Ejector CFD Simulation Training Package, 5 Projects by ANSYS Fluent

$399.00 $199.50 Student Discount

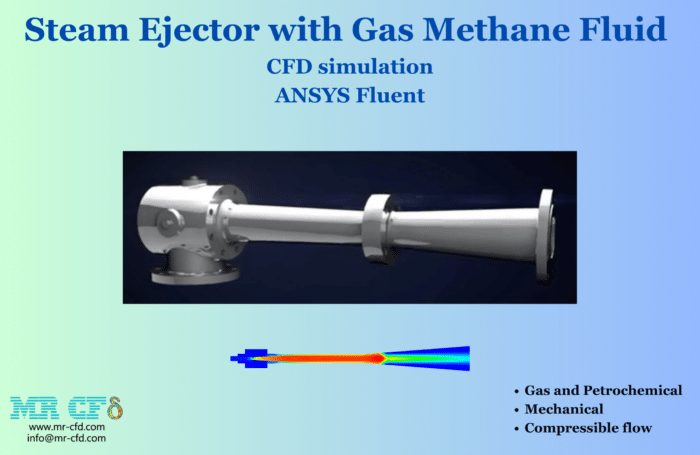

- Steam Ejector with Gas Methane Fluid CFD Simulation: Master gas-gas interaction modeling in steam ejectors with methane as secondary fluid

- Wet Steam for Condensation inside a Steam Ejector: Understand phase change physics and condensation modeling approaches

- Ejector Two-Phase Flow CFD Simulation: Explore VOF, Eulerian, and mixture models for two-phase flow simulation

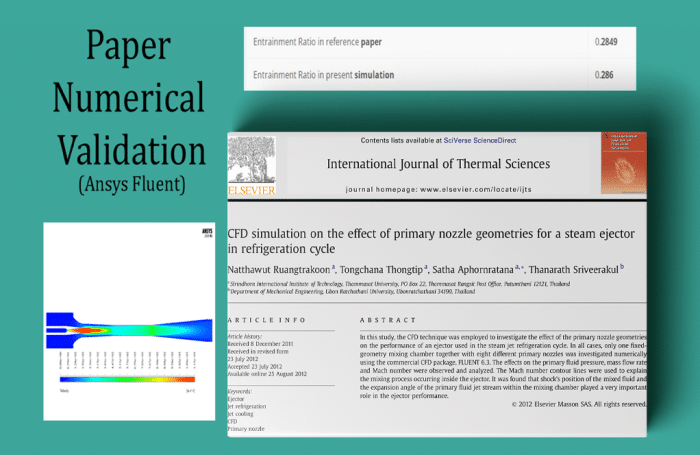

- Steam Ejector in Refrigeration Cycle, Paper Validation: Validate simulation results against published research data

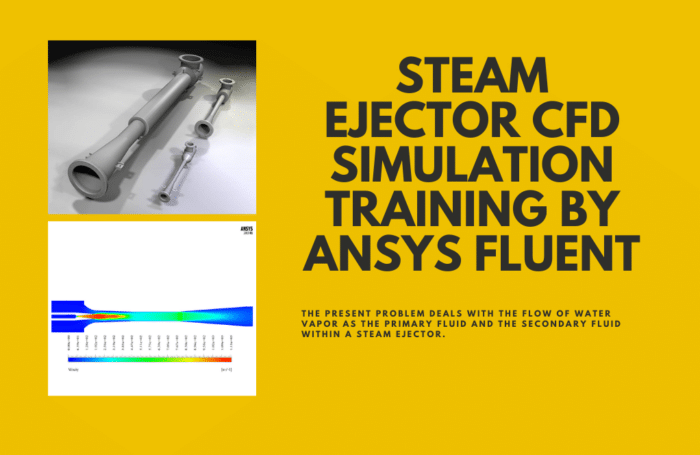

- Steam Ejector ANSYS Fluent CFD Simulation Tutorial: Set up basic steam ejector simulations with proper boundary conditions

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Comprehensive ANSYS Fluent Ejector Simulation Training

Overview of Ejector CFD Simulation Training

This comprehensive training package offers in-depth instruction on Computational Fluid Dynamics (CFD) simulation of ejectors using ANSYS Fluent, one of the industry’s leading simulation platforms. Designed for engineers, researchers, and graduate students, this course bridges theoretical knowledge with practical simulation skills essential for ejector design and optimization.

Industrial Applications and Simulation Importance

Industrial Applications and Importance

Ejectors are critical components in various industrial applications including refrigeration, desalination, and vacuum generation. Their performance optimization requires sophisticated simulation approaches to capture complex flow phenomena including supersonic flows, shock waves, mixing of different fluids, and phase change processes.

Core Simulation Modules and Techniques

Foundational Module: Steam Ejector Simulation Basics

Starting with fundamental concepts, the package progressively builds toward advanced simulation techniques. The Steam Ejector ANSYS Fluent CFD Simulation Tutorial provides essential foundations, covering geometry creation, meshing strategies specific to ejector flow passages, boundary condition setup, and solution initialization techniques. Participants will learn to interpret simulation results and extract key performance indicators.

Advanced Gas Dynamics Simulation

Advanced Gas Dynamics: Methane-Steam Interaction

The Steam Ejector with Gas Methane Fluid CFD Simulation module extends these skills to multi-species flows, focusing on the interaction between steam as primary fluid and methane as secondary fluid. This module addresses the challenges of simulating different molecular weight gases, compressibility effects, and appropriate turbulence modeling for accurate prediction of entrainment ratios and pressure recovery.

Phase Change and Condensation Modeling

Phase Change Phenomena in Ejectors

For applications involving phase change, the Wet Steam for Condensation inside a Steam Ejector module introduces specialized models for condensation phenomena. Participants will implement non-equilibrium condensation models, analyze nucleation and droplet growth, and evaluate how condensation affects the overall ejector performance and efficiency.

Two-Phase Flow Simulation Approaches

Multiphase Flow Modeling Techniques

The Ejector Two-Phase Flow CFD Simulation module tackles the complexities of liquid-gas interactions within ejectors. Through hands-on exercises, participants will explore various multiphase modeling approaches in ANSYS Fluent, learn to set appropriate interphase exchange coefficients, and develop skills for troubleshooting convergence challenges in these complex simulations.

Validation and System Integration Methods

Validation and System Integration

The package culminates with the Steam Ejector in Refrigeration Cycle, Paper Validation module, where simulation methodologies are validated against published experimental data. This module emphasizes the importance of validation in computational studies and demonstrates how ejector models can be integrated into complete system simulations for refrigeration applications.

Learning Resources and Expected Outcomes

Learning Resources and Outcomes

Each module includes step-by-step tutorials, sample case files, and comprehensive explanation of the underlying physics and numerical methods. Upon completion, participants will possess both the theoretical understanding and practical skills needed to conduct advanced ejector simulations for research or industrial applications.

Reviews

There are no reviews yet.