DPM Applications in Engineering Systems: Basic Training Package (Level 2), 15 Practical Exercises

$299.00 $149.50 Student Discount

Short Description

- Advanced DPM training package featuring 15 comprehensive ANSYS Fluent examples, designed for engineers and CFD practitioners seeking practical expertise.

- Covers diverse industrial applications including cyclone separators, spray systems, particle transport, and environmental engineering challenges.

- Focuses on real-world scenarios such as medical inhalers, gas turbine intakes, dehumidification systems, and nanoparticle processing.

- Builds upon fundamental DPM concepts with emphasis on time-dependent analysis, optimization techniques, and design improvements.

- Includes complete simulation files, step-by-step tutorials, and detailed documentation for each case study.

- Suitable for professionals and researchers working in process engineering, HVAC systems, the pharmaceutical industry, and environmental applications.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Course Overview

This advanced training builds upon Level 1 fundamentals, offering deeper insights into practical DPM applications through detailed case studies and industrial examples.

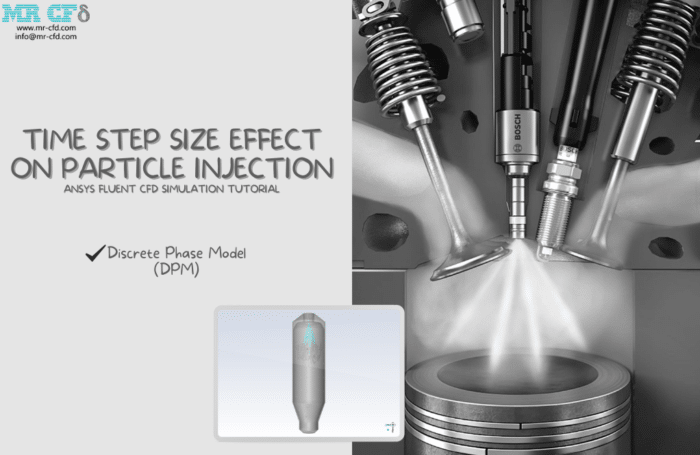

Module 1: Time-Dependent Particle Dynamics

The initial segment focuses on temporal aspects of particle behavior, featuring combustion chamber analysis and medical inhaler applications. Students master time-step sensitivity and particle-fluid interaction dynamics.

Module 2: Industrial Separation Systems

Topics 4-7 delve into industrial separation processes, with extensive coverage of cyclone separators. Participants analyze particle collection efficiency, pressure drop optimization, and various operational parameters in different cyclone configurations.

Module 3: Environmental and HVAC Applications

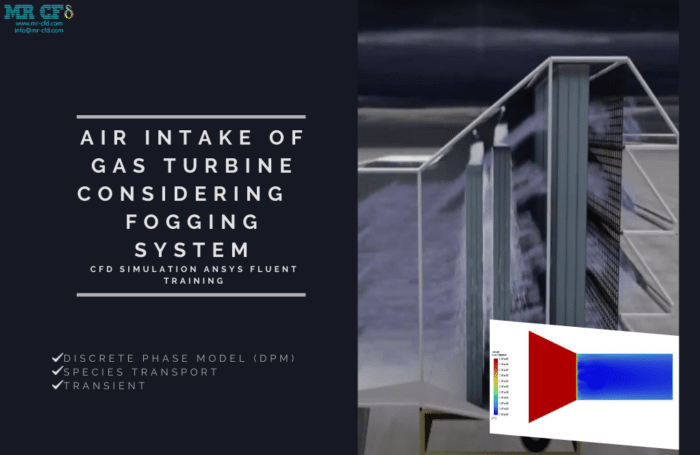

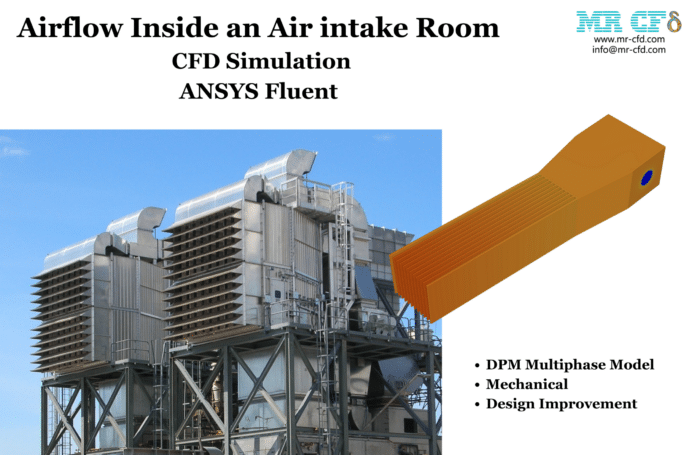

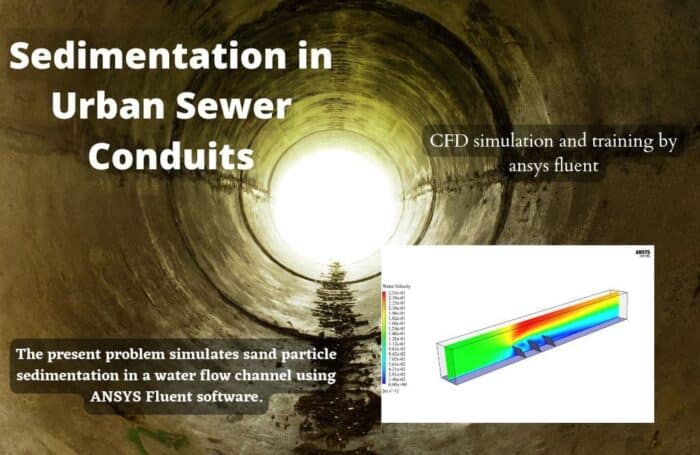

Topics 5, 8, and 9 address environmental engineering challenges, including sewer sediment transport and air quality management. Students work with dehumidification systems and gas turbine intake applications.

Module 4: Spray Systems and Erosion Analysis

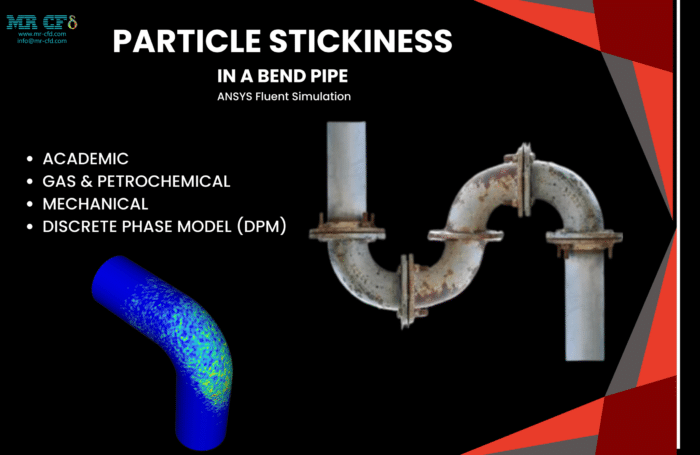

Topics 10-11 cover practical spray applications and erosion phenomena, focusing on consumer products and industrial equipment protection. Participants learn optimization techniques for spray patterns and erosion mitigation.

Module 5: Advanced Particle Processing

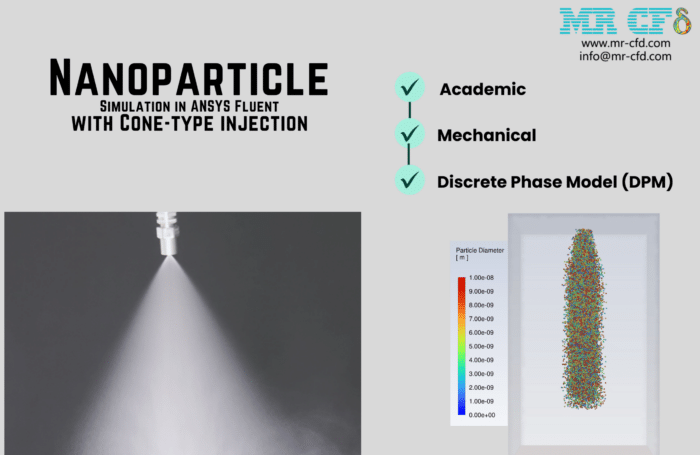

The final segment (topics 12-15) explores specialized applications including nanoparticle injection, chemical decomposition processes, and air purification systems. Students develop skills in complex multi-phase flow and Fuel Injection analysis and design optimization.

Learning Outcomes

By completion, participants will master:

– Time-dependent particle tracking

– Industrial separator design principles

– Environmental particle transport

– Spray system optimization

– Advanced particle processing techniques

This course is ideal for engineers, researchers, and industry professionals seeking practical expertise in advanced DPM applications.

Reviews

There are no reviews yet.