Energy Dissipation on Stepped Spillways using blocks CFD Simulation

$100.00 $50.00 Student Discount

- This study investigates the effects of energy dissipation blocks on the energy dissipation efficiency of stepped spillways using computational fluid dynamics (CFD) simulations.

- Two spillway configurations, with and without blocks, were analyzed under different flow conditions.

- The results showed that the presence of blocks enhanced energy dissipation by 6% compared to the conventional stepped spillway design. These findings contribute to the optimization of stepped spillway designs for improved energy dissipation and downstream channel protection.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Energy Dissipation on Stepped Spillways using blocks CFD Simulation, ANSYS Fluent

Description

Spillways play a crucial role in dam safety by preventing water from overtopping the dam structure and mitigating the risk of dam failure. However, in large dams, the kinetic energy of the water at the spillway toe can be significant, potentially causing scouring and erosion downstream. As a result, the dissipation of flow energy at the spillway’s downstream has become a primary focus for researchers in the field of hydraulic engineering.

To address this issue, various dissipater structures such as steps, stilling basins, baffles, plunge pools, and flip buckets are employed. These structures are designed to reduce the kinetic energy of the water flow and minimize the potential for erosion and damage to the downstream channel. In recent years, the need to increase discharge capacity has led to the development and implementation of nonlinear weirs, which offer improved hydraulic performance compared to traditional linear weirs.

Stepped spillways have gained popularity due to their ability to dissipate energy effectively. The steps act as roughness elements, promoting turbulence and energy dissipation along the face of the spillway. This energy dissipation mechanism significantly reduces the required length of the stilling basin at the downstream, making stepped spillways an attractive option for dam designers and engineers.

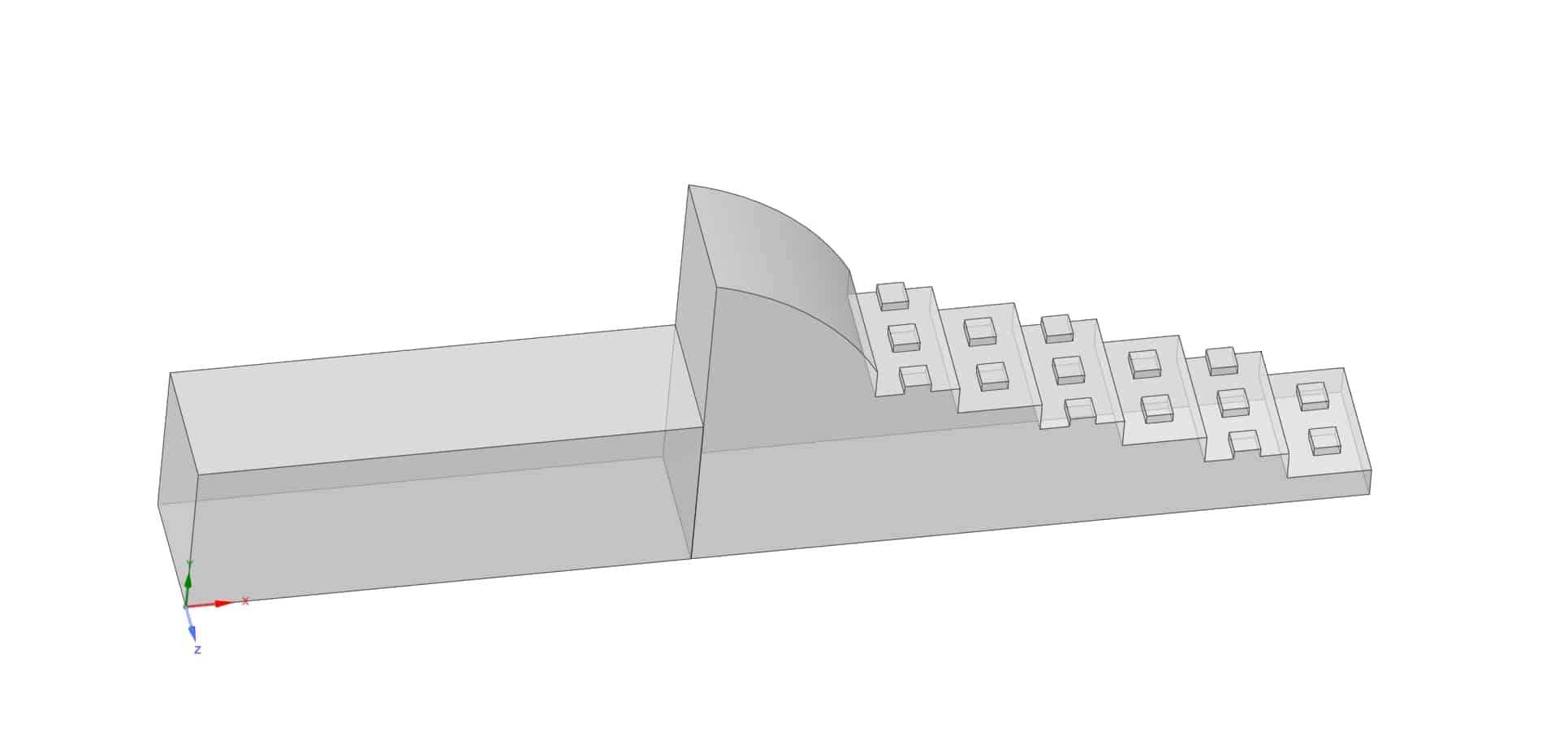

The present study objective is investigate the effects of block barriers, which are additional energy dissipation elements placed on the steps, on the overall energy dissipation efficiency of the spillway.

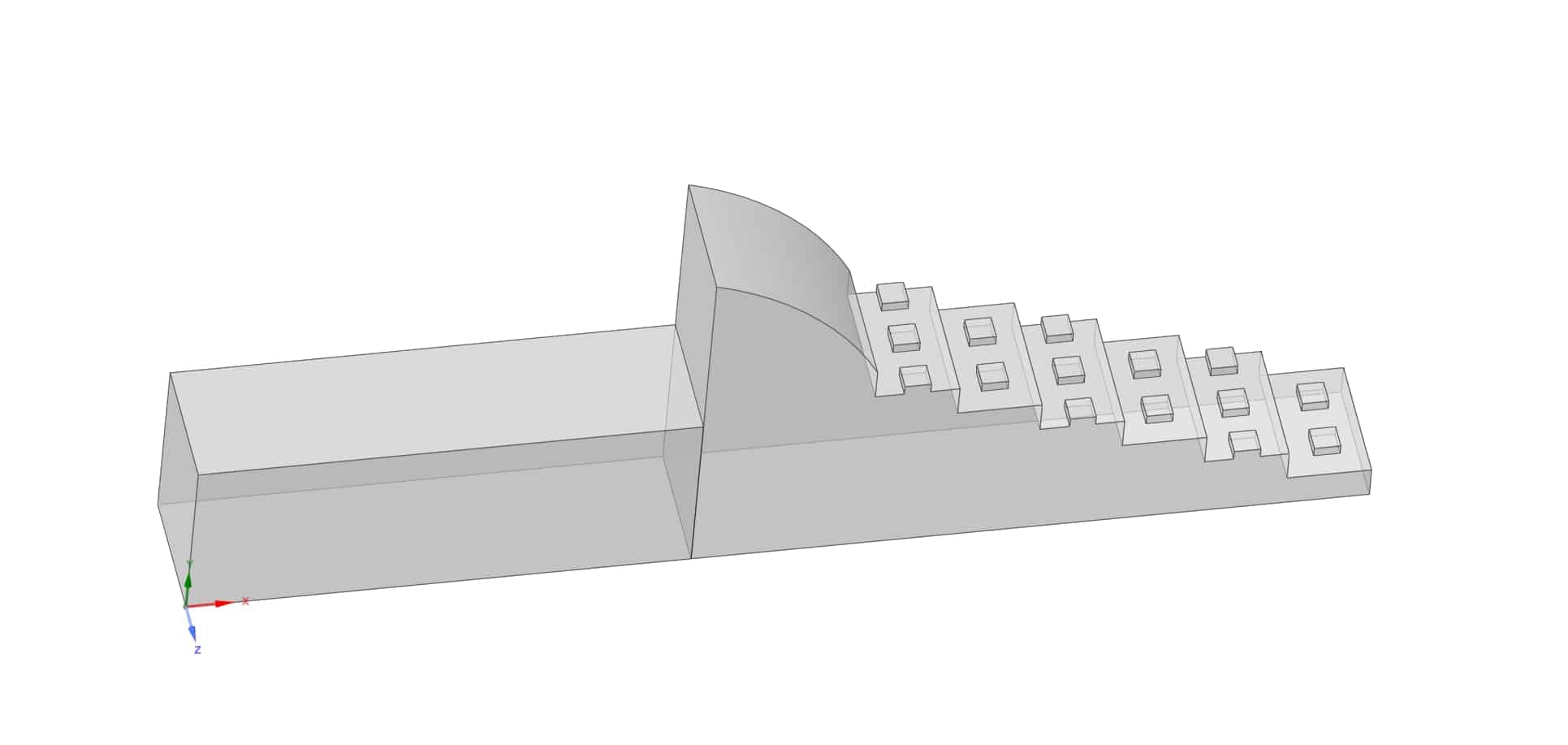

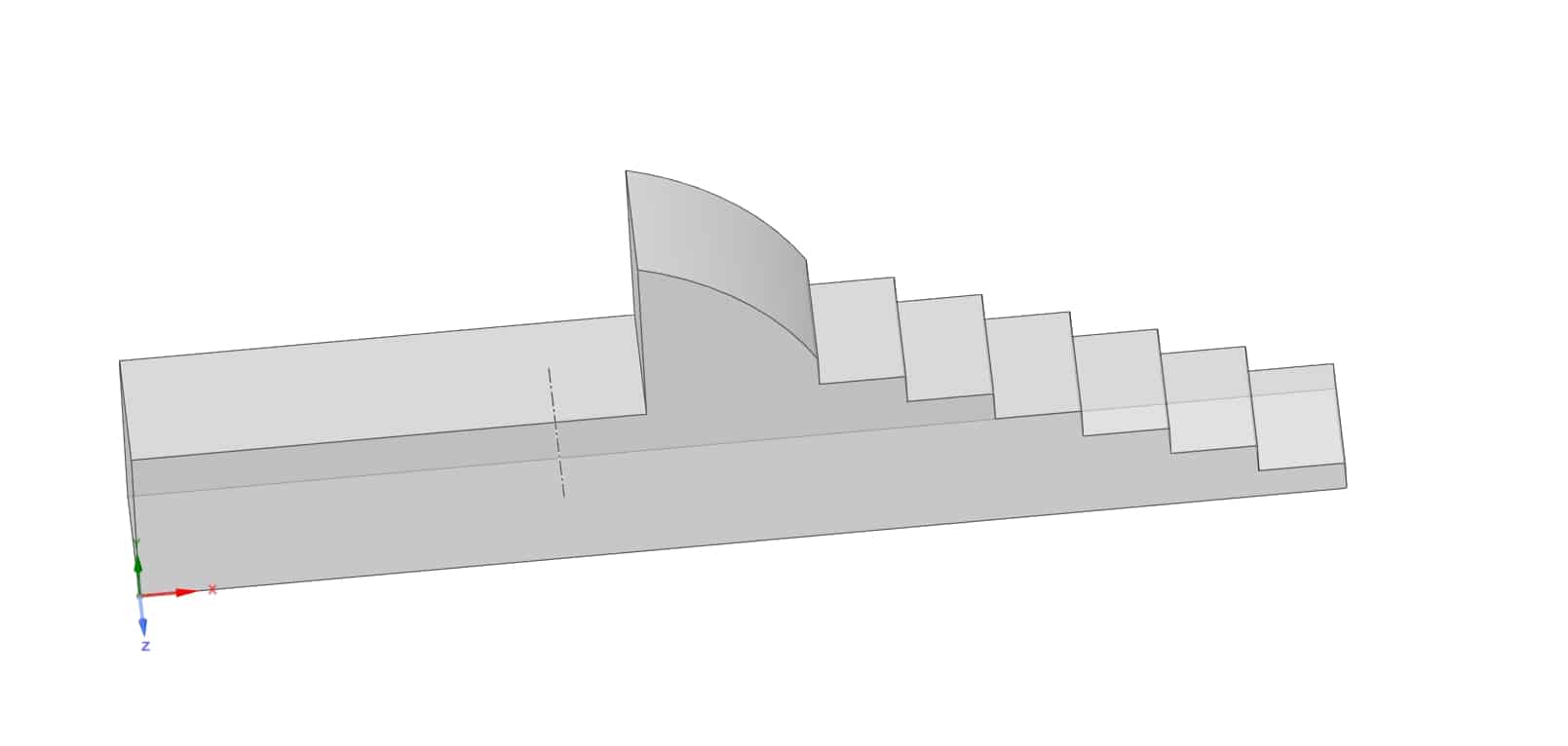

For this simulation, two geometries were designed in the SpaceClaim software, one featuring nonlinear blocks and the other without such blocks. The design of these two distinct geometries enables the investigation and compare the energy dissipation rate in spillways.

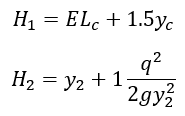

The amount of dissipated energy is obtained from the difference between the total energy at the upstream and the energy at the spillway’s toe.

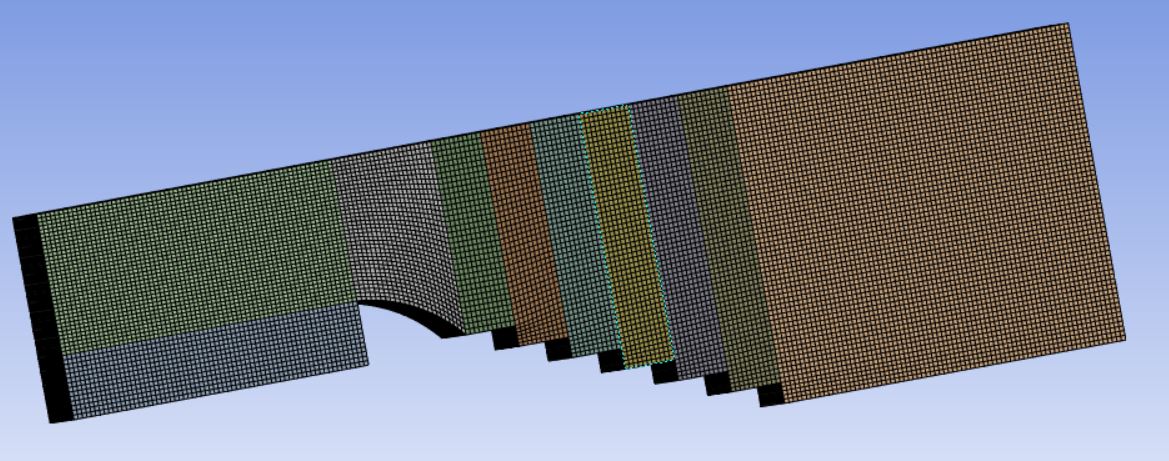

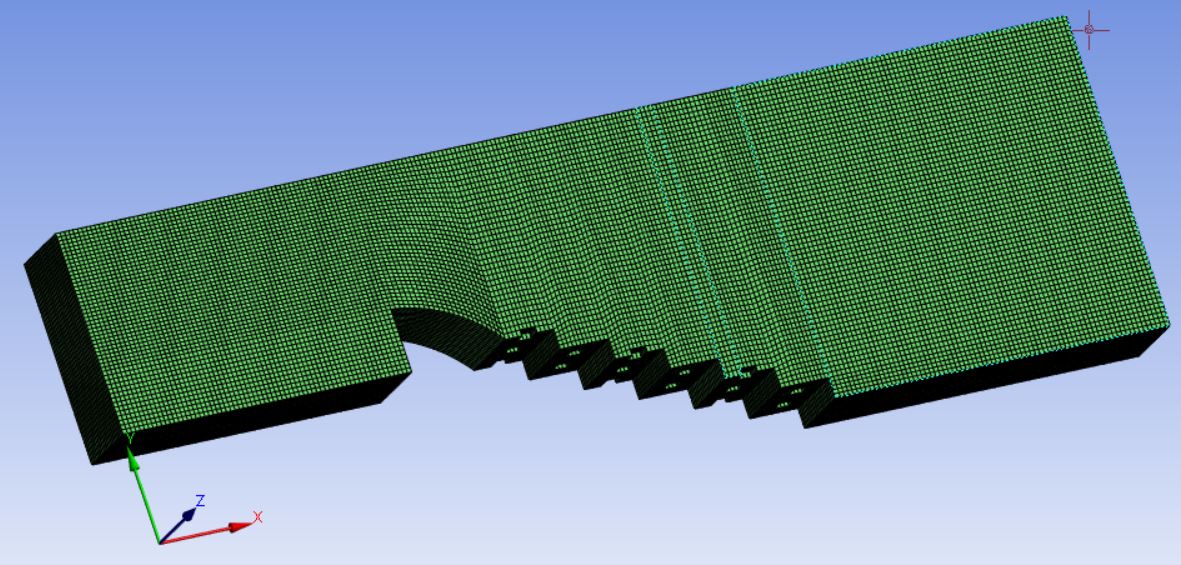

The meshing process, carried out using ANSYS Meshing, resulted in a high-quality structured mesh. For the geometry without blocks, a mesh consisting of 240,000 elements was generated, while for the geometry with the presence of blocks, a mesh with 260,000 elements was employed.

Methodology

A pressure-based, unsteady solver was employed to capture the energy dissipation on stepped spillways with and without energy dissipated blocks and the RNG k-epsilon turbulence model with standard wall function was chosen to capture the turbulent nature of the flow.

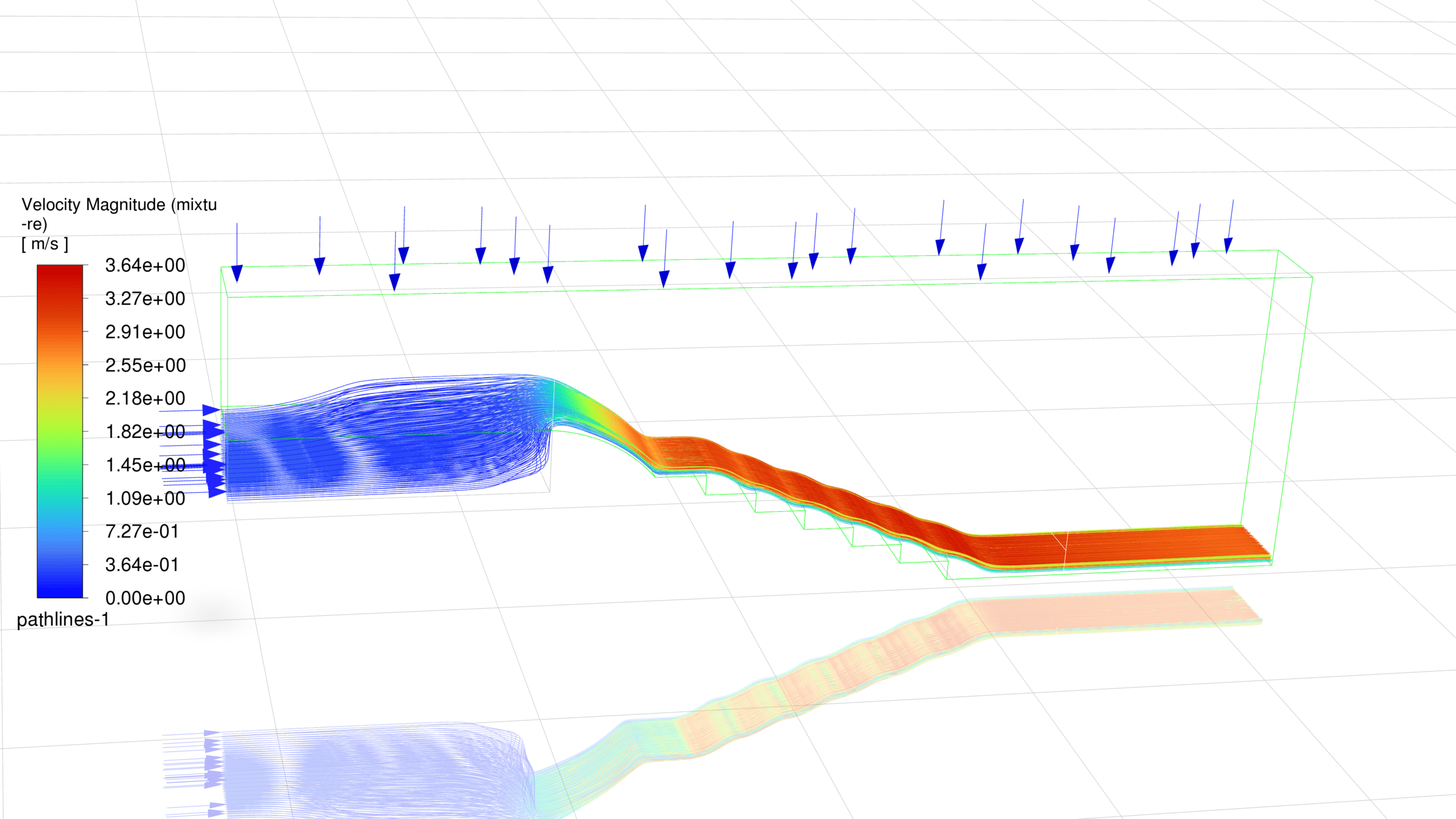

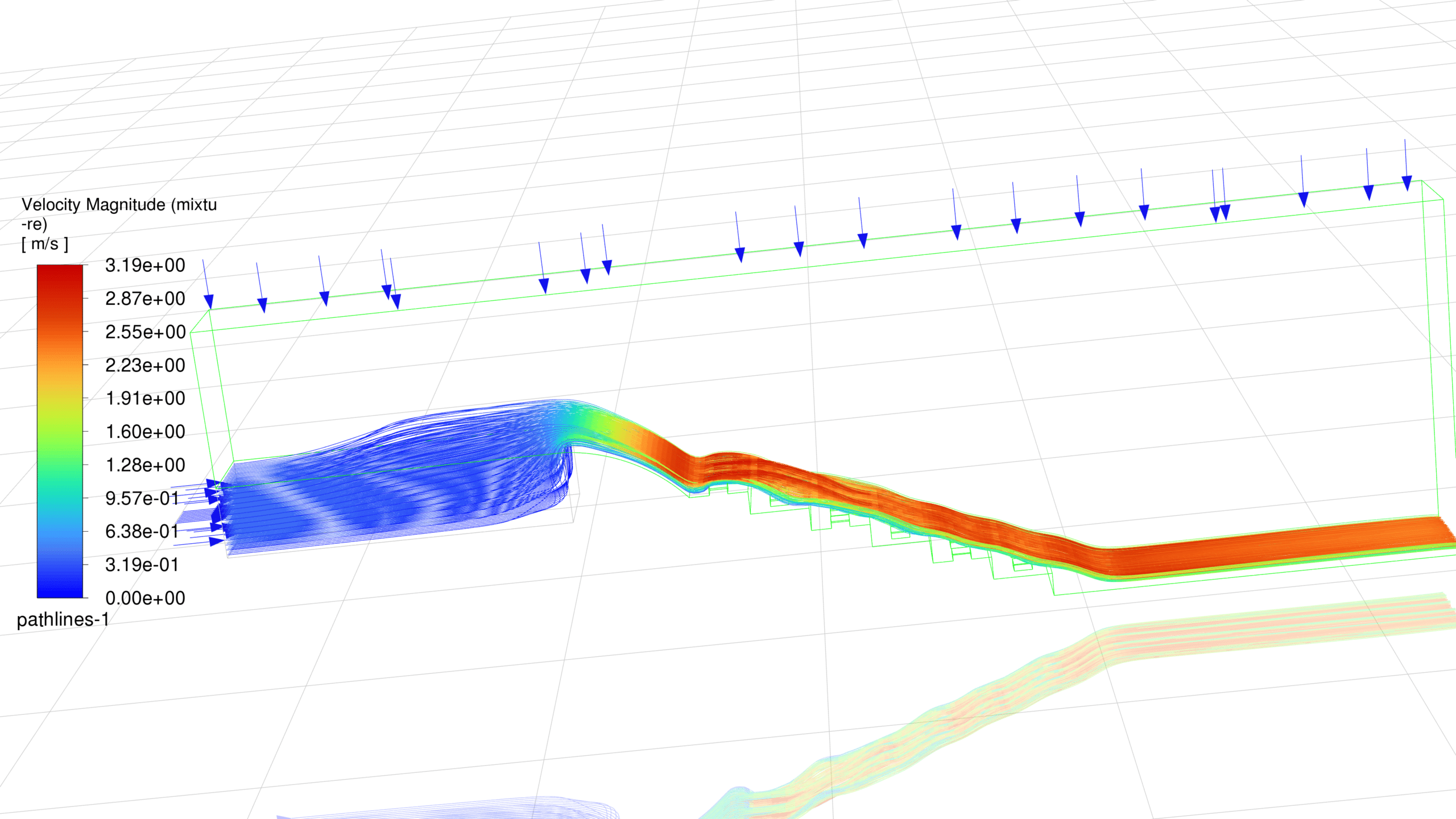

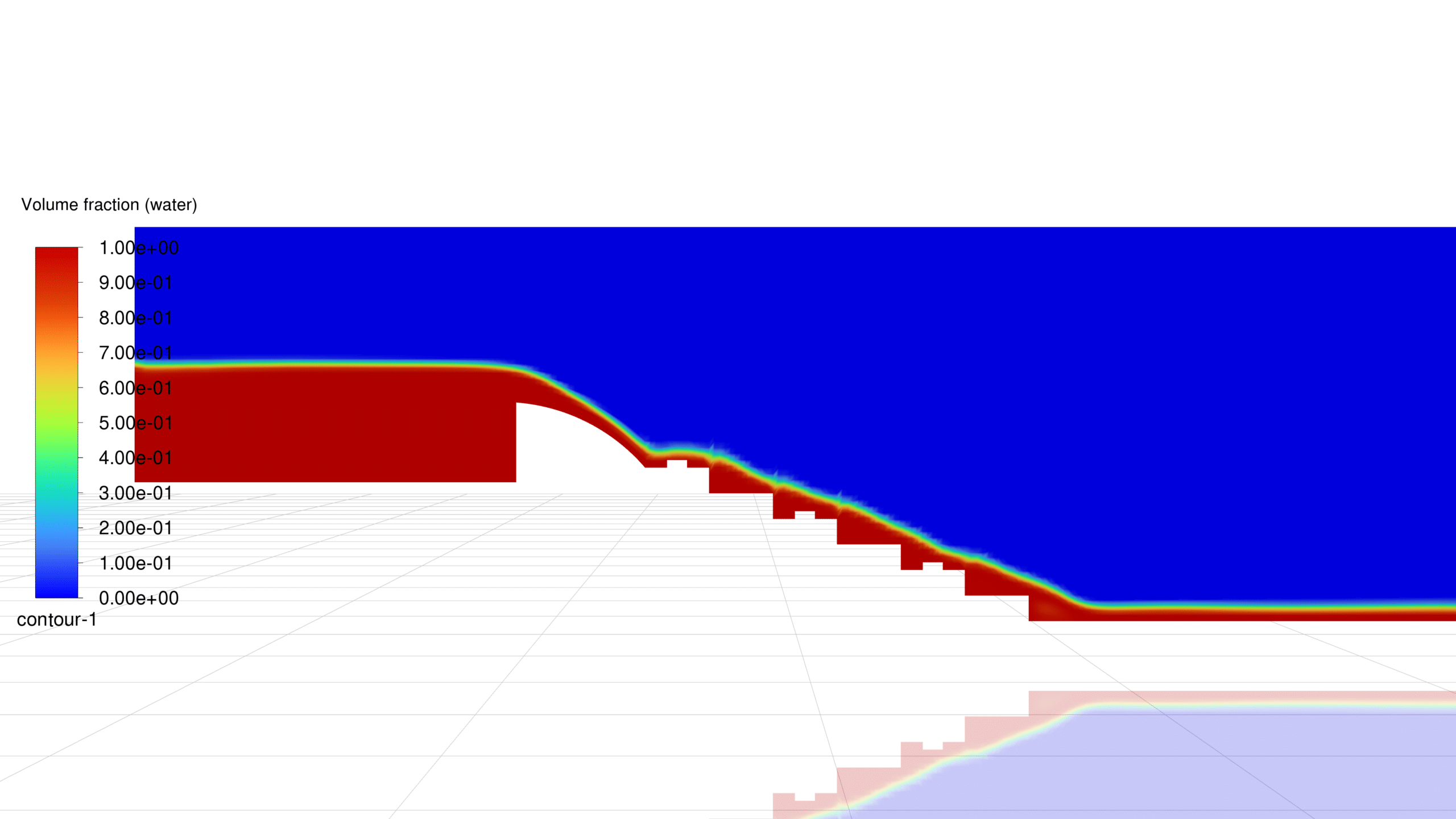

The VOF multiphase model with implicit formulation for volume fraction parameters was used to define the free surface of the flow. Open channel Model and constant Surface tension force were used to account for interfacial effects, and two phases were defined: a primary phase (air), and secondary phase (water).

A velocity inlet boundary condition with a velocity of 1 m/s was specified at the water inlet, while a pressure outlet boundary condition was imposed at the outlet. Following the initialization of the simulation, the water was patched to a height matching the spillway crest. Subsequently, the governing equations were solved using the coupled solver approach.

Results

In this computational fluid dynamics (CFD) study, the dissipated energy was quantified for two distinct configurations of a stepped spillway. The first case considered a conventional stepped spillway without any additional energy dissipation measures, while the second case incorporated energy dissipation blocks placed along the spillway.

By comparing the calculated values of dissipated energy between these two scenarios, the effectiveness of the energy dissipation blocks in enhancing the overall energy dissipation capacity of the stepped spillway can be assessed. This comparative analysis provides valuable insights into the potential benefits of incorporating such blocks in the design of stepped spillways, particularly in terms of reducing the kinetic energy of the flow and mitigating downstream erosion risks.

The results of this simulation contribute to a better understanding of the hydraulic performance of stepped spillways and the role of energy dissipation blocks in optimizing their design. The findings can guide engineers and researchers in making informed decisions when designing and rehabilitating stepped spillways for improved energy dissipation and downstream channel protection.

Simulation without Blocks: In the simulation conducted at a inlet velocity of 0.4m/s and a critical depth to step height ratio (yc/h) of 0.73, the energy dissipation in the absence of blocks was observed to be 66%. This baseline value serves as a reference point to assess the impact of introducing blocks into the system.

Simulation with Blocks: Under the same flow conditions (velocity = 0.4 m/s, yc/h=0.73), the simulation was repeated with the presence of blocks. The results showed that the energy dissipation increased to 72% when blocks were incorporated into the system. This increase in energy dissipation highlights the effectiveness of blocks in reducing the overall energy of the flow.

Comparative Analysis: Comparing the results of the two simulations reveals that the introduction of blocks led to a 6% reduction in energy. The presence of blocks enhanced the energy dissipation from 66% in the absence of blocks to 72% when blocks were included. This improvement can be attributed to the increased turbulence and flow disruption caused by the blocks, which promote energy dissipation through various mechanisms such as flow separation, vortex shedding, and increased surface roughness.

Reviews

There are no reviews yet.