Electric Field Effect on Nanofluid Considering Charge Density, CFD Simulation, ANSYS Fluent Training

$270.00 $135.00 Student Discount

- The problem numerically simulates the Electric Field Effect on Nanofluid Considering Charge Density using ANSYS Fluent software.

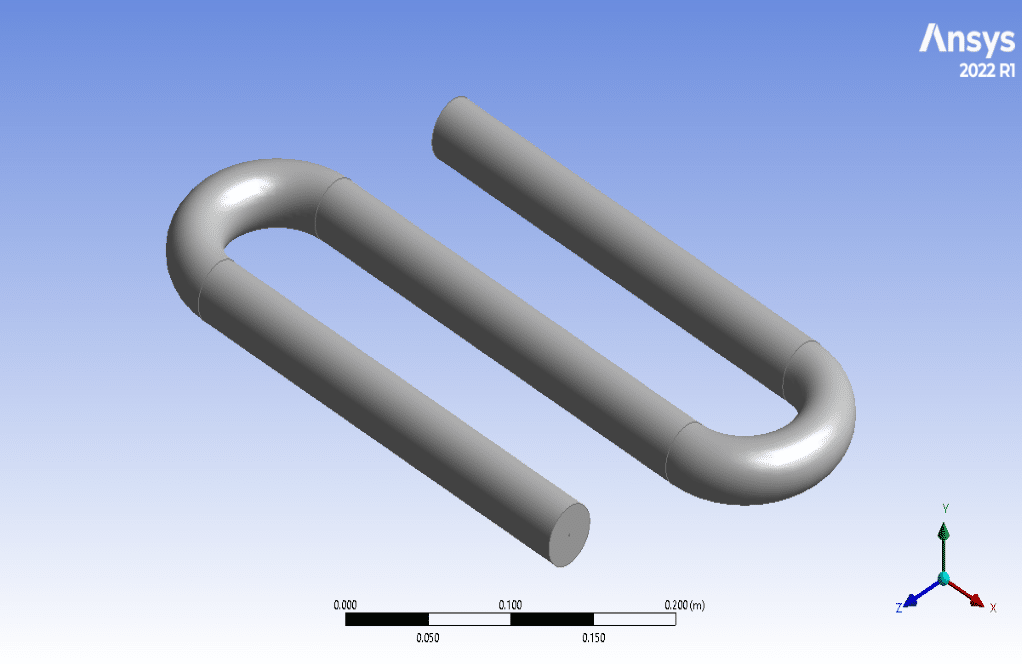

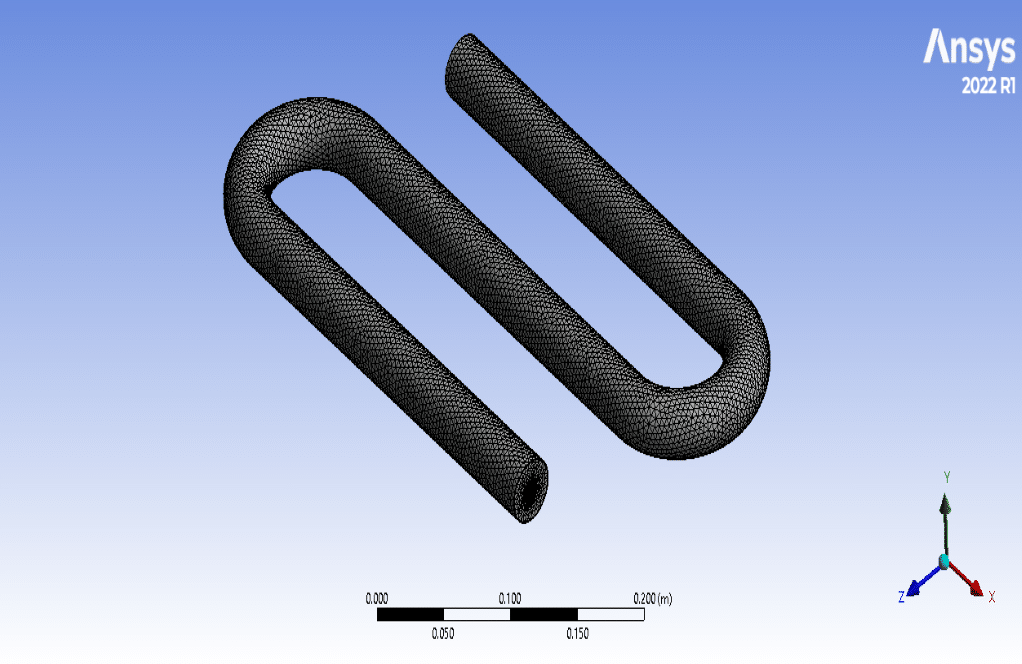

- We design the 3-D model by the Spaceclaim and create the mesh using ANSYS Meshing software.

- The element number equals 904,145.

- The EHD model is used to simulate the electric field effect.

- The DPM model simulates the second phase, which is aluminum nanoparticles.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

A nanofluid is a fluid containing nanometer-sized particles called nanoparticles. Nanofluids have novel properties that make them potentially useful in many applications in heat transfer. They exhibit enhanced thermal conductivity and the convective heat transfer coefficient compared to the base fluid.

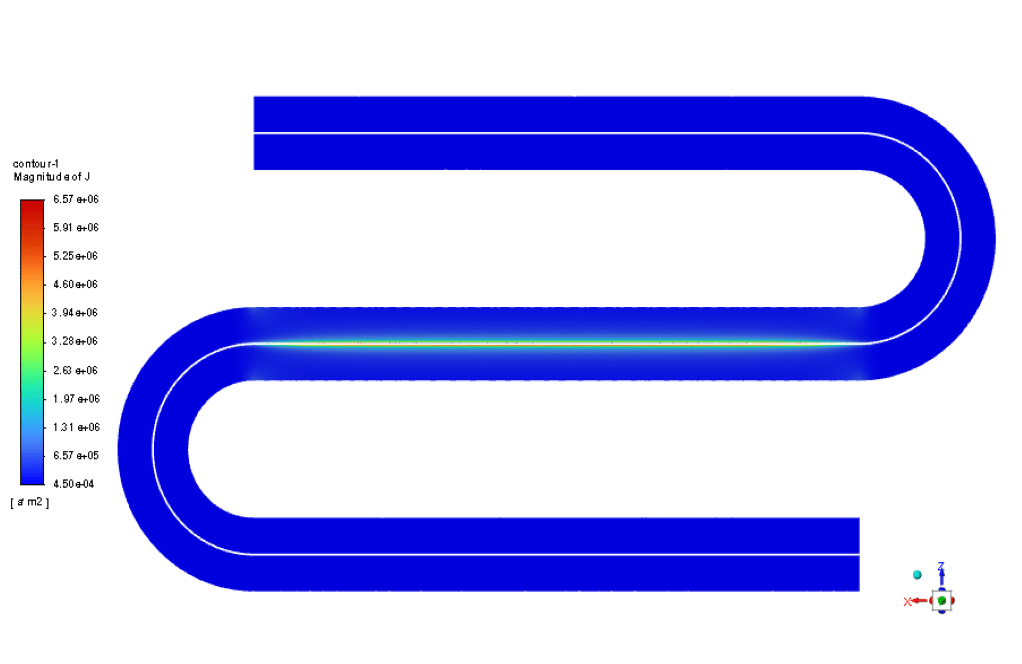

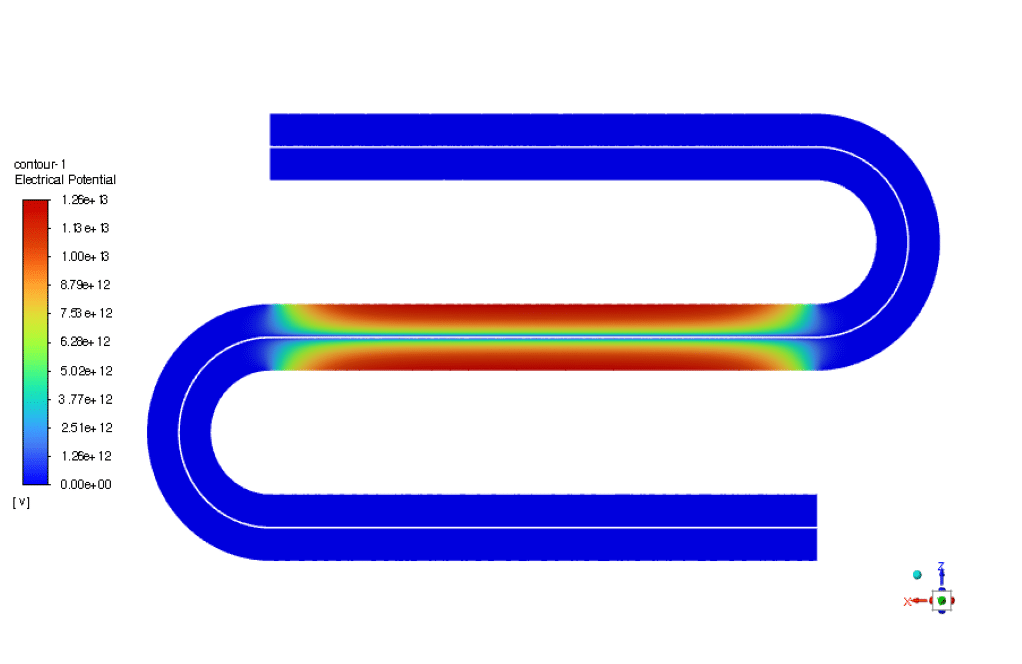

Knowledge of nanofluids’ rheological behavior is critical in deciding their suitability for convective heat transfer applications. The electro field has generated potential difference created by a shell of a tube and a wire inside the pipe. Shell has a higher potential, and wire acts as a negative pole, making particles move in directed against the electrodes.

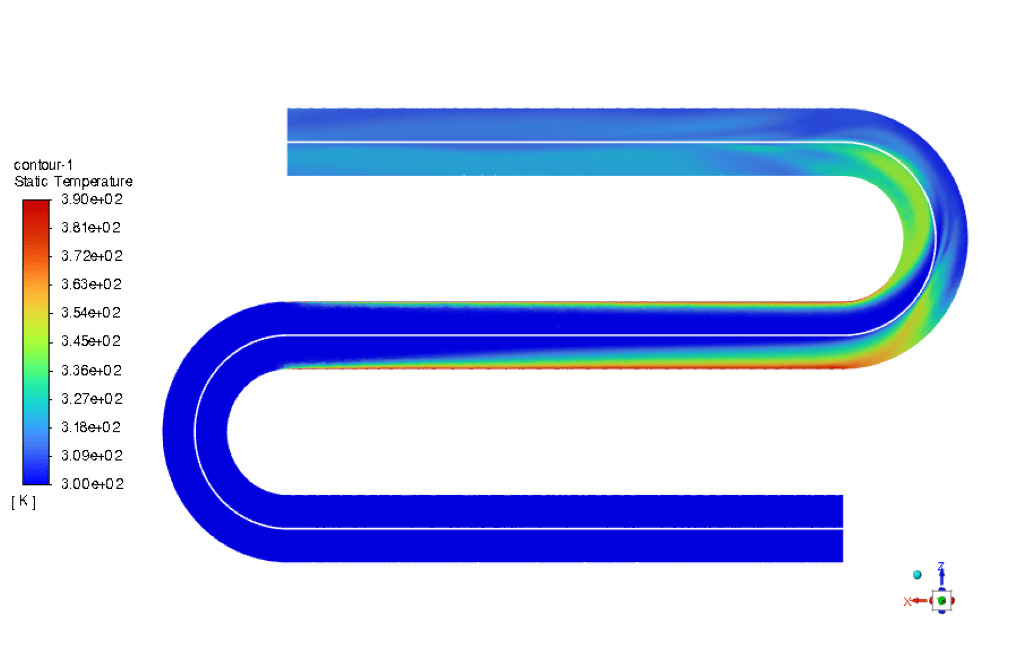

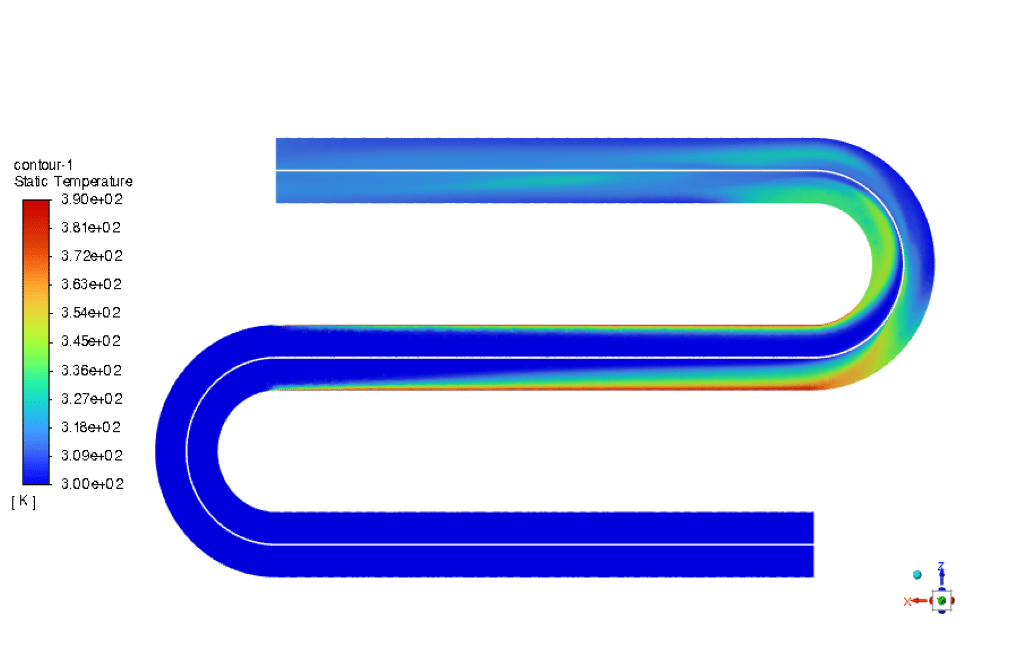

In this case, an N-shaped curved pipe is used to model a cross-section of Cooling System pipes. A thin wire is placed in the middle of this pipe to apply an electromagnetic charge. Cool water enters the pipe at the inlet. There are hot walls in the parts of the pipe body with a temperature of 390 Kelvin.

The cold water exchanges heat with the walls, and the temperature increase at the outlet is monitored. Aluminum nanoparticles with a Charge Density of 23 were used to increase the heat transfer coefficient of the coolant liquid, and their behavior in the presence of an electromagnetic field was investigated. Finally, the data of both modes without particles and particles have been compared.

The present model in the 3-D domain of this simulation has been designed in Spaceclaim . Domain has an inlet, outlet, hot zone, and inner wall for wire inside and outer wall as pipe shell.

The meshing of this present model has been generated by ANSYS Meshing software. The mesh grid is unstructured; the total cell number is 2,966,928 elements and 720300 nodes. The figure below shows an overview of the performed mesh.

Methodology: Electric Field Effect on Nanofluid

In this simulation, the EHD Model with DPM Model has been used, which simulates the current created by the positive and negative poles to check the heat transfer from the walls, a fixed temperature of 390 k has been considered, and the temperature value in the scope and outlet is investigated.

The particles itself has been modeled with the DPM with Interaction with the Continuous Phase model as inert solid particles with a diameter of 0.00001m with a total flow rate of 1e-20 kg/s.

Also, the Energy Equation is On to capture the temperature.

Conclusion

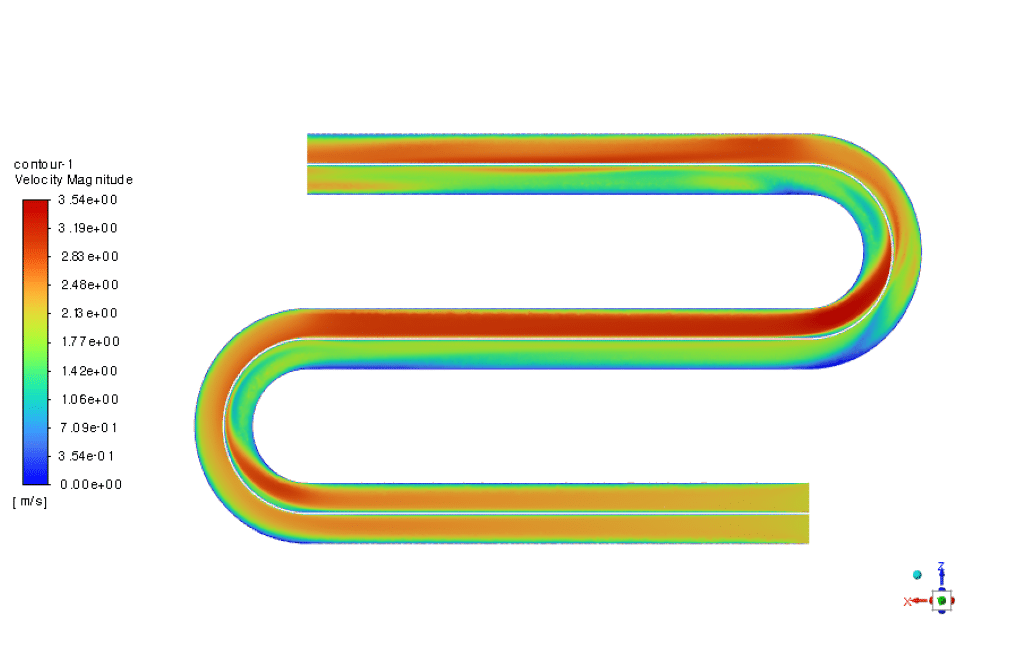

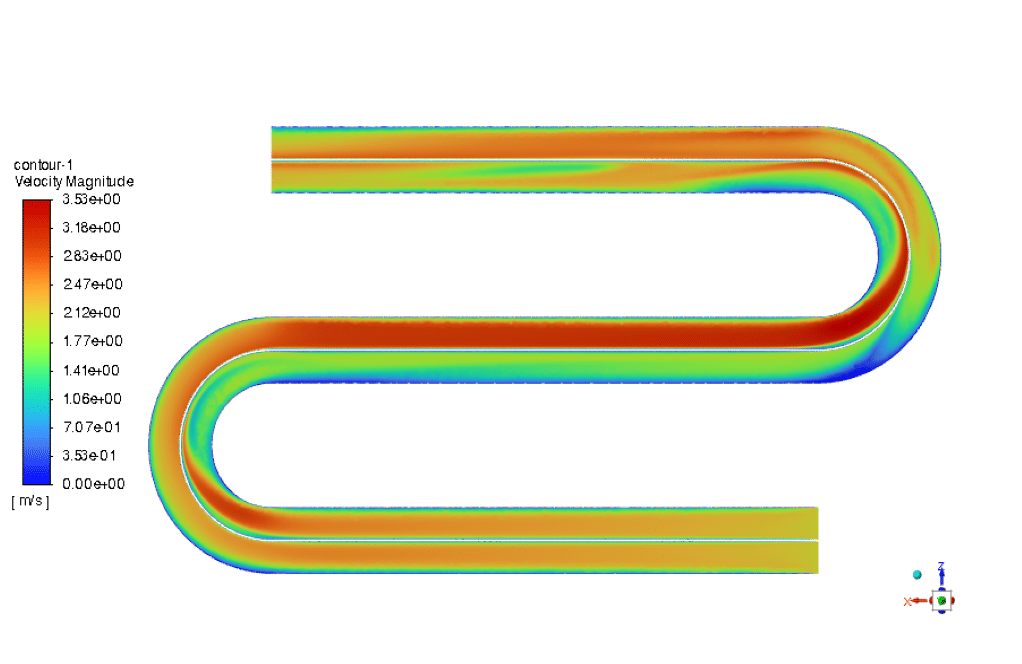

In the two investigated cases, by comparing the contour of temperature and velocity with each other, it is clear that in the case with particles, it is spread more evenly, and the average temperature calculated in the range of temperature increase shows 0.1 Kelvin compared to the model without particles as can be seen in the following table.

On the other hand, the mean temperature at the outlet also shows an increase of 0.5 K in the model with electromagnetic field particles.

Also, the velocity contour shows that in the model used, nanoparticles affect the cooling fluid due to the presence of the magnetic field and the shaping of the particles, and the velocity field is more uniform.

| The average temperature in the domain | The average temperature at the outlet | |

| With particle and electric field | 310.43 k | 316.59 k |

| Without particle and electric field | 310.31 k | 316.16 k |

Ms. Pearline Satterfield MD –

The results indicate a temperature increase with nanofluid; how significant is this improvement in industrial applications?

MR CFD Support –

The improvement in the cooling performance due to the nanofluid is quite evident from the simulation results, and even a small increase in temperature efficiency can be significant in industrial applications. Enhanced heat transfer means better cooling, which can lead to increased efficiency, prolonged equipment life, and reduced energy costs, providing substantial benefits to industries that rely on effective thermal management systems.

Chad Macejkovic –

What are the challenges with working with nanofluids in terms of computational modeling, and how does MR CFD address them in this training?

MR CFD Support –

In terms of computational modeling, challenges with nanofluids include accurately capturing nanoparticle-fluid interaction, modeling charge density effects on particle dynamics, and simulating enhanced thermal properties and their effects on fluid flow and heat transfer. MR CFD addresses these challenges by incorporating advanced simulation techniques like the EHD and DPM models, as well as accounting for the interaction of the particles with the continuous phase. This enables realistic predictions of nanofluid behavior in the presence of an electric field.

Mr. Jovany Gulgowski –

I really enjoyed seeing how the inclusion of an electric field and charged nanoparticles can influence the overall heat transfer in the nanofluid. The results showing the average temperature increase with and without particles are quite impressive. Great application of the EHD and DPM models!

MR CFD Support –

Thank you for your appreciation of our CFD simulation of the Electric Field Effect on Nanofluid. We are delighted to hear you recognized the value of incorporating electric fields and nanoparticles into the heat transfer enhancement studies. Stay tuned for more innovative simulation projects!

Dayna Doyle IV –

I’m excited about the potential efficiency improvement observed! Could you elaborate more on how the charge density on the aluminum nanoparticles influenced the convective heat transfer?

MR CFD Support –

The charge density on the aluminum nanoparticles creates an interaction between the nanoparticles and the electric field, resulting in a directed movement of the particles. This directed movement augments the convective heat transfer by enhancing fluid motion and particle distribution. The coordinated motion of charged particles in the presence of an electromagnetic field increases the rate of heat exchange between the hot walls and the cooling fluid. The improved uniformity in temperature and velocity fields corroborates the beneficial effect of utilizing electromagnetic forces to enhance the heat transfer in nanofluids.

Mr. Kristopher Kemmer III –

What are the major benefits of using nanoparticles in this cooling system according to the simulation results?

MR CFD Support –

The major benefits of using nanoparticles in the cooling system, as indicated by the simulation results, are the enhanced conductivity and uniform temperature distribution within the fluid. The presence of aluminum nanoparticles with an electric field significantly improves the even spread of the coolant temperature, resulting in a more efficient heat exchange compared to the model without particles and electric field. Additionally, the velocity field becomes more uniform, which can potentially lead to improved cooling performance and reduced hotspots within the system.

Tatyana Feil –

I really appreciate the well-detailed explanation on the electric field effect on the nanofluid and the inclusion of the charge density aspect in this CFD simulation. It’s fascinating to see how the aluminum nanoparticles and the electromagnetic field influence the heat transfer rate in the coolant fluid. The outcomes between models with and without particles are also clearly outlined and insightful. Great job illustrating the impact of these variables on the flow and temperature distribution!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear you found the simulation results and the detailed explanation insightful. It’s always rewarding to see our customers engage so deeply with the content and appreciate the complex relations between the different variables in our computational simulations. Your feedback is greatly appreciated!