DPM Applications in Engineering Systems: Expert Training Package (Level 5), 8 Practical Exercises

$399.00 $199.50 Student Discount

- Expert-level DPM training package featuring 8 highly specialized ANSYS Fluent examples, focusing on complex industrial processes and advanced particle-fluid interactions.

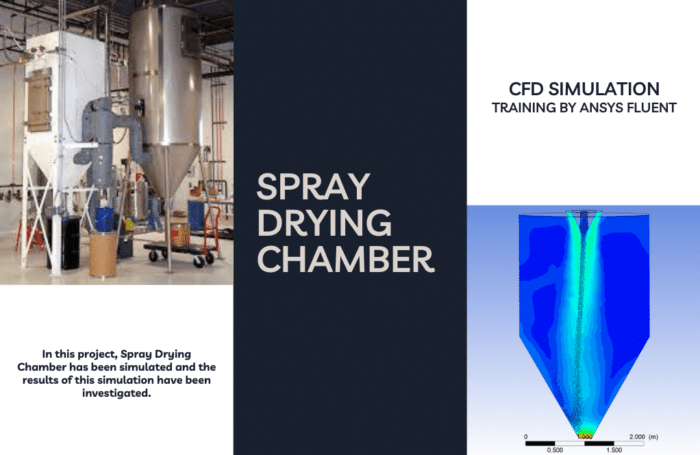

- Covers sophisticated applications including spray drying, fluidized bed systems, gasification, and magnetic separation technology.

- Integrates multiple physics phenomena including radiation models, magnetic fields, phase changes, and advanced particle tracking.

- Emphasizes industrial-scale equipment simulation with complex geometries and challenging operating conditions.

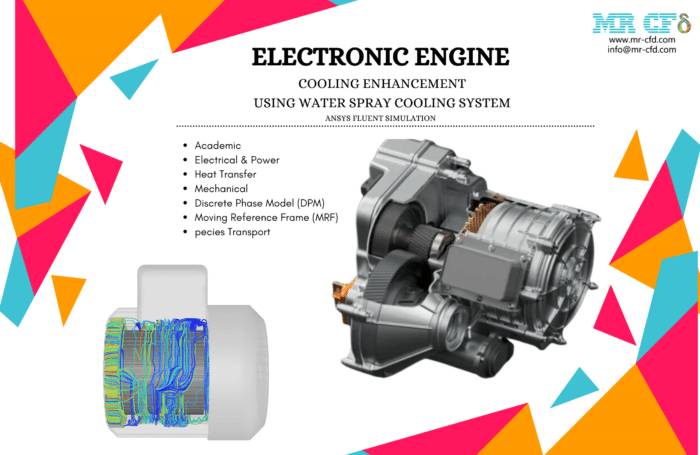

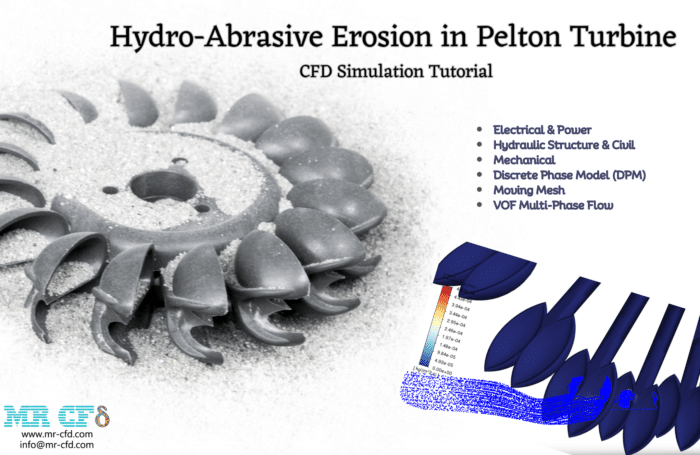

- Includes advanced modeling techniques for specialized applications like hydro-abrasive erosion in turbines and thermal management systems.

- Designed for industry experts and researchers requiring mastery in specialized particle-fluid applications and industrial process optimization.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Course Overview

An expert-level program focusing on complex industrial applications (DPM Applications), combining advanced particle modeling with specialized physics and industrial process optimization.

Module 1: Advanced Process Equipment

Topics 1-3 cover sophisticated industrial processes:

– Hydro-abrasive erosion in turbomachinery

– Circulating fluidized bed systems

– Multi-phase heat transfer

– Advanced particle-wall interactions

Module 2: Thermal Processing Systems

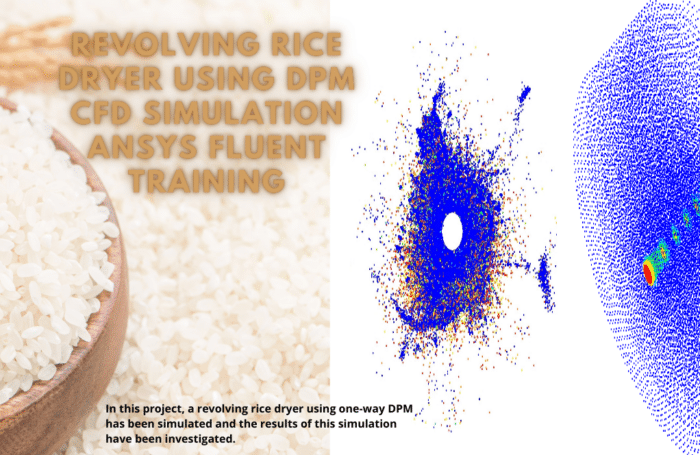

Topics 4-5 focus on thermal applications:

– Radiation modeling

– Rotating equipment simulation

– Particle drying dynamics

– Heat and mass transfer optimization

Module 3: Specialized Industrial Applications

Topics 6-8 address unique challenges:

– Magnetic separation technology

– Particle classification

– Process efficiency optimization

Advanced Technical Components

– Complex geometry handling

– Custom field functions

– UDF implementation

– Advanced post-processing

– Performance optimization strategies

Learning Outcomes

Participants will master:

– Industrial-scale process simulation

– Complex multi-physics modeling

– Advanced particle tracking methods

– Equipment design optimization

– Industrial process troubleshooting

This course is specifically designed for industry experts and researchers working on specialized industrial processes requiring advanced particle modeling capabilities.

Reviews

There are no reviews yet.