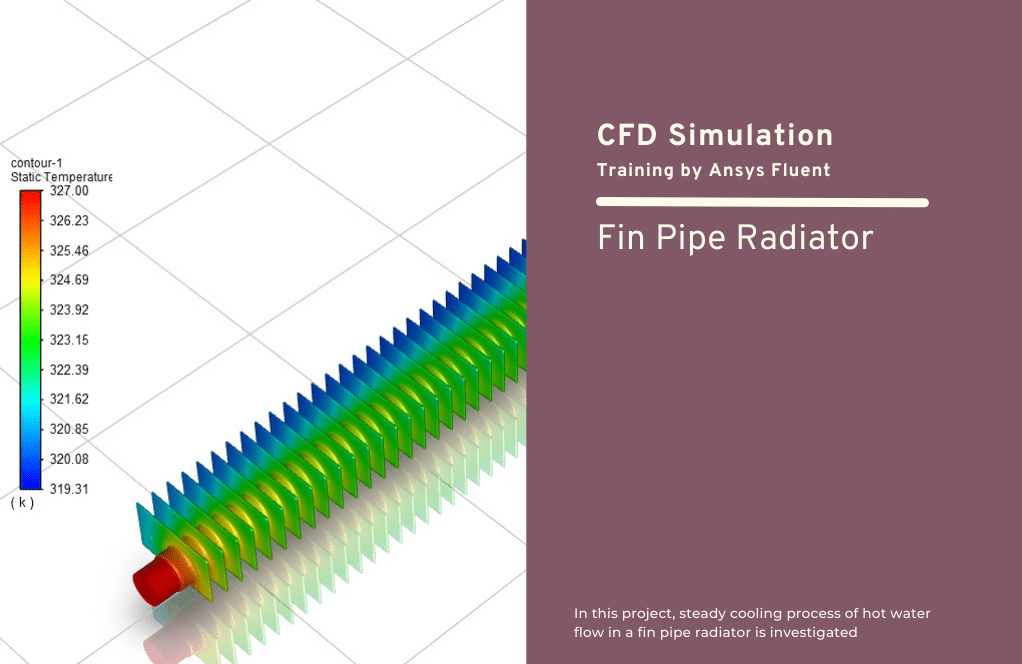

Fin Pipe Radiator, (CHT) Conjugated Heat Transfer CFD Simulation, ANSYS Fluent Training

$80.00 $40.00 Student Discount

- The problem numerically simulates the Fin Pipe Radiator using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 290250.

- We perform the Conjugate Heat Transfer analysis for a radiator.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

In this project, the steady cooling process of hot water flow in a fin pipe radiator is investigated by ANSYS Fluent software.

Due to the high computational cost, only one fin pipe of a radiator is simulated. The present model is designed in three dimensions using Design Modeler software.

The geometry for analyzing this simulation consists of a room and a balcony. The meshing of the model has been done using ANSYS Meshing software.

The mesh type used for this geometry is structured, and the element number is 290250.

Fin Pipe Methodology

The Conjugate Heat Transfer (CHT) analysis type allows for the simulation of heat transfer between solid and fluid domains by exchanging thermal energy at the interfaces between them.

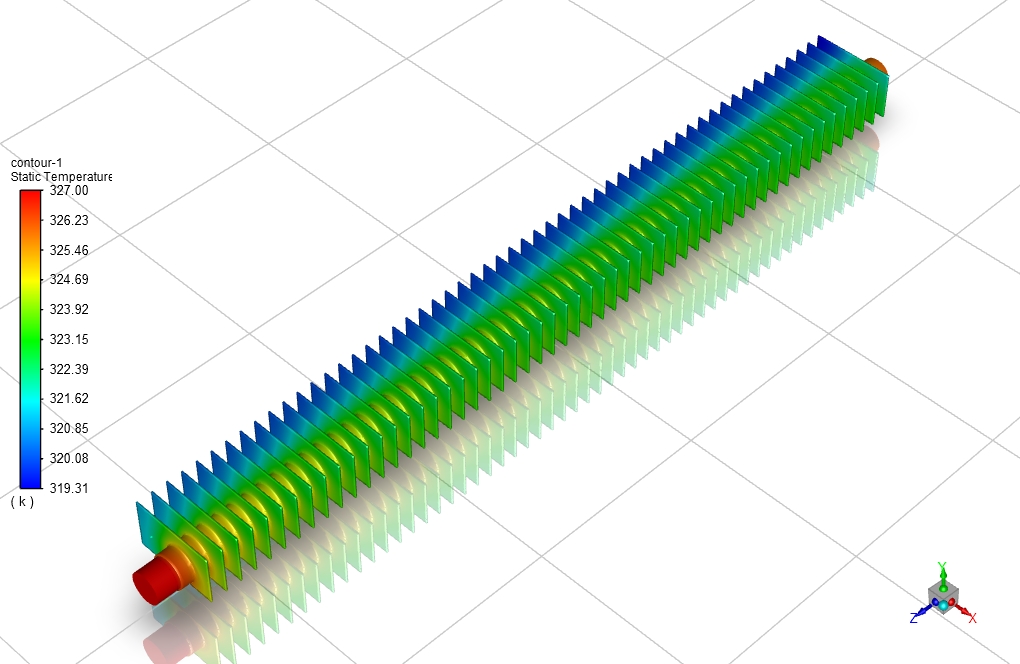

In this project, water flows in the pipe between concentric fins while free convection boundary condition is imposed at the fin surface. Also, the water inside the pipe exchanges heats with the fin based on forced convection.

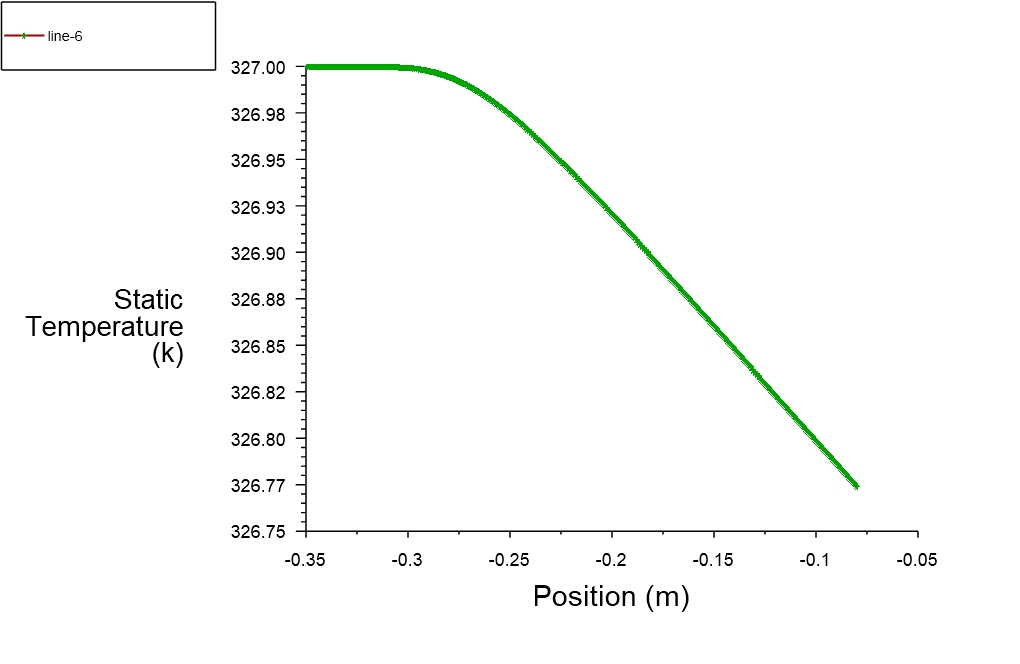

Water enters and exits the domain with a temperature equal to 327K and 326.6214K, respectively. Moreover, the standard k-epsilon model and energy equation are enabled to solve the turbulent fluid equation and calculate temperature distribution within the tube and the fins.

Fin Pipe Conclusion

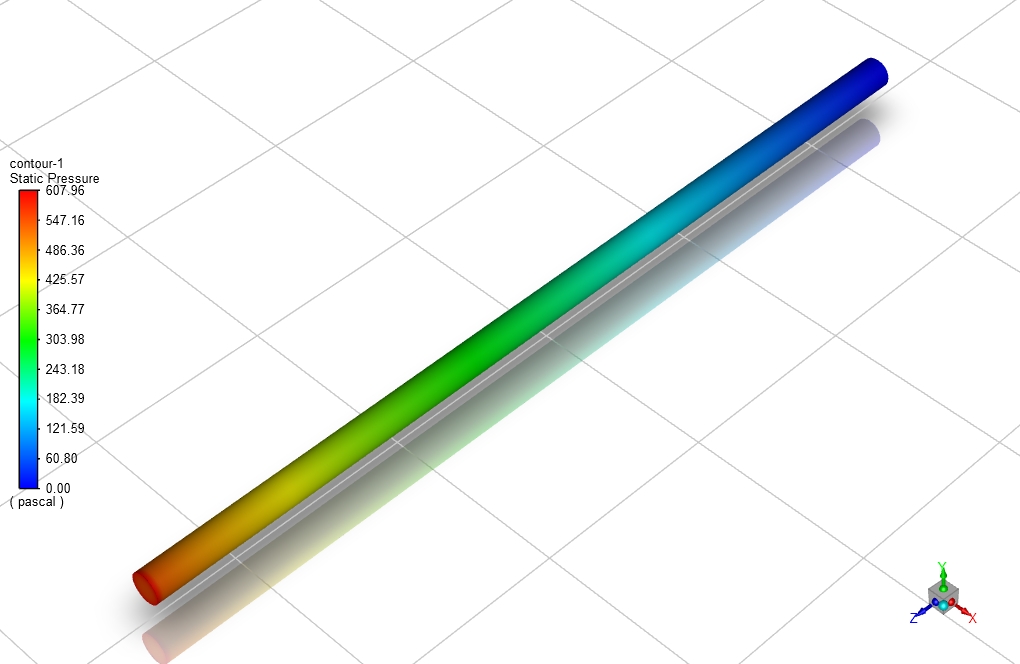

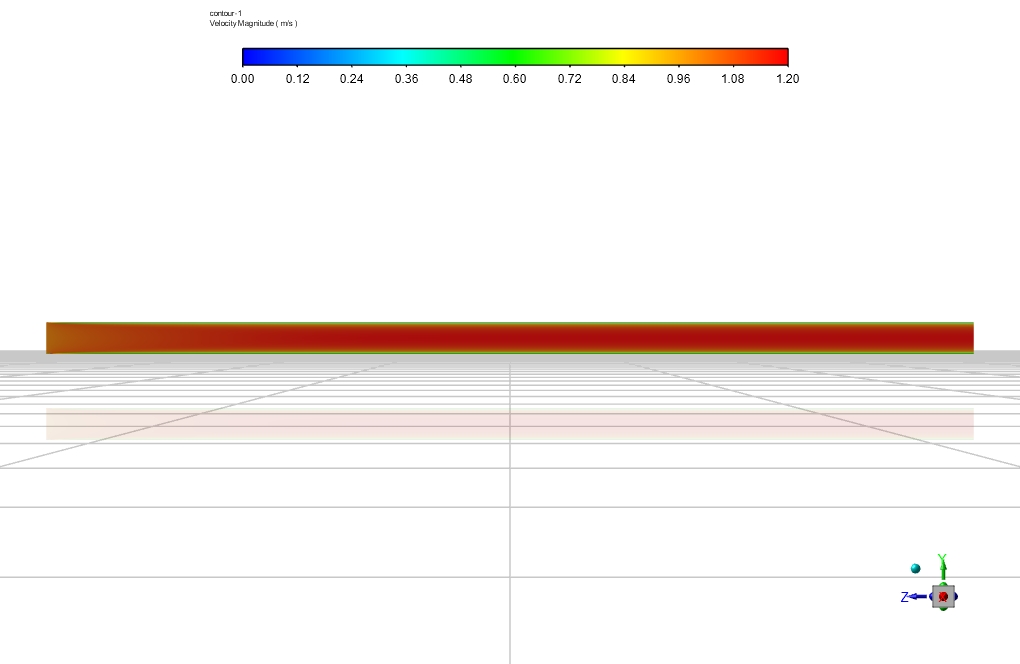

At the end of the solution process, two and three-dimensional contours related to the velocity, temperature, pressure, and velocity vectors are obtained.

Based on the calculated data, the Water mass flow rate at the inlet is 0.0783 kg/s.

Water temperature at the inlet and outlet is equal to 327K and 326.6K respectively which is the result of a heat transfer rate equal to 124 w for the steady cooling process.

The first and the second graphs show the fins and fluid temperature as a function of position, respectively.

Dr. Danyka Upton DVM –

Can this simulation be used to optimize the design of the radiator?

MR CFD Support –

Absolutely, this simulation can be used as a tool for design optimization. By changing the design parameters and observing the resulting heat transfer performance, you can identify ways to improve the design of the radiator.

Amparo Kuhic –

What kind of post-processing options are available for analyzing the simulation results?

MR CFD Support –

The post-processing options include the visualization of temperature and velocity fields, as well as the calculation of heat transfer coefficients and pressure drops.

Graciela O’Kon –

I’m really impressed by how detailed this training session was on simulating a fin pipe radiator. Your focus on practical outcomes like actual temperature readings at the different points really solidifies the learning experience. Great job!

MR CFD Support –

Thank you so much for your positive feedback! We’re glad to hear that the detailed approach in the training has been helpful and has enhanced your learning experience. If you have any further questions or need more assistance, feel free to reach out. We appreciate your support!

Jason Luettgen Sr. –

After reading the review on the Fin Pipe Radiator CFD Simulation using ANSYS Fluent training, I am left with one key question: Was the effect of radiator placement within the room considered in the simulation and does the training address how to evaluate the influence of environmental factors like room temperature on the heat transfer process?

MR CFD Support –

While the simulation focuses on the steady cooling process within the radiator itself, it does take into account the interaction with the surrounding environment by introducing free convection boundary conditions at the fins surface. The software ANSYS Fluent goes further by allowing the simulation of the entire fin pipe and its interaction with room temperature, taking into account environmental factors. This includes demonstrating how facility placement within different areas of a room can influence heat transfer. The training material should provide you approaches to evaluate these scenarios, offering insights on incorporating complex environmental variables into the simulations for comprehensive CHT analyses.

Juwan Lowe –

The quality of insights provided using the contours was fantastic, really aided in visualizing the simulation’s details.

MR CFD Support –

We’re thrilled to hear that the contour visualizations enhanced your understanding of the simulation! Thank you for your positive feedback, and we look forward to providing you with more valuable insights in future projects.

Carlee McKenzie –

I am really impressed with the step-by-step approach used in this fin pipe radiator simulation! The explanation of the methodology is assigned and the resulting heat transfer rate clearly illustrates the effectiveness of the design. Excellent work on capturing the intricacies of thermal dynamics.

MR CFD Support –

Thank you for your positive feedback. We’re delighted that the detailed methodology and clear explanations met your expectations, and that you found the simulation results effective and informative. If you have any further questions or require assistance with other simulations, do not hesitate to reach out!

Otto Hodkiewicz DDS –

Great experience learning from the Fin Pipe Radiator Heat Transfer CFD Simulation by MR CFD. It provided comprehensive knowledge on setting up and solving CHT analysis in ANSYS Fluent. The details were clear, and the project results were very interesting, showing the effectiveness of the radiator design.

MR CFD Support –

Thank you so much for your positive feedback! We’re delighted to hear that our Fin Pipe Radiator Heat Transfer tutorial was informative and helpful for you. It’s always our goal to provide clear and comprehensive training materials. If you have any further questions or need more guidance, feel free to reach out to us!

Dr. Marco Beahan –

Can this simulation handle different types of fluids?

MR CFD Support –

Yes, this simulation can handle different types of fluids. You just need to specify the fluid properties such as density, viscosity, specific heat capacity, and thermal conductivity.

Emil Conn –

I found the explanation of how the CHT analysis works within in this simulation quite useful. The precise temperature details at the inlet and outlet helped me grasp the effectiveness of the radiator design in conducting heat. Great work!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that the detailed information on Conjugate Heat Transfer analysis was helpful to you. If you have any further questions or need more clarity on radiator simulations using ANSYS Fluent, feel free to ask. Your satisfaction is our top priority!

Dr. Bradley Douglas –

This has been an excellent training resource. The step-by-step approach used in the simulation of a fin pipe radiator with conjugate heat transfer analysis enlightened me on many aspects of CFD related to heat exchangers. The structured mesh detail and how boundary conditions influence heat transfer between solid and fluid domains are explained very well. Furthermore, the visual representation of temperature and velocity gradients made it easier to conceptualize the cooling process. Very impressed with the level of detail in the CHT analysis using ANSYS Fluent!

MR CFD Support –

We’re thrilled to hear you found the training resource excellent and that it provided clear insights into the simulation of heat exchangers using CFD. Your appreciation for the structured approach to meshing and boundary condition application in conjugate heat transfer analysis means a lot to us. It’s encouraging to know that the visual data effectively aided your understanding of the cooling process. Thank you for your detailed and positive feedback!

Chelsea Johnson –

I found the simulation results fascinating, with the detailed temperature and velocity contours. The heat transfer rate calculated to be 124 w for a steady cooling process is impressive. What I’d like to know is whether the ambient temperature and properties of the air in the room were considered in the simulation for calculating free convection?

MR CFD Support –

In the preparation of this simulation called the Fin Pipe Radiator, external environmental factors, such as the ambient temperature and air properties, indeed play a significant role. The simulation and training module would involve setting up an external environment which may include room temperature, properties of the air, and possible interactions at the boundaries of the radiator fins, which contribute to the assessment and calculations of the free convection cooling phenomena of the radiator.

Dr. Boris Heidenreich –

I was impressed by the detail of the temperature distribution results shown in the training product for the Fin Pipe Radiator CFD Simulation. The visuals were clear and helped me understand where and how heat transfer occurred. Great work!

MR CFD Support –

Thank you for your positive feedback! We’re thrilled to hear that our training product helped you understand the heat transfer in the Fin Pipe Radiator simulation. Our team works hard to create clear and detailed visuals to enhance learning. If you have any more questions or require further assistance, don’t hesitate to reach out.

Prof. Ardella Rolfson –

I started working with ANSYS Fluent recently, and I’m impressed with the application of CHT in this example. Can you explain how the heat transfer coefficient is determined in the simulation?

MR CFD Support –

In this simulation, the heat transfer coefficient is calculated based on the flow properties – such as velocity, viscosity, and thermal conductivity – as well as the geometry of the fins and the pipes. The simulation leverages the standard k-epsilon model for turbulent flow which impacts the heat transfer coefficient. It results from the interaction of the flowing fluid with the solid surfaces and the related boundary layers that develop, and is an outcome of the Conjugate Heat Transfer analysis in ANSYS Fluent.

Miss Anabelle Halvorson –

Absolutely ecstatic with the results! It became so much easier to grasp thermal management concepts thanks to this practical Fin Pipe Radiator simulation. The interactivity and detailed visualization of temperatures and flow through the conduit and fins provided me with an immersive learning experience that felt hands-on, even though it was all digital.

MR CFD Support –

Thank you for your glowing review! We’re delighted to know our Fin Pipe Radiator heat transfer simulation helped you understand thermal management better. It’s great to hear that our detailed visualization and interactivity contributed to your immersive and hands-on learning experience. Your feedback makes all our efforts worthwhile!

Alexie Mayer –

Fantastic learning tool! The level of detail in both the simulation setup and results helped clarify many concepts of heat transfer and fluid dynamics for me.

MR CFD Support –

We’re thrilled to hear that you found our Fin Pipe Radiator CFD Simulation course beneficial and educational. Thank you for your positive feedback!