Evaporation: 6 Practical Exercises, Intermediate

$399.00 $199.50 Student Discount

- Master advanced evaporation modeling techniques using ANSYS Fluent

- Develop custom UDFs for complex mass transfer phenomena

- Analyze membrane distillation and heat exchanger systems

- Simulate industrial-scale gasification processes

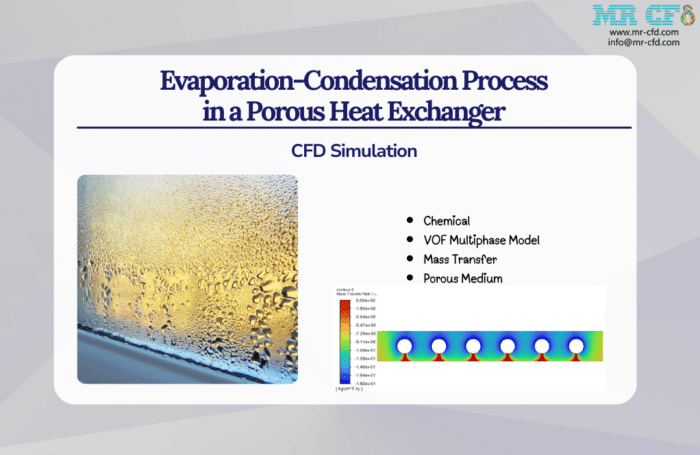

- Study coupled heat and mass transfer in porous media

- Implement advanced particle-fluid interaction models

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Evaporation CFD Simulation Training Package, 6 Practical Exercises by ANSYS Fluent: Intermediate Users

This specialized training package is designed for intermediate users seeking to enhance their ANSYS Fluent expertise in advanced evaporation and phase change simulations. The course focuses on sophisticated modeling techniques and industrial applications.

Systematic Advanced Learning

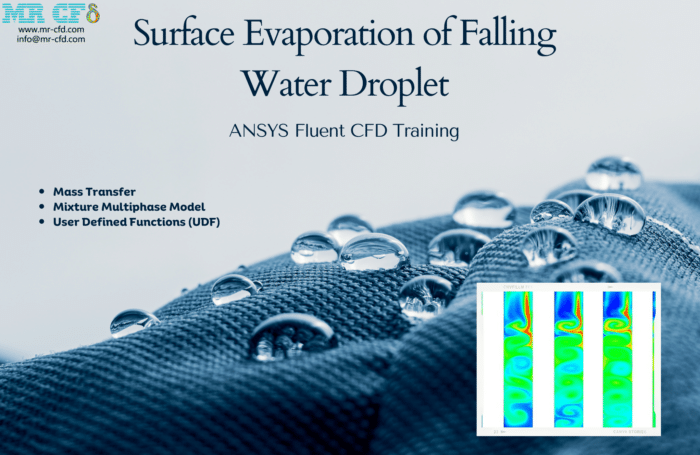

The training begins with fundamental mass transfer concepts, exploring surface evaporation of falling droplets and custom UDF implementation for precise evaporation-condensation rate calculations. These foundational modules establish advanced modeling methodologies essential for complex simulations.

Moving to industrial applications, participants explore membrane distillation technology through AGMD simulation, incorporating complex heat and mass transfer mechanisms. The course progresses to advanced heat exchanger analysis, focusing on evaporation-condensation processes in porous media.

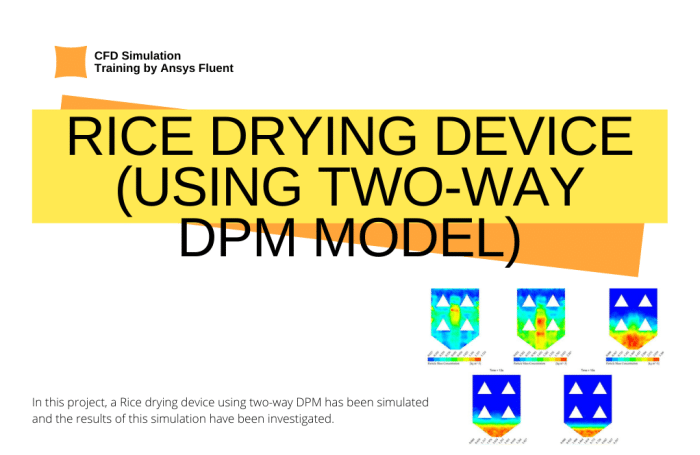

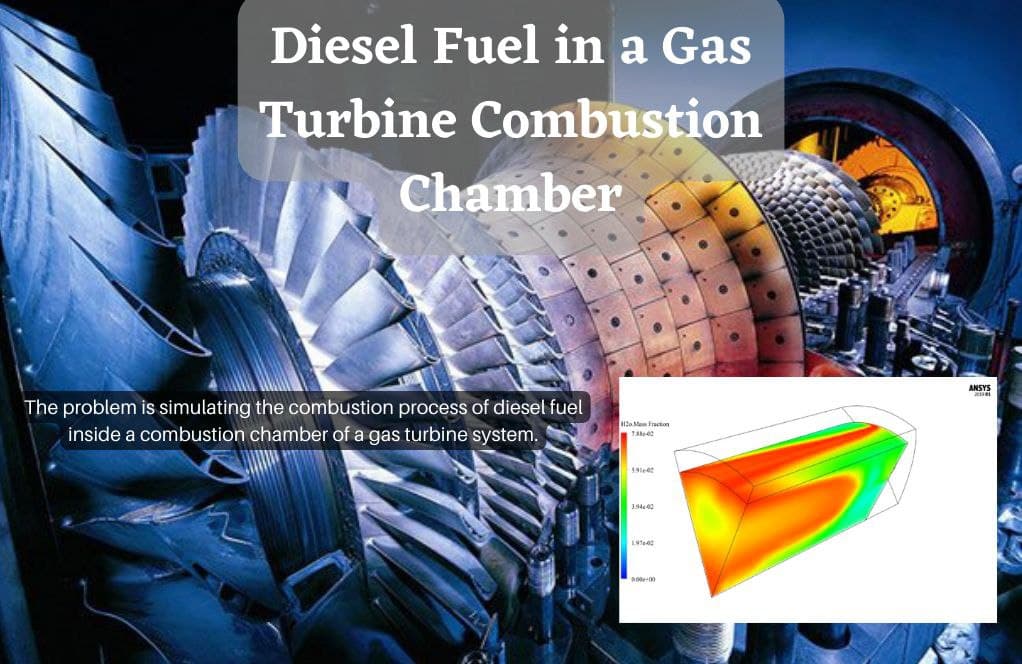

The program culminates with sophisticated industrial processes, including grain drying using two-way coupled DPM modeling and gasification chamber simulation with P1 radiation modeling. These modules integrate multiple physics phenomena and advanced numerical techniques.

Professional Application Focus

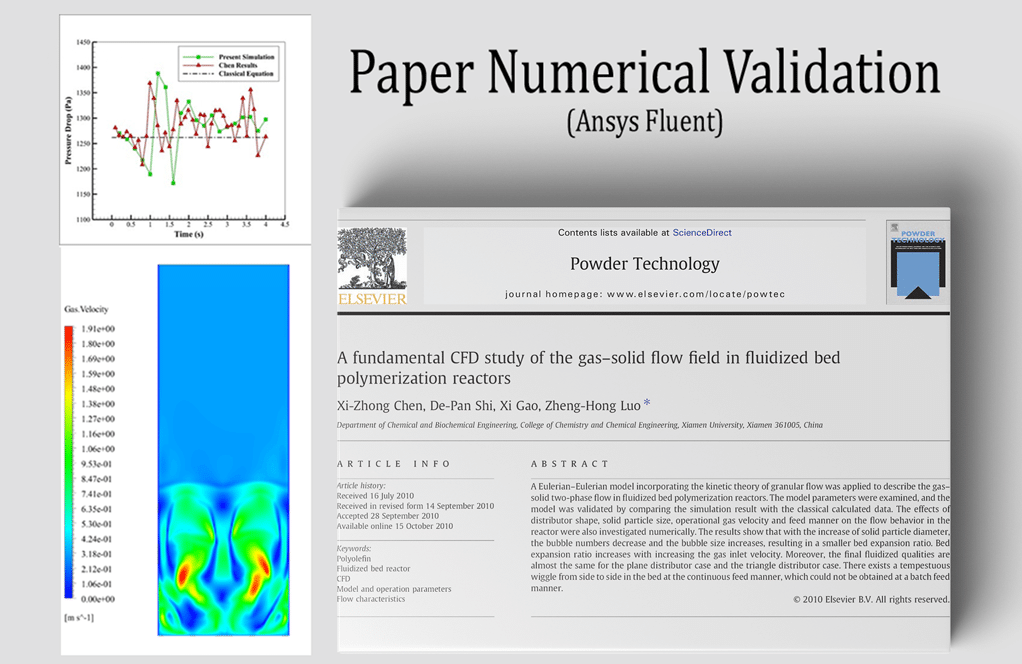

Each module emphasizes practical implementation and troubleshooting of complex numerical models, preparing participants for challenging industrial applications. Special attention is given to model validation and optimization strategies.

Advanced Technical Proficiencies

Upon completion, participants will master:

– Custom UDF development for mass transfer

– Advanced multiphase modeling techniques

– Coupled heat and mass transfer analysis

– Radiation modeling in complex geometries

– Two-way particle-fluid coupling

– Membrane transport phenomena

– Industrial process optimization

– Advanced numerical method implementation

Reviews

There are no reviews yet.