Dynamic Mesh Concepts in ANSYS Fluent

Free

- Introduction to Dynamic Mesh Model in ANSYS Fluent software

- Introduction to Mesh Update Methods (Smoothing, Layering, Remeshing)

- Introduction to Options (In-Cylinder, Six DOF, Implicit Update, Contact Detection)

- Introduction to Dynamic Mesh Zones (Stationary, Rigid Body, Deforming, User-Defined, System Coupling)

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Introduction to Dynamic Mesh Concepts

This video aims to talk about Dynamic Mesh Concepts. This lesson will give you a general introduction to the dynamic mesh and an overview of available sections of dynamic mesh settings in ANSYS Fluent.

This product is the first chapter of the Dynamic Mesh Training Course.

We introduce the working environment of the dynamic mesh model in three different sections. This introduction will be detailed and comprehensive, So you will not have any questions after reading it.

In the first section, we will introduce you to Mesh Update Methods. When the computational zone or its boundaries are moved or deformed, how are the meshing of the model and its cells updated?

There are three mesh update methods available:

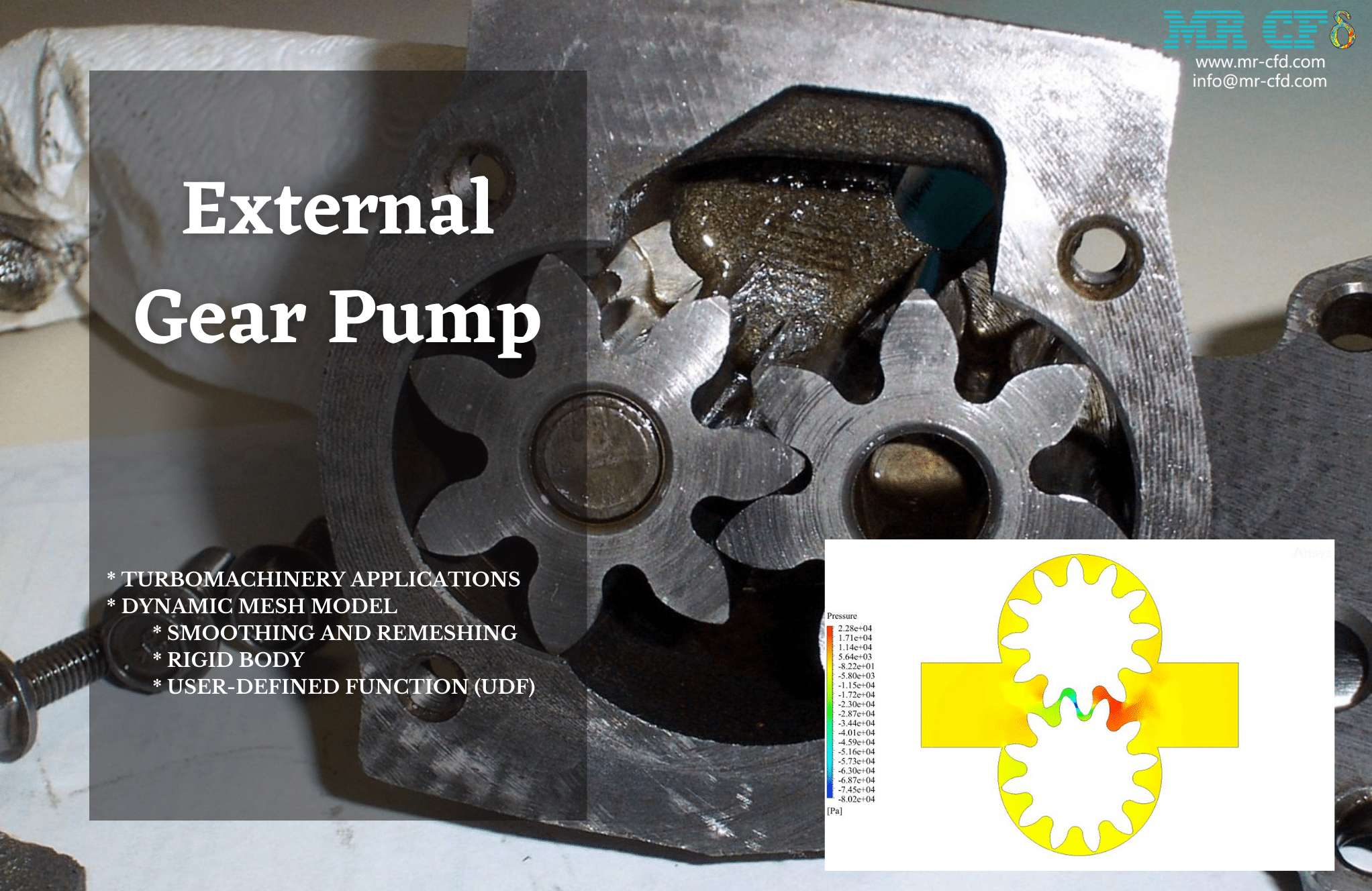

- Smoothing (spring/Laplace/boundary layer, diffusion, linearly elastic solid)

- Layering

- Remeshing (local cell, local face, face region, 2.5D)

In the second section, we will introduce you to the Options part of the dynamic mesh model. Here, we can use unique dynamic mesh models according to the modeling of our case study.

These Options include:

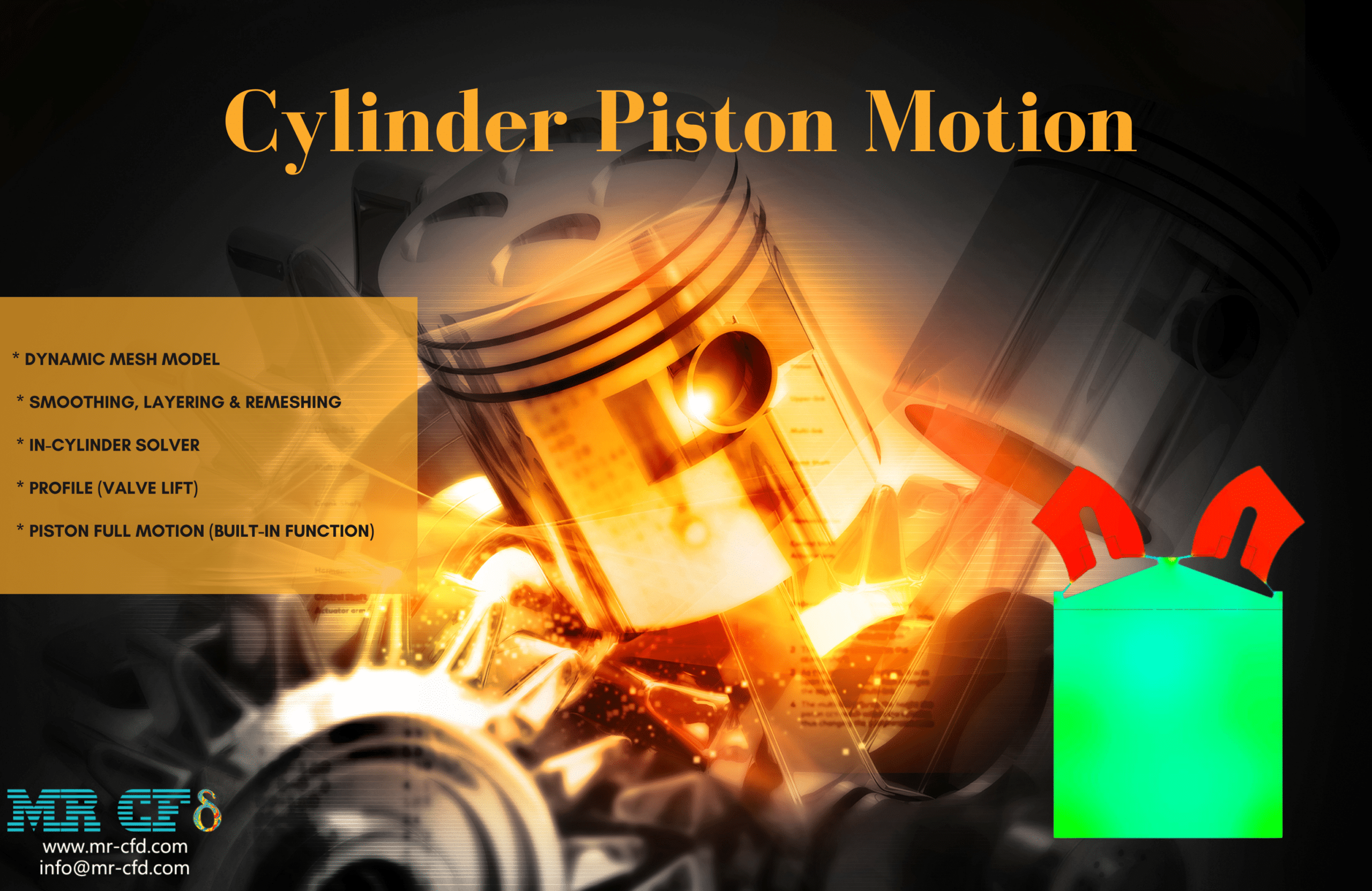

- In-Cylinder

- Six DOF

- Implicit Update

- Contact Detection

In the third section, we will introduce you to Dynamic Mesh Zone. Here, we determine the movement or deformation of the dynamic zones. In the settings of this section, we specify how the boundaries move or how the zones deform.

The types of dynamic behaviors available to apply to boundaries and regions are:

- Stationary

- Rigid Body

- Deforming

- User-Defined

- Coupling System

Prof. Jimmy Durgan –

I am truly fascinated by how the dynamic mesh adapts to movement. However, can you explain how the ‘In-Cylinder’ option among the dynamic mesh models is particularly used?

MR CFD Support –

Absolutely, ‘In-Cylinder’ is one of the specialized dynamic mesh models. It is used to simulate the internal moving parts of cylindrical structures, such as pistons in an engine. This option allows for the mesh to update accurately as the piston moves within the cylinder, adjusting the size and shape of the mesh cells accordingly to maintain a high-quality mesh throughout the simulation.

Angie Rohan –

What are the different mesh update methods explained in the video, and how do they relate to the simulation scenarios?

MR CFD Support –

In the video, three mesh update methods are elaborated: Smoothings such as spring method, and Laplace method, which help adjust mesh under motion without remeshing. Layering for adding or removing layers in boundary zones during mesh motion, particularly useful in simulating pistons or valves. Remeshing allows complete reconstruction of mesh in parts of the domain, crucial for large deformations. Each update method caters to different dynamic scenarios, providing flexibility in simulating complex motions.

Kenneth Schamberger –

I am really pleased with the clear explanation of dynamic mesh concepts provided in this training product. It was quite detailed and I understand the concepts better now.

MR CFD Support –

Thank you for the positive feedback! We are thrilled to hear our Dynamic Mesh Concepts video was helpful in clarifying this complex topic for you. If you have any further questions or need additional information, please don’t hesitate to reach out.

Jimmy Runolfsdottir Sr. –

I just finished the ‘Dynamic Mesh Concepts in ANSYS Fluent’ course and it was fascinating! I love how in-depth the video goes, especially with the Mesh Update Methods. It’s clear that a lot of thought went into creating these learning materials.

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that you found the ‘Dynamic Mesh Concepts in ANSYS Fluent’ course detailed and insightful. It’s great to know that our efforts to create comprehensive learning materials are appreciated by our customers. If you ever need further assistance or have any more feedback, we’re here to help!

Rosina Tromp –

The video sounds very informative! Can the dynamic mesh concepts presented here be applied to any types of simulations or are they specific to certain cases?

MR CFD Support –

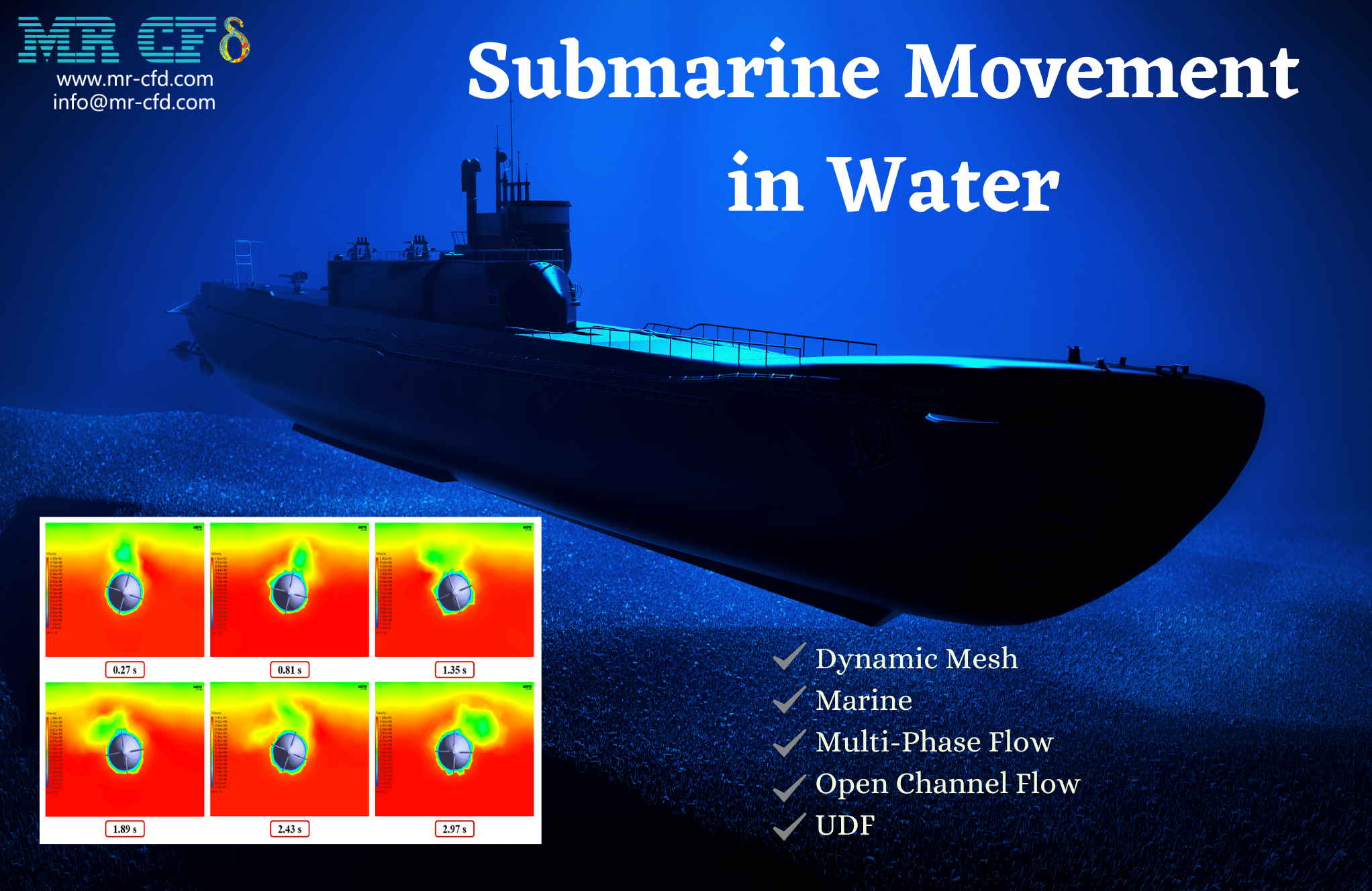

Thank you for your kind words! The dynamic mesh concepts introduced in this chapter of the Dynamic Mesh Training Course are versatile and can be applied to a variety of simulations where mesh adaptation is necessary. These include cases involving moving parts, deformable boundaries, fluid-structure interactions, and complex fluid motions. While the principles are broadly applicable, the specific application and setup may vary depending on the case study’s unique characteristics and requirements.

Ana Gutkowski –

I just finished the first chapter of the Dynamic Mesh Training Course on ‘Dynamic Mesh Concepts in ANSYS Fluent’—well-explained and elaborate. However, it left me curios—are there predefined motions or interactions within the Fluent software that would typically use the Six DOF (six degrees of freedom) solver?

MR CFD Support –

Thank you for the positive feedback on our Dynamic Mesh Training Course’s first chapter. Yes, the Six DOF (six degrees of freedom) solver within ANSYS Fluent handles the motion of objects that are free to move in all three translational and all three rotational axes. This solver is often used for simulations involving floating bodies, moving bodies in a fluid domain (like vehicles or aircraft maneuvers), or even cases with multiple interacting bodies. It’s particularly useful when the movements of the object are not predefined and result from the fluid forces and moments acting on the object.

Prof. Gust Stehr I –

I just finished the Dynamic Mesh Concepts course and I am impressed with the depth of content! But I do have one query: how does the local cell remeshing affect overall simulation accuracy in complex moving geometries?

MR CFD Support –

I’m glad to hear that our course has been insightful for you! Regarding your question, local cell remeshing can significantly affect simulation accuracy in complex moving geometries. Remeshing updates small regions of the mesh to prevent highly skewed cells as the geometry deforms, helping ensure that numerical errors remain low. Accurate predictions depend on maintaining a good-quality mesh throughout the simulation, even as the geometry moves and deforms. Sensitivity runs are recommended to determine the specific impact on each project.

Walton Sipes –

I just wanted to compliment this overview on Dynamic Mesh Concepts. I found it really comprehensive and didn’t have any questions after reading. It laid a great foundation for my understanding of dynamic meshing in ANSYS Fluent!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our introduction to Dynamic Mesh Concepts provided you with a clear and comprehensive understanding. Your satisfaction is our top priority, and we’re thrilled that our product met your expectations.

Juana Moore –

I’m new to using ANSYS Fluent for simulations with dynamic meshes. How do I go about choosing the right mesh update method for my project?

MR CFD Support –

Choosing the right mesh update method in ANSYS Fluent for your project depends on the nature of the boundaries and interactions you’re modeling. Smoothing might be suitable for small deformations or when boundaries move slightly, Layering can be great for boundary motions that cause topological changes like rotational elements, and Remeshing is ideal for large deformations or highly dynamic interactions. Consider your project’s specifics and, if needed, consult the comprehensive Dynamic Mesh Training Course to understand the conditions and constraints for each method.

Selena Kling –

What are the prerequisites for understanding the material covered in the ‘Dynamic Mesh Concepts in ANSYS Fluent’ video?

MR CFD Support –

To fully grasp the material covered in the ‘Dynamic Mesh Concepts in ANSYS Fluent’ video, it is beneficial to have a basic understanding of fluid dynamics, some experience with CFD analysis, and familiarity with the ANSYS Fluent software interface. Prior knowledge of general meshing concepts would also be helpful.