Fluid-Structure Interaction Analysis of a High-Speed Airfoil

$150.00 $75.00 Student Discount

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Fluid-Structure Interaction Analysis of a High-Speed Airfoil Using ANSYS Fluent

Introduction

This report presents a comprehensive Computational Fluid Dynamics (CFD) and Fluid-Structure Interaction (FSI) analysis of a high-speed airfoil using ANSYS Fluent. The study aims to investigate the complex flow behavior around the airfoil and its resulting displacement under high-speed conditions. This analysis provides valuable insights into the aerodynamic performance and structural response of the airfoil, which is crucial for applications in aerospace engineering and high-speed vehicle design.

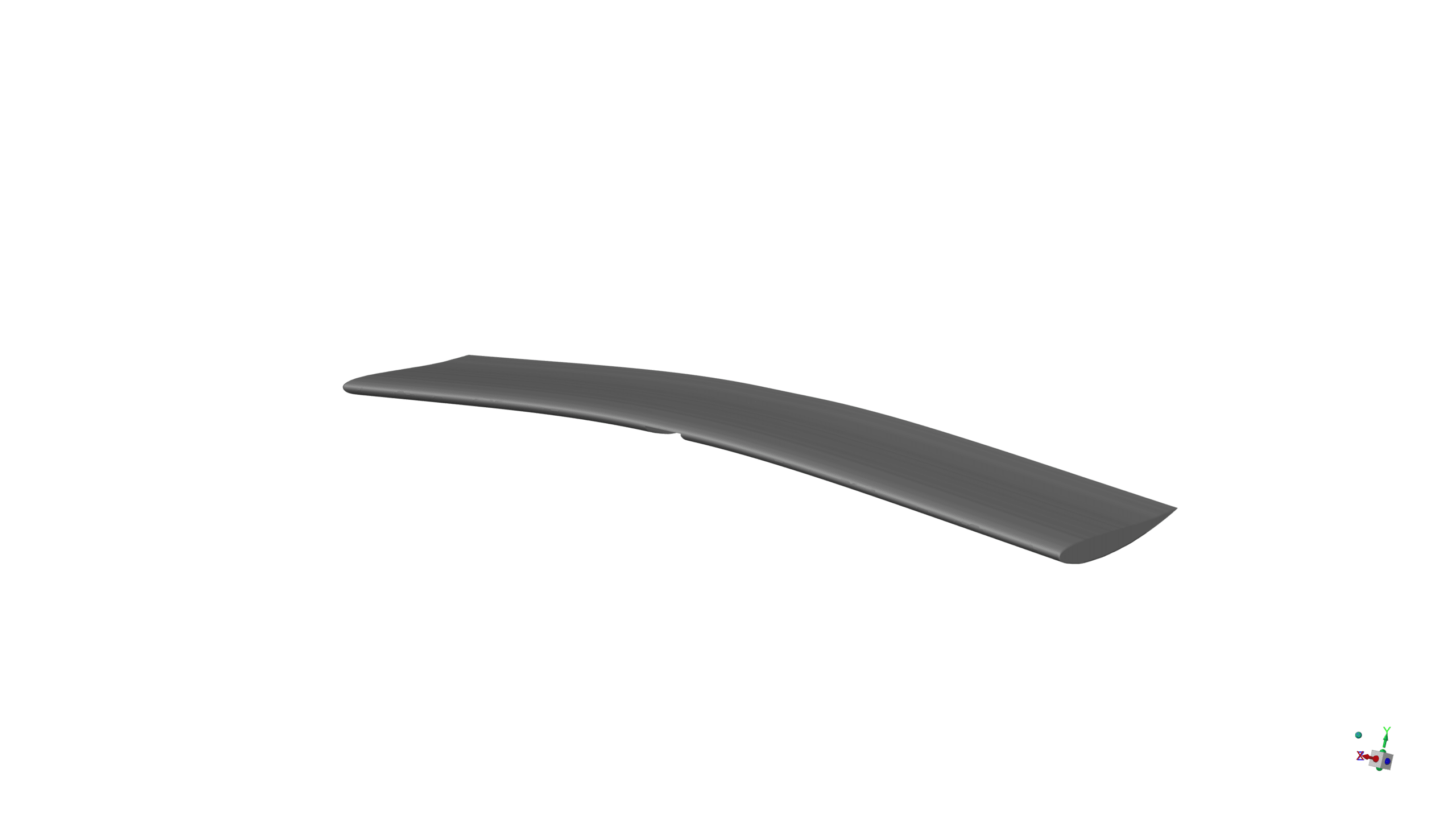

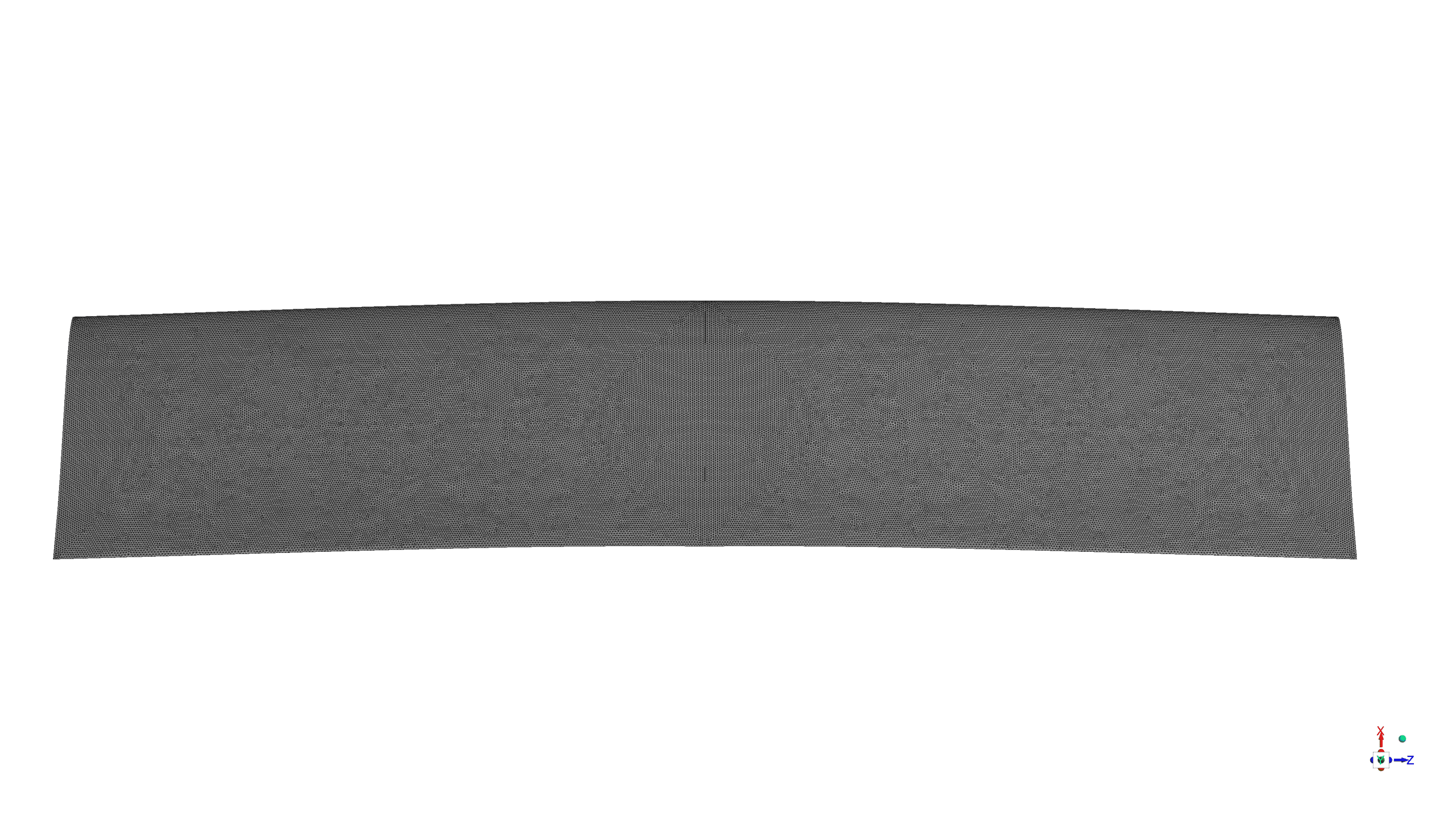

The simulation geometry, designed using ANSYS Design Modeler, consists of a curved airfoil profile. The computational domain is optimized to capture the flow characteristics and structural deformation of the airfoil under high-speed conditions.

ANSYS Meshing was employed to generate a high-quality mesh comprising 2,398,833 elements. This mesh density provides sufficient resolution to accurately capture the flow dynamics, turbulence effects, and structural deformation within the domain. The mesh quality ensures efficient computation and helps in resolving the complex flow patterns expected around the high-speed airfoil.

Methodology

A pressure-based, transient solver was employed to capture the time-dependent flow characteristics and structural response of the airfoil.

The Realizable k-epsilon turbulence model with standard wall function was chosen to accurately represent the turbulent nature of the high-speed flow around the airfoil.

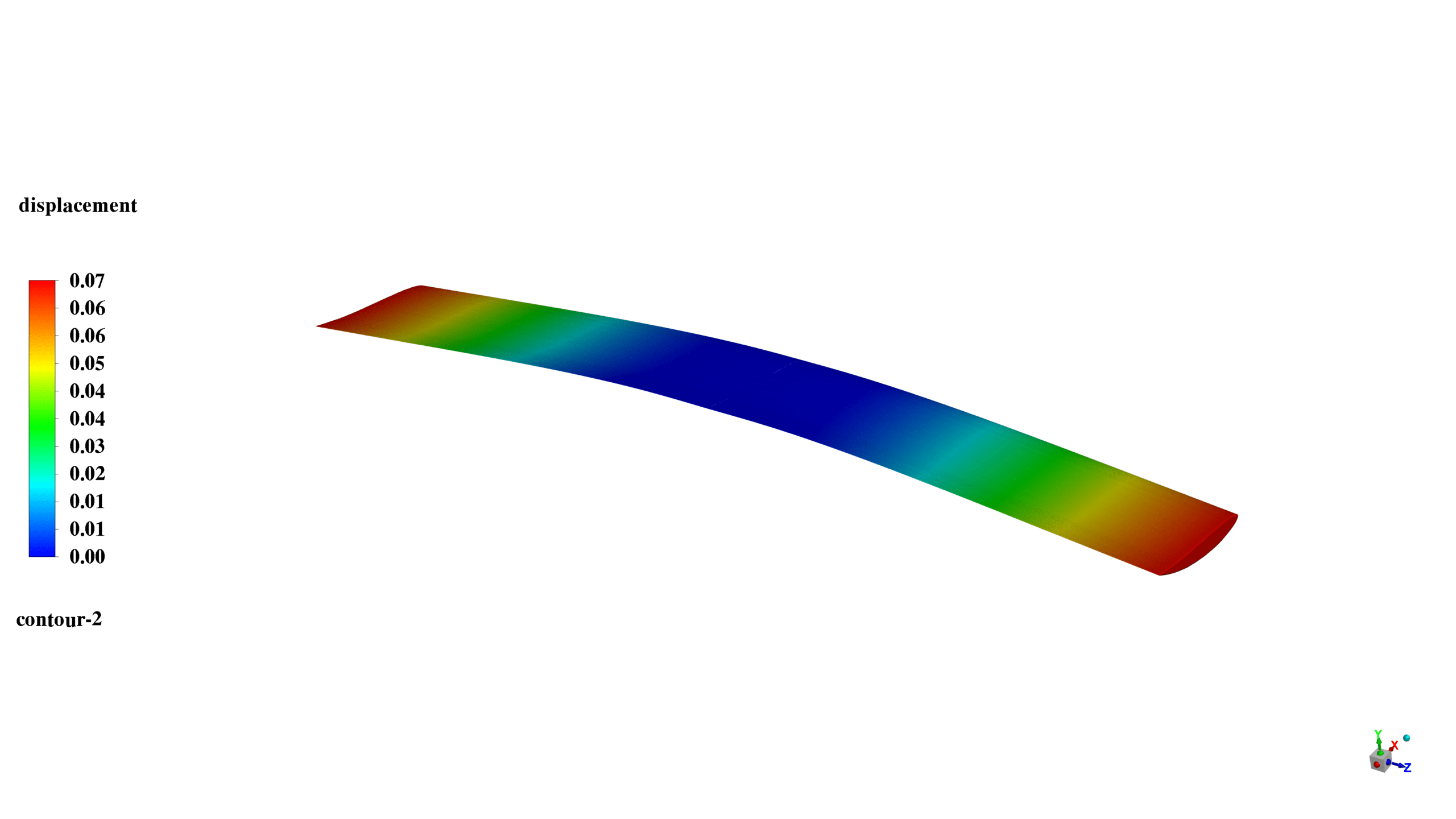

The Structure model with Linear Elasticity option was enabled to investigate the displacement of the airfoil, allowing for the analysis of fluid-structure interaction.

Results

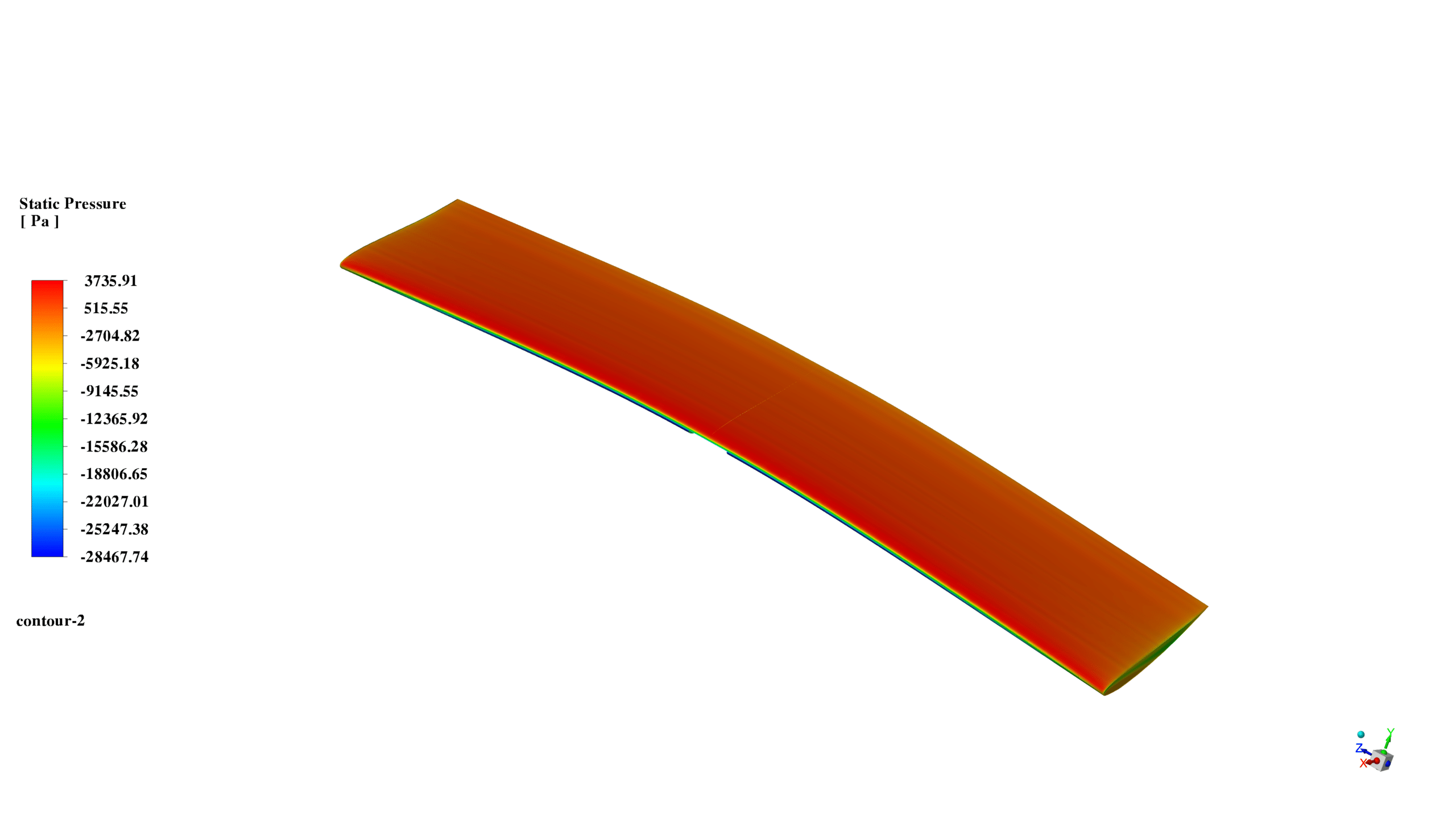

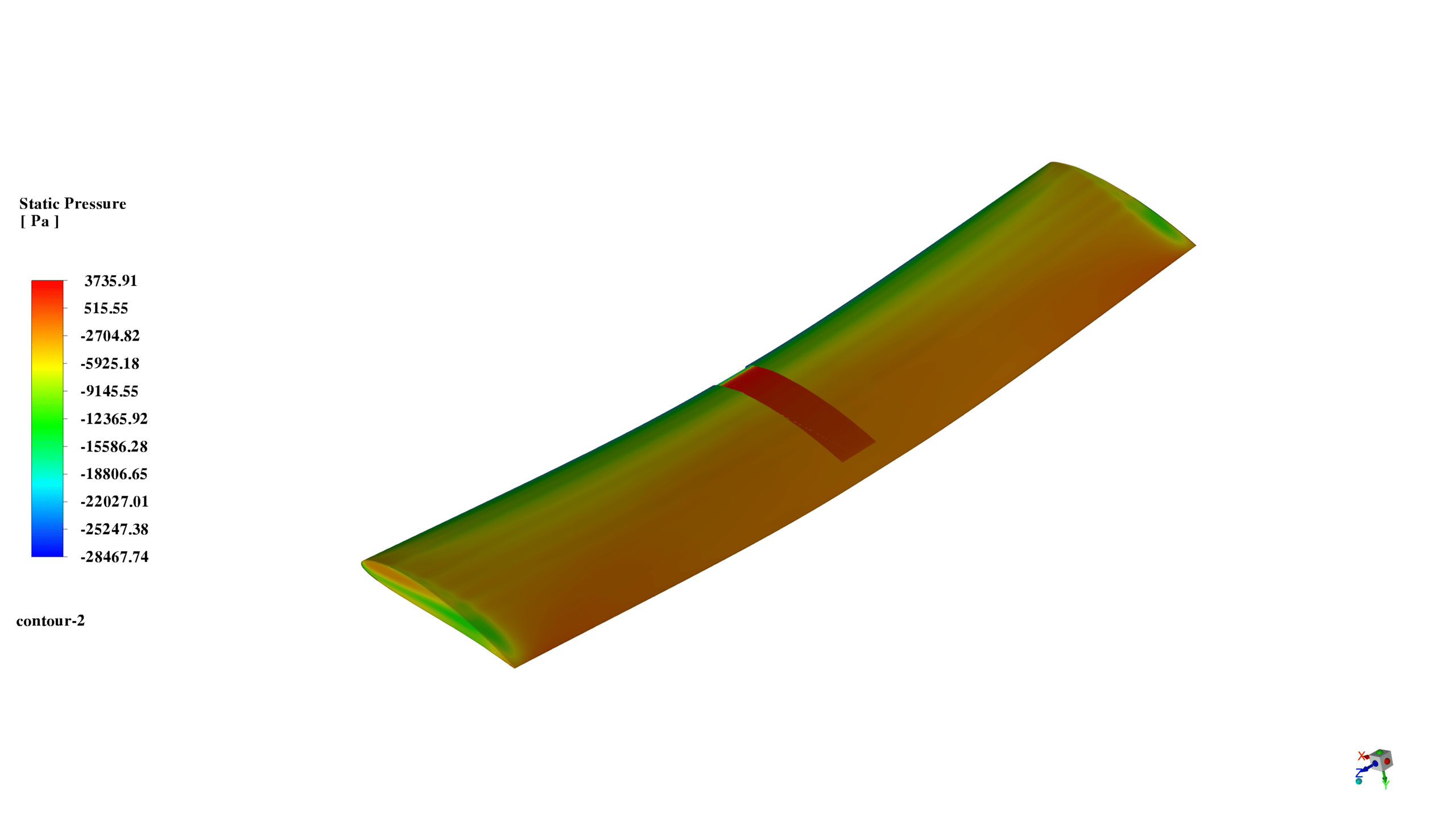

The static pressure contours reveal the pressure distribution around the airfoil. A high-pressure region is observed on the lower surface of the airfoil, particularly near the leading edge, with values reaching up to 3735.91 Pa. The upper surface shows lower pressure regions, with the minimum pressure of -28467.74 Pa occurring near the top surface. This pressure differential is responsible for generating lift on the airfoil.

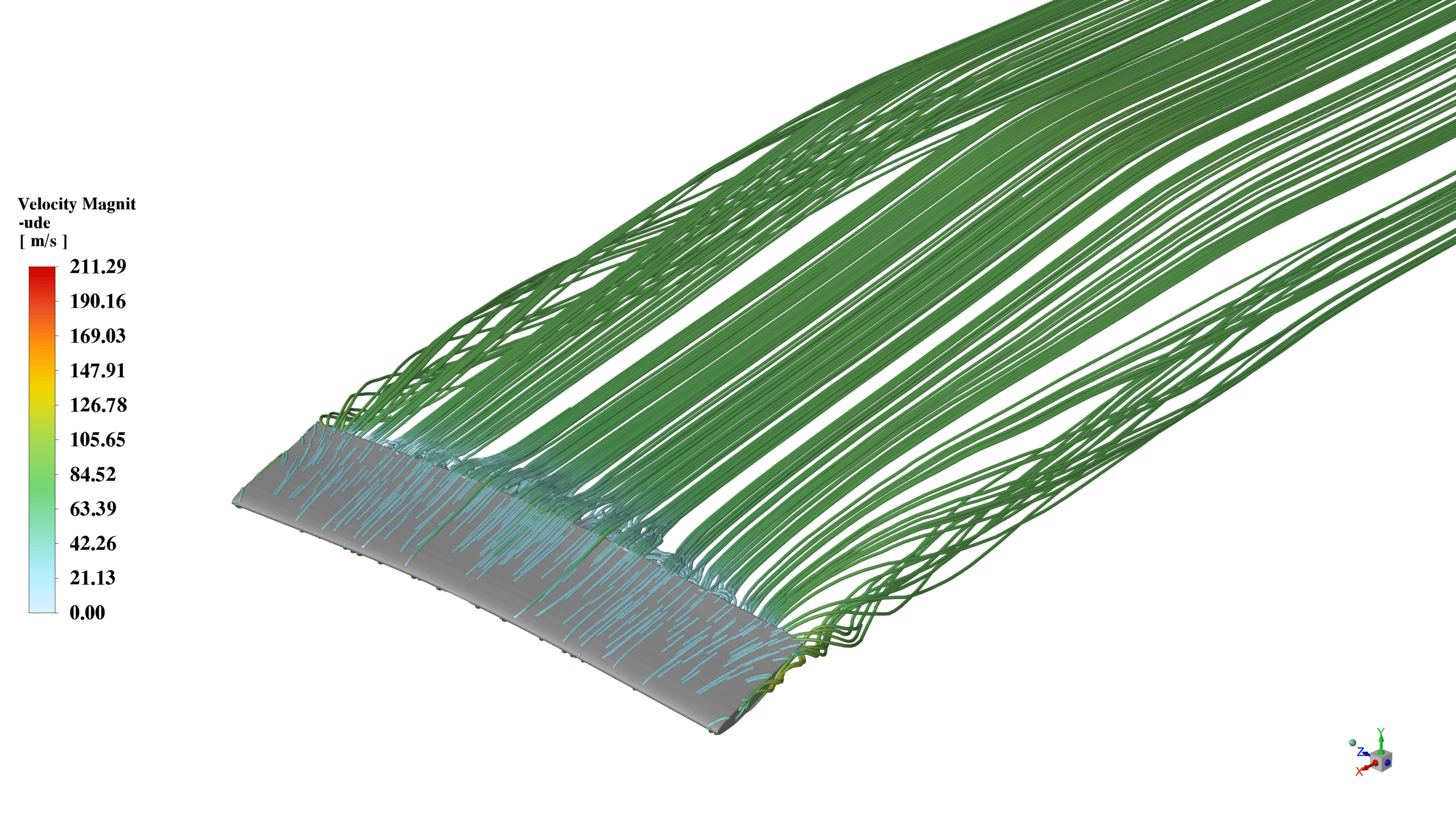

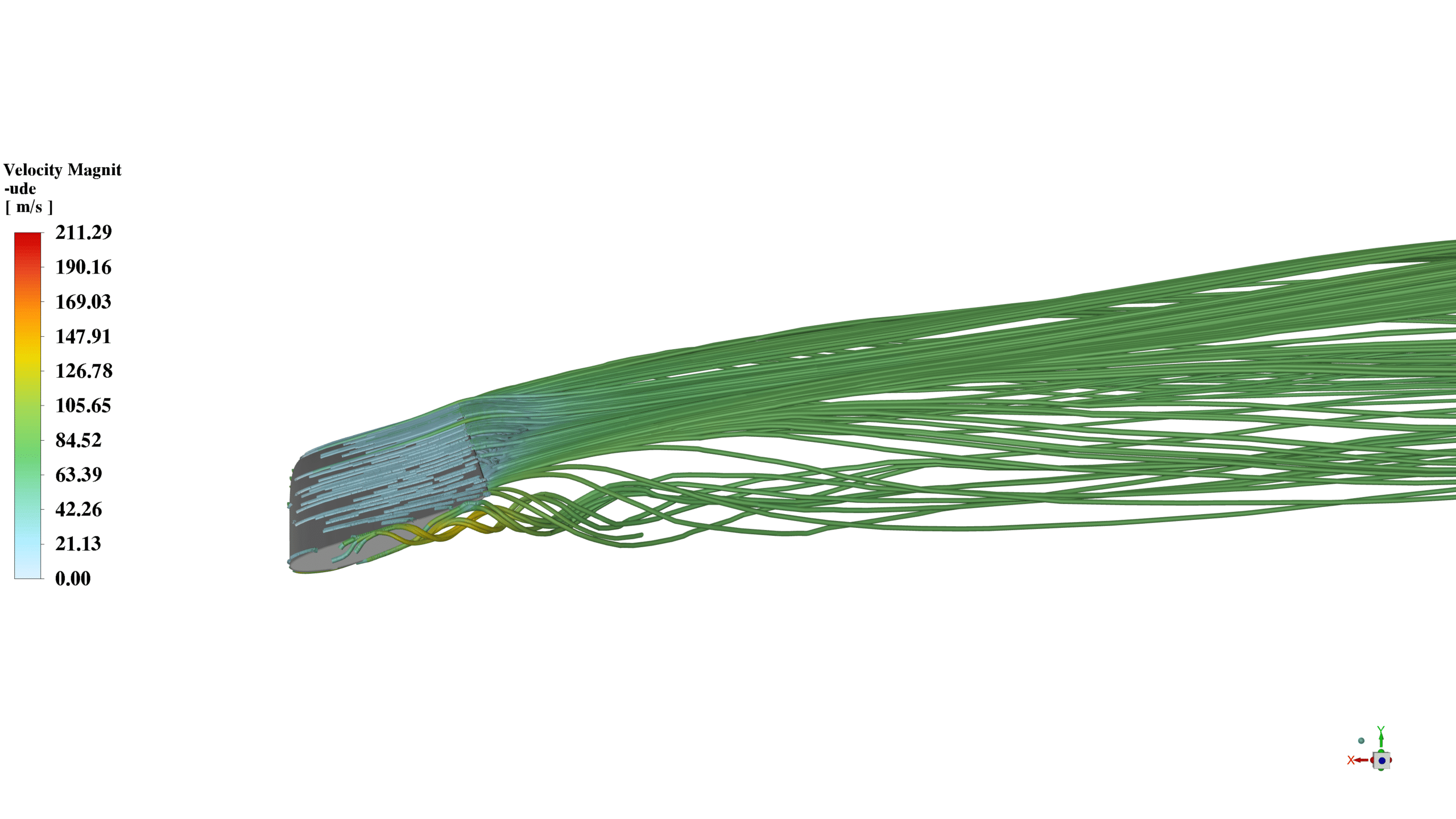

The velocity magnitude contours illustrate the flow acceleration around the airfoil. Low velocities are observed near the leading edge and in the wake region behind the airfoil. The highest velocities, reaching up to 211.29 m/s, occur over the upper surface of the airfoil, consistent with the lower pressure region observed in the pressure contours.

The displacement contours show the structural response of the airfoil to the aerodynamic loads. The maximum displacement of 0.07 units (presumably meters or millimeters, depending on the scale) occurs at the trailing edge of the airfoil, with a gradual decrease towards the leading edge. This deformation pattern is consistent with the expected bending of an airfoil under aerodynamic loading.

The streamlines visualization provides insight into the flow patterns around the airfoil. The streamlines show smooth flow over most of the airfoil surface, with some evidence of flow separation near the trailing edge, as indicated by the curling of streamlines in this region.

Reviews

There are no reviews yet.