Elliptical Nozzle With Inviscid Flow CFD Simulation

$80.00 $40.00 Student Discount

In this project, Inviscid Flow in Elliptical Nozzle has been simulated, and the simulation results have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Elliptical Nozzle With Inviscid Flow, ANSYS Fluent CFD Simulation Training

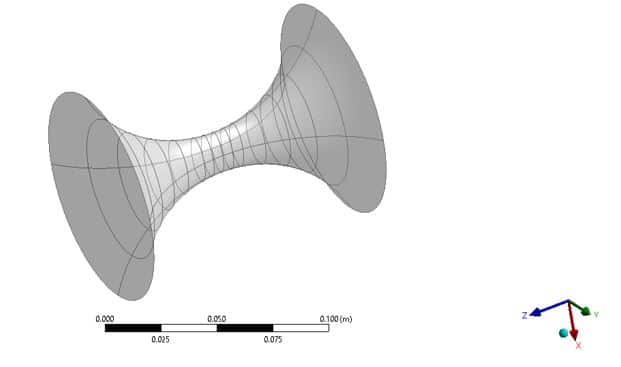

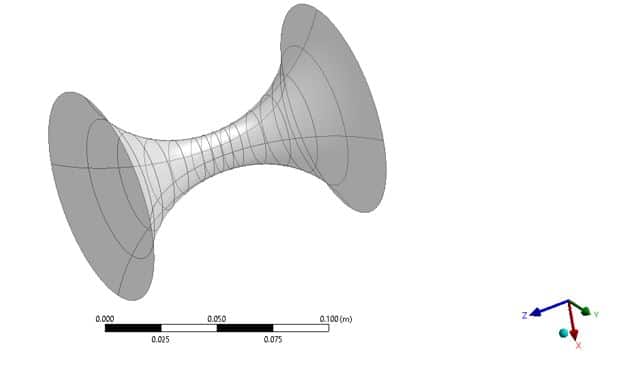

The geometry of the solution consisted of an elliptical nozzle. In this project, the airflow will enter the convergent-divergent nozzle with 9800000 pascal and 3710-kelvin pressure. After passing the throat zone, the airflow will gain speed and lose its temperature as it passes through the diffuser. (Elliptical Nozzle With Inviscid Flow)

Geometry and mesh

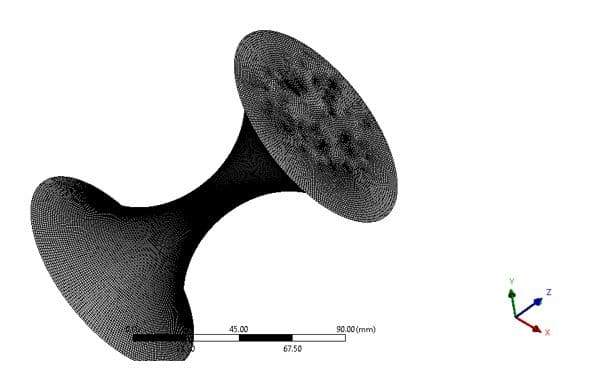

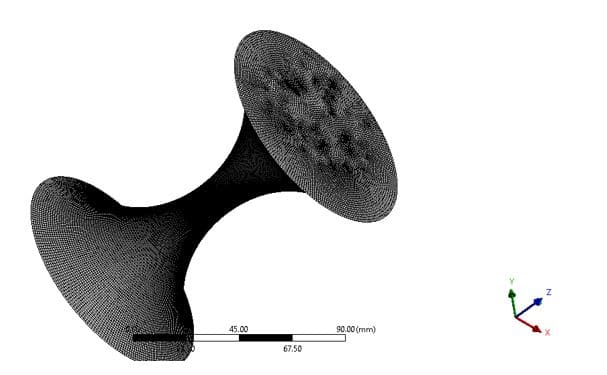

The geometry of the fluid domain is designed in the Design Modeler, edited with SpaceClaim, and the computational grid is generated using ANSYS Meshing.

Mesh is created with ANSYS meshing software, and the mesh type is unstructured. The number of cells is 1246820.

CFD Simulation

We consider several assumptions to simulate the present model:

- The pressure-based solver method has been selected.

- The simulation is steady.

- The effect of gravity is ignored.

The following table represents a summary of the defining steps of the problem and its solution:

|

Models

|

||

|

Energy |

On

|

|

|

Viscous |

inviscid

|

|

|

Materials

|

||

|

Fluid

|

Definition method

|

Fluent Database |

|

Material name

|

Air |

|

|

solid

|

Definition method

|

Fluent Database |

|

Material name

|

Aluminum |

|

|

Boundary conditions

|

||

|

inlet

|

Type

|

Pressure inlet |

|

pressure

|

9800000 pa |

|

|

temperature

|

3710 k |

|

|

outlet

|

Type

|

Pressure outlet |

|

pressure

|

101325 pa |

|

|

temperature

|

300 k |

|

|

Material Properties

|

|

|

|

air

|

||

|

|

Molecular weight |

20 kg/kmol |

|

|

Specific heat |

2494 j/kg-k |

|

Solution Methods

|

||

|

Pressure-velocity coupling

|

coupled |

|

|

Spatial discretization

|

pressure |

Second-order |

|

momentum |

second-order upwind

|

|

|

Energy

|

second-order upwind |

|

|

Density

|

second-order upwind |

|

|

Initialization

|

||

|

Initialization method

|

Standard |

|

|

Compute from

|

inlet |

|

Elliptical Nozzle With Inviscid Flow results

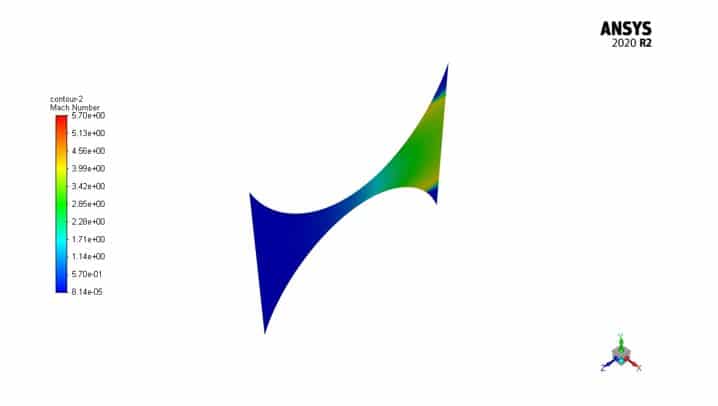

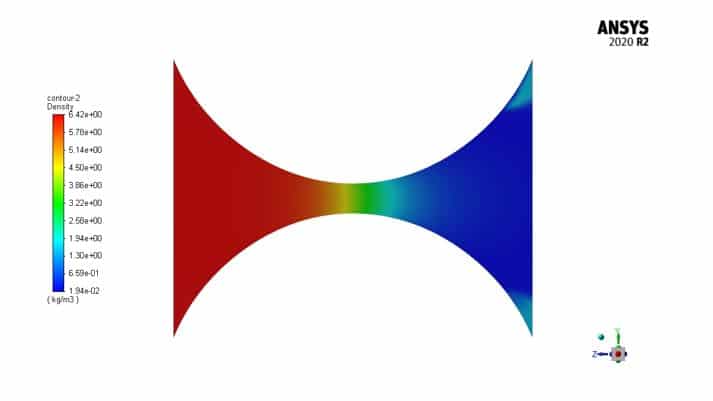

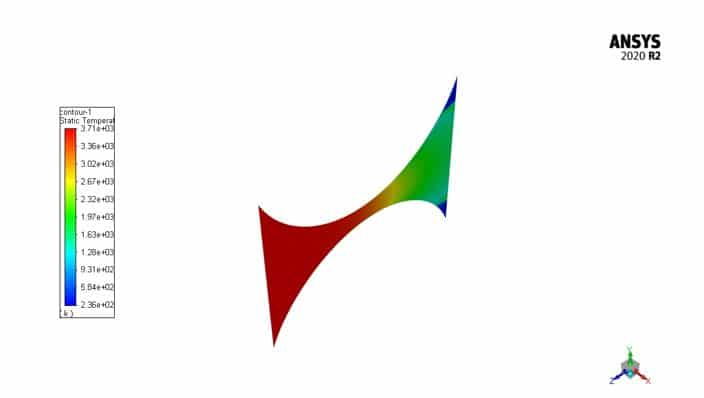

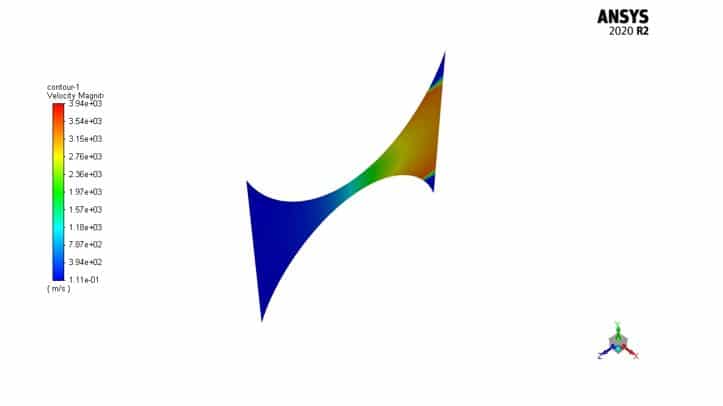

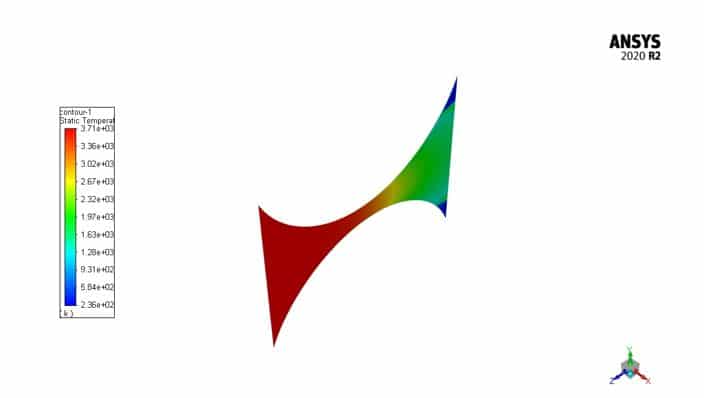

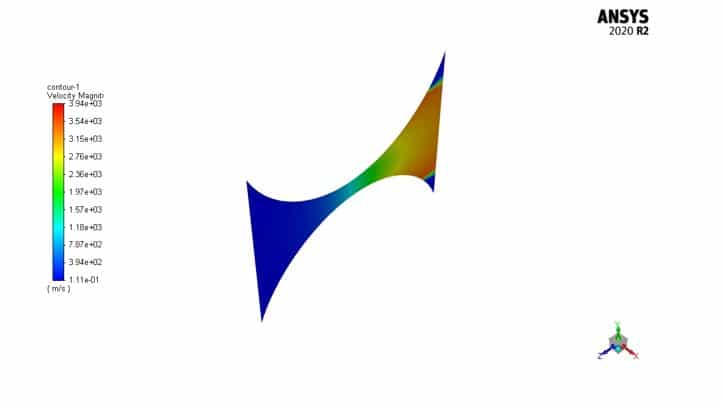

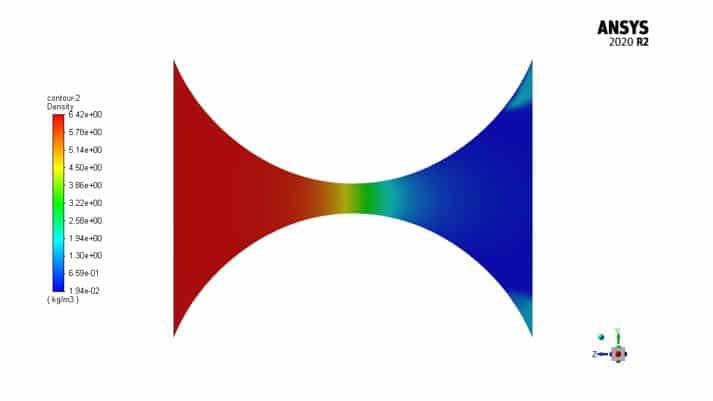

The elliptical nozzle under consideration is carried out at an inlet pressure of 9800000 pa, temperature 3710, outlet pressure of 101325 pa, and temperature of 300 K using an inviscid model. The contours of pressure, temperature, velocity, Mach number, etc., are presented. The airflow loses its heat as clear from the contours after passing through the nozzle opening.

It increases its speed as the nozzle opening becomes more extensive than before the volume of passing air increases. Due to the constant air mass, its density decreases, so the velocity increases along with the nozzle according to the continuity law.

As can be seen from the Mach contour, the Mach number in the nozzle throat, according to the design mode, is equal to one and then increases in the nozzle’s divergent part.

Miss Rossie Armstrong –

The training course was fierce and full of detailed information! The provided value for inlet pressure is particularly impressive – 9800000 pascals! How did you ensure that the simulation accurately captured the physics at such an extreme condition?

MR CFD Support –

We ensured accurate simulation at high-pressure conditions through meticulous setups including calibration of the initial conditions, appropriate selection of boundary conditions, and periodic monitoring of convergence criteria. Using inert (inviscid) flows and assuming the flow to be steady, we’re able to focus on the dominant physics that govern high pressure effectively.

Claude Davis –

What a detailed explanation of the elliptical nozzle with inviscid flow simulation! This clarity in documentation makes it easier to understand the parameters and results of the CFD process. MR CFD’s comprehensive approach to simulations like these truly enhances the learning experience!

MR CFD Support –

Thank you for your positive feedback! At MR CFD, we take pride in providing detailed and clear tutorials to support our customers’ learning journey. We’re glad to hear that our documentation has been helpful to you!

Vernice Langosh –

After watching the simulation, I saw impressive pressure and temperature contours! The inverse relationship between the two through the nozzle was visualized perfectly. The training made understanding the compressible flow concepts in an elliptical nozzle very intuitive.

MR CFD Support –

Thank you for your feedback! We’re delighted to hear our simulation helped you visualize and understand the compressible flow dynamics in an elliptical nozzle. It’s great to know our efforts to make complex concepts more accessible are appreciated. If you have any further questions or need more information, feel free to inquire. We’re here to ensure you receive the best learning experience possible!

Coby Abernathy MD –

Can inviscid flow modeling accurately predict turbulence and boundary layer effects around complex geometries like an elliptical nozzle?

MR CFD Support –

In an inviscid flow model, boundary layer effects and turbulence are not accounted for since it assumes the fluid has no viscosity. An inviscid model is best used for idealized flow situations to predict bulk flow characteristics. To accurately predict complex flow behaviors, including turbulence and boundary layer phenomena, a viscous model would be necessary.

Ms. Dana Parisian –

I found the detailed presentation of the temperature and velocity contours particularly insightful. It was fascinating to see how the inviscid flow model was implemented so effectively in this project. Thank you for showcasing the cooling effect and speed increase through the elliptical nozzle design using convincing visual aids.

MR CFD Support –

Thank you for your positive feedback on our Elliptical Nozzle With Inviscid Flow CFD simulation training. We are thrilled to hear that you found the visual representation of the simulation data helpful and insightful. It’s our goal to provide clear and comprehensive learning materials to aid understanding of complex concepts in fluid dynamics. We appreciate your review and hope our products continue to support your learning and interest in CFD.

Demond Beatty –

In the simulation results, have there been any plots or factor analyses concerning nozzle efficiency or comparisons with theoretical predictions?

MR CFD Support –

In this training product, there hasn’t been any specific mention of nozzle efficiency plots or a comparison with theoretical predictions. It focuses on the basic flow properties such as pressure, temperature, velocity, and Mach number within the nozzle. For a detailed efficiency analysis or theoretical comparisons, further post-processing and analysis beyond the provided scope would be required.

Lucious Gaylord –

The provided training enabled me to fully understand the concept of an inviscid flow within an elliptical nozzle. Just wanted to say that the quality of the CFD simulation training with such detailed parameters was top-notch and helped me a lot in my research!

MR CFD Support –

We are thrilled to hear that our Elliptical Nozzle with Inviscid Flow CFD Simulation training has significantly contributed to your research! Thank you for your positive feedback and for choosing MR CFD Company. If there are further topics or simulations we can help you with, please let us know!

Eloy Thiel –

The training for the elliptical nozzle with inviscid flow in ANSYS Fluent was amazing. It was thorough, and the step-by-step approach really helped enhance my understanding of nozzle flow dynamics.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our training material was clear and informative, helping you grasp the complex concepts involved with nozzle flow in CFD simulations. Your understanding and mastery of the topic are paramount to us, and we’re thrilled we could contribute to your learning journey. If you ever have more questions or need further assistance, please don’t hesitate to ask!

Derrick Mante –

I enjoyed learning with the Elliptical Nozzle With Inviscid Flow CFD Simulation. The step-by-step results along with the visualization of pressure and temperature variations gave me real insights into the behavior of airflow through the nozzle. The detailed explanation of the accompanying changes in Mach number provided a clear understanding of supersonic flow phenomena. Great learning experience!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our Elliptical Nozzle With Inviscid Flow CFD Simulation made the complex concepts accessible and understandable. It’s great to know that our efforts in providing detailed visualizations and clear explanations have helped enhance your learning experience. If you have any more questions or need further clarification, we’re always here to help. Keep enjoying our learning products!

Dr. Kaitlyn Nolan –

This course helped me understand supersonic flows much better. The simulations are detailed and the explanations for temperature and pressure changes are clear. Thanks for a great learning experience!

MR CFD Support –

Thank you for your valuable feedback. We’re delighted to hear that our course on Elliptical Nozzle With Inviscid Flow CFD Simulation has enhanced your understanding of supersonic flows. We strive to provide clear and detailed explanations in our simulations, and we’re glad that you found them to be beneficial. If you have any more questions or need further assistance in your learning journey, feel free to contact us.

Prof. Jarod Klocko –

The simulations settings and results sound robust, but how does the inviscid flow assumption affect the accuracy of the simulation regarding heat and fluid boundary layers?

MR CFD Support –

The inviscid flow assumption disregards the effects of fluid viscosity, including boundary layer and shear stress considerations. This simplification is valid for flows where viscous effects are negligible, such as high-speed gas flow through a nozzle. As a result, the simulation focuses on predicting bulk flow characteristics like pressure, temperature, and velocity. The accuracy regarding boundary layers and heat transfer near walls may be lower, but for certain analyses and flow conditions, assuming inviscid flow can provide a good approximation of real behavior. By not accounting for viscosity, the computational resources and time can also be reduced.

Elva Williamson –

The concept of the inviscid flow model in this simulation was brilliantly executed. The thorough analysis and detailed elucidation of the airflow behavior through the nozzle provides critical insight into the dynamics of elliptical nozzles.

MR CFD Support –

Thank you so much for your thoughtful review! We are thrilled to hear that you found the simulation and analysis both informative and valuable. Please let us know if there is anything else we can assist you with.