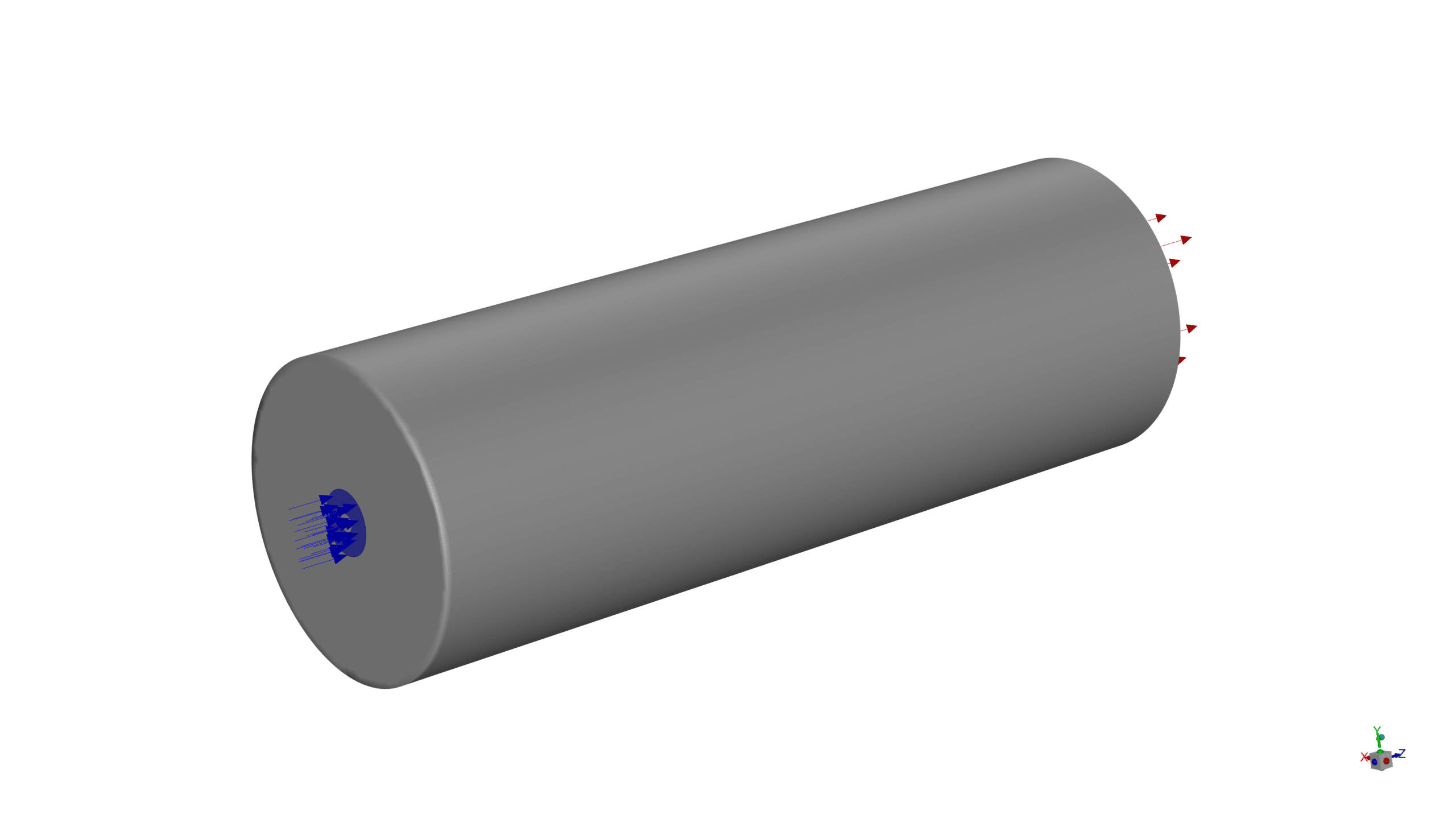

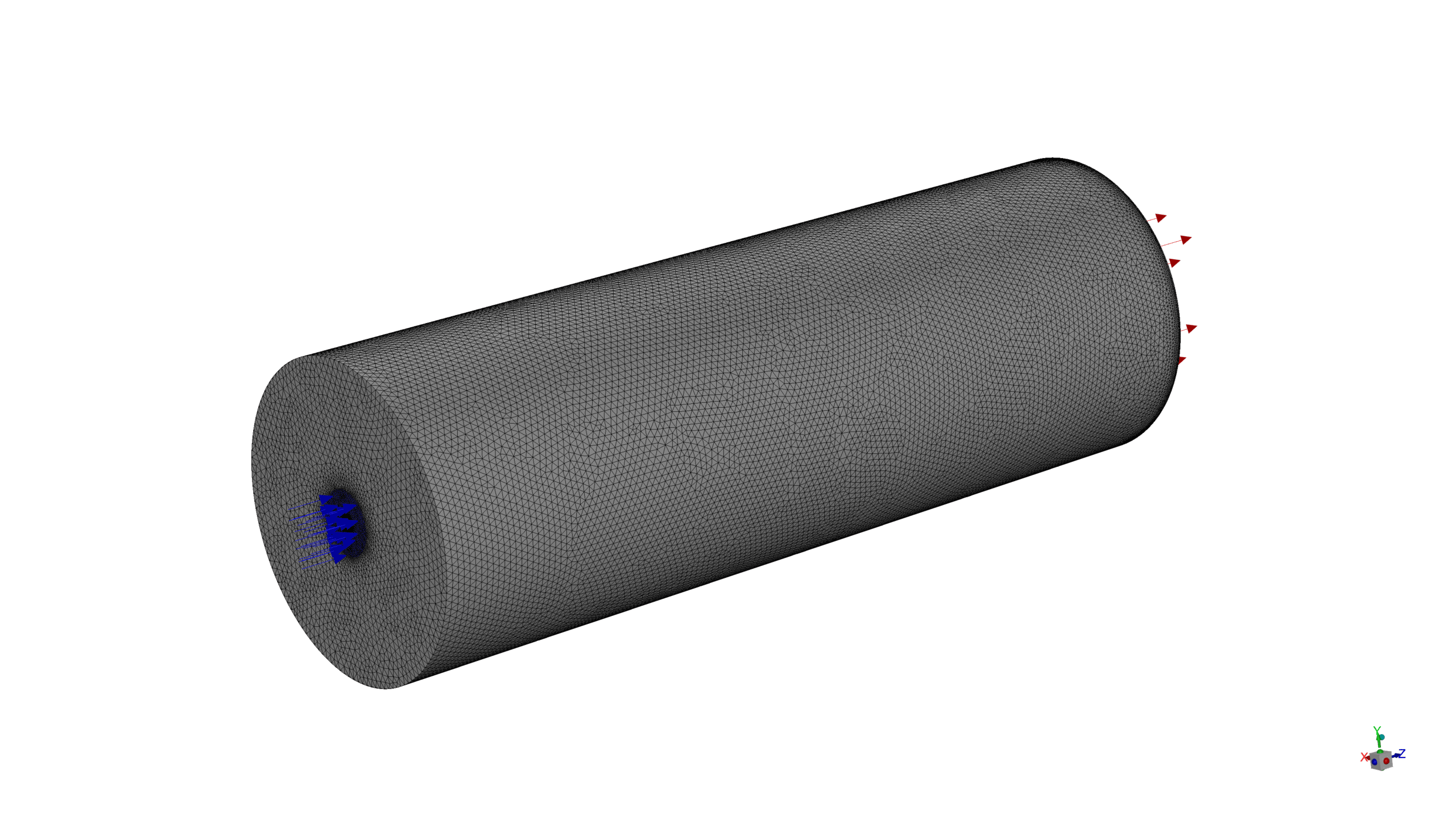

The simulation was conducted on a 3D geometry of a cylindrical chamber designed in SpaceClaim, representing a simplified combustion chamber. The mesh, consisting of over 2 million elements, was generated using ANSYS Meshing, ensuring sufficient resolution to capture the complex flow phenomena.

Methodology

A pressure-based, transient solver was employed. The Standard k-epsilon turbulence model with standard wall function was used to capture the turbulent nature of the flow.

The energy equation was enabled to capture the temperature field.

The Species Transport model with Eddy-Dissipation for Turbulence-Chemistry Interaction was used to model the mixing of diesel and air.

The Discrete Phase Model (DPM) was used to simulate the movement and evaporation of fuel droplets, treating them as discrete entities. Two-way coupling was enabled to represent the interaction between the dispersed phase (droplets) and the continuous phase (air). Also, Temperature-dependent latent heat effects were considered to account for the energy required for droplet evaporation.

Evaporation of the droplets was allowed within the domain, capturing the mass transfer process. Diesel fuel was injected from the center of the inlet, with air entering from the surrounding region. The simulation was run for 5 seconds to observe the transient behavior of the mixture.

Results

The CFD simulation yielded valuable insights into the flow behavior of the diesel-air mixture. The key observations are:

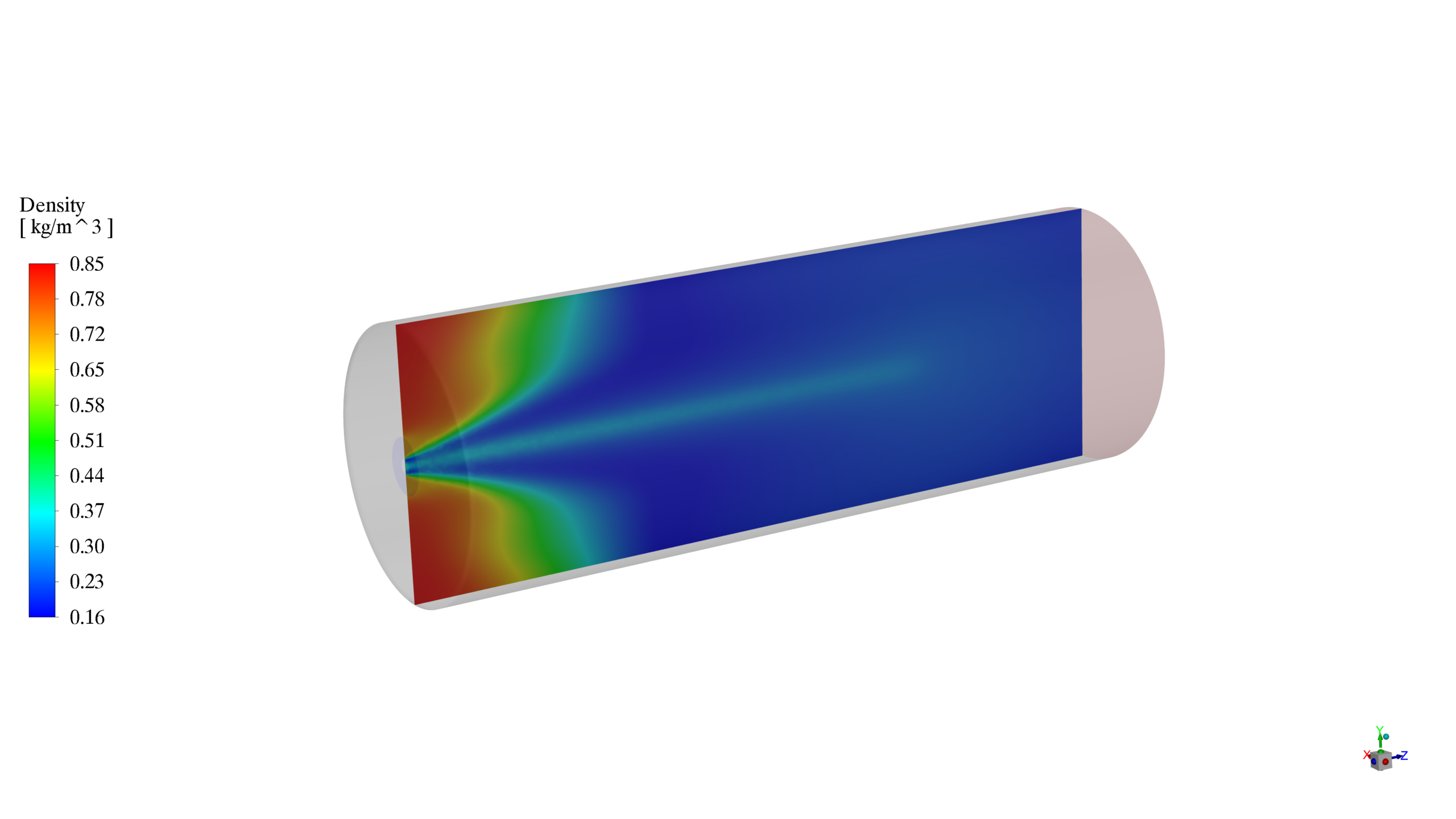

The density contours show that the mixture density is higher near the injection point, decreasing as the diesel jet spreads and mixes with the air. This difference in density is a result of the higher density of the diesel fuel compared to the air.

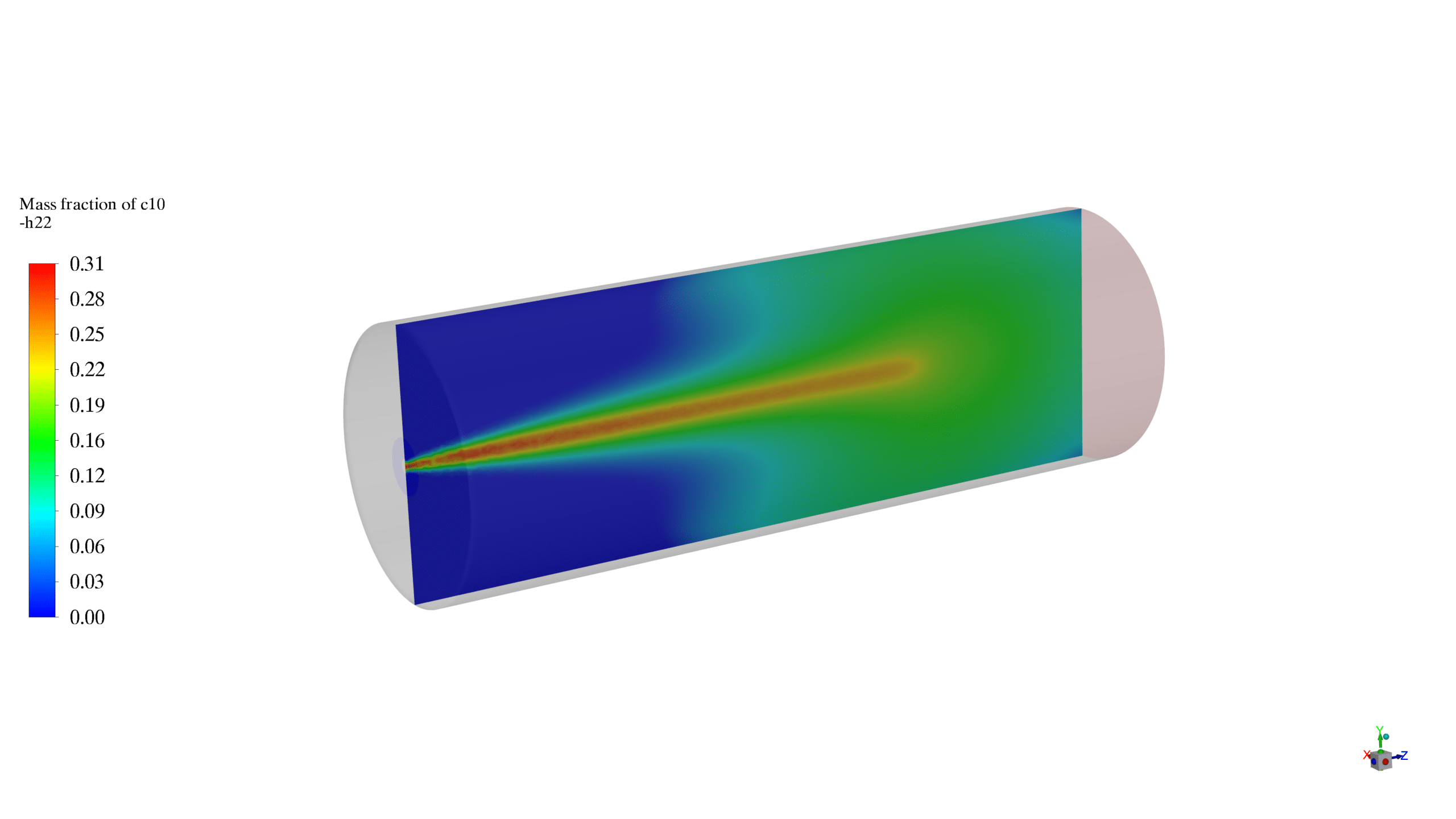

The mass fraction contours for c10 (diesel) show the diesel jet extending into the chamber, with the concentration of diesel progressively decreasing as it mixes with the air. This demonstrates the mixing process of the diesel fuel with the surrounding air.

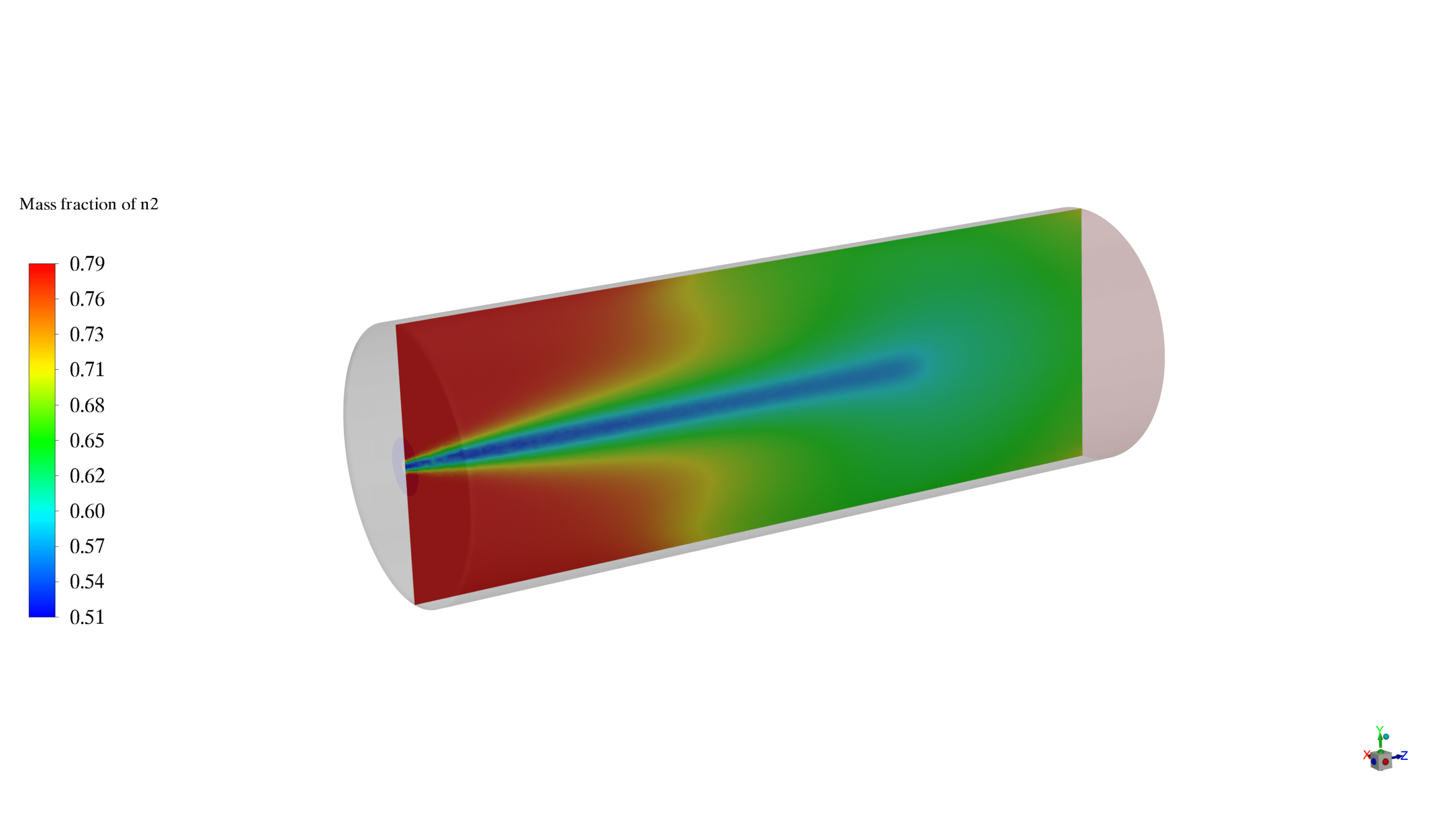

Moreover, the mass fraction contours for n2 (nitrogen) show a decrease in the nitrogen concentration near the injection point, indicating that the diesel jet displaces the nitrogen in the air.

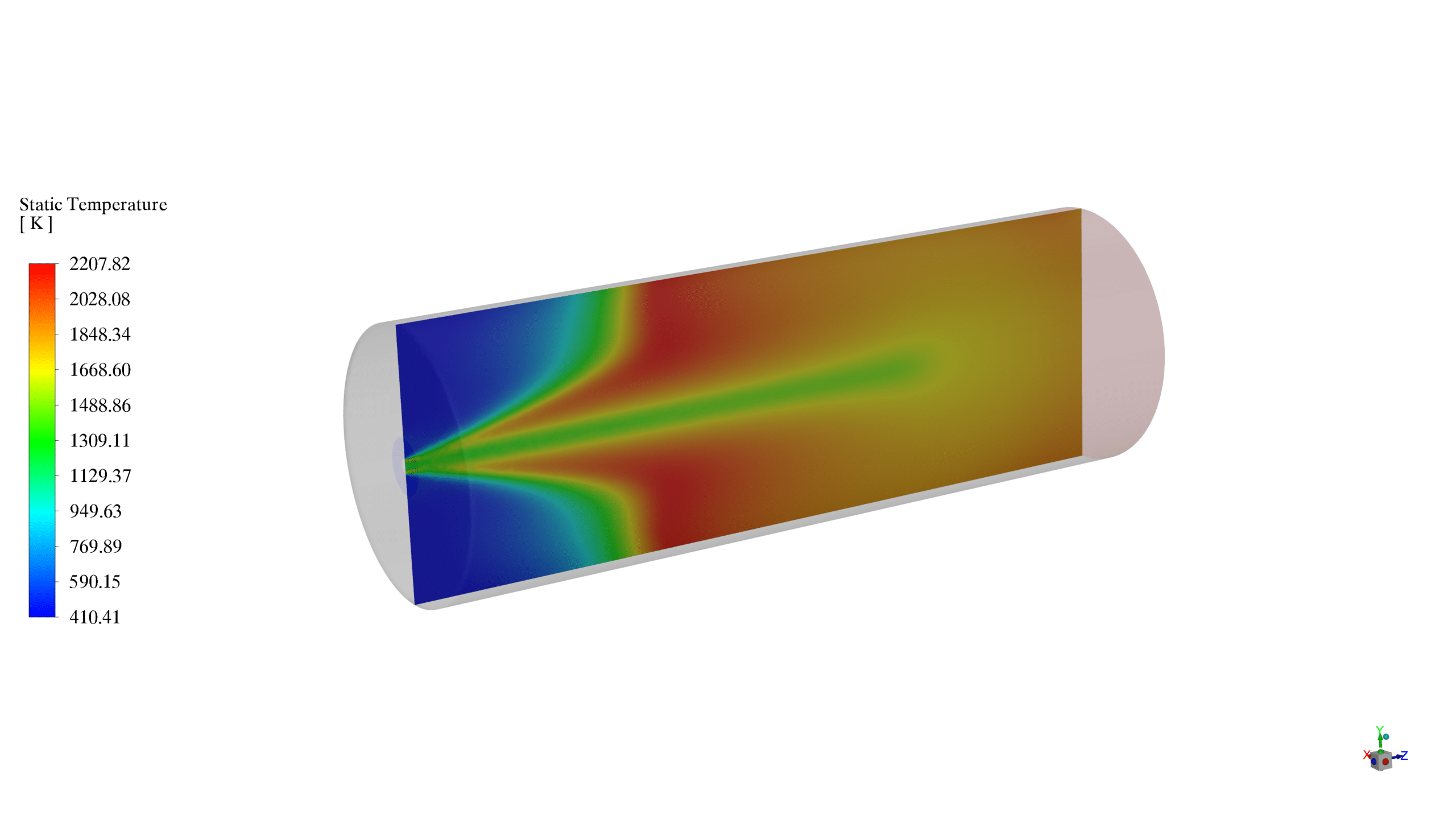

The static temperature contours show a significant increase in the region where the diesel jet interacts with the air, indicating the heat release associated with the combustion process.

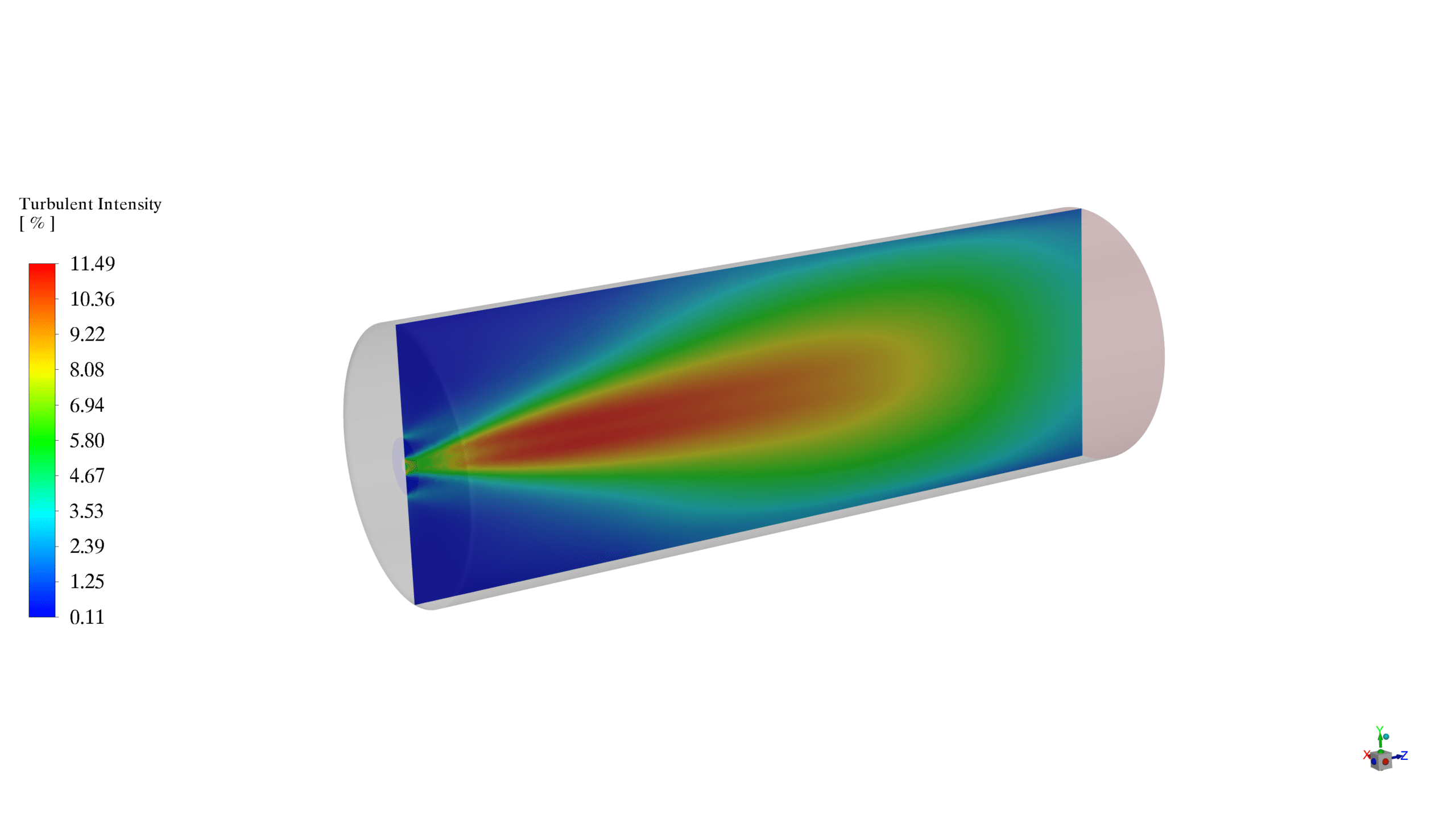

The turbulent intensity is high in the regions near the jet, indicating a strong mixing process between the diesel and air.

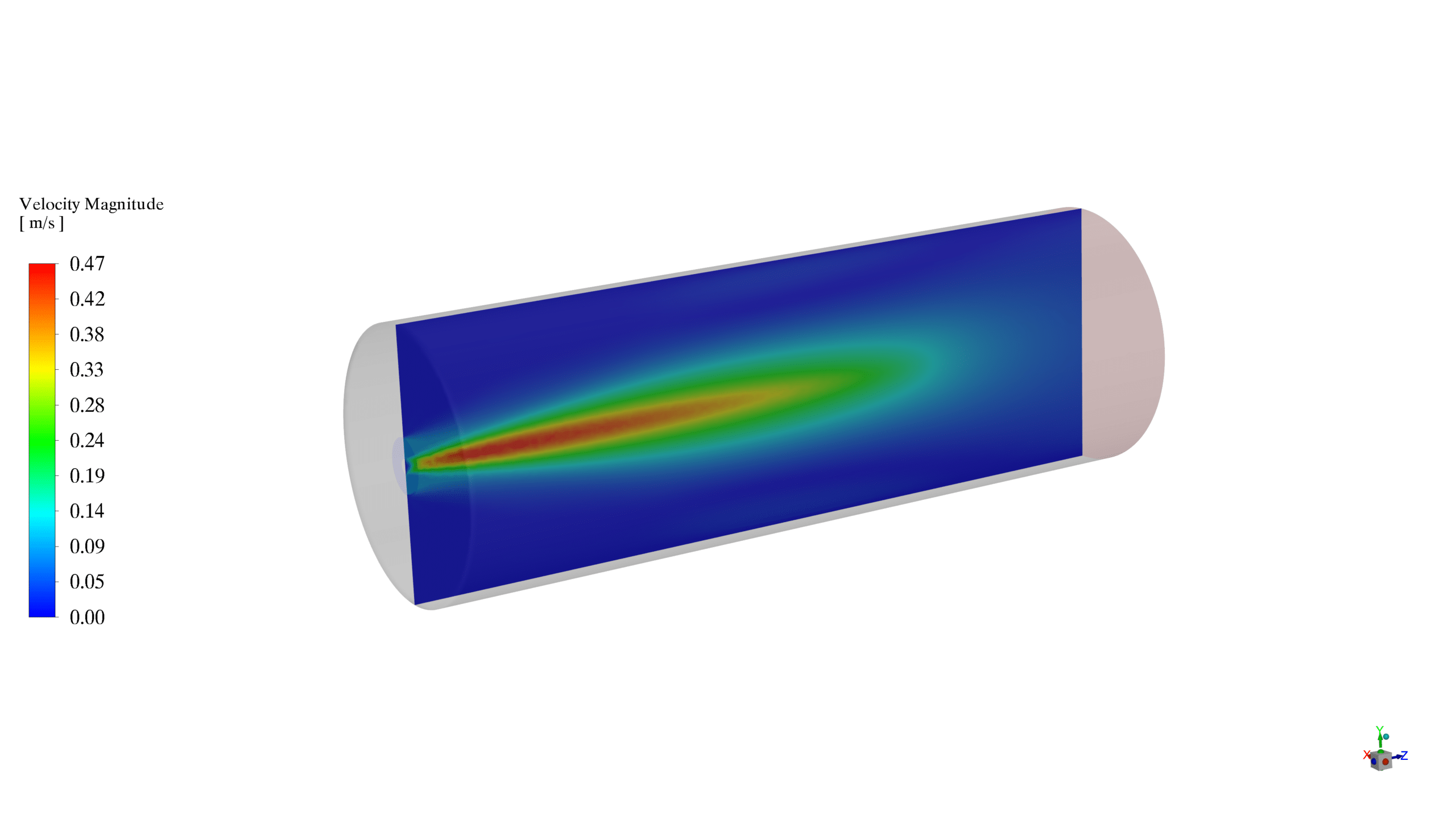

Furthermore, the velocity magnitude contours show high velocity at the jet’s core and a gradual decrease as the jet spreads, indicating the momentum transfer from the injected diesel.

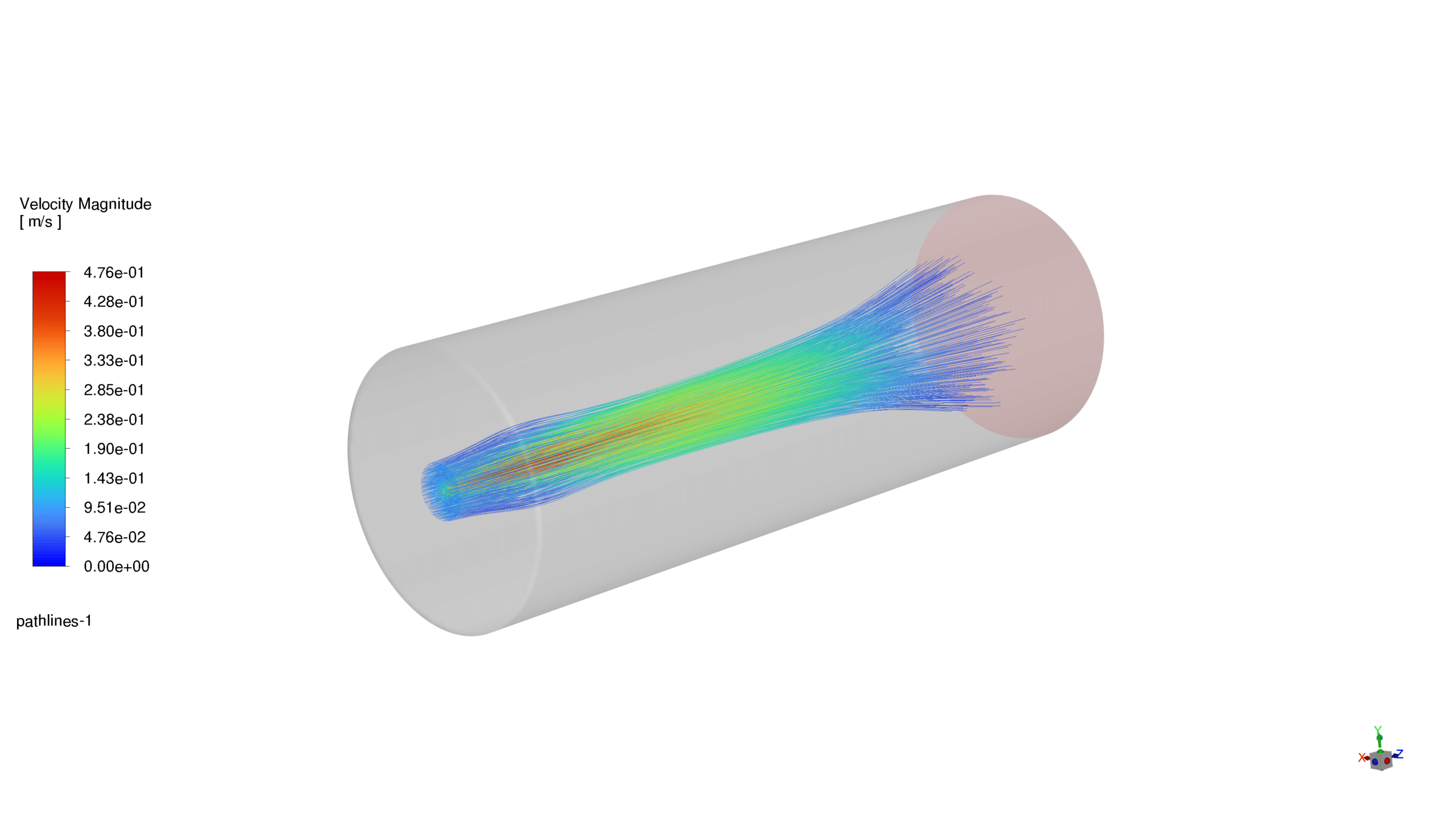

The particle trajectories obtained from the DPM model show the dispersion and evaporation of individual fuel droplets within the chamber. Smaller droplets evaporate faster, leading to shorter residence times.

Finally, the particle residence time, visualized by the particle tracks, shows the time each droplet spends in the domain, varying depending on the droplet size and location.

Reviews

There are no reviews yet.