Double Pipe Counter Flow Heat Exchanger Simulation, ANSYS Fluent Training

$80.00 $40.00 Student Discount

- The problem numerically simulates the Double Pipe Counter Flow Heat Exchanger using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 115635.

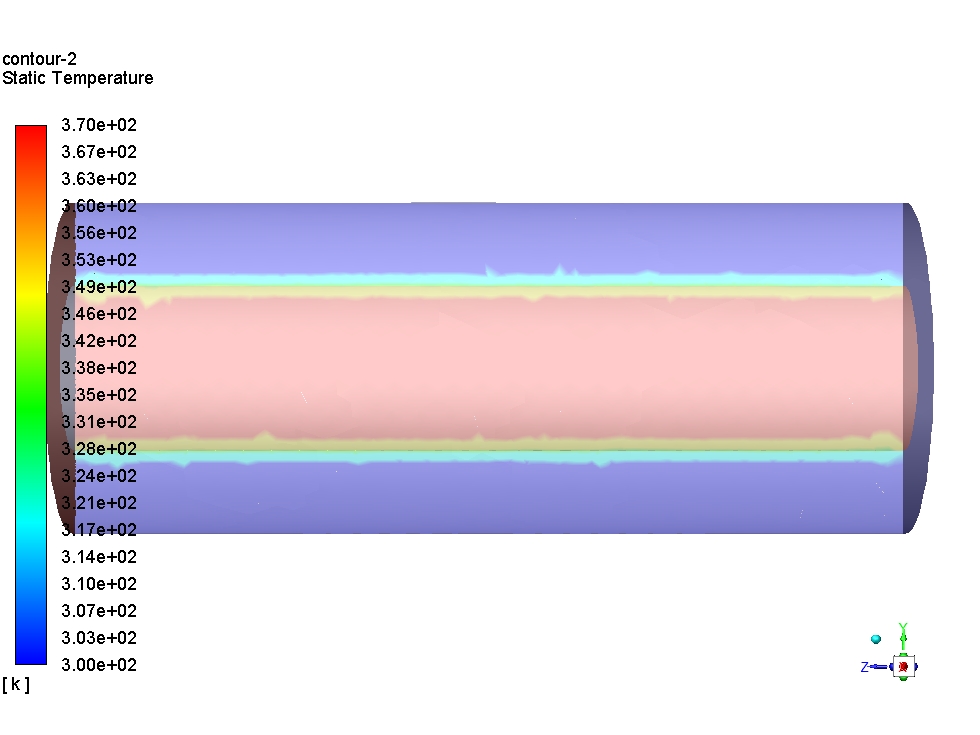

- The Energy Equation is activated to consider heat transfer.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this project, ANSYS Fluent software investigates the Double Pipe Counter Flow Heat Exchanger.

Heat exchangers are widely used in industrial applications where the vital need is to cool down a fluid. Counter-flow heat exchangers are the simplest form of heat exchangers where the exchange of thermal energy between hot and cold flows is done through a shared interface between these flows.

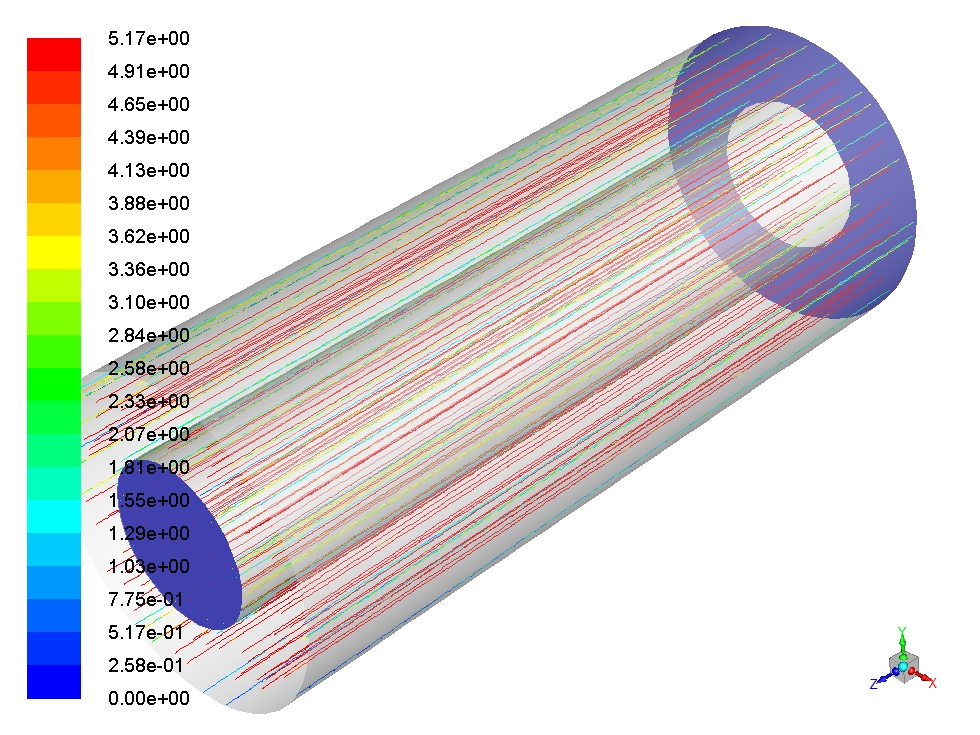

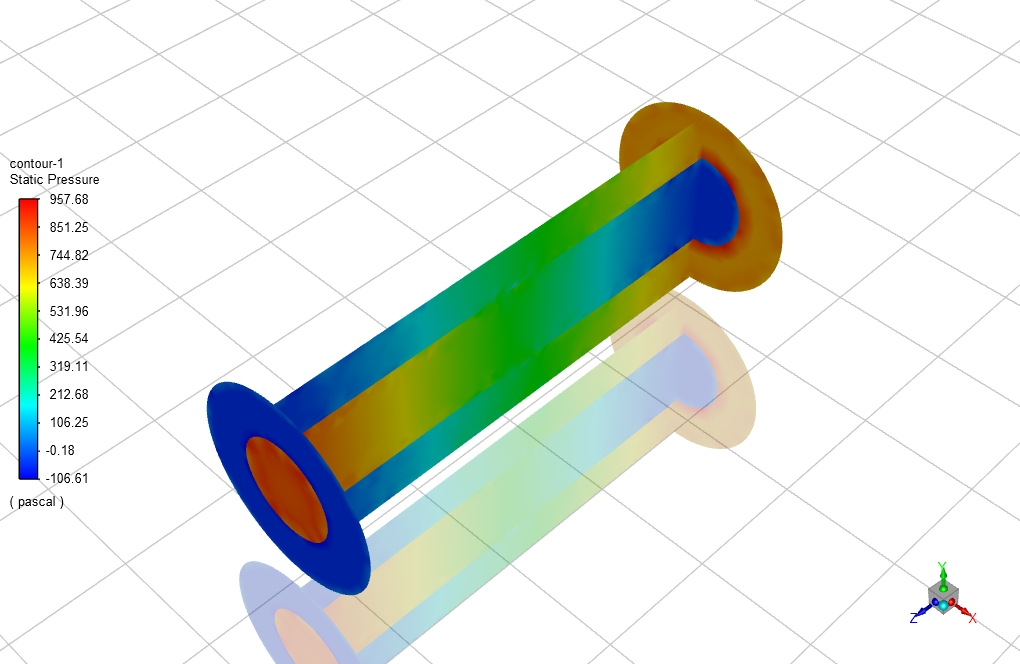

The geometry of the fluid domain is designed in the Design Modeler, and the computational grid is generated using ANSYS Meshing. The mesh type is unstructured, and the element number is 115635.

Double Pipe Methodology

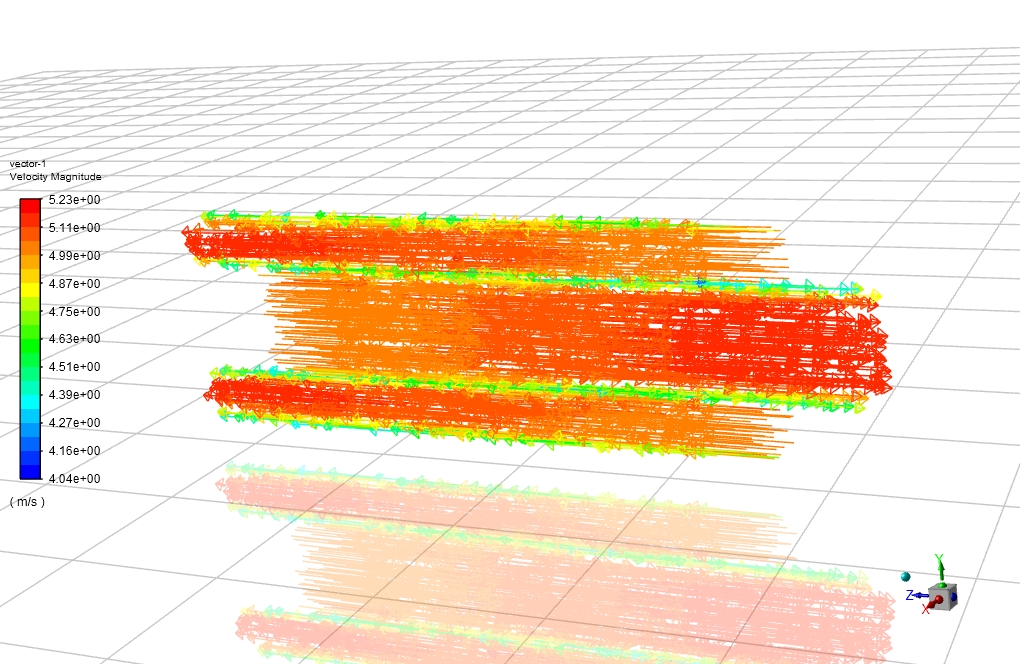

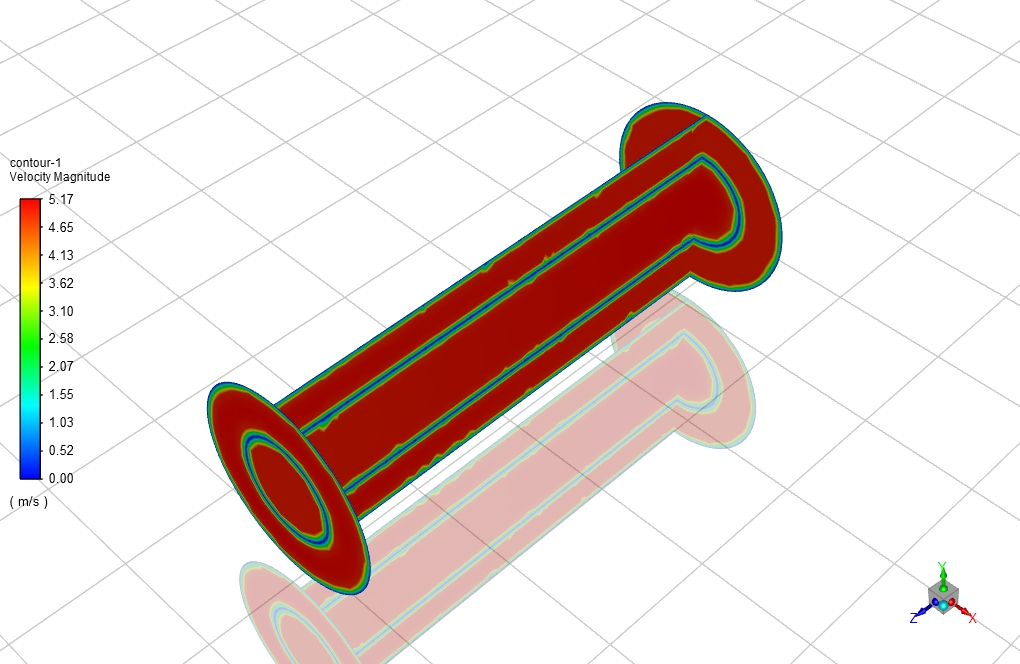

The water mass flow rate at the inlet is 117.59 kg/s and 38.94 kg/s for hot and cold flows, respectively.

Double Pipe Conclusion

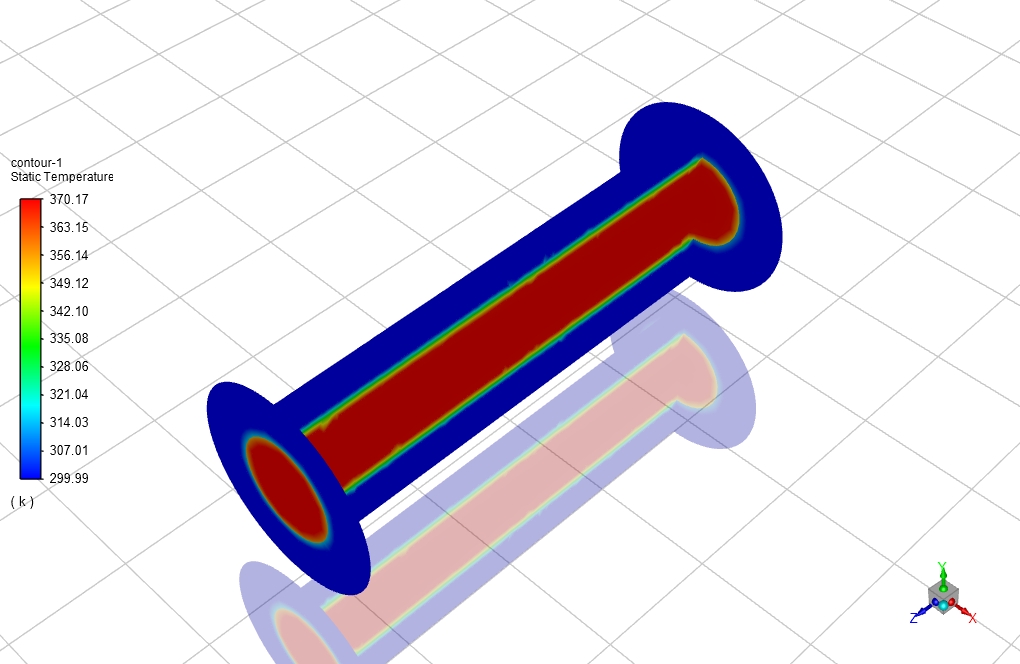

Hot water flow enters and exits the domain with temperatures equal to 370 and 369.67k, respectively. Cold water flow enters and exits the domain with temperatures equal to 300 and 300.11k, respectively. Heat exchange between the flows is equal to 53KW.

Dimitri Strosin –

Can the simulation handle non-Newtonian fluids or is it strictly for Newtonian fluids?

MR CFD Support –

The current model is set up for Newtonian fluids, but the simulation can be modified to handle non-Newtonian fluids as well.

Newton Miller IV –

Great learning materials! It was very helpful to see the effects of the mass flow rates on the heat exchange process. My understanding of counter flow heat exchangers has significantly improved.

MR CFD Support –

We’re thrilled to hear that our training materials were beneficial for your understanding of heat exchangers! Thank you for your feedback, it’s much appreciated.

Lenny Dibbert –

The practical application section of the training was exceptional. It thoroughly explained the concepts and setup, which was perfect for applying the theory to a real-world situation. The step-by-step guidance through the simulation process made the complex procedures accessible.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our training material was instrumental in bridging the gap between theoretical knowledge and practical application. We strive to provide clear and concise step-by-step guidance, and we’re glad it was helpful. If there’s anything more you need or would like to learn about, we’re here to support you further on your CFD journey!

Dr. Ubaldo Crona MD –

The explanation provided for the counter flow heat exchanger is succinct and effective. The temperatures and flow rates for both the hot and cold water demonstrate a meticulous attention to detail in the simulation setup. It’s impressive to see the precise heat exchange value calculated from the simulation.

MR CFD Support –

We’re thrilled to hear that you found our Double Pipe Counter Flow Heat Exchanger Simulation beneficial! Thank you for acknowledging the meticulous details and accuracy in our training material using ANSYS Fluent. We strive to deliver the best learning experience to our users.

Brooke Friesen –

I’m very impressed with the accuracy and efficiency of the Double Pipe Heat Exchanger simulation. It provides a detailed understanding of the temperature exchange which is fundamental in many industrial applications.

MR CFD Support –

Thank you for your feedback! We’re delighted to hear that you found our Double Pipe Heat Exchanger simulation to be accurate and efficient. Your satisfaction with the understanding it provides on temperature exchange is very important to us.

Dr. Raleigh Ryan –

The detail in the temperature changes for the hot and cold water flows was fascinating to see. It really showcased the precision of the heat exchange!

MR CFD Support –

Thank you for your positive feedback! We’re pleased to hear you are satisfied with the precision and detail of our Double Pipe Counter Flow Heat Exchanger simulation. We always strive to provide accurate and detailed simulations to help our users understand and visualize the physics of heat exchange processes. Don’t hesitate to reach out if you need further assistance or information on our products.

Samanta Sauer –

I am truly impressed by the accuracy and efficiency presented in the Double Pipe Counter Flow Heat Exchanger simulation. The detail on flow rate and temperature differences provides clear insights into the heat exchange process.

MR CFD Support –

Thank you for your kind words! We’re glad to hear you found the simulation details and insights helpful and accurate. If you have any further questions or require more information, feel free to reach out. Your feedback is appreciated.

Prof. Gerry Gutmann V –

The results from this heat exchanger simulation are really impressive! It provided precise temperatures at the outlets for both hot and cold water flows. Efficient thermal energy exchange is crucial, and the heat transfer of 53KW indicates a well-designed system.

MR CFD Support –

Thank you for your positive feedback on our Double Pipe Counter Flow Heat Exchanger simulation training! We’re thrilled to hear that you found the simulation results impressive and informative. Our goal is to provide high-quality education that empowers our users, and feedback like yours lets us know we’re on the right track. If you have any future inquiries or need further assistance, don’t hesitate to reach out!

Mr. Houston Rice –

What is the computational cost of the simulation? Can it be run on a standard laptop?

MR CFD Support –

The computational cost depends on the complexity of the geometry and the number of cells in the mesh. A standard laptop should be sufficient for the current model.

Megane Konopelski –

The Double Pipe Counter Flow Heat Exchanger training by ANSYS Fluent was fantastic! It was easy to follow and provided a clear understanding of the heat exchange process.

MR CFD Support –

Thank you for the positive feedback! We are thrilled to hear that you found our training easy to understand and helpful. We pride ourselves on providing clear and comprehensive learning materials for our users. If you need any further assistance or want to explore more advanced topics, feel free to reach out!

Kaleigh Rogahn Jr. –

The training on the Double Pipe Counter Flow Heat Exchanger was very clear and informative. I now understand how these systems work in practice. Great job on the tutorial!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that the tutorial for the Double Pipe Counter Flow Heat Exchanger in ANSYS Fluent was helpful and provided clarity on the operational aspects of such systems. We appreciate your kind words and are glad to have supported your learning journey!

Jay Aufderhar –

The training material on the Double Pipe Counter Flow Heat Exchanger Simulation was extremely informative. I applied the concepts I learned directly to my work project, and the results were spot on. The illustration of temperature changes and the detailed explanation of the shared interface for thermal exchange were really helpful.

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our training material helped you in your project. Our goal is to provide clear and practical simulations that can be applied in real-world scenarios. We look forward to providing you with more useful resources in the future!

Ora Walsh I –

Can the simulation model phase change, like condensation or boiling?

MR CFD Support –

The current model does not include phase change. However, we can modify the model to include phase change upon request.

Katrina Stracke –

Can the simulation be extended to three dimensions?

MR CFD Support –

Yes, the simulation can be extended to three dimensions. Please contact us for a customized solution.

Anderson Kshlerin –

The level of detail shared in the simulation results on heat transfer was fascinating. It’s clear how well the heat exchange process reaches equilibrium in a double pipe counter flow setup. Great work!

MR CFD Support –

Thank you for taking the time to share your positive feedback! We’re thrilled to know that the results from the Double Pipe Counter Flow Heat Exchanger simulation were so well-received and that the details provided were to your satisfaction. If you need any further insights or assistance, feel free to reach out.

Providenci Lowe –

Excellent resource for understanding counter-flow heat exchangers. Clear presentation and easy to follow simulations.

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that you found the training materials clear and easy to follow. If you have any further questions or need more information, please do not hesitate to reach out.

Carley Schoen –

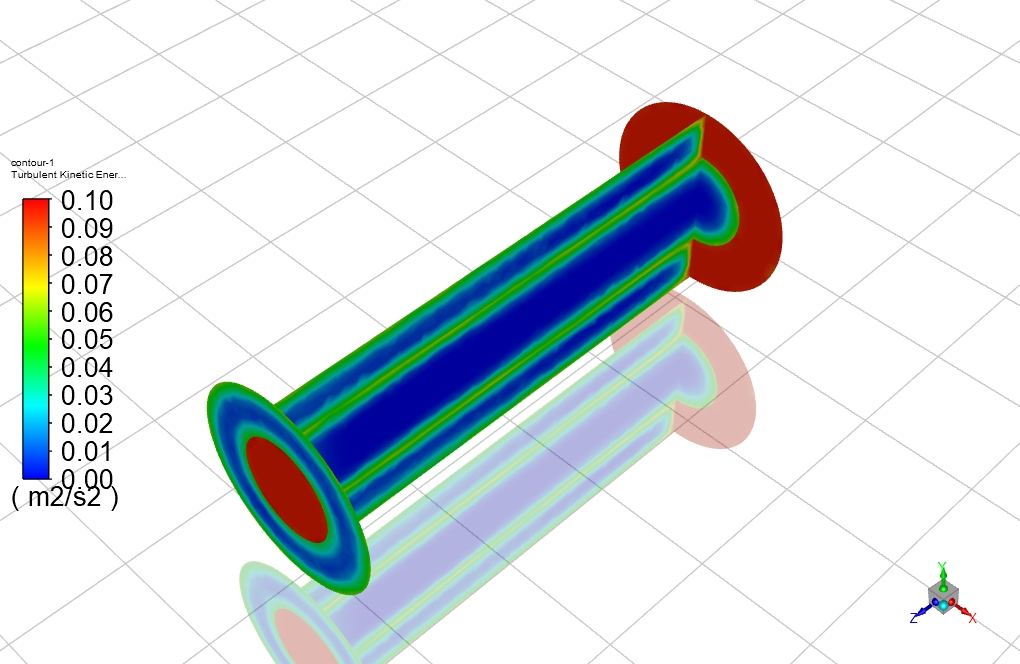

The depth of analysis in the heat exchange results is impressive. Could you share how turbulence was accounted for in the simulation?

MR CFD Support –

In the Double Pipe Counter Flow Heat Exchanger simulation, turbulence was likely modeled using one of the standard turbulence models such as the k-epsilon or k-omega model. These models help in capturing the chaotic fluctuations of fluid velocity and pressure which are a critical aspect of accurately simulating a heat exchanger’s performance. The choice of model and its parameters would depend on the flow conditions and Reynolds number.

Miss Maggie Collier –

The thorough investigation and explanation of the Double Pipe Counter Flow Heat Exchanger’s operation using ANSYS Fluent was enlightening. The detailed analysis and resultant data have greatly expanded my understanding of thermal energy exchange within such systems.

MR CFD Support –

Thank you for your feedback! We’re pleased to hear that our training on Double Pipe Counter Flow Heat Exchanger in ANSYS Fluent has enhanced your understanding of heat transfer applications. Your comprehension of the subject is indeed an endorsement of our teaching methodology.

Germaine Harris MD –

I must say the Double Pipe Counter Flow Heat Exchanger Simulation by MR CFD was thoroughly intriguing! The detailed analysis provided clear insights into the heat exchange process, and it was impressive seeing the temperature differential being effectively utilized. The precise calculations and the unstructured mesh approach gave an in-depth understanding of how the double pipe system works in various industrial applications. Overall, I learned a lot and thoroughly enjoyed diving into the complexities of thermal energy transfer within such systems.

MR CFD Support –

Thank you for your kind words and for taking the time to write such a comprehensive review of our Double Pipe Counter Flow Heat Exchanger Simulation! We are thrilled to hear you found the simulation insightful and educational. Our team is committed to providing high-quality learning materials that not only explain complex principles but also demonstrate their real-world applications. It’s great to know that we achieved our goal with this product. Thank you for choosing MR CFD for your learning experience!

Jalon Torphy MD –

I’m extremely impressed with the accuracy and the clarity of results in the Double Pipe Counter Flow Heat Exchanger simulation by MR CFD. The detail provided in the training made it easy to understand these complex systems. Great work!

MR CFD Support –

We are thrilled to hear such positive feedback! Thank you for taking the time to complement our Double Pipe Counter Flow Heat Exchanger simulation training. At MR CFD, we are committed to providing clear and detailed simulations that help our customers understand complex systems efficiently. Your satisfaction is our top priority!

Dave Lesch –

This is a fantastic resource for understanding the intricacies of heat exchanger operation! I’m thoroughly impressed by the clarity of the simulation process and the detail of the final results.

MR CFD Support –

Thank you for your kind words! We’re delighted to hear that our simulation was helpful for your understanding of counter-flow heat exchangers and pleased that the details provided clarity. If you have any further inquiries or need more information, feel free to reach out.

Ms. Velva Dooley –

This product has served as a fantastic introduction to CFD analysis for heat exchangers. The methodology is clearly demonstrated with distinct inlet and outlet temperatures, giving a clear perception of the heat exchange processes in industrial scenarios. The use of unstructured mesh and the precise detailing of element numbers show the complexity yet the manageability of simulations within ANSYS Fluent.

MR CFD Support –

We’re thrilled to read such positive feedback! Knowing that our customers clearly understand and can follow the methodologies used in our simulations is wonderful. Your acknowledgment of details like mesh structure and element count reassures us that we are providing valuable and technical insight. Thank you for taking the time to leave a review! We hope our product continues to contribute effectively to your learning experience.

Miss Margaretta Littel –

The Double Pipe Counter Flow Heat Exchanger tutorial was truly insightful! Following the steps improved my understanding of thermal energy exchange in industrial equipment. The provided data was clear, and seeing the temperature change from hot to the cold water gave a practical insight into the effectiveness of the design.

MR CFD Support –

We’re thrilled to hear that our Double Pipe Counter Flow Heat Exchanger simulation tutorial was helpful for you! Thanks for acknowledging the clarity of data and for pointing out the value in seeing the temperature changes practically. We always strive to provide useful learning material for our users, and your feedback is very much appreciated. – MR CFD Team

Emelia Cormier –

The counter flow heat exchanger CFD training provided an excellent hands-on experience with engaging and well-presented content, and the clear demonstration of thermal patterns and heat transfer efficiency was particularly insightful.

MR CFD Support –

Thank you for your review and for recognizing the clarity and effectiveness of our Double Pipe Counter Flow Heat Exchanger Simulation training. We strive to deliver engaging and comprehensive CFD educational content, and we are delighted to know that it met your expectations. If you have more questions or need further insights, please feel free to reach out.

Cristopher Kub –

I’m amazed at the precision and the clarity of the results obtained from the Double Pipe Counter Flow Heat Exchanger simulation. The detail in temperature change and the heat exchange value is vital for industrial design validation, and this training has outlined it perfectly.

MR CFD Support –

Thank you for your positive feedback! We are glad to hear that our training materials met your expectations and provided clear and precise results for your industrial design validation. Your satisfaction is our top priority. If you have further questions or need additional assistance, feel free to reach out.

Lorenz Feil –

I found the temperature change in the cold water flow to be very minimal. Can you explain why there’s such a small temperature difference after the exchange?

MR CFD Support –

In the project, the small temperature change in the cold water flow may be attributed to factors such as the specific heat capacity of the cold fluid, the mass flow rate, the effectiveness of the heat exchanger design, and the surface area available for heat transfer. Admin should be able to provide more specifics.

Dr. Price Maggio –

I just finished the Double Pipe Counter Flow Heat Exchanger simulation tutorial using ANSYS Fluent. I am impressed with the clarity and depth of the content. It was fascinating to learn how heat transfer works in counter-flow systems and to see the effects on the temperature distribution in both hot and cold water. Great job!

MR CFD Support –

Thank you so much for your positive feedback. We’re thrilled to hear that our tutorial on the Double Pipe Counter Flow Heat Exchanger simulation was able to enhance your understanding of heat transfer processes. If you have more questions or need further clarifications on other simulations, please feel free to reach out.

Prof. Wellington Fahey Sr. –

Could you explain if there’s a routine procedure for checking the mesh independence in this kind of simulation?

MR CFD Support –

Absolutely, a mesh independence study is critical in CFD analyses to ensure accuracy of results. Typically, the procedure involves starting with a coarse mesh and progressively refining it until variations in the output (like temperature, velocity, pressure fields) fall within an acceptable small percentage range. This specific routine allows the CFD engineer to establish that further mesh refinement does not significantly alter the simulation outcome, indicating that the mesh is adequately capturing the physics of the situation.