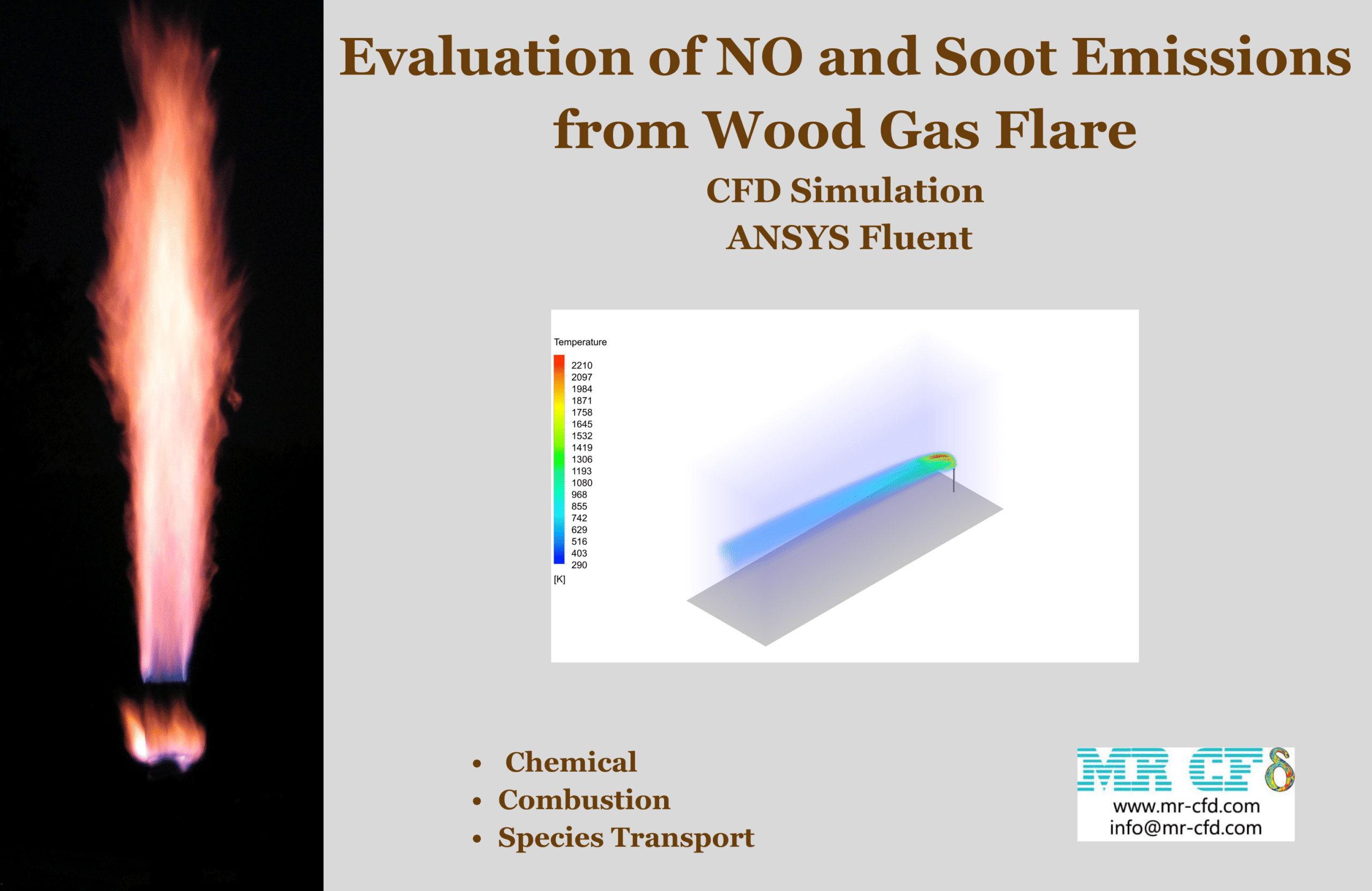

Evaluation of NO and Soot Emissions from Wood Gas Flare, ANSYS Fluent

$140.00 $70.00 Student Discount

- The problem numerically simulates Evaluation of NO and Soot Emissions from Wood Gas Flare using ANSYS Fluent software.

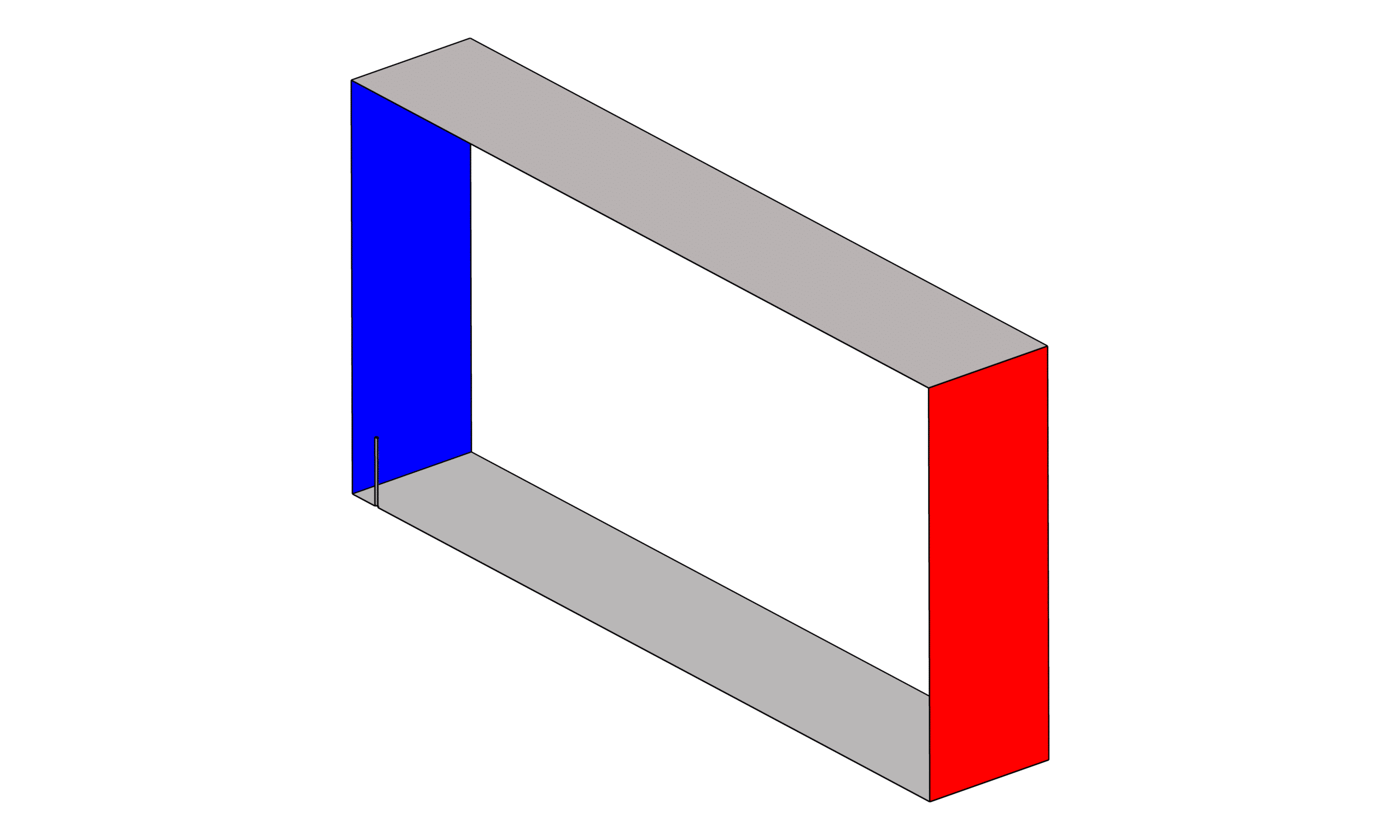

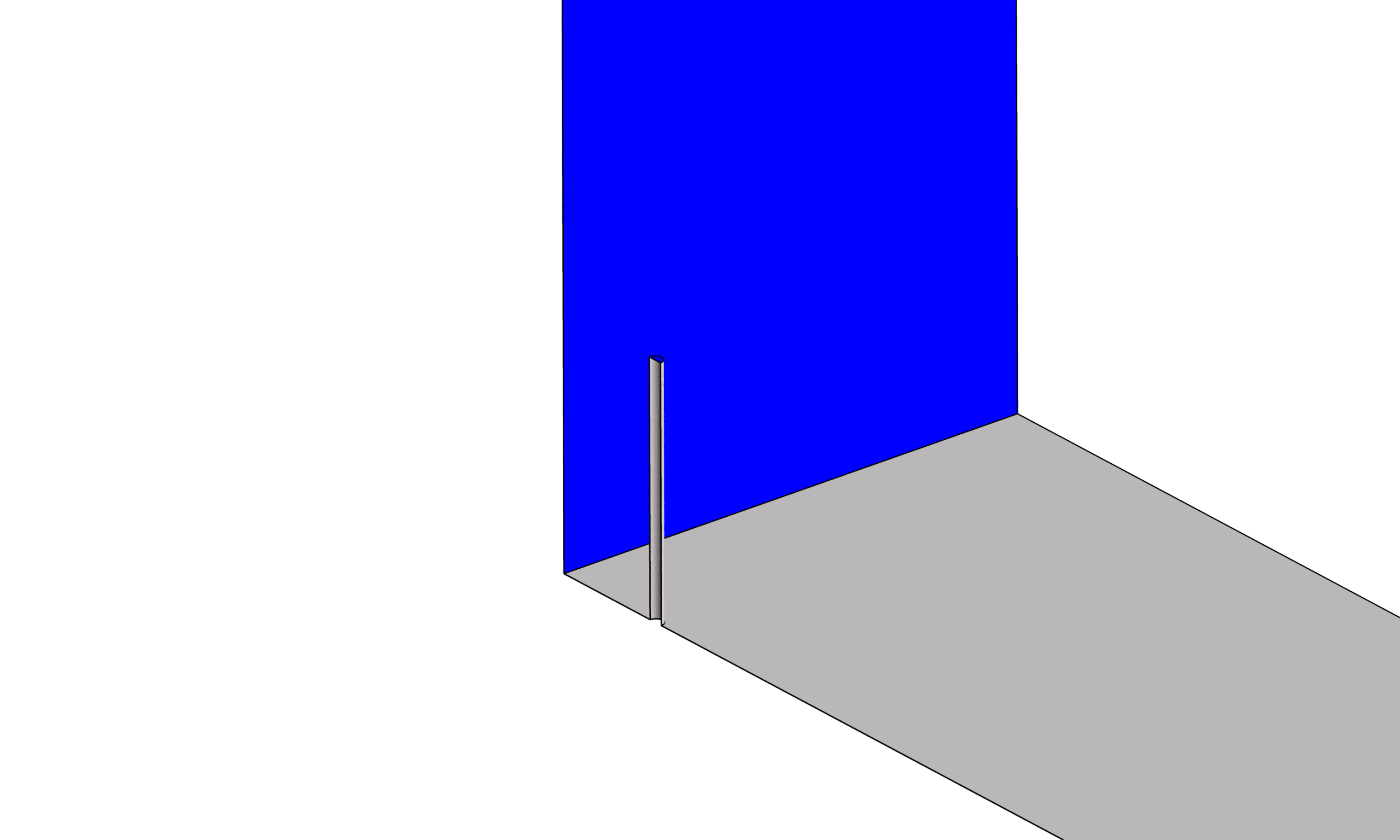

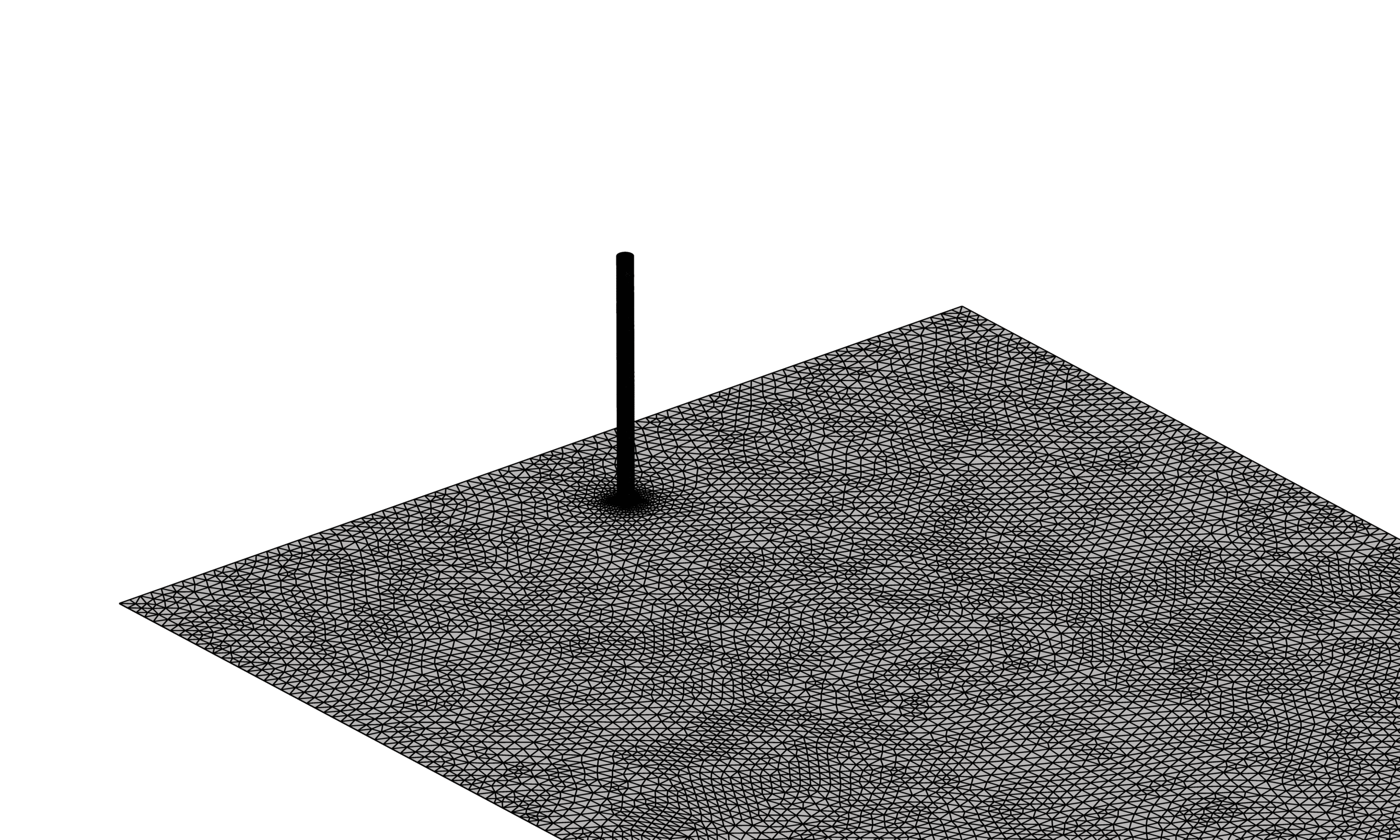

- We design the 3-D model with the SpaceClaim software.

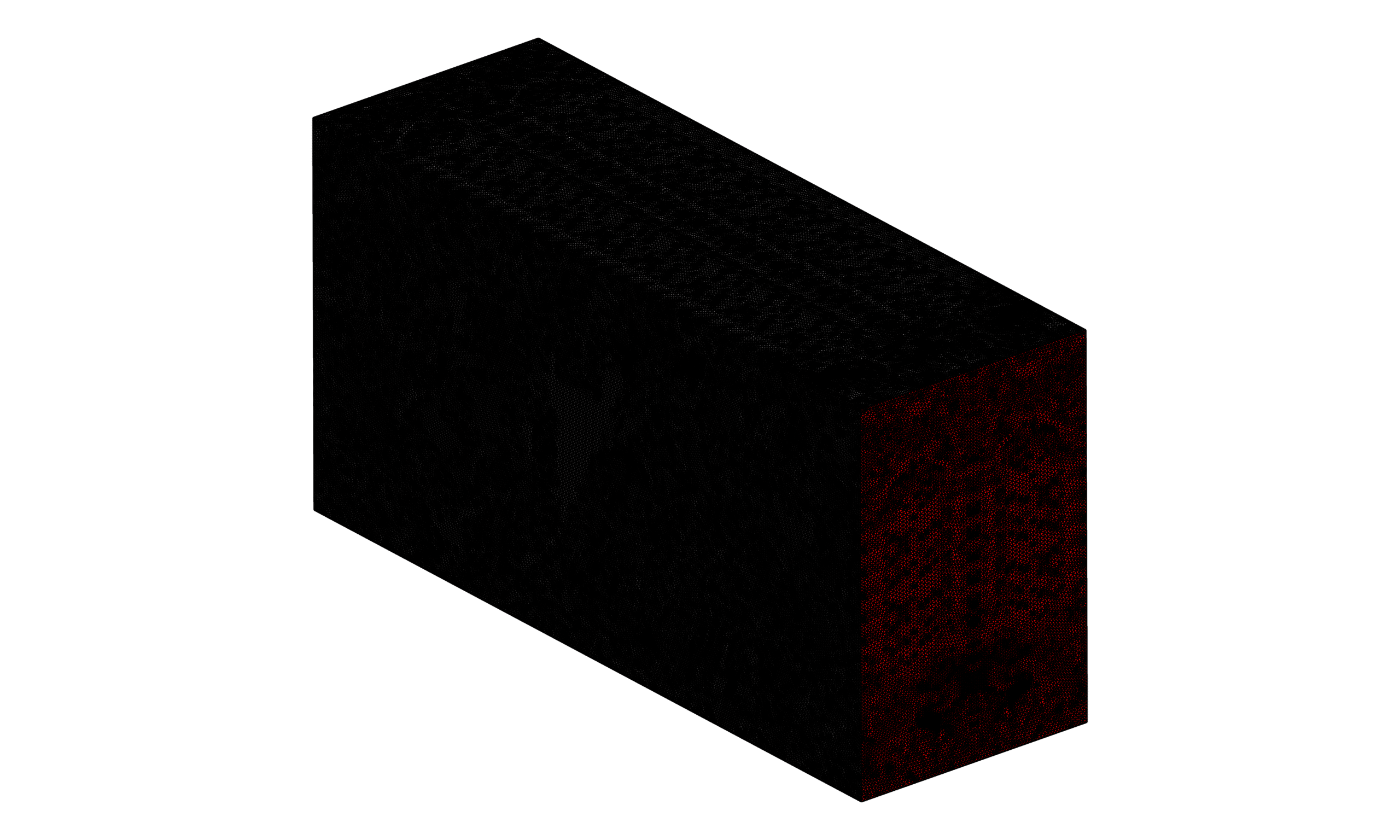

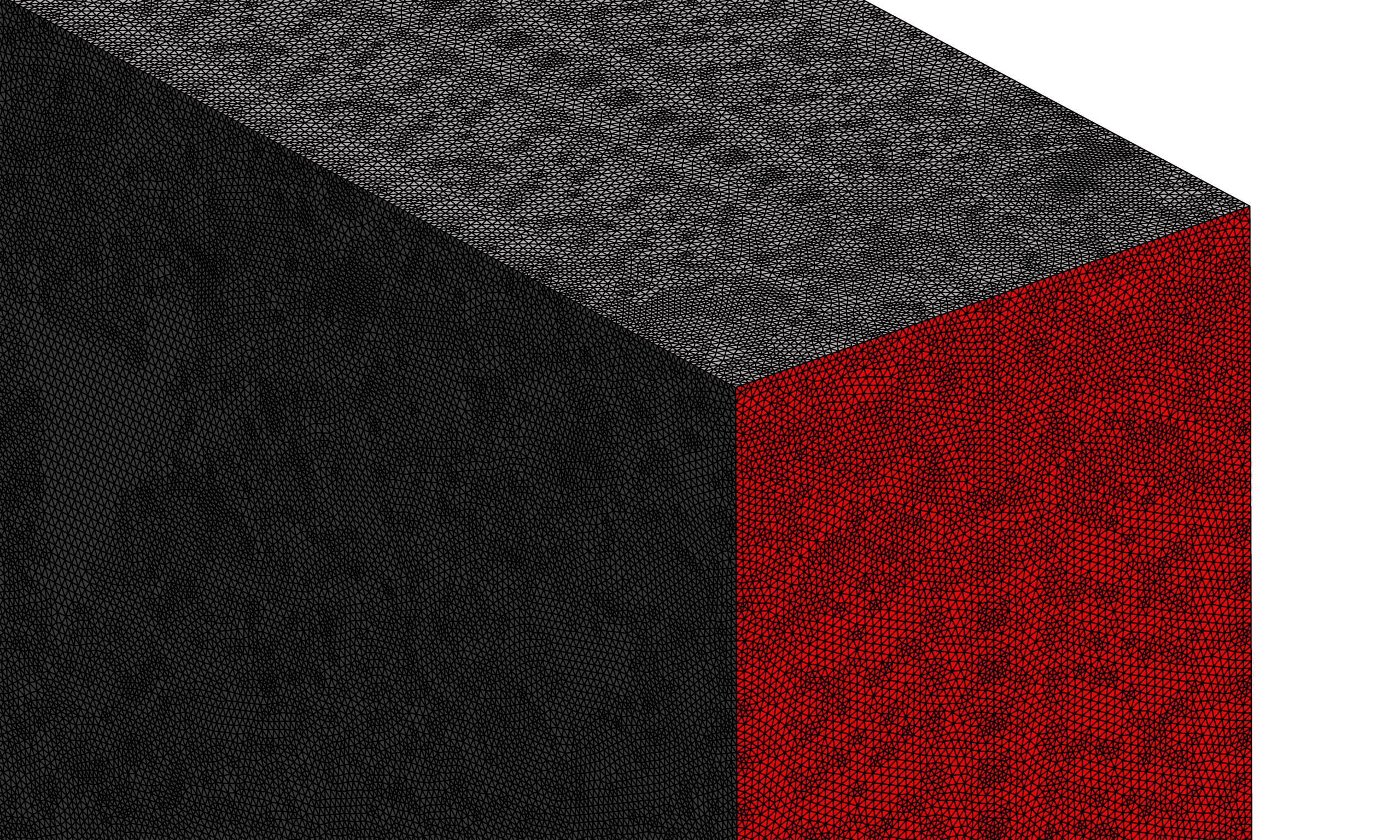

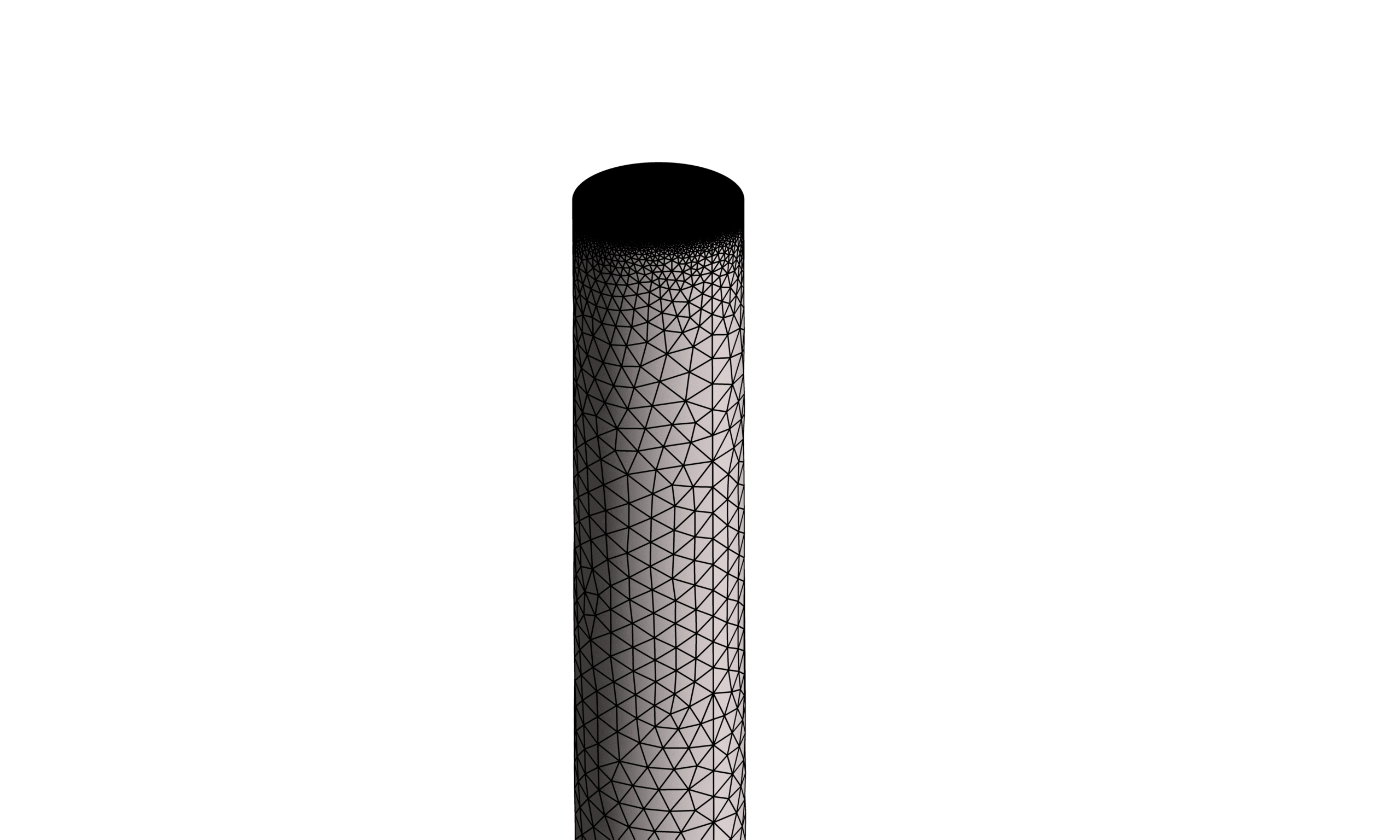

- We Mesh the model with ANSYS Meshing software, and the element number equals 2.8 millions.

- Energy and species transport models were enabled to account for heat transfer and chemical reactions.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

The primary objective of this simulation study was to investigate the formation and dispersion of the harmful pollutants nitric oxide (NO) and soot particles from a wood gas flare system. Understanding and quantifying these emissions is crucial for assessing the environmental impact and developing mitigation strategies.

The simulation was carried out using ANSYS Fluent, a computational fluid dynamics (CFD) software. The geometry of the flare system was created in SpaceClaim software and imported into ANSYS Meshing for meshing and simulation. The computational mesh consisted of approximately 2.8 millions cells to ensure accurate representation of the flow patterns.

Methodology

The simulation setup included the following key parameters:

- Inlet conditions:

- Wind velocity: 3 m/s

- Flare inlet mass flow rate: 1.2 kg/s

- Flare inlet species composition:

- Nitrogen (N2): 50.9%

- Carbon monoxide (CO): 27.0%

- Hydrogen (H2): 14.0%

- Carbon dioxide (CO2): 4.5%

- Methane (CH4): 3.0%

- Oxygen (O2): 0.6%

- Energy and species transport models were enabled to account for heat transfer and chemical reactions.

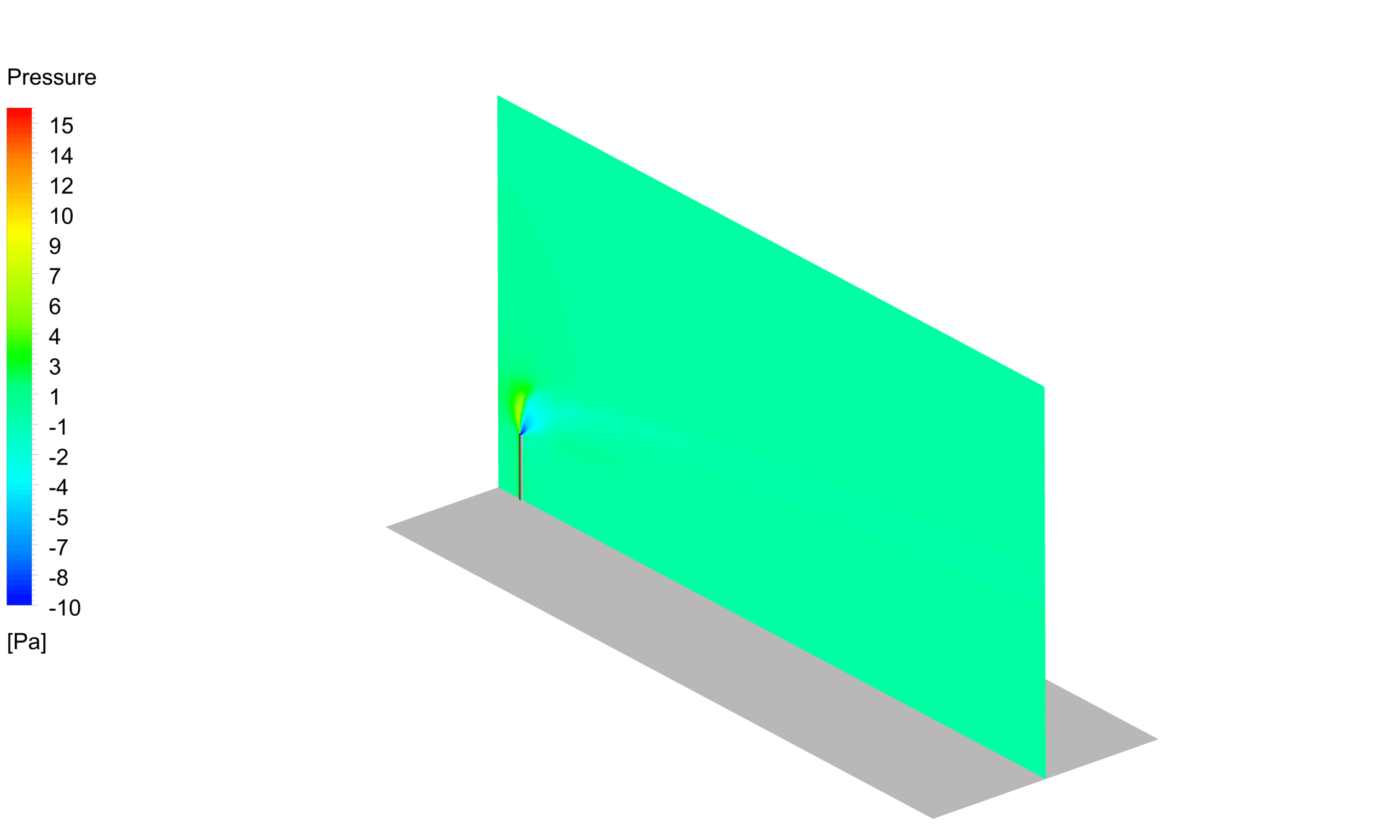

- A simple algorithm was used for coupling between velocity and pressure.

- Standard initialization was performed.

- The simulation was set as a steady-state, pressure-based solver.

Results and Discussion

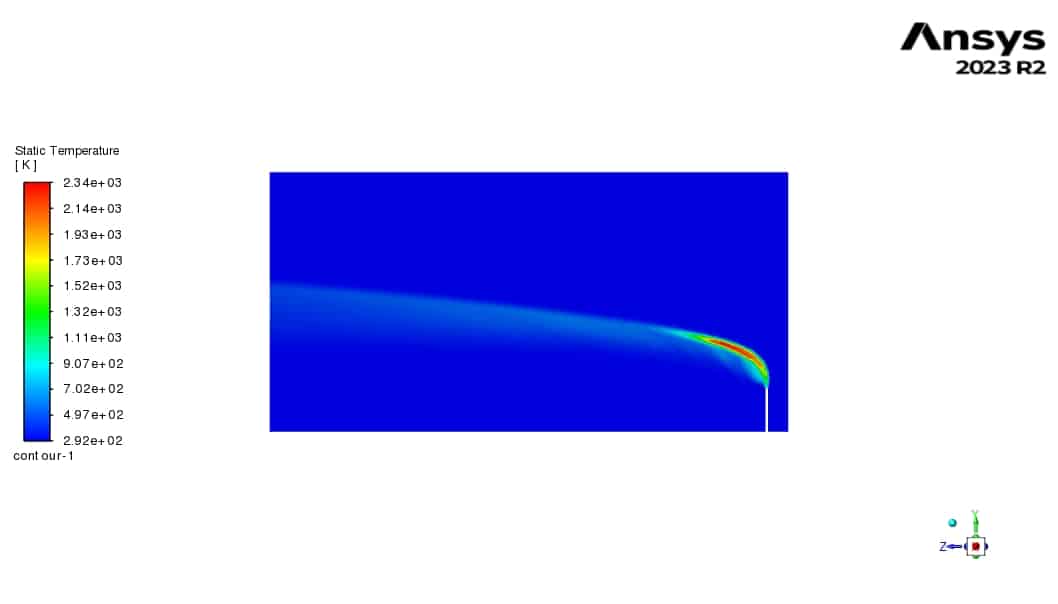

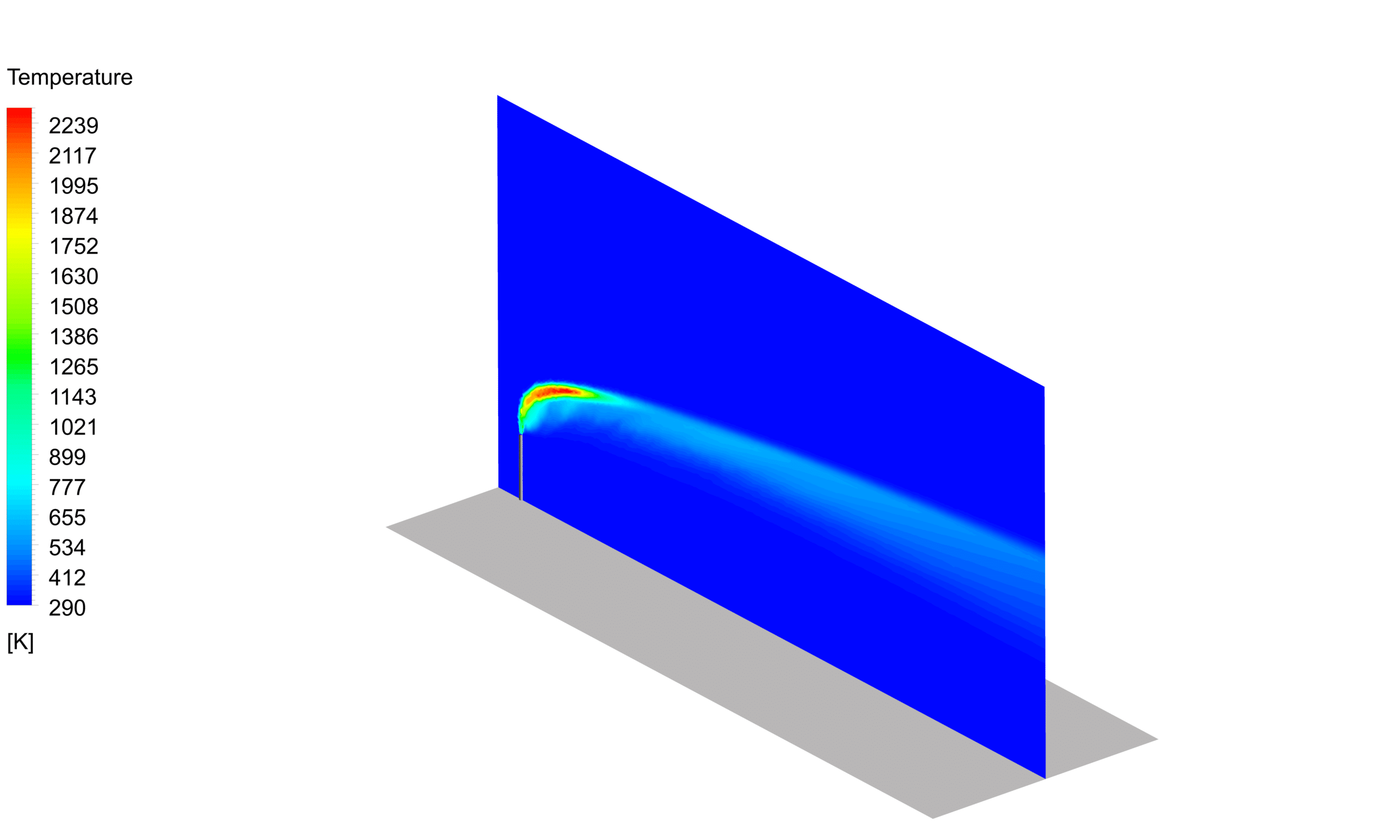

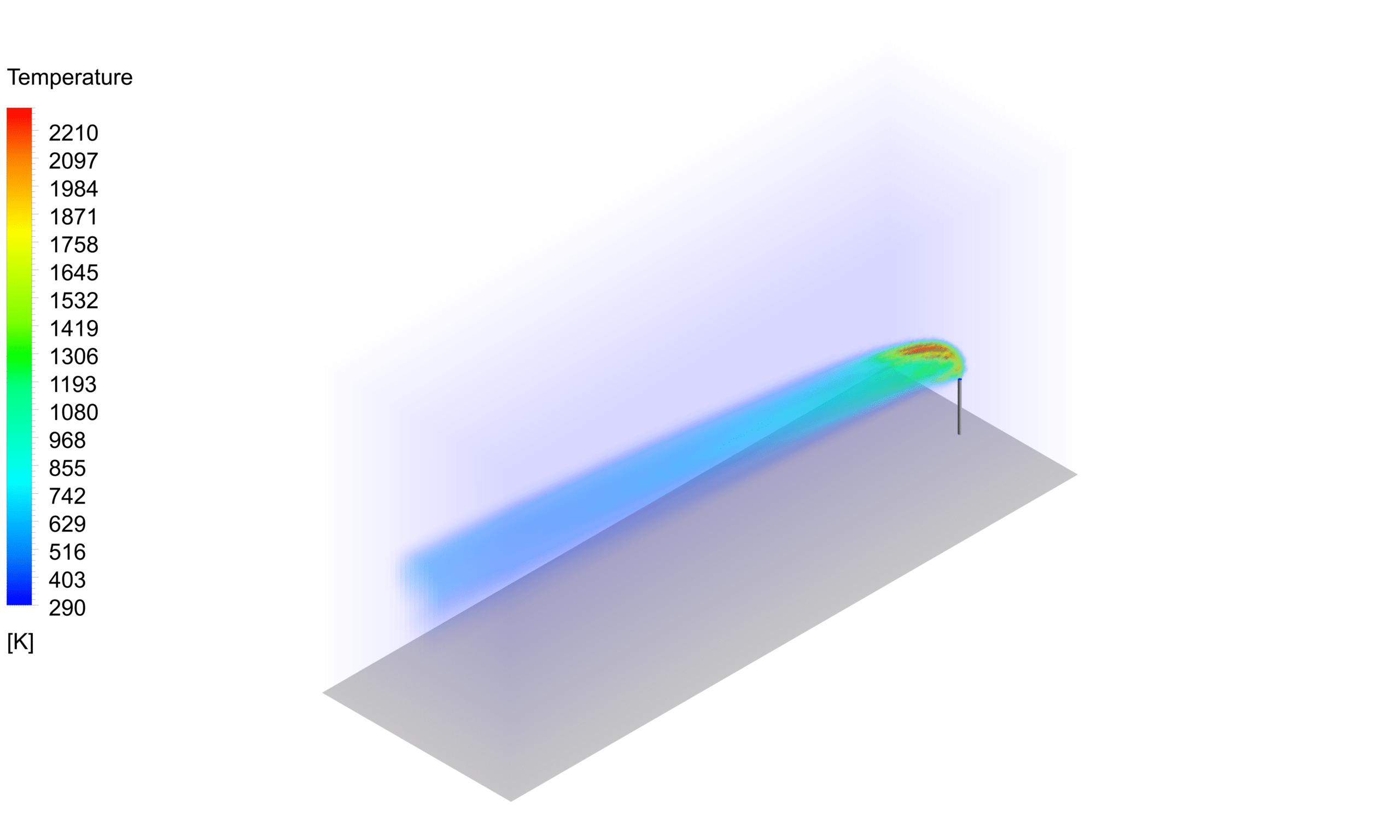

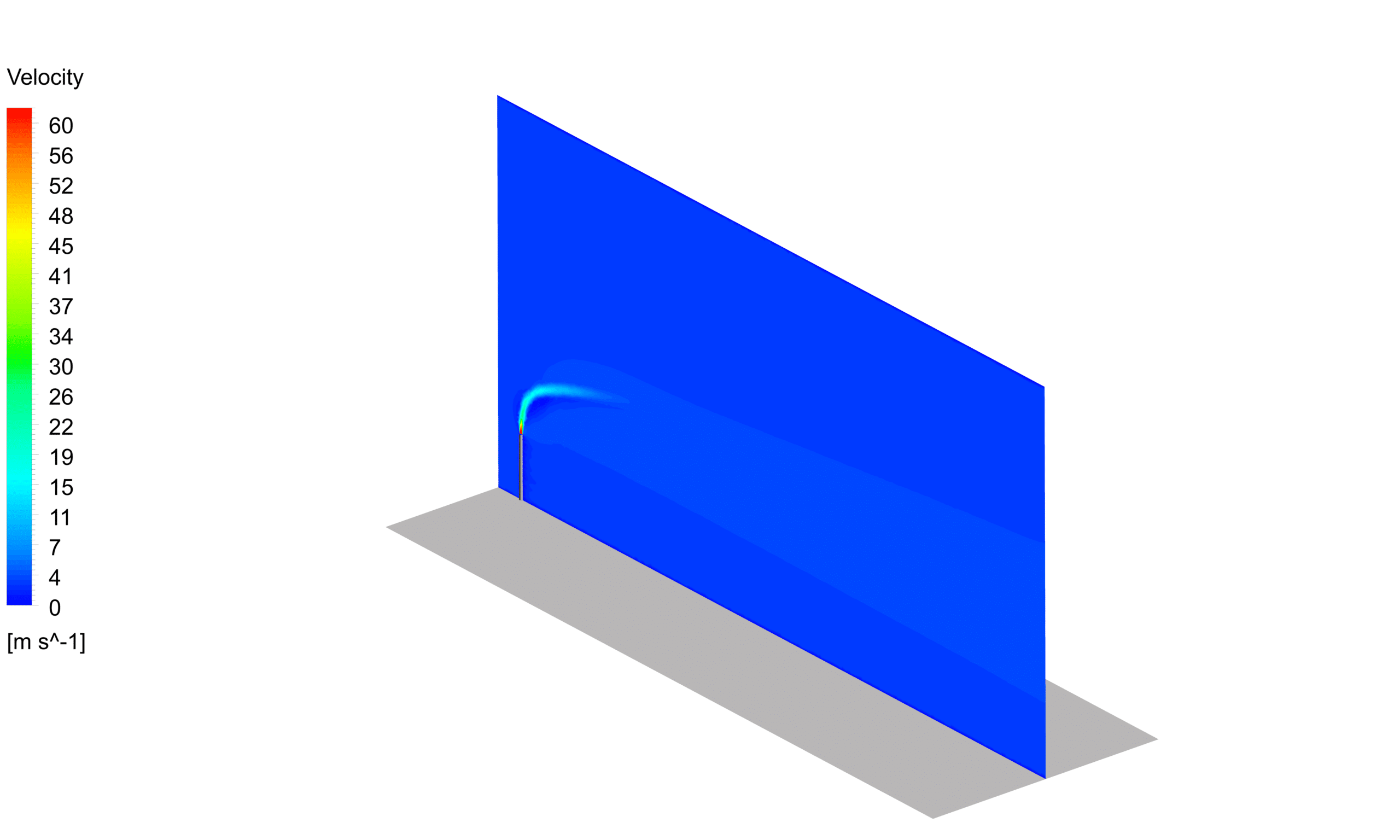

- Flare Outlet Velocity and Temperature: The velocity contours at the flare outlet, depicts the high-velocity jet of wood gas being released into the atmosphere. The temperature contours, indicates the elevated temperatures of the wood gas as it exits the flare mouth.

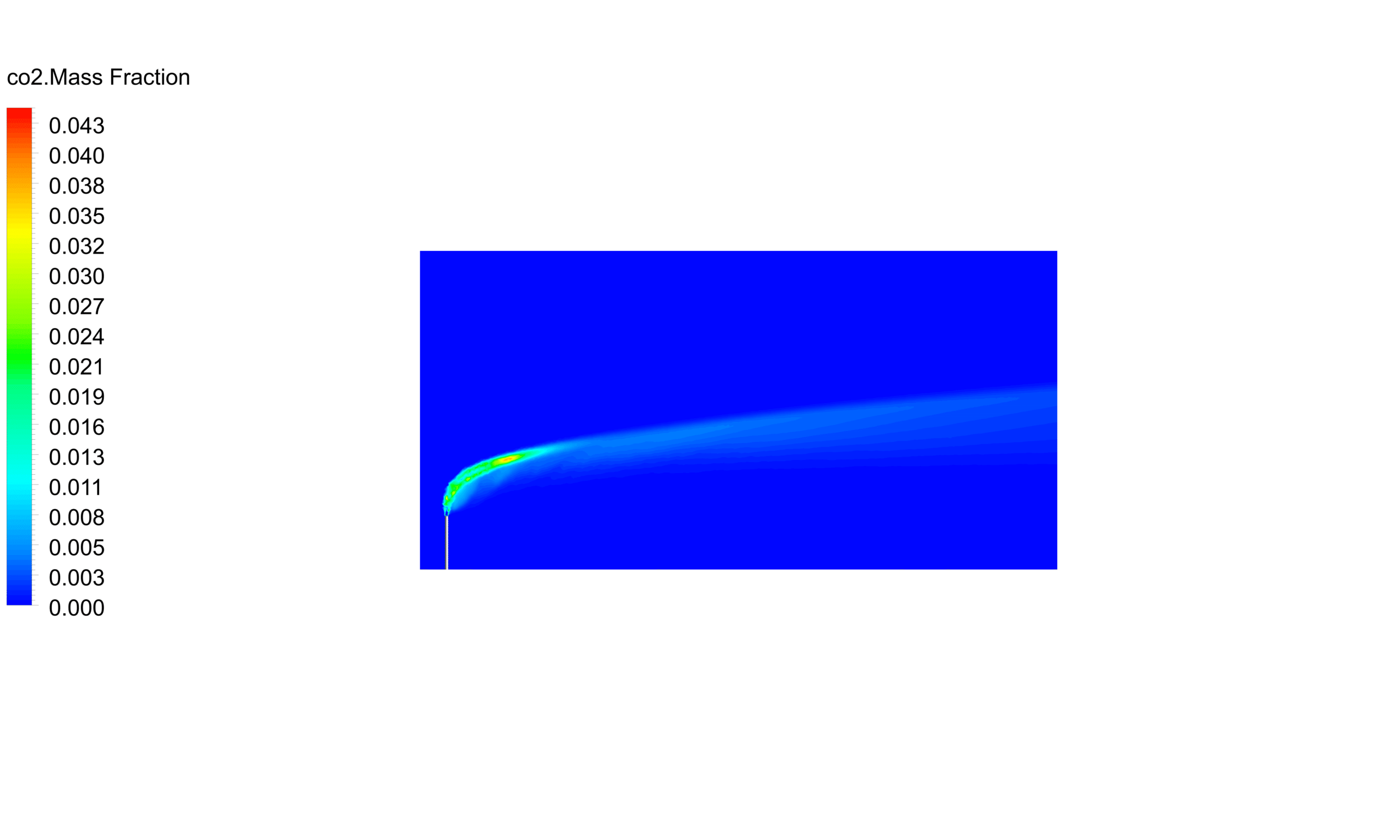

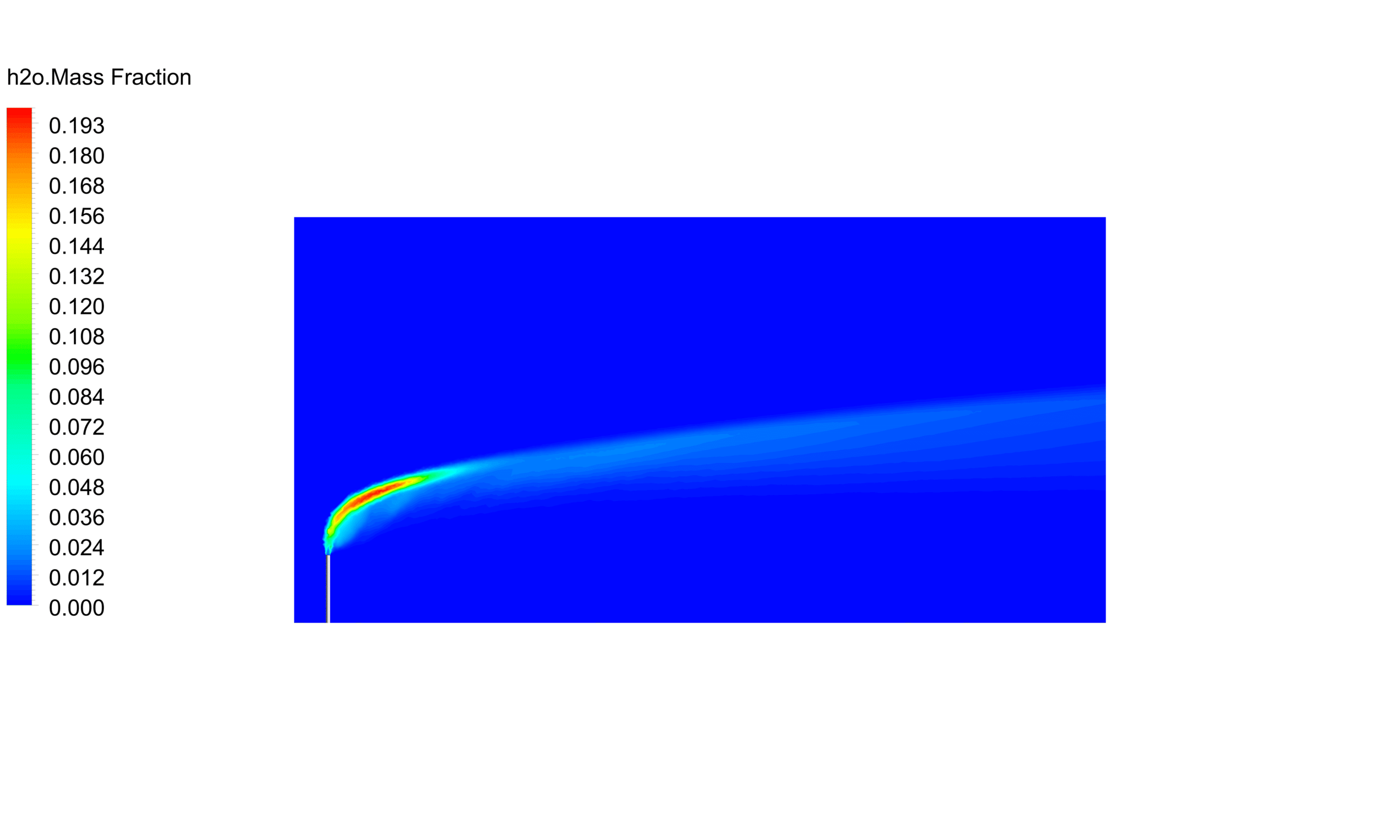

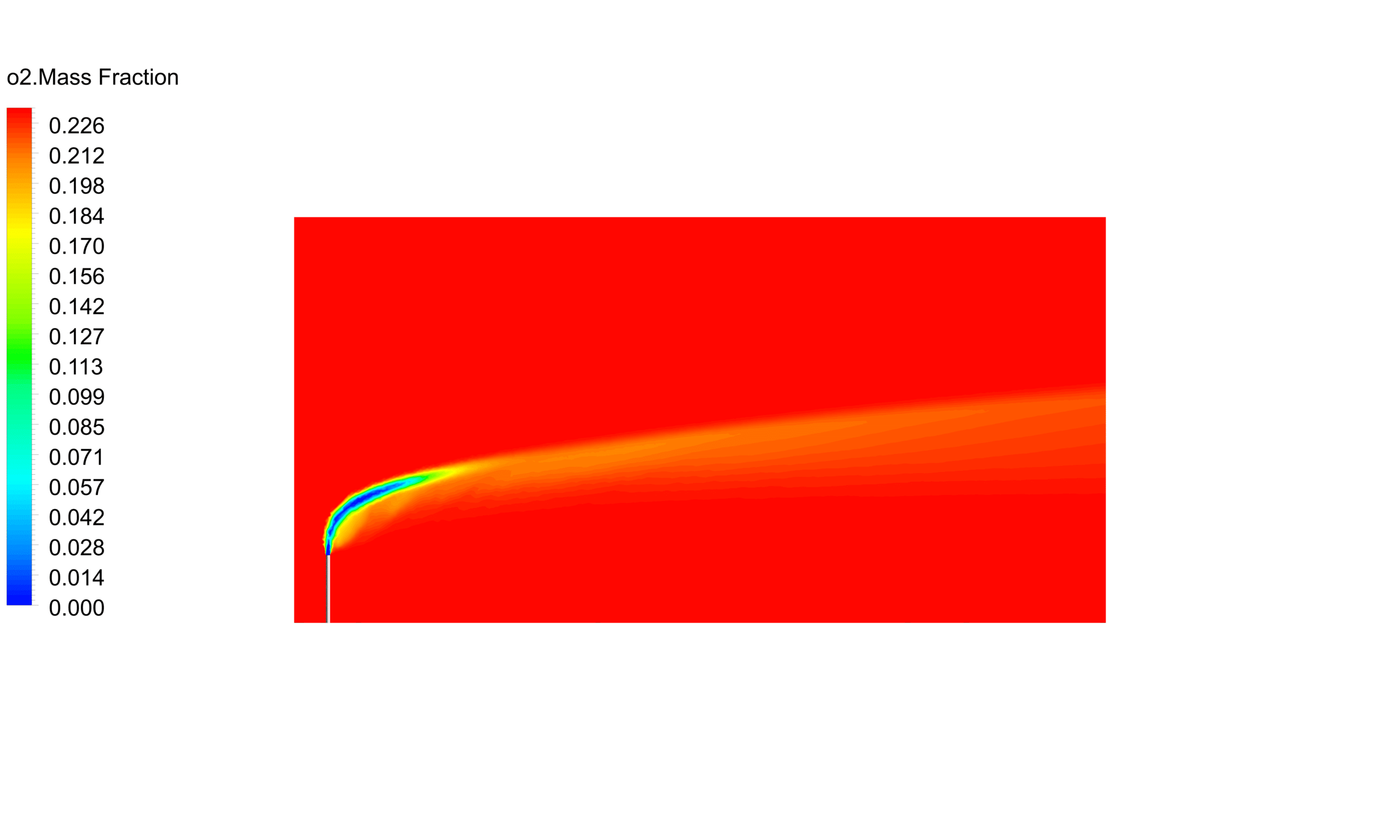

- Dispersion and Dilution: Other figures illustrate the dispersion and dilution of the wood gas plume as it travels away from the flare outlet. The contour plots show the gradual decrease in species concentrations, such as carbon dioxide (CO2), carbon monoxide (CO), methane (CH4), and hydrogen (H2), as the plume mixes with the surrounding air.

- Atmospheric Interactions: The contour plots also reveal the influence of atmospheric conditions, such as wind speed and direction, on the dispersion and dilution of the wood gas plume. The plume appears to be carried and dispersed by the prevailing wind, with the species concentrations decreasing as the distance from the flare outlet increases.

- Potential Impacts: The simulation results provide insights into the potential impacts of the wood gas plume on the surrounding environment. The concentration gradients of various species, such as CO2, CO, and CH4, can be used to assess the potential effects on air quality, vegetation, and nearby communities.

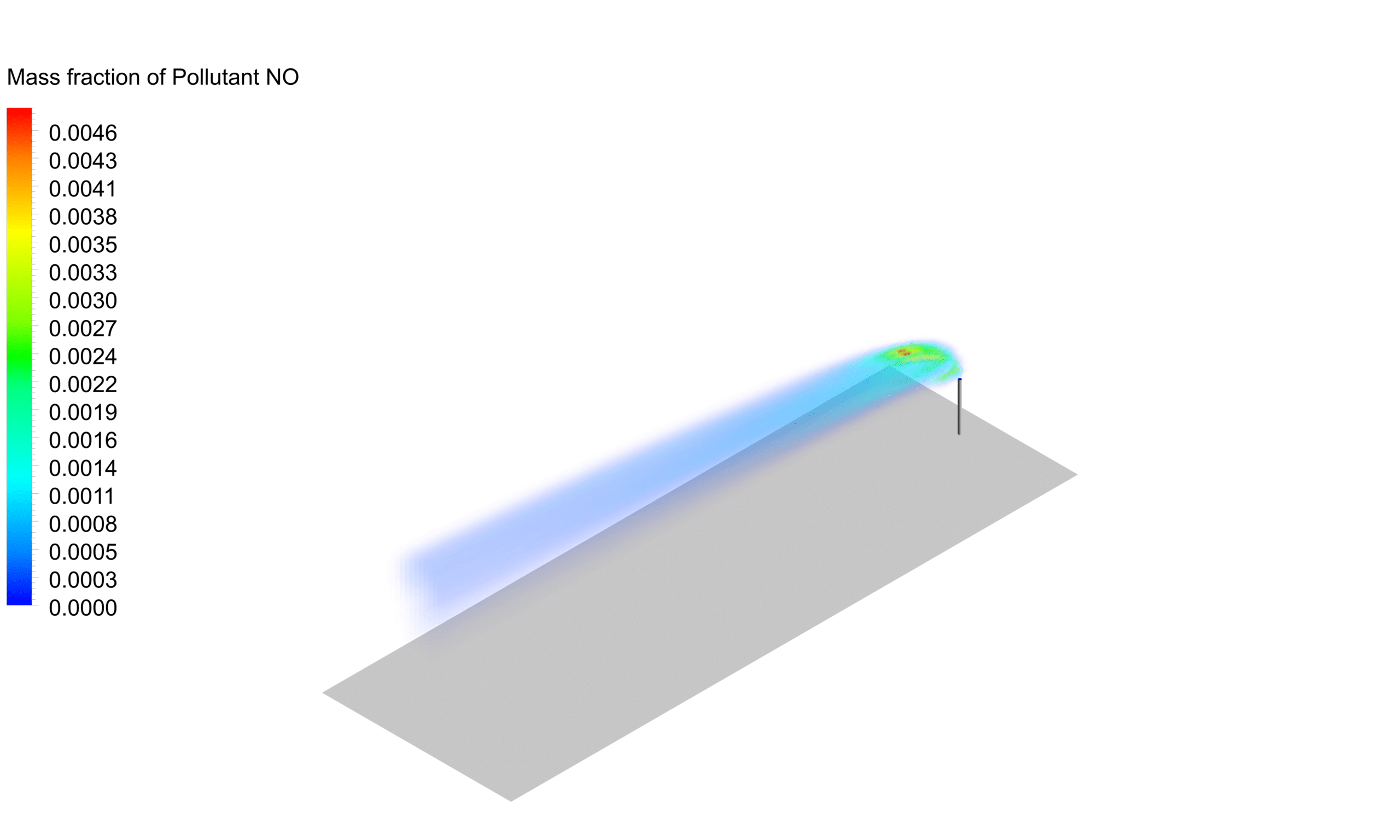

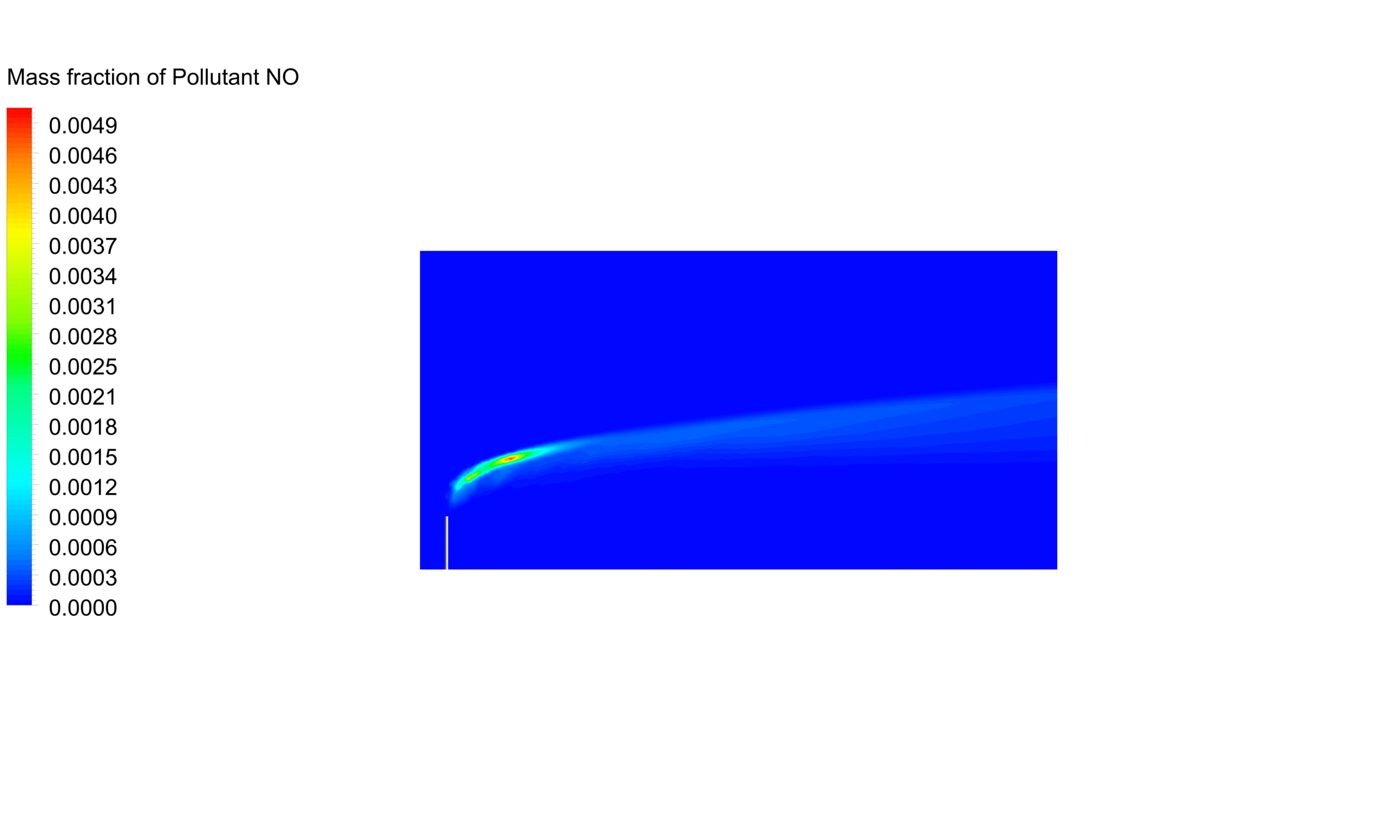

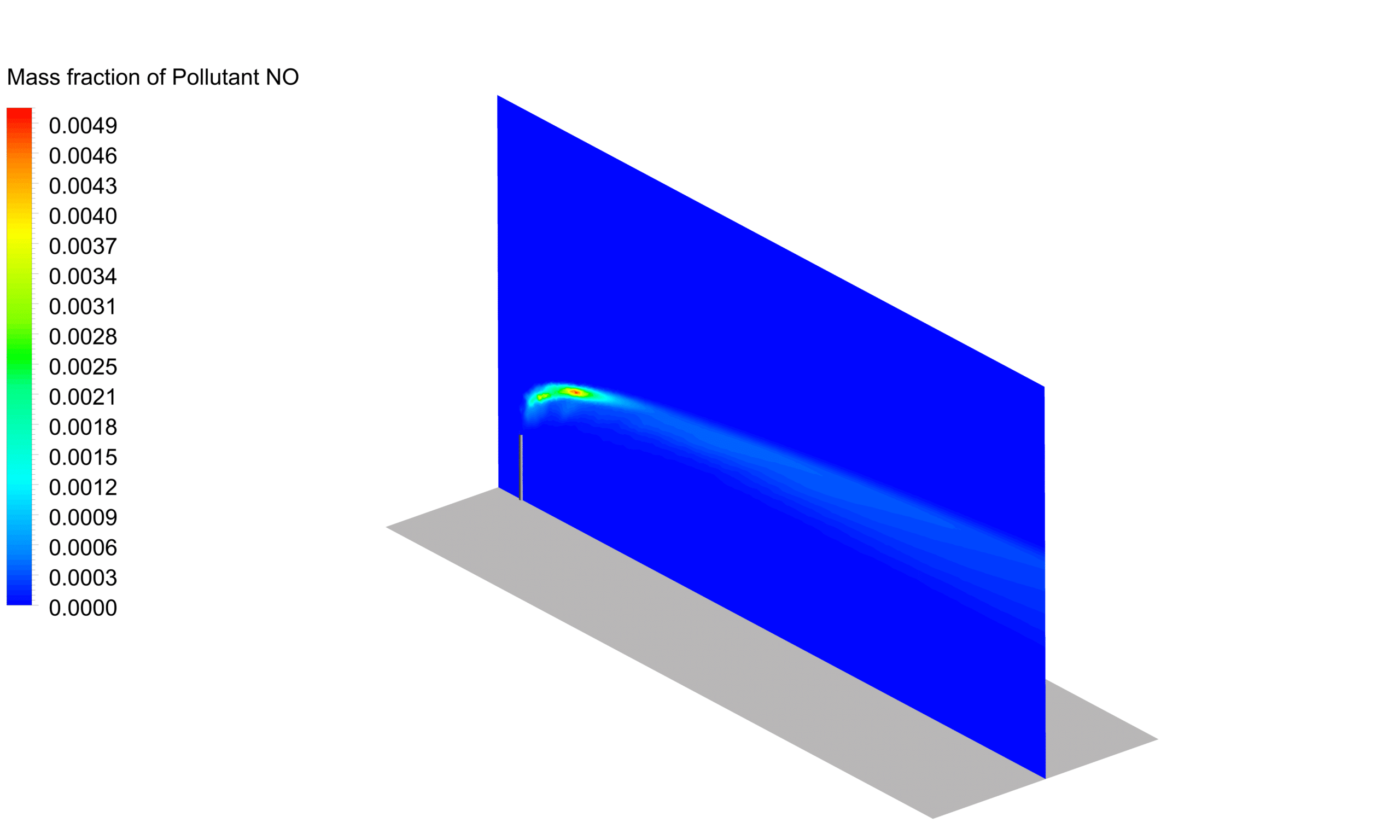

- NO Formation: Contours of NO mass fraction within the flare system and the surrounding atmosphere show that the high temperature regions inside the flare chamber and at the flare tip are conducive to thermal NO formation via the oxidation of atmospheric nitrogen. The simulation results highlight areas with elevated NO concentrations, allowing for the identification of potential hotspots.

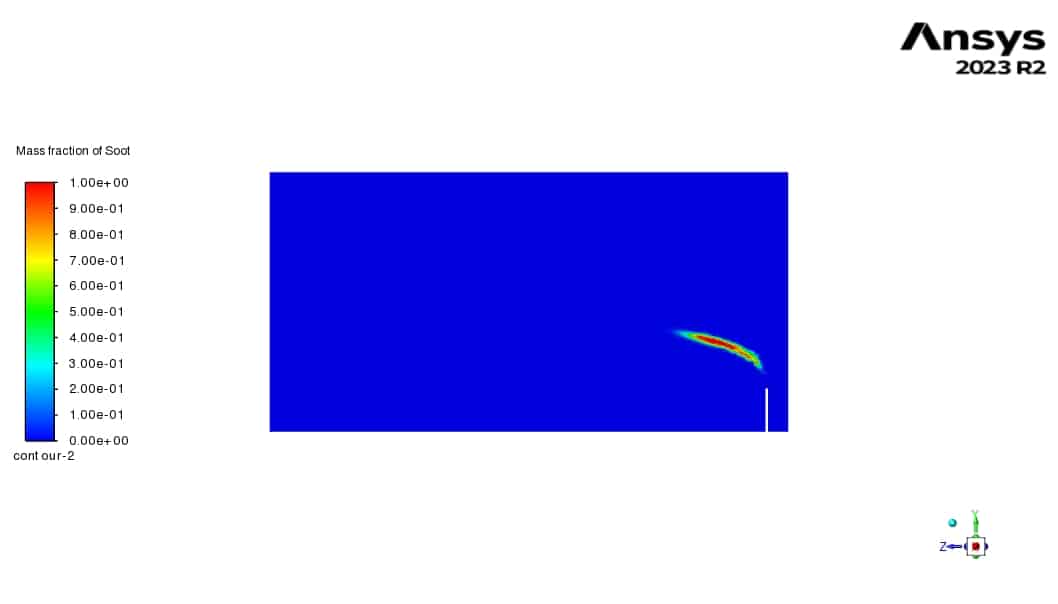

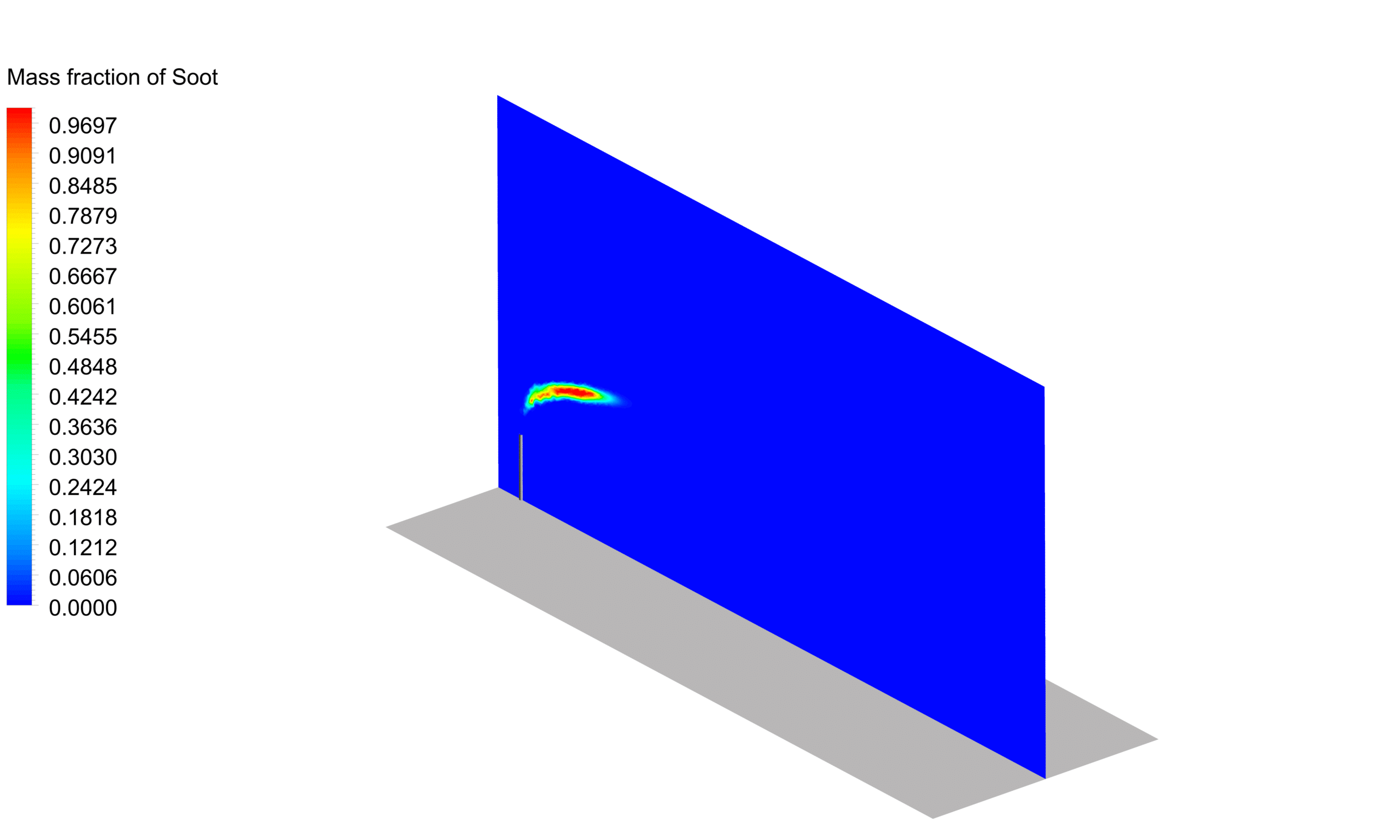

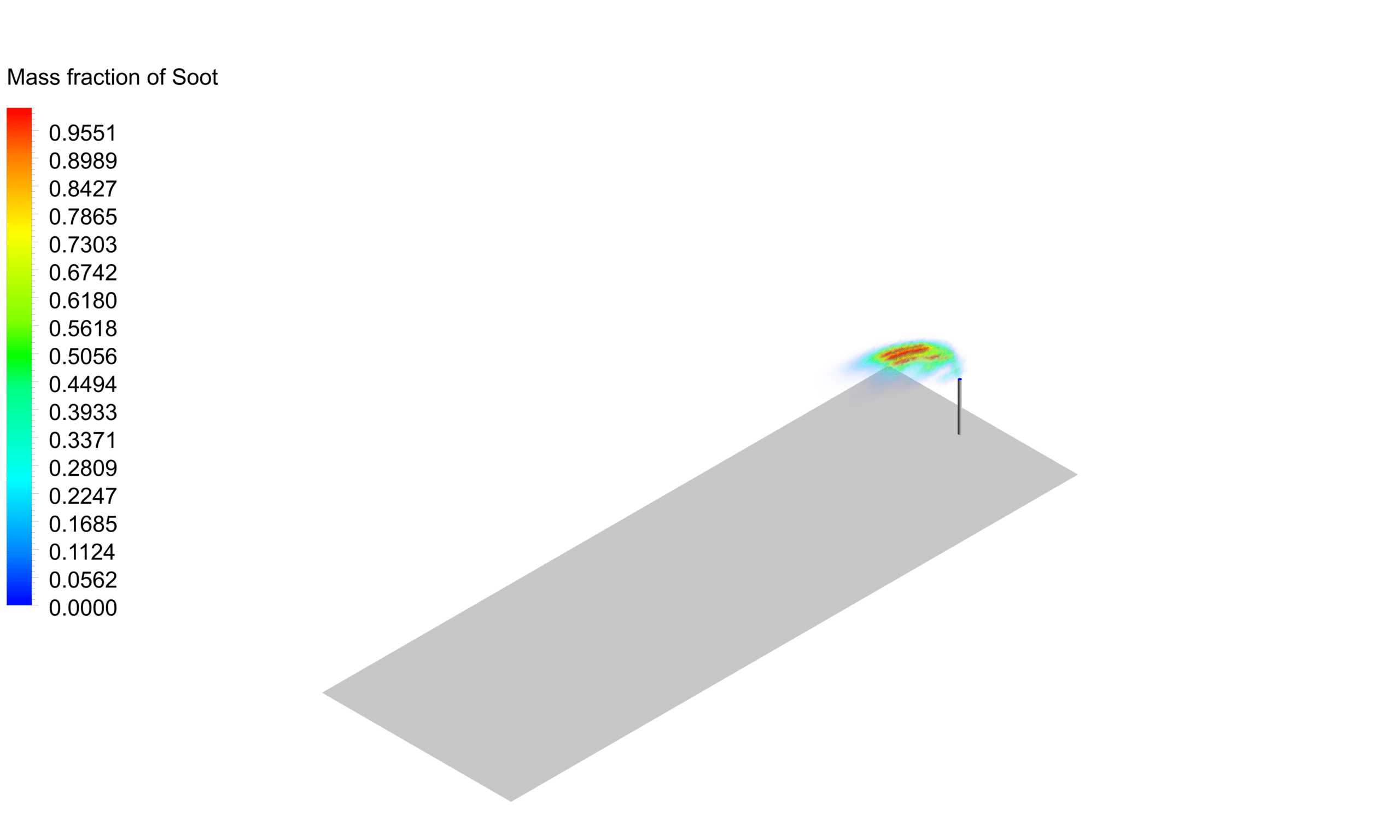

- Soot Formation: Soot particles are generated due to incomplete combustion and fuel-rich conditions(shown in contours of soot mass fraction). The contour plots reveal regions where soot formation is likely to occur, such as in the flare chamber and the initial plume region.

Conclusions

The ANSYS Fluent simulation has successfully demonstrated the flow, dispersion, and dilution behavior of the wood gas plume as it is released from the flare system. The results highlight the influence of factors such as flare outlet conditions, atmospheric conditions, and chemical reactions on the dispersion and dilution patterns.

These findings can be valuable for assessing the environmental impact of the flare system and developing strategies for mitigating potential risks associated with the wood gas emissions. Further analysis and validation with field measurements or environmental monitoring data would enhance the accuracy and applicability of the simulation results.

Reviews

There are no reviews yet.