DPM Applications in Engineering Systems: Intermediate Training Package (Level 3), 10 Practical Exercises

$299.00 $149.50 Student Discount

- Advanced DPM training package featuring 10 complex ANSYS Fluent examples, focusing on multi-phase interactions and industrial equipment simulation.

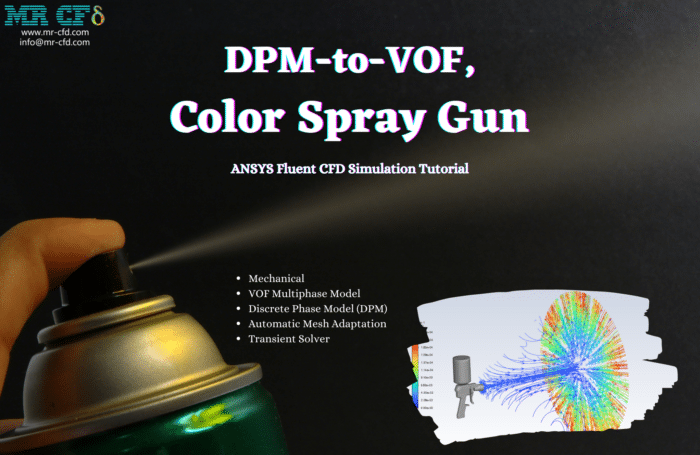

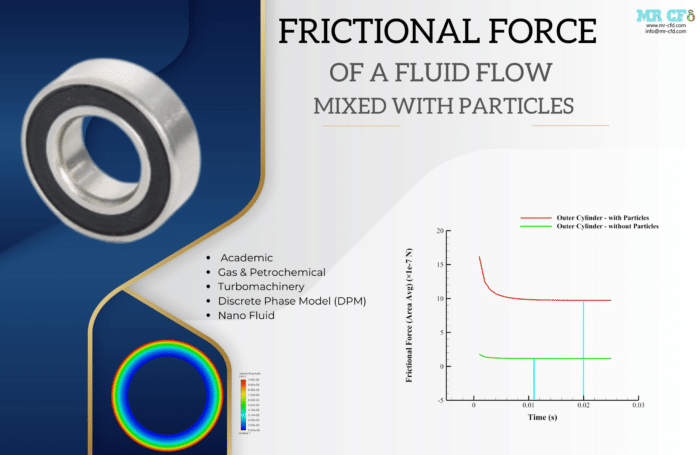

- Specializes in advanced particle modeling techniques including DDPM, VOF-DPM coupling, and erosion prediction in critical equipment.

- Covers high-value industrial applications such as spray coating systems, turbomachinery, and fluid-particle interaction analysis.

- Emphasizes practical challenges in equipment reliability, focusing on erosion prediction, particle accumulation, and surface interaction.

- Includes comprehensive simulation files, advanced modeling techniques, and detailed guidelines for complex multi-phase scenarios.

- Designed for experienced CFD engineers and researchers working in manufacturing, power generation, and process industries.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Course Overview

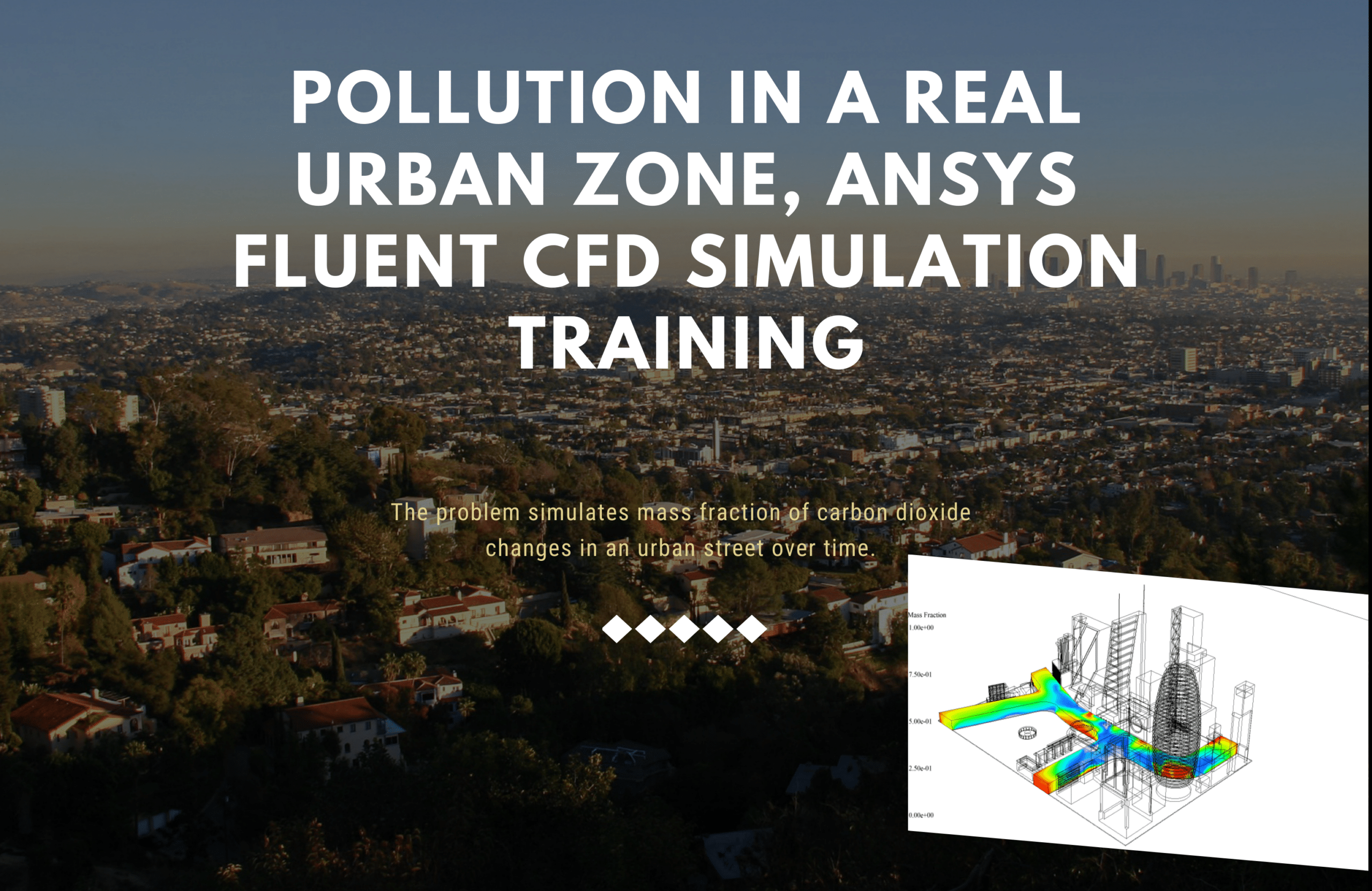

An advanced-level training program that bridges sophisticated particle modeling techniques with critical industrial applications (DPM applications), focusing on equipment reliability and process optimization.

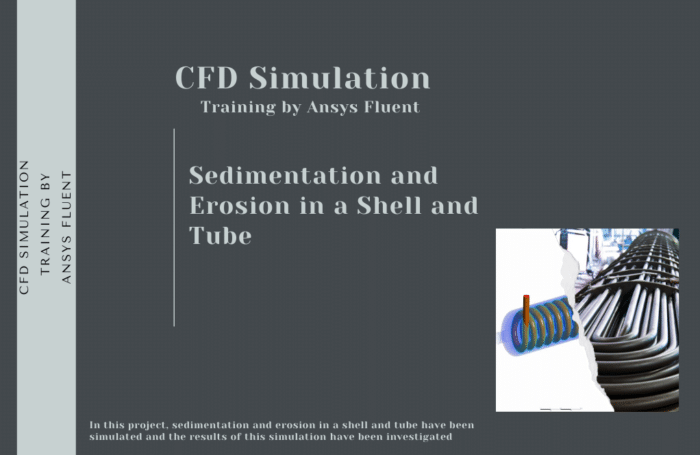

Module 1: Industrial Equipment Protection

Topics 1-2 address critical challenges in process equipment, covering:

– Sedimentation and erosion analysis in heat exchangers

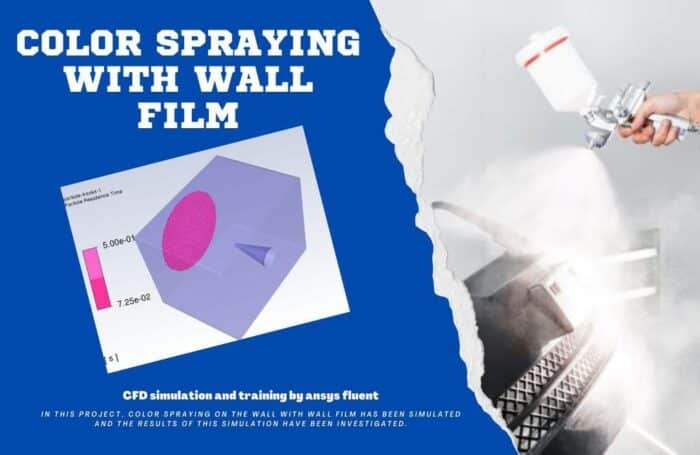

– Advanced spray coating with wall film interaction

– Surface treatment and protection strategies

Module 2: Separation and Particle Transport

Topics 3-5 focus on specialized separation applications:

– Mist eliminator design optimization

– Particle-fluid interaction analysis

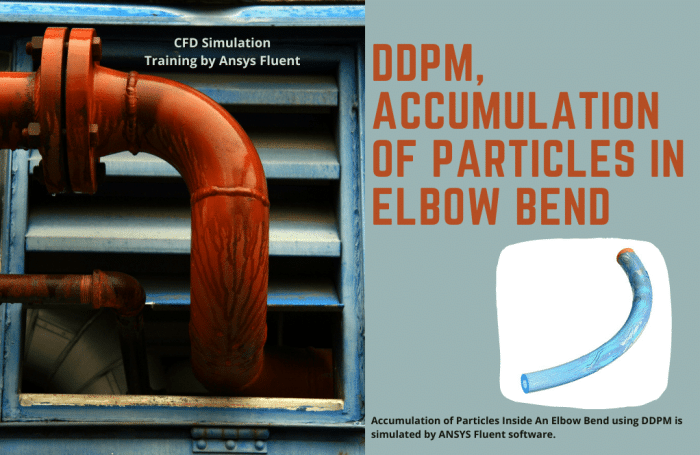

– Dense particle transport using DDPM

Module 3: Advanced Multi-Phase Modeling

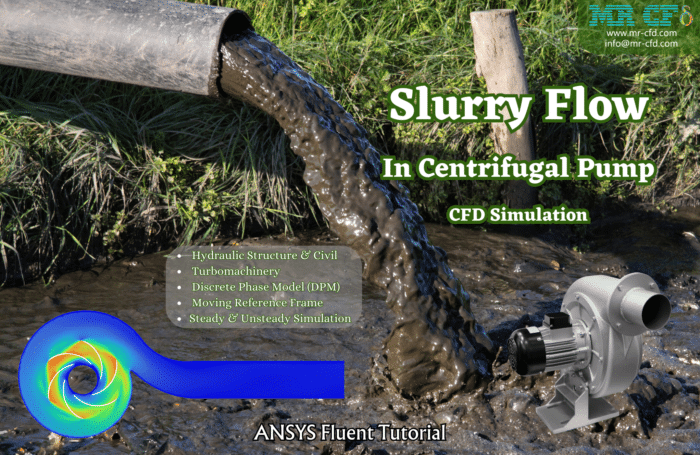

Topics 6-7 explore complex multi-phase scenarios:

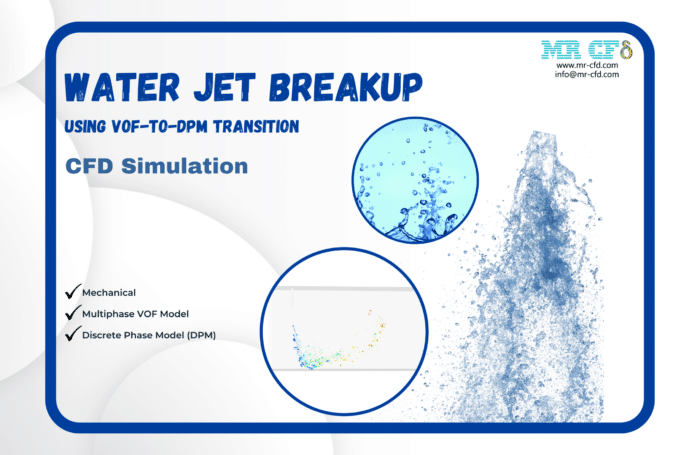

– VOF-DPM coupling techniques

– Spray gun simulation with phase transition

– Slurry erosion in rotating equipment

Module 4: Industrial Applications

Final topics (8-10) integrate advanced concepts:

– Hydropower equipment erosion analysis

– Liquid jet breakup phenomena

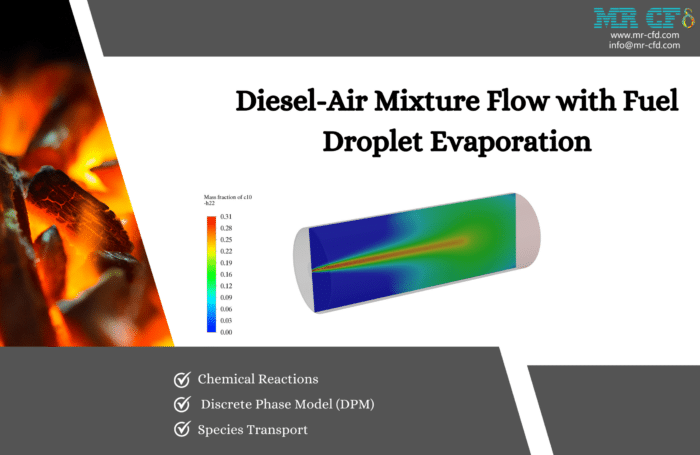

– Fuel spray evaporation and mixing

Learning Outcomes

Participants will master:

– Advanced particle modeling techniques

– Multi-phase coupling methods

– Equipment reliability prediction

– Complex industrial process optimization

– Advanced erosion analysis

This course is specifically designed for experienced CFD practitioners requiring advanced particle modeling capabilities for complex industrial applications.

Reviews

There are no reviews yet.