DPM CFD Simulation Training Package, ADVANCED Users, 10 Learning Products

$299.00 $149.50 Student Discount

This CFD training package is prepared for ADVANCED users of ANSYS Fluent software in the Discrete Phase Modeling (DPM) area, including 10 practical exercises.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Discrete Phase Model (DPM) CFD Simulation Package, ANSYS Fluent Training for ADVANCED Users

This CFD training package is prepared for ADVANCED users of ANSYS Fluent software in the Discrete Phase Modeling (DPM) area, including 10 practical exercises. You will learn and obtain comprehensive training on how to simulate projects. The achieved knowledge will enable you to choose the most appropriate modeling approaches and methods for applications and CFD simulations.

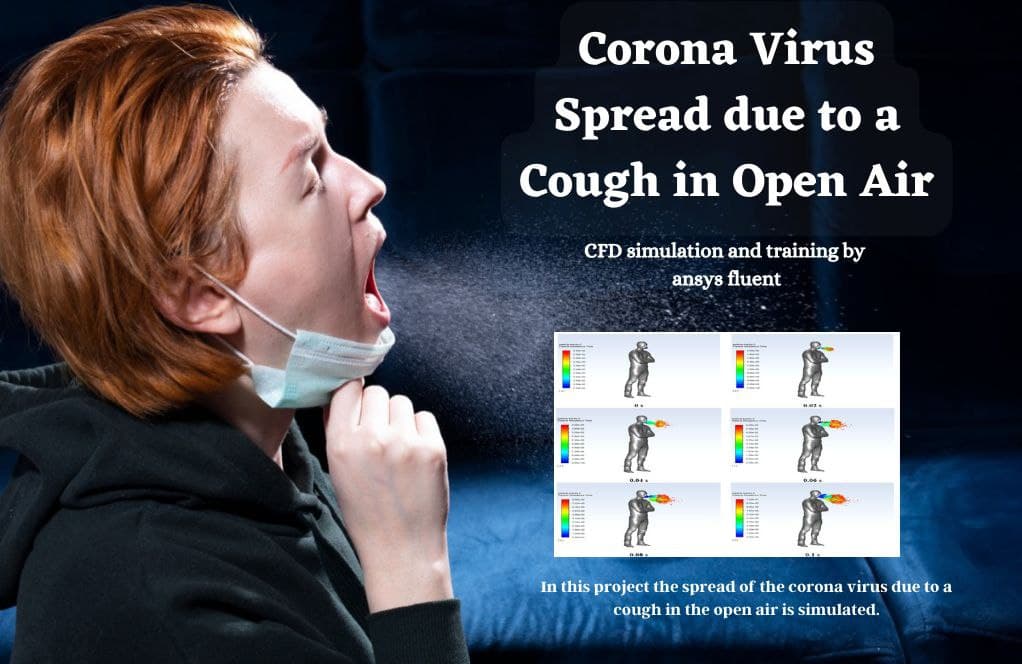

Coronavirus (COVID-19)

Today, the world is facing one of the biggest and most fundamental human challenges called corona disease (Covid 19). This disease’s main and dangerous problem is its high contagious power from an illness to a healthy person. The main way the disease is transmitted from person to person is through viruses in the patient’s oral and nasal secretions. In project number 1, virus particles injected by COUGH in the open air are simulated. Water is defined as a Droplet material, and water vapor is defined as an evaporating gas. These droplets have a temperature of 310 K, a velocity of 31.85 m.s-1, and a flow rate of 0.018 kg.s-1, which are emitted in the interval of 0 s to 0.1 s.

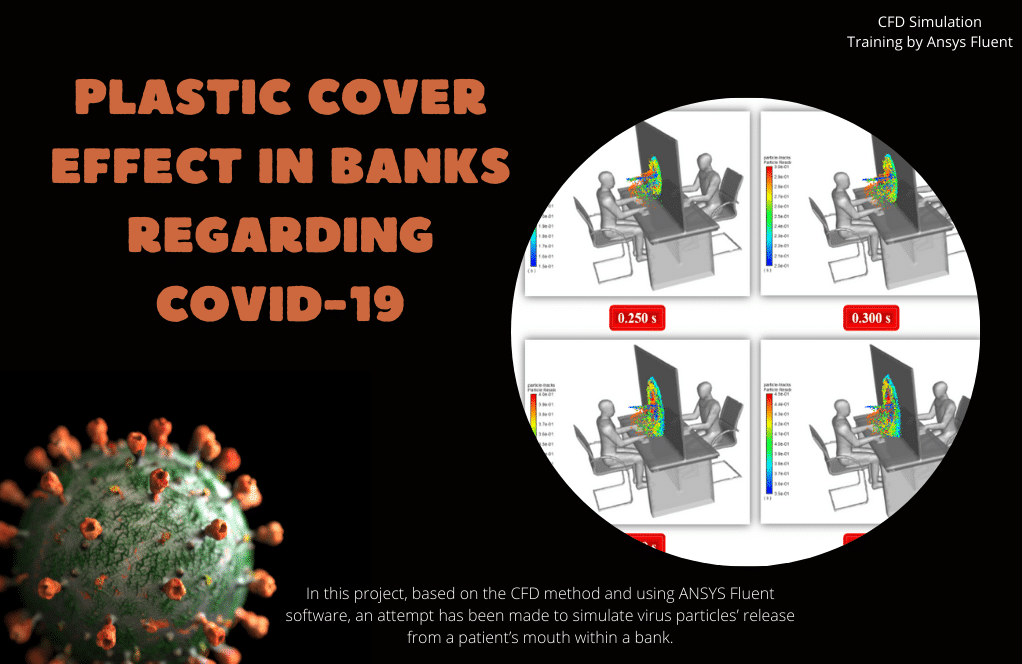

Project number 2 investigates the ability of coronavirus particles to spread inside the bank from a customer to a healthy employee. Three different gases, including oxygen (O2), nitrogen (N2), and water vapor (H2O), activated, and thus the computational area of our model will have airflow. The purpose of this study is to investigate the ability of coronavirus particles to spread inside the bank from a bank customer to a healthy bank employee. This simulation process is performed in two different modes. In the first modeling, no Cover is located between the client and the bank employee to show the virus’s transmission power. In the second model, an attempt is made to make a thin Plastic Cover between them.

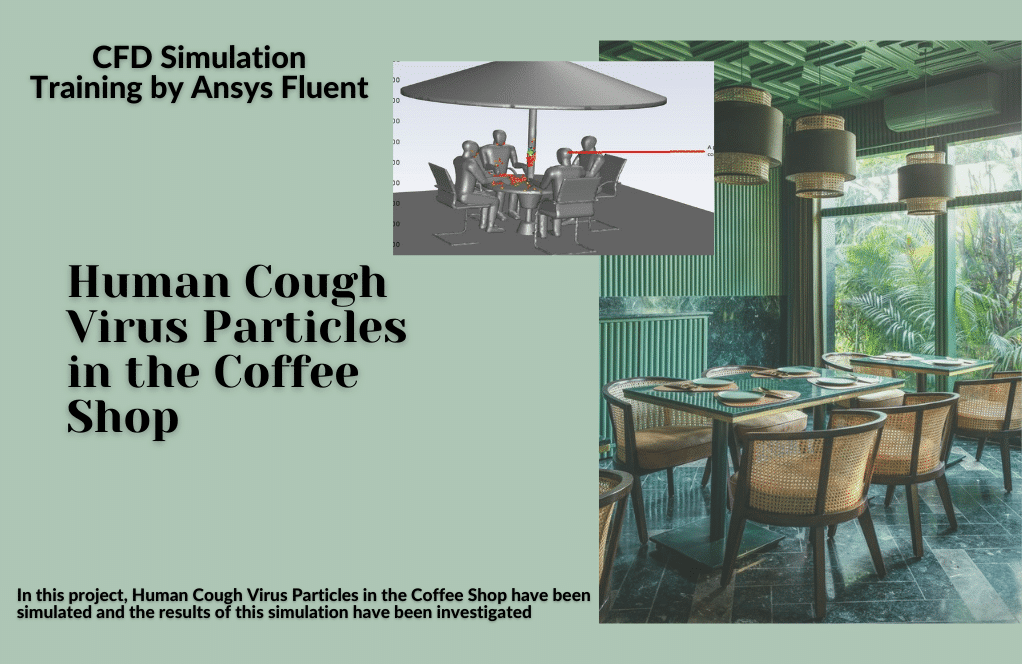

In project number 3, human cough virus particles in the coffee shop have been simulated using two-way DPM. According to this definition of injection, human cough virus particles are physically expelled from the patient’s mouth by water droplets evaporating in space. The boundaries of people’s bodies and all the walls related to the tables and chairs have a WALL FILM mode, and for the floor, use the Trap model, which means that particles are trapped and accumulate on these surfaces.

Industrial Equipments

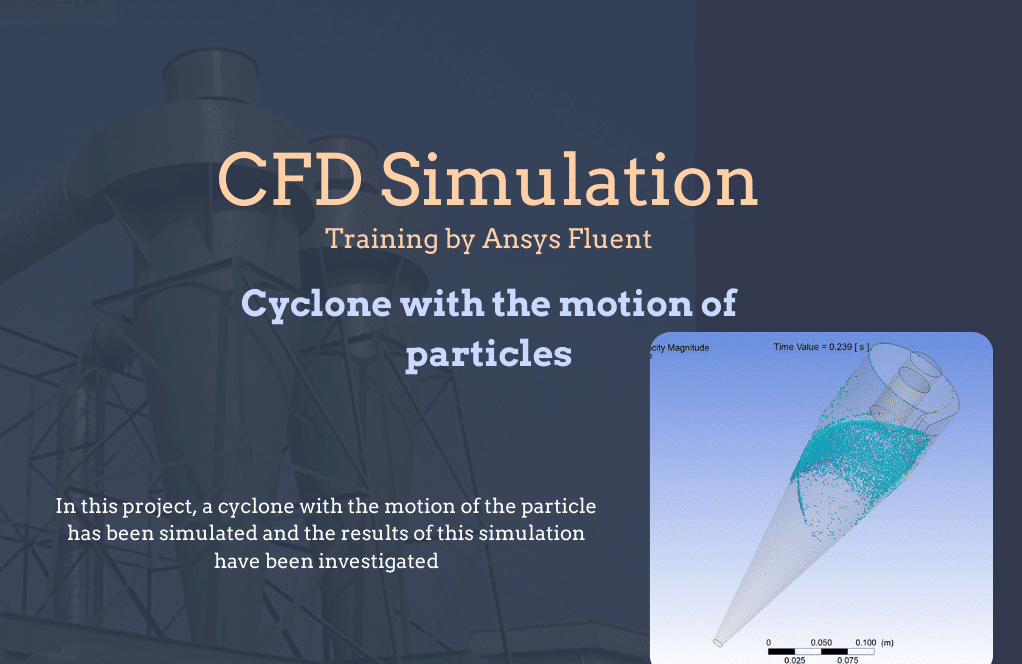

Cyclone Separator is a particulate control system used in industries to control the particulate emissions to the atmosphere. The cyclone separator separates the particles of different sizes from gas by centrifugal force. In project number 4, the motion of particles in a cyclone has been simulated. We used the one-way DPM to simulate the discrete phase.

In project number 5, the motion of particles in a Fly Ash Cyclone has been simulated. We used the one-way DPM to simulate the discrete phase. The gas is treated as a continuum, and Lagrangian tracking tracks individual solid particles through the flow field to determine their position. In cyclone separators, the drag and gravity forces are considered significant due to the large ratio of the gas-particle density.

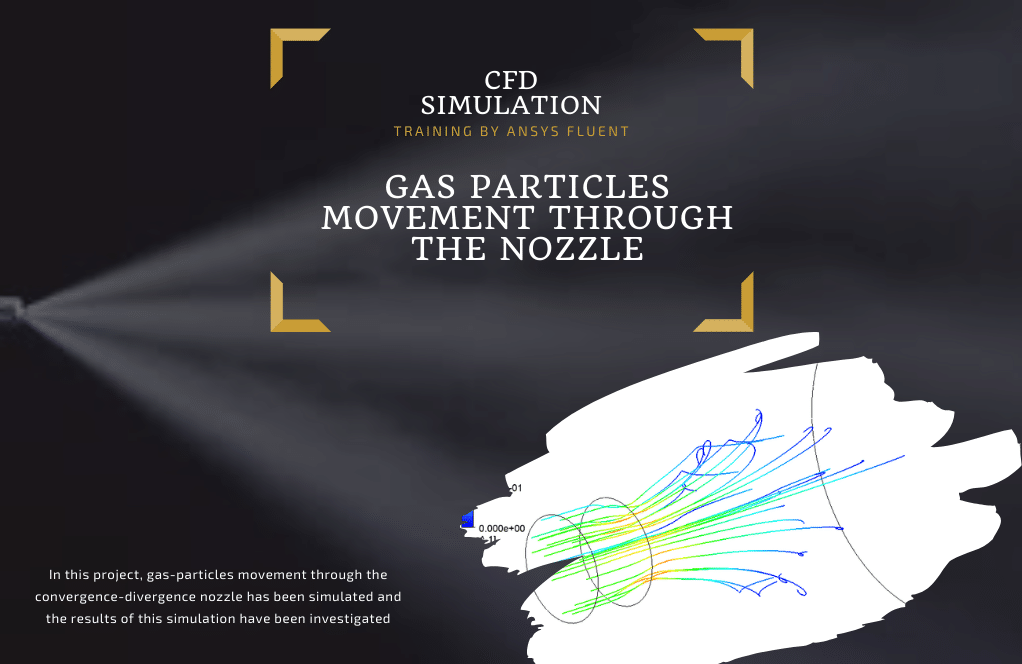

In Project number 6, gas-particles movement through the convergence-divergence nozzle by a Two-way DPM model is simulated. The nozzle is in grossly overexpanded condition. These kinds of nozzles are used in the gas and petrochemical industry.

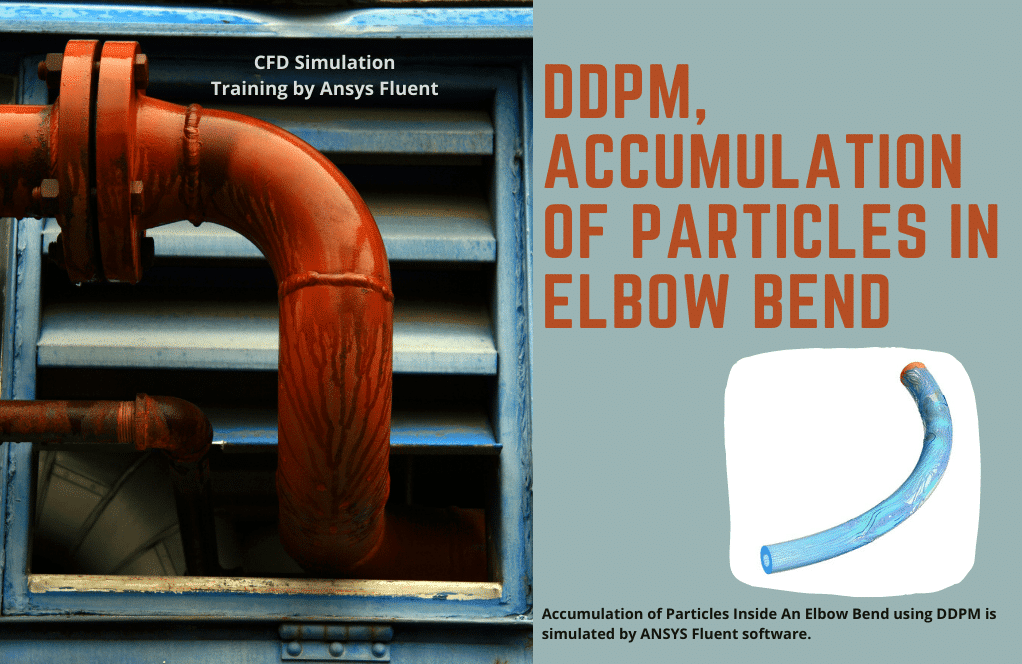

DDPM

While the DPM strategy for CFD solutions proved to be an excellent method to calculate flow particle-flow studies, this approach cannot provide reliable answers for dense particle simulations. As a result, the DDPM (Dense-Discrete-Phase-Method) is mostly employed in CFD projects. For instance, In project number 7, we have simulated a simple elbow bend. However, the fast injection would result in a dense accumulation of particles. Therefore, a dense DDPM model is employed. Our computational domain comprises a 25 [mm] air and particle mass flow annulus of 4.34×10-7 [kg/s]. The diameter of particles considered 10.06×10-12 [m] with a velocity magnitude of 0.09625 [m/s].

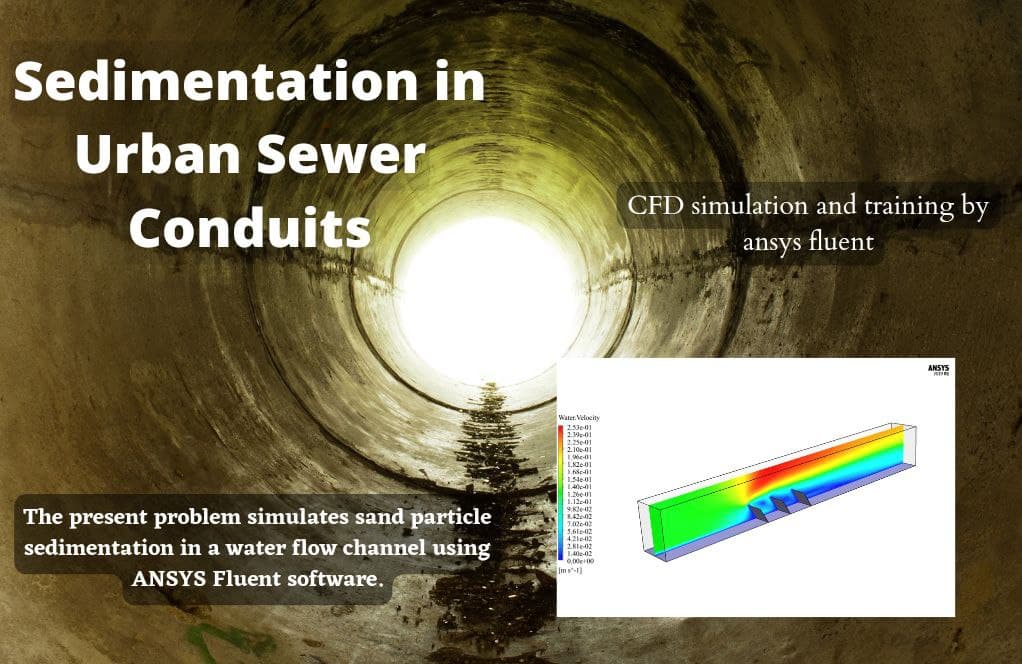

Project number 8 simulates sand particle sedimentation in a water flow channel. The sedimentation phenomenon is one of the destructive phenomena in the quality of performance of any equipment. Sedimentation can occur when the base fluid contains excess soluble particles. In the present simulation, the Eulerian-Lagrangian perspective on computational fluid dynamics (CFD) is used; So that the Eulerian multiphase model is coupled with the dense discrete phase model (DDPM). The material of sand is defined as stagnant particles that have a density equal to 2650 kg.m-3. The water flows with a flow rate of 15 kg.s-1 enters the channel horizontally. Simultaneously, the flow of sand particles enters the channel discretely with a flow rate of 0.21 kg.s-1 and a velocity of 0.083 m.s-1.

Air Conditioning

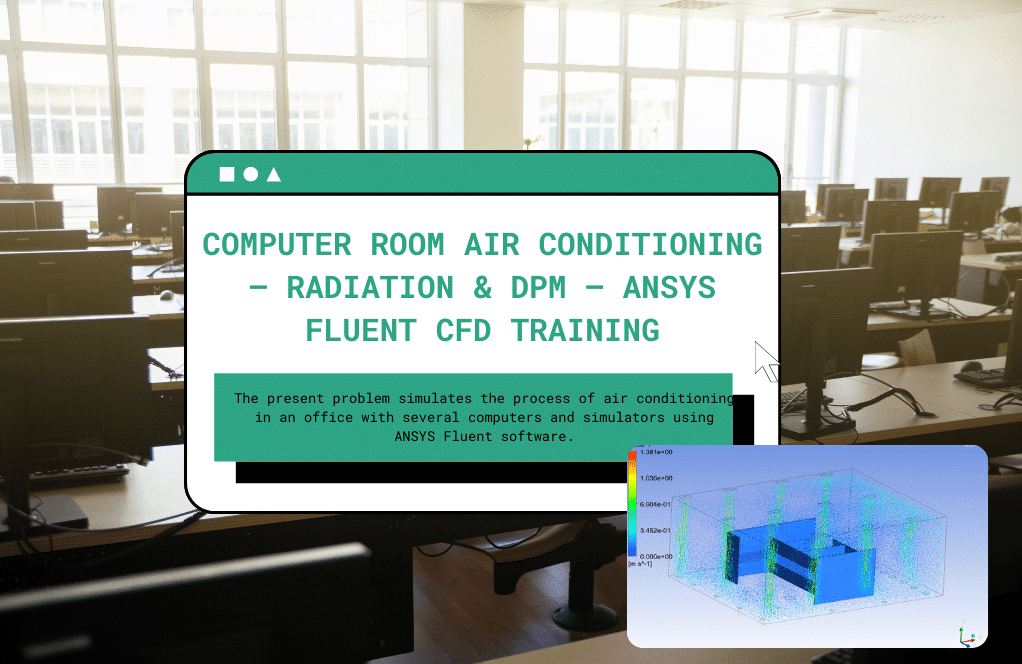

In project number 9, the air conditioning process in an Office with several computers and simulators is simulated. The air conditioning system in the current model is of floor heating and ceiling cooling; In this model, due to the presence of radiant heat transfer between the surfaces inside the office, the radiation model is defined. Also, to study the behavior of airflow and the type of its circulation inside the interior of the office, particles are defined using the DPM model of inlet sections.

Decomposition (DPM)

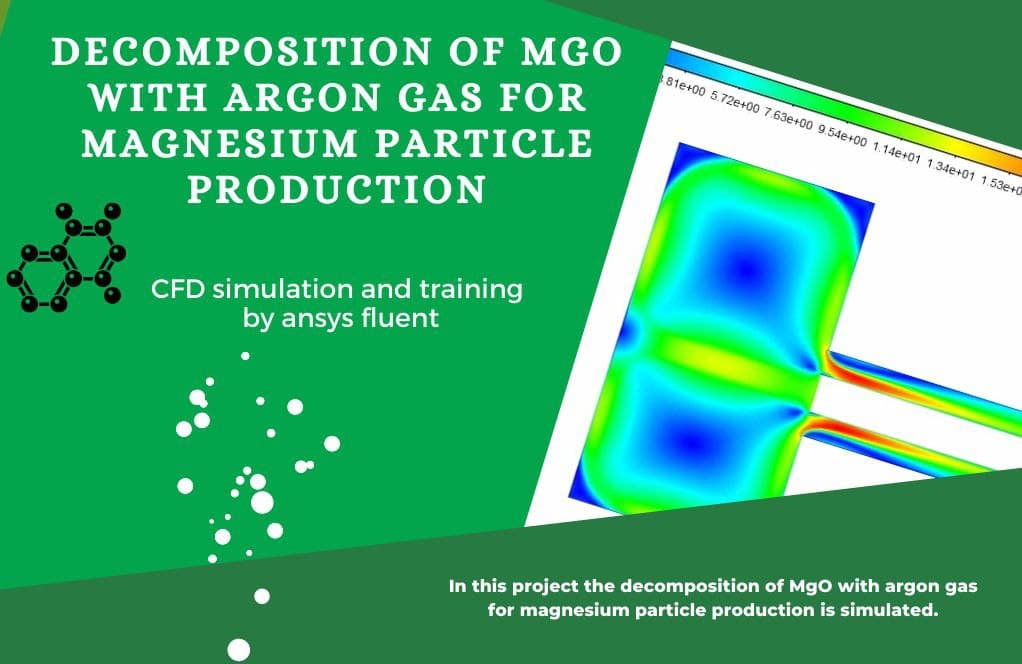

Thermal decomposition, or thermolysis, is a chemical decomposition caused by heat. The decomposition temperature of a substance is when the substance chemically decomposes. The reaction is usually endothermic as heat is required to break chemical bonds in the compound undergoing decomposition. In project number 10, According to the following equation, the decomposition reaction of magnesium oxide is endothermic, and this process is done by preheating through argon gas.

MgO(s)→Mg(s)+O2(g)

Reviews

Related products

-

Gasification in Gasifier Chamber, P1 Radiation Model

Rated 4.83 out of 5$240.00$120.00 Student Discount

Ms. Dorothea Powlowski –

Does the package cover the effect of chemical reactions on particle behavior?

MR CFD Support –

Yes, indeed. The package includes exercises that delve into the effect of chemical reactions on particle behavior. This is particularly useful in processes where chemical reactions play a significant role.

Prof. Clark Moore –

Can the package simulate particle breakage and coalescence?

MR CFD Support –

Absolutely. The package includes exercises that cover particle breakage and coalescence. These are important phenomena in many industrial processes, and our package ensures you’re well-equipped to simulate them

Oscar Rempel MD –

Does this package cover the effect of the particle’s temperature on its behavior?

MR CFD Support –

Yes, it does. The package includes exercises that explore the effect of the particle’s temperature on its behavior. This is particularly useful in processes where heat transfer plays a significant role.

Greyson Monahan –

I’m interested in simulating particle-wall interactions. Does the package cover that?

MR CFD Support –

Absolutely. The package includes exercises that focus on particle-wall interactions. This is particularly useful in predicting erosion or deposition in various industrial equipment.