Ejector Two-Phase Flow CFD Simulation, ANSYS Fluent

$100.00 $50.00 Student Discount

In this project, a two-phase flow of vapor and liquid ammonia in a two-phase ejector has been simulated by ANSYS Fluent software.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Ejector CFD Simulation, Two-Phase Flow, ANSYS Fluent Training

In general, an ejector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower-pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts, except a valve to control inlet flow. A steam ejector is a typical application of the principle used to deliver cold water to a boiler against its pressure, using its own live or exhaust steam, replacing any mechanical pump.

Project Description

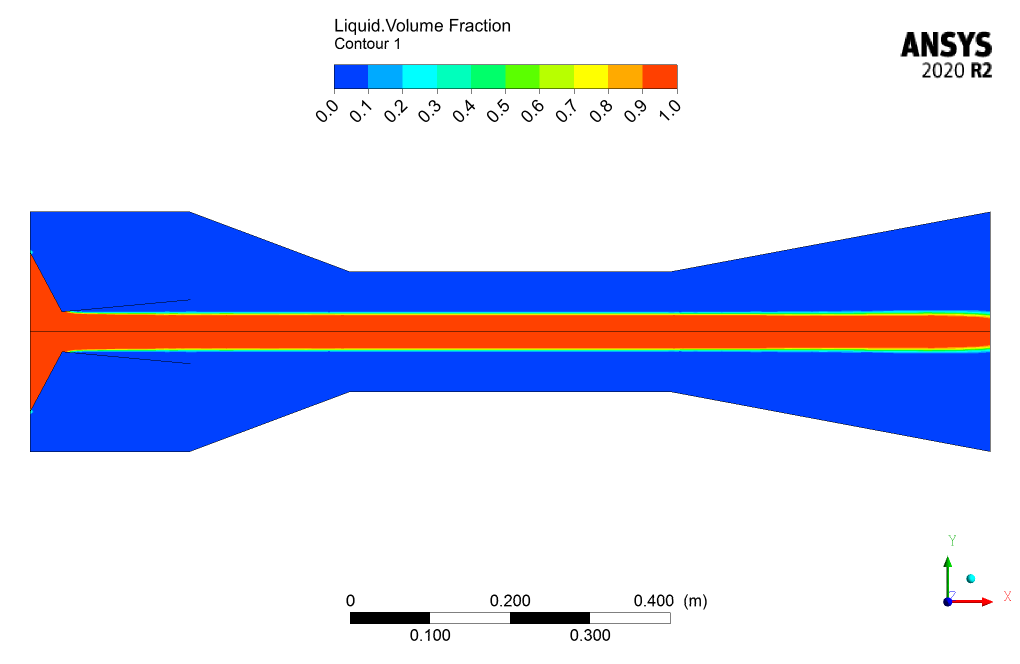

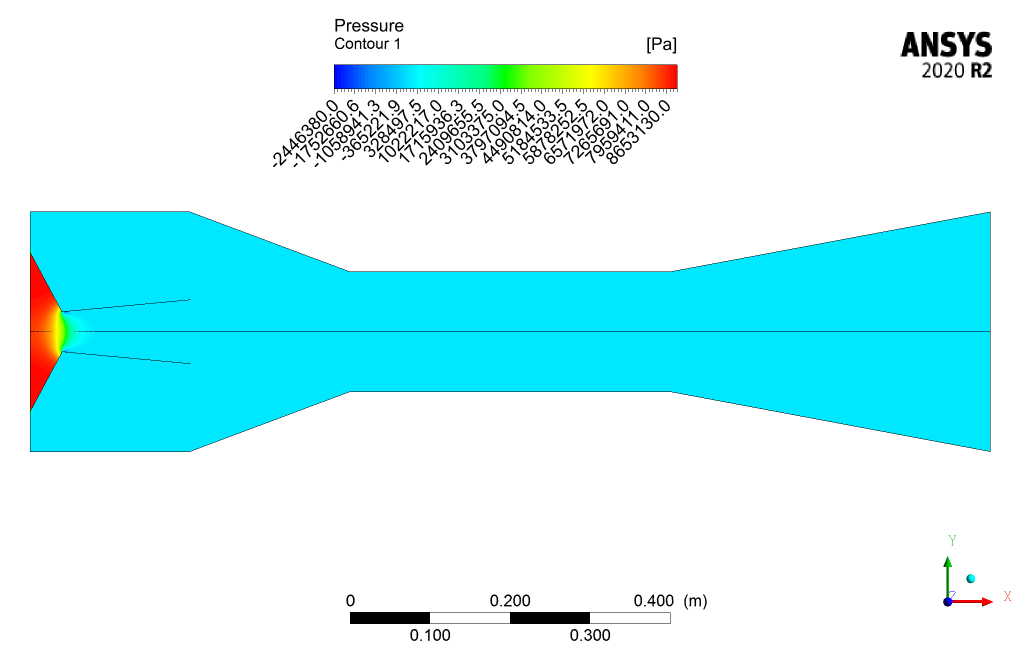

In this project, a two-phase flow of vapor and liquid ammonia in a two-phase ejector has been simulated by ANSYS Fluent software. The realizable k-epsilon model is used for flow analysis. The VOF multi-phase model for two phases of liquid ammonia and vapor ammonia has been used to investigate the phase interactions. The energy equation is also activated in this analysis. The liquid ammonia will enter the computational domain through the primary inlet with a pressure of 9MPa and a temperature of 393K. This flow will induce the vapor ammonia to exit the ejector along with liquid ammonia.

Ejector Geometry & Mesh

The geometry of this model is designed and meshed in Gambit®. The mesh type used for this geometry is structured and the element number is 11808.

CFD Simulation Settings

The key assumptions considered in this project are:

- Simulation is done using a pressure-based solver.

- The present simulation and its results are steady.

- The effect of gravity is ignored.

The applied settings are summarized in the following table.

| (ejector) | Models | |

| Viscous model | k-epsilon | |

| Model | realizable | |

| Near wall treatment | Standard wall function | |

| Energy model | On | |

| Multi phase | VOF | |

| Phase 1 | Ammonia vapor | |

| Phase 2 | Ammonia liquid | |

| (ejector) | Boundary conditions | |

| Outlets | Pressure outlet | |

| Gauge pressure | 0 Pa | |

| Temperature | 312 K | |

| Walls | wall motion | stationary wall |

| New wall | Heat flux | 0 W/m2 |

| wall | Coupled | |

| (ejector) | Solution Methods | |

| Pressure-velocity coupling | Simple | |

| Spatial discretization | pressure | PRESTO! |

| Volume fraction | compressive | |

| momentum | second order upwind | |

| energy | second order upwind | |

| Turbulent kinetic energy | First order upwind | |

| Turbulent Dissipation rate | First order upwind | |

| (ejector) | Initialization | |

| Initialization method | Hybrid | |

Results

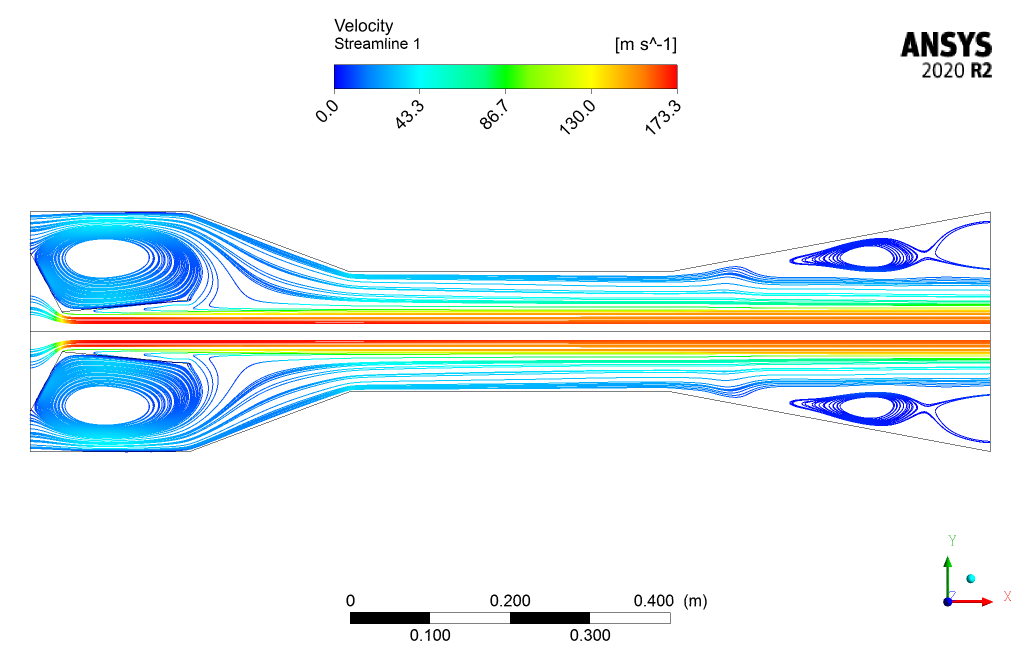

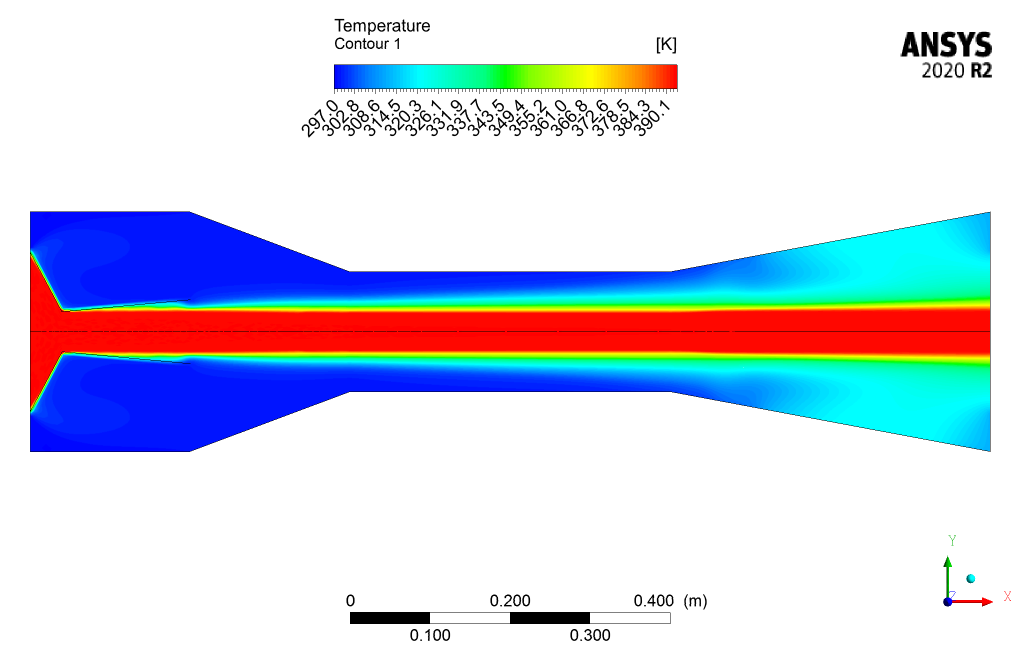

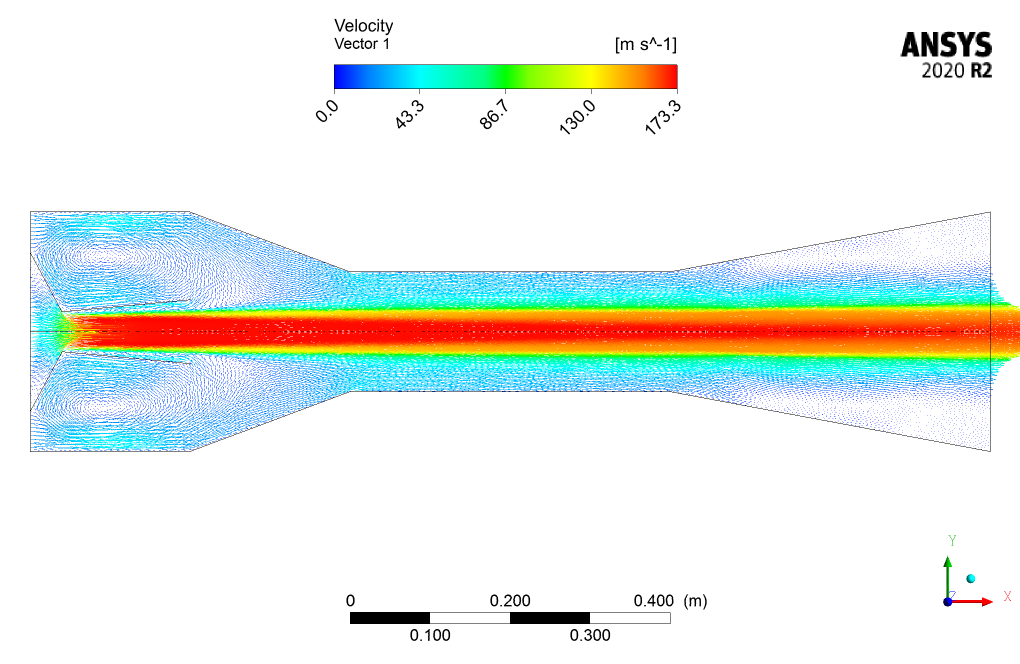

We present the contours of, pressure, temperature, velocity, etc.

Casey Botsford –

Which parts of the ejector are visualized in the simulation results, and how do they show the ejector’s performance?

MR CFD Support –

In the simulation results, the contours of pressure, temperature, and velocity are visualized to show the ejector’s performance. Areas with changes in these parameters indicate how efficiently the ejector mixes the vapor and liquid ammonia, induces flow, and its effectiveness in transferring the mixture to a region of higher pressure without mechanical parts.

Ubaldo Champlin –

This Ejector CFD simulation course sounds thorough. Can I know more about how the phase interactions between the vapor and liquid ammonia are calculated in the VOF multi-phase model?

MR CFD Support –

In the VOF (Volume of Fluid) multi-phase model used for this simulation, the interaction between vapor and liquid ammonia is calculated by tracking the volume fraction of each fluid through the computational domain. The fluids are allowed to coexist in the same grid cell, with each cell having a volume fraction that represents the amount of space it occupies. The interface between the two phases is captured using an algorithm that ensures the volume fractions remain bounded between 0 and 1 and the sum over all phases in each cell is equal to 1. The ANSYS Fluent software then solves the momentum and continuity equations for the mixture, while tracking the volume fraction fields to characterize dynamics such as inter-phase mixing and pressure effects.

Kendall Schoen –

The level of detail in your two-phase flow simulation for the ejector is fascinating. Figuring out the nuanced interaction between liquid and vapor phases must offer valuable insights. Kudos to the MR CFD team for utilizing the VOF model effectively.

MR CFD Support –

Thank you for the kind words! Indeed, capturing the intricate dynamics between liquid and vapor ammonia is crucial for the successful simulation of the ejector system. We’re glad you appreciate the level of detail and our application of the VOF model. Your acknowledgment encourages us to keep providing high-quality CFD simulations.

Freddie Macejkovic –

I was really impressed with the detail of the Ejector Two-Phase Flow CFD Simulation training content. The methodology and use of the realizable k-epsilon model for understanding the interaction between liquid ammonia and vapor were quite insightful. Moreover, the structure and arrangement of the project information from geometry to solution methods have enabled me to fully grasp the process being studied.

MR CFD Support –

We’re delighted to hear that you found our Ejector Two-Phase Flow CFD Simulation with ANSYS Fluent training content so informative and well-structured. Our goal is to provide simulations that are not only technically accurate but also clearly presented for an enriching learning experience. Thank you for your positive feedback!

General Pagac –

I’m amazed by how well the simulation visualizes the physics of an ejector. The contours really helped me understand the interactions between the two-phase flow.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation could enhance your understanding of ejector dynamics and the behavior of two-phase flows. Visualization of complex physical phenomena is a crucial part of our training products, and we’re glad it proved valuable to you.

Murl Wisozk DVM –

This product provided a useful introduction into ejector design via sw simulation. Well done!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found our resource on Ejector Two-Phase Flow CFD Simulation valuable for understanding ejector design and simulation. If you need any further assistance or have more questions about ejector systems, feel free to reach out anytime! We’re here to help.

Lexie Kuphal MD –

The results section mentions contours, but can you explain how the temperature of the two-phase flow specifically changes throughout the ejector in this simulation?

MR CFD Support –

In the simulation, vapor and liquid ammonia enter at high temperature and pressure, mix within the ejector, and as they progress through different sections, pressure conversion and adiabatic expansion cause the temperature to decrease. The exact details of how temperature changes can be analyzed through the temperature contours obtained from the Fluent software, which would show the variation along the length of the ejector.

Laron Heidenreich –

Really found the focus on two-phase flow dynamics in ejectors interesting. Great to see how the VOF model is used to simulate liquid-vapor interaction. Pros and Cons?

MR CFD Support –

Thank you for your interest! A major pro is that the simulation provides a detailed analysis of interactions between two phases in an ejector, helping understand the efficiency of this equipment. However, as a con, since the CFD simulation uses simplifications and assumptions, such as ignoring gravity, the practical application may vary from these results. It’s essential to validate CFD results with experimental data whenever possible.

Ms. Creola Smitham V –

The detailed results provided are quite comprehensive. I can see the flow interaction between liquid and vapor ammonia using the VOF multi-phase model. Excellent explanations on how the ejector operates and good use of the realizable k-epsilon model for the simulation.

MR CFD Support –

Thank you for your positive feedback on the ejector CFD simulation training. We’re glad to hear that you found the explanation clear and the use of the VOF multi-phase model enlightening. Our aim is to provide comprehensive learning materials that enable a deeper understanding of complex flow mechanisms. Your appreciation is much valued!

Garett Langworth –

The description is incredibly detailed, but could you clarify what factors influenced the choice of the realizable k-epsilon model for this ejector CFD simulation?

MR CFD Support –

We chose the realizable k-epsilon model due to its enhanced accuracy in predicting the spread of jets and wakes, which is important in the simulation of the ejector’s two-phase fluid dynamics. This model is preferred in flows involving strong curvatures, swirls, and vortices due to its improved formulation of the turbulent viscosity and its ability to handle the effects of streamline curvature and rotation better.

Dr. Billie Rohan MD –

I’m fascinated by how vapor and liquid phase interact within the ejector. How does the VOF model help in capturing this interaction accurately during the simulation?

MR CFD Support –

The VOF (Volume of Fluid) multi-phase model is specifically designed to capture the interface between multiple phases, in this case, liquid and vapor ammonia. It tracks the volume fraction of each phase throughout the computational domain, allowing us to accurately visualize the interaction and mixing of the two phases within the ejector. This provides an invaluable insight into the phase distribution and the ejector’s performance under varied operating conditions.

Ali Osinski –

I’m very impressed with the way the ejector CFD simulation with two-phase flow was carried out in ANSYS Fluent. The use of the realizable k-epsilon model and the VOF multi-phase model to capture the fluid dynamics and phase interaction for ammonia in vapor and liquid states sounds both complex and fascinating. It’s remarkable that such simulations have no moving parts and can still effectively mimic the mechanism of an ejector and predict the behaviour of fluid flow. Results showing pressure, temperature, and velocity contours must provide insightful visuals. Congratulations on a well-executed simulation!

MR CFD Support –

Thank you for your kind words! We are glad to hear that you are impressed with the ejector two-phase flow CFD simulation carried out using ANSYS Fluent. It’s our goal to provide detailed and accurate simulations that can help understand complex fluid dynamics and assist in the design and analysis of various engineering applications. Your acknowledgment of the efforts put into the simulation and the accuracy of the results is deeply appreciated. Should you have any further inquiries or need assistance with other simulations, feel free to reach out. Thank you for choosing our training for your learning experience!