External Gear Pump CFD Simulation, Dynamic Mesh

$240.00 $120.00 Student Discount

- The problem numerically simulates the External Gear Pump using ANSYS Fluent software.

- We design the 2-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 9,254.

- We perform this simulation as unsteady (Transient).

- We use the Dynamic Mesh Model to define deforming and moving zones.

- We use the user-defined function (CG-Motion UDF) to define the rotational motion of gears.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

This project is related to the External Gear Pump numerical simulation using ANSYS Fluent software. A pump is a mechanical device for moving and transferring all liquids from one place to another. In this way, by increasing the pressure, pumps cause liquids to move to a higher height (by increasing the head) and even lower (such as tanks).

This product is the fifth chapter of the Dynamic Mesh Training Course.

In fact, the pump takes mechanical energy from an external source, such as a motor, and transfers it to the fluid passing through it. As a result, the energy of the fluid increases after leaving the pump.

The energy transfer to the pump fluid is done in two dynamic and displacement methods. Therefore, pumps are divided into two categories: positive displacement pumps and dynamic or non-positive displacement pumps. Positive displacement pumps are divided into two groups: rotary (such as gear, lobe, and vane) and reciprocating (piston and diaphragm).

A gear pump is one of the most common pumps to increase the hydraulic power of a fluid. Gear pumps move liquids using gears. These gear pumps are made of two types of internal and external gears.

External gear pumps consist of two gears that rotate in opposite directions. When two gears make contact with their teeth, fluid is trapped. Now, when the teeth are separated from each other due to rotation, high-pressure fluid is rotated through the ribs to the outlet.

In this project, we simulated the water flow inside an external gear pump.

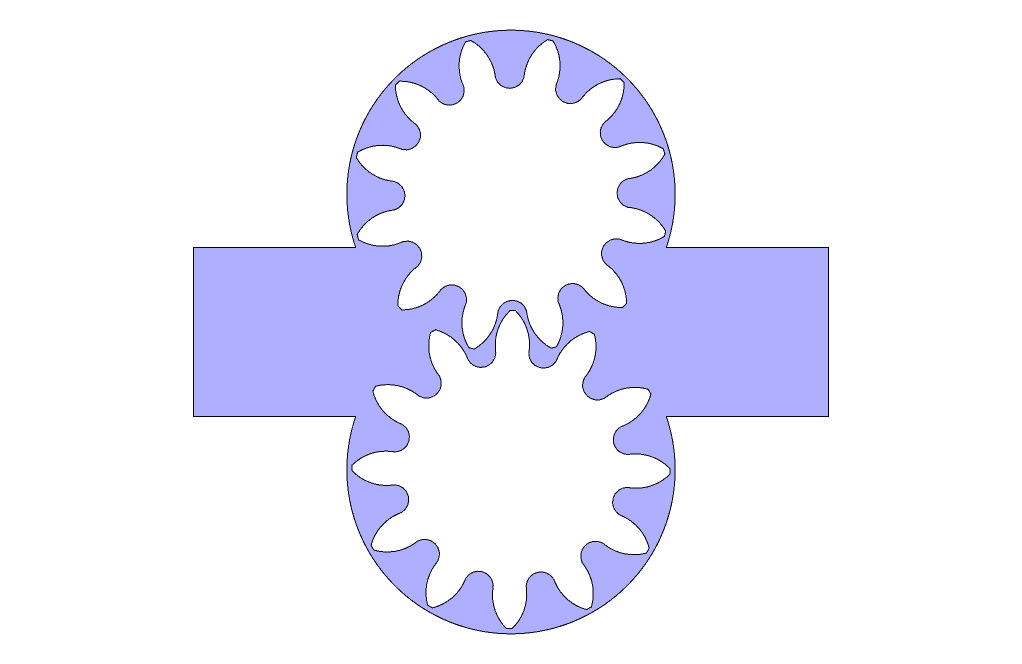

We aim to model the rotation of two gears inside the pump. The gears’ rotation changes the fluid’s behavior in the pump momentarily. So, the mesh of the computing domain deforms over time.

We modeled the geometry of the project using Design Modeler software. The geometry is related to an external gear pump. The computational domain includes the internal space of the pump with two superimposed gears. Then we meshed the model with ANSYS Meshing software. The model mesh is unstructured, and the number of cells equals 9,254.

External Gear Pump Methodology

The Dynamic Mesh Model is used in this simulation. We generally use a dynamic mesh whenever we have a moving boundary or a deforming zone.

Here, two gears are rotating in opposite directions. So this causes the mesh to deform over time. Therefore, we define a Rigid Body to define the rotational motion of the gears. We use a user-defined function (UDF) to define the motion of the rigid body.

According to the rotational motion of the gears as a rigid body, the mesh zone around the gears is deformed. So, for this zone, we use the Deforming option.

Due to the nature of this modeling, fluid behavior is time-dependent. Hence, we use the unsteady (Transient) solver.

Conclusion

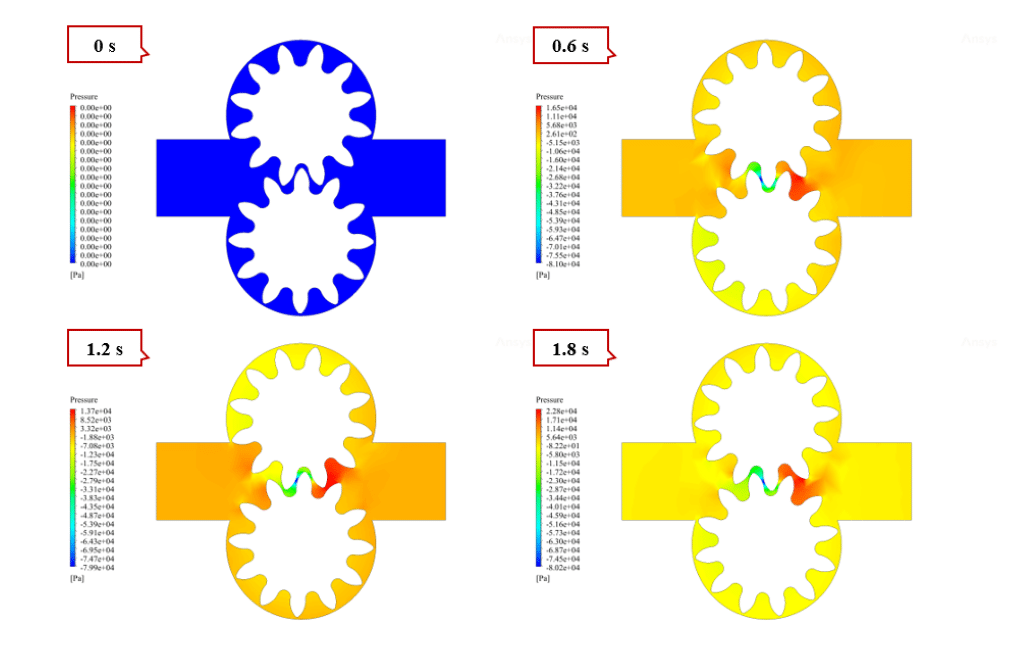

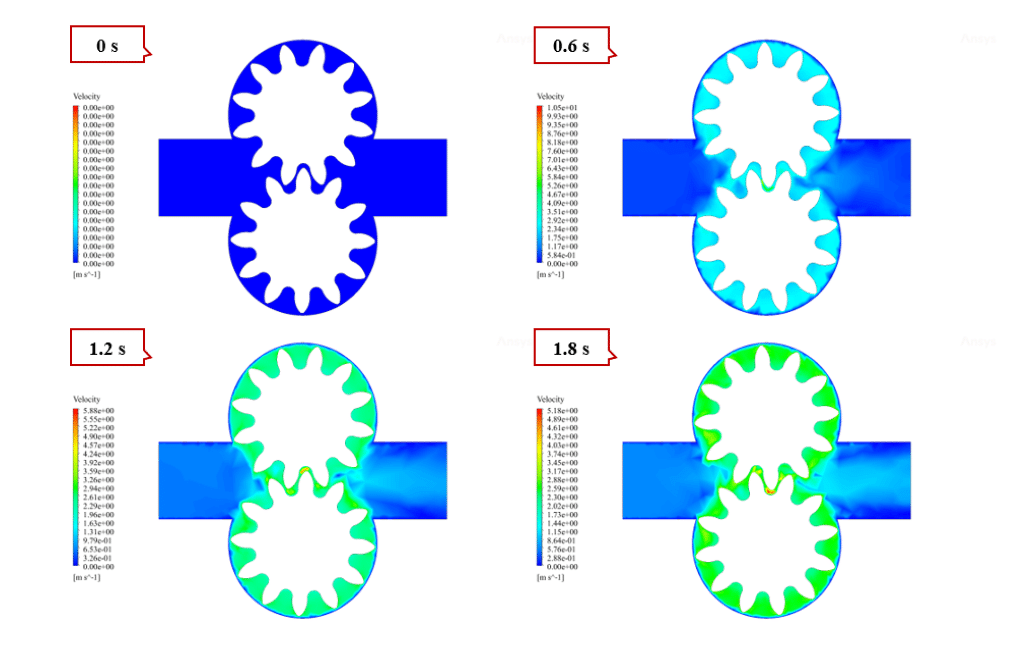

After the solution, we obtained pressure and velocity contours. Because the gears rotate over time, we obtained the animation of the velocity and pressure contours.

The results show that this gear pump is working correctly. This pump can transfer the fluid well and increase the fluid’s pressure. The fluid is trapped in the space between the gears in contact. Then this fluid is pushed towards the outlet with high pressure.

Prof. Douglas Littel –

The project’s results are intricate and convincing. Watching the gears operate in motion with dynamic meshes illustrates how powerful simulation tools can become when investigating fluid dynamics in mechanical devices.

MR CFD Support –

Thank you for your positive feedback on the External Gear Pump CFD Simulation project. We’re thrilled to hear that you found the results compelling and that you appreciated the effectiveness of employing dynamic meshing in analyzing fluid movements within mechanical systems. Your insights emphasize the strength of simulation as a tool for better understanding complex engineering processes.

Dr. Era Carroll –

I was amazed at how well the simulation replicated the gear pump’s functionality. The deformation of the mesh alongside the gears’ rotation was impressive. It provided a clear visualization of how fluid pressure and velocity change throughout the pump.

MR CFD Support –

Thank you so much for your feedback! We’re thrilled to hear that you found the simulation to be accurate and helpful in visualizing the pump’s operation. The dynamic mesh technique is indeed critical for simulating such complex movement accurately. We appreciate your compliments on the functionality and clarity of our simulation.

Prof. May Barrows Jr. –

The dynamic mesh training course sounds very thorough. I was particularly impressed by the real-time deformation factor of the simulation tied to gear rotation. The illustration of fluid pressure and velocity using animation brings a comprehensive understanding of the pump operations. Keep up the great work!

MR CFD Support –

Thank you for the kind words! We’re glad you found the dynamic mesh course impressive and informative. It’s great to hear that the real-time simulation and animated illustrations added value to your understanding of the pump’s function. If you have any further questions or need assistance, feel free to reach out. Your feedback is very much appreciated!

Antonia Towne –

What a detailed course! It’s awesome to see the application of the Dynamic Mesh Model, especially with the challenge of simulating the rotation of gears in an external gear pump. Your use of a UDF to dictate the rigid body motion of the gears is very intriguing to me. Does the course provide the UDF script, or do we need to code it ourselves?

MR CFD Support –

The Dynamic Mesh Training Course provides you with the necessary UDF script as part of the learning material. You’re guided through the implementation process of this UDF to ensure you understand how the motion of the gears is simulated within ANSYS Fluent.

Mr. Lesley Simonis –

I’m thrilled with the dynamic mesh modeling feature! The visual animations of velocity and pressure truly help me understand how the pump operates over time.

MR CFD Support –

Thank you for your praise! We’re glad the animations enhanced your understanding of the gear pump’s mechanisms. Dynamic mesh tools in ANSYS Fluent are indeed powerful in bringing such complex simulations to life.

Joannie Wyman –

I’m thrilled with the detailed explanation of the external gear pump simulation. It really helped me understand the dynamics of gear pumps and the significance of a dynamic mesh in capturing such fluid behaviors.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that our External Gear Pump CFD Simulation could enhance your understanding of gear pump dynamics and the application of dynamic mesh in simulations. Your feedback is greatly appreciated!

Destany Jaskolski –

I followed the project simulation, and the animations of the velocity and pressure contours were intriguing. Seeing how the fluid moves and pressure increases within the pump was educational. Can we see these flux characteristics at varied speeds to simulate different operational conditions?

MR CFD Support –

It’s great to hear you found the animations valuable for understanding the dynamics inside the external gear pump! Absolutely, varied speeds can be simulated by changing the rotational velocity of the gears using the User-Defined Functions (UDFs) in the simulation setup. This allows you to study how different operational conditions affect the fluid flow and pressure built-up inside the pump.

Agnes Mueller –

The description gave me a clear understanding of the dynamic mesh technique used to simulate rotor dynamics. Could you explain how interpolation is handled between the rotating and stationary regions in this kind of simulation?

MR CFD Support –

In simulations involving moving and stationary parts, particularly with the dynamic mesh technique, interpolation is key for the interaction between the domains. In ANSYS Fluent, the interpolation handles the transmission of data such as velocities and pressures from the cells of the rotating domain to the stationary one and vice versa. Fluent often uses a conservative interpolation scheme to ensure mass and momentum are conserved as the mesh updates through each timestep. User-Defined Functions (UDF) supports specifying the boundary movement to accurately model the interfaces between rotating gears and the fluid domain.

Prof. Tate Nolan I –

The dynamic meshing and UDF implementation for the gear pump simulation sound intriguing. Could you elaborate more on the challenges faced when setting up the dynamic mesh for this particular CFD problem?

MR CFD Support –

Certainly! Severe mesh deformation was a challenge for the dynamic gear pump simulation since the gears are constantly rotating. Ensuring a high-quality mesh that adapts properly during rotation is critical to avoid convergence issues or inaccurate simulations. Implementing a UDF to accurately model the gears’ rotational movement also requires meticulous scripting and debugging to ensure it interacts as expected with the dynamic mesh. Smooth transitions within the deforming zones around the rotating gears had to be maintained throughout the simulation to avoid errors and ensure accuracy in the fluid flow prediction.

Ms. Ressie Abbott –

I absolutely loved the detailed explanation of the External Gear Pump simulation in the Dynamic Mesh Course! It was intriguing to visualize how the movement of the gears impacts fluid flow and pressure within the pump environment. Great work employing UDF for gear motion – the animation of contours provided a practical comprehension of the velocity and pressure changes. Superb material for anyone looking to get hands-on with gear pump CFD simulations using ANSYS Fluent.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear you found the External Gear Pump’s simulation explanation informative and useful. It’s always rewarding to know our materials are helping others gain a better understanding of CFD simulations in practical, real-world applications. We appreciate your feedback and are glad you’re satisfied with the quality of our Dynamic Mesh Training Course!

Dallin Kautzer III –

I’m very curious about how the gears’ motion was mimicked in the simulation. Can you provide more details on the dynamic mesh method used?

MR CFD Support –

In the simulation, the gears’ motion is replicated using the Dynamic Mesh Model and a user-defined function (UDF). The UDF is responsible for dictating the rotational motion of the gears as rigid bodies. Due to the moving gears, the mesh in the vicinity of these parts deforms dynamically over time. This is achieved by designating the moving zones around the gears as ‘Deforming’ within ANSYS Fluent, meaning that the mesh adapts its shape as the gears turn.

Miss Jessica Wilkinson DDS –

I found the external gear pump simulation to be truly remarkable. It has thoroughly demonstrated the efficiencies of dynamic mesh applications.

MR CFD Support –

Thank you for the kind words and positive feedback on the external gear pump simulation! We’re delighted to hear that you found the application of dynamic mesh in demonstrating the pump’s operation to be effective and informative.

Cary Mills –

I’m impressed with how the External Gear Pump simulation demonstrates the fluid dynamics at play within a gear pump set up. The combination of a well-structured dynamic mesh with the proper use of a UDF to simulate the gears’ movement seems spot on. Great work incorporating realistic mechanical simulations into fluid behaviour analysis!

MR CFD Support –

Thank you for the positive feedback! We’re thrilled to hear that you appreciate the work and details that went into the simulation. Our goal is always to provide accurate and educational simulations that represent real-world scenarios, and it’s gratifying to know when we’ve achieved that. If you have any more questions or need further guidance, feel free to reach out!

Elmore Marks –

A very informative course! It nicely outlined the rotation of the gears and the resulting fluid flow dynamics. But, could you provide more details on how the UDF precisely controls the gear motion in the simulation?

MR CFD Support –

Thank you for your kind words about our External Gear Pump course! To answer your question, the User-Defined Function (UDF) controls the gear motion by prescribing the rotational velocity as a function of time. This ensures that the mesh updates correctly throughout the simulation to reflect the true physical movement of the gears. The UDF tracks the angular rotation, applies it to the rigid body zones of the gears, and updates the dynamic mesh at each time step, keeping the simulation consistent with the real-life operation of an external gear pump.

Thad Johnson –

The training course on Dynamic Mesh seems very practical, especially for understanding the behavior of gear pumps. The application of UDF for the gear’s motion is quite intriguing; how often do the mesh zones update during the simulation, and does this significantly affect computational resources?

MR CFD Support –

In this simulation, the dynamic mesh zones update at every time step to reflect the gears’ movement accurately. The frequency of update and computational resources required can vary based on the complexity of the geometry and the desired accuracy of the simulation results. More frequent updates can lead to more accurate simulation results but will require more computational power and time.

Isabella Cassin –

Absolutely enthralled by the mastery displayed in simulating the fluid dynamics within an external gear pump! The use of dynamic mesh to model the gear rotation and resulting fluid movement is ingenious. Having the gears’ rotating action coupled with the fluid pressure and velocity changes captured over time provides a rich, detailed insight into the pump’s operation. Brilliant work by MR CFD in delivering such a complex simulation in a comprehendible and detailed manner! Looking forward to applying this knowledge in real-world applications.

MR CFD Support –

Thank you for your thoughtful and positive feedback! We’re thrilled to hear that our External Gear Pump CFD Simulation with Dynamic Mesh has provided you with valuable insights and a clearer understanding of the pump’s operations. It’s great to know that our product could exceed your expectations and that you’re looking forward to implementing this knowledge in practical scenarios. If you need any more information or support, feel free to reach out. We are always here to help!

Aliza Larson –

I absolutely loved going through the External Gear Pump CFD Simulation tutorial. The dynamic mesh technique is fascinating, and the clear animations helped me understand the process fully. Keep up the great work!

MR CFD Support –

Thank you very much for your kind words! We’re delighted to hear that you found the tutorial informative and that the animations of the dynamic mesh were helpful in understanding the gear pump simulation. Your feedback is encouraging and much appreciated. If you need further information or have any more questions, please don’t hesitate to reach out. Thank you for choosing our learning products, and we hope they continue to be a valuable resource for you!

Miss Flavie Strosin –

What an informative project overview on external gear pump simulation. I’ve actually learned a lot from this. The clear definition of the dynamic mesh and how the UDF was applied for the rotations was particularly insightful. Seeing fluid pressure increase due to the gear intervention was fascinating as well! Great work on illustrating these mechanical principles through simulation.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that you found the simulation insightful and that it helped clarify the concepts of dynamic mesh and using UDFs for modeling rotating gear motion in an external gear pump. It’s wonderful that the simulation could effectively demonstrate the mechanical principles and the functioning of the gear pump. We appreciate your compliments and hope to continue providing valuable learning experiences.

Hailey Collier –

Everything in this simulation is impressive! I was awestruck seeing how accurate the movement of the gears is reflected. It feels so realistic, just like looking into an actual gear pump in operation.

MR CFD Support –

We’re delighted to know that our simulation of the External Gear Pump met your expectations! It’s fantastic to hear you appreciated the dynamic details and real-world accuracy of the gear movements. Thank you for your positive feedback!

Adella Nolan –

I’m amazed by the detail in representing the fluid’s behavior with the movement of the gears. The animation must give a clear view of the process. Great job explaining the applications and workings of dynamic mesh in the gear pump simulation. Keep up the excellent work!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our simulation effectively demonstrated the fluid dynamics involved in a gear pump’s operation with rotating gears. Your appreciation means a lot to us, and it encourages us to continue delivering high-quality, informative simulations. If you have any further questions or need assistance with other simulations, feel free to reach out!

Marisol Wolff –

The product has a detailed methodology section that meticulously addressed the characteristics of dynamics mesh modeling in gear pump simulations. Well done to the MR CFD team for providing comprehensive information that enhances understanding.

MR CFD Support –

Thank you for your kind words! We are delighted to hear that our product on External Gear Pump simulation with Dynamic Mesh has been helpful to you. We strive to provide detailed and understandable CFD tutorials. It is great to know that our efforts are appreciated!

Prof. Wallace Eichmann DDS –

Definitely a brilliant resource for understanding dynamic mesh in action within gear pumps. The animations included in the outputs must provide great insights into the flow behavior over time. Were any validation studies referenced or comparisons with experimental data made to establish the credibility of the simulation results?

MR CFD Support –

Thank you for your positive feedback on the External Gear Pump CFD Simulation! Regarding your question about validation studies, for educational content, actual validation data specific to this course may not have been provided. However, the methodologies and principles taught are typically based on industry-standard practices and hypothetical scenarios that reflect realistically possible conditions. For more detailed studies or commercial projects, validation against experimental data would indeed be a crucial aspect to ensure simulation accuracy.

Amari Weissnat –

I’m currently learning from your ‘External Gear Pump CFD Simulation, Dynamic Mesh’ course and found the explanation regarding the gear rotation and mesh deformation incredibly insightful. A clear understanding of the gear interactions and fluid dynamics was crucial, and your course made it accessible. The visual materials and animations were particularly helpful in visualizing the process. Great work!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that the course materials and explanations have enhanced your understanding of the gear pump mechanics and mesh dynamics. Your feedback is greatly appreciated, and we look forward to providing more valuable learning resources.

Daisha Swaniawski –

The dynamic mesh simulation seems intricate! Were the velocities of the gears predefined, or were they a result of the simulation? How was this aspect controlled in Fluent?

MR CFD Support –

The rotational velocities of the gears were predefined parameters in the simulation setup. These motions were controlled using a User-Defined Function (UDF) to properly define the rigid body motion of each gear within Fluent. The UDF allowed for precise control of the gear rotation speed, critical for ensuring the mesh deforms accurately over time as the gears turn. As a result, the simulation could accurately capture the fluid’s dynamic behavior in response to the gear’s movements.