Polymer Electrolyte Membrane Fuel Cell (PEMFC)

$270.00 $135.00 Student Discount

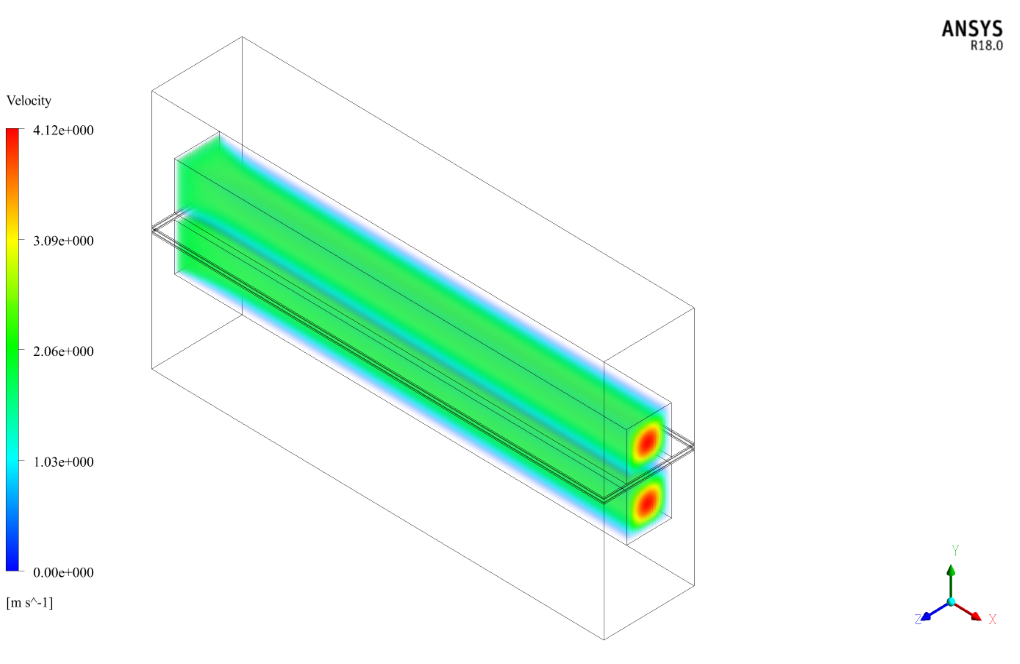

- The present problem simulates a fuel cell using PEMFC (polymer electrolyte membrane fuel cell) model in porous medium by ANSYS Fluent software.

- The geometry of the present model is three-dimensional and has been designed using Design Modeler software.

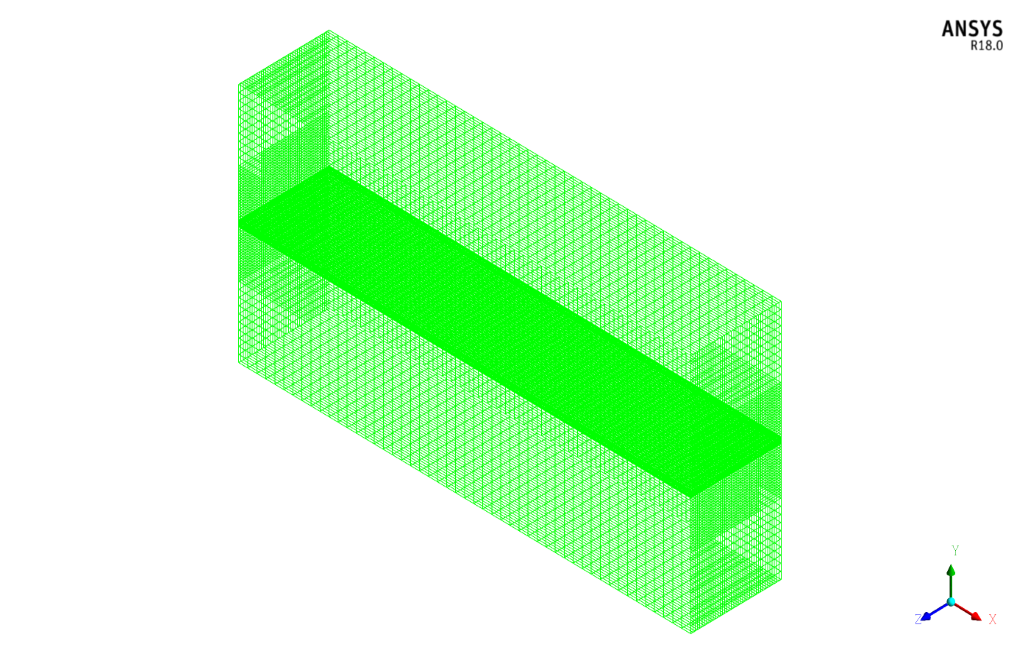

- The meshing of the model has been done using ANSYS Meshing software. The mesh type is structured , and the element number is 142,000.

- Species Transport, Porous & Fuel cell, and electrolysis models are used.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Polymer Electrolyte Membrane Fuel Cell (PEMFC) CFD Simulation, ANSYS Fluent Training

Description

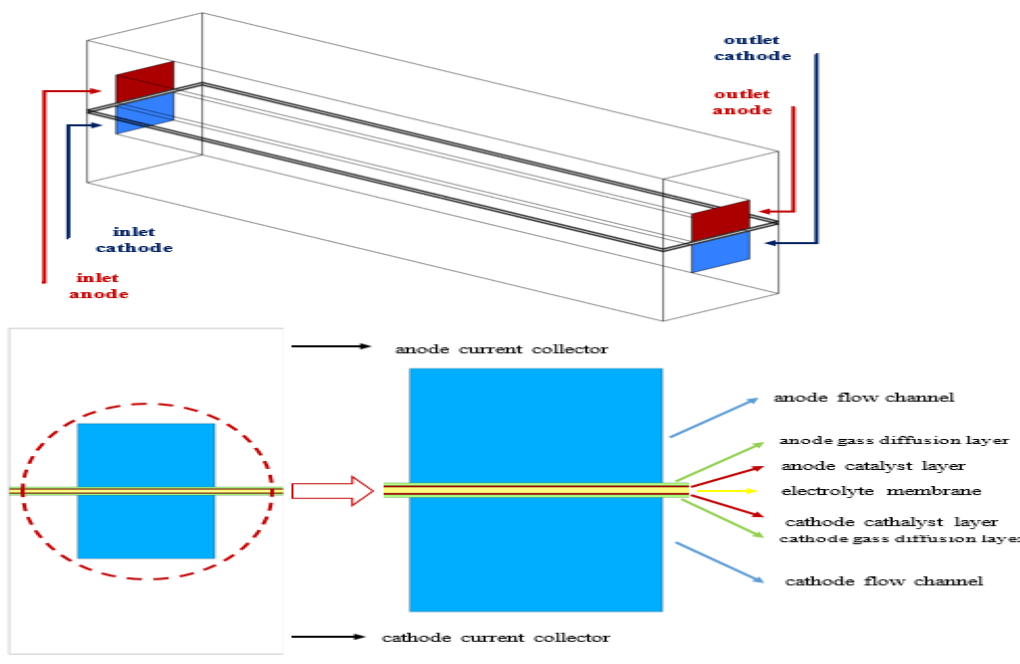

The present problem simulates a fuel cell using PEMFC (polymer electrolyte membrane fuel cell) model in porous medium by ANSYS Fluent software. The model consists of two main cathode and anode segments. Each has four layers: a flow collector, a flow channel, a gas distribution area, and a catalytic section, and the space between the anode and cathode layers is filled by the polymer membrane.

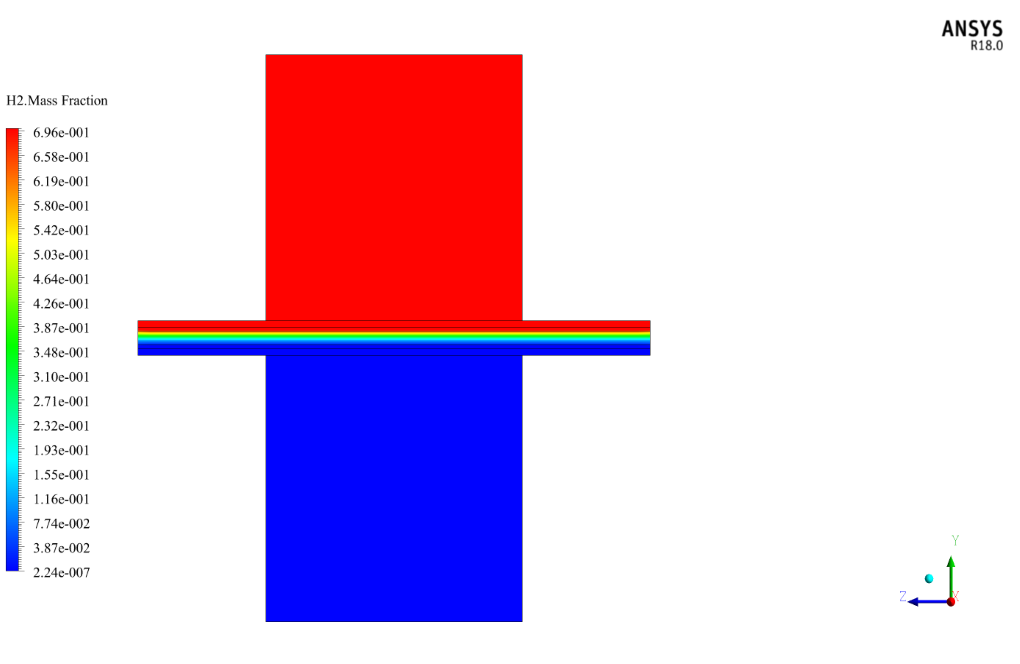

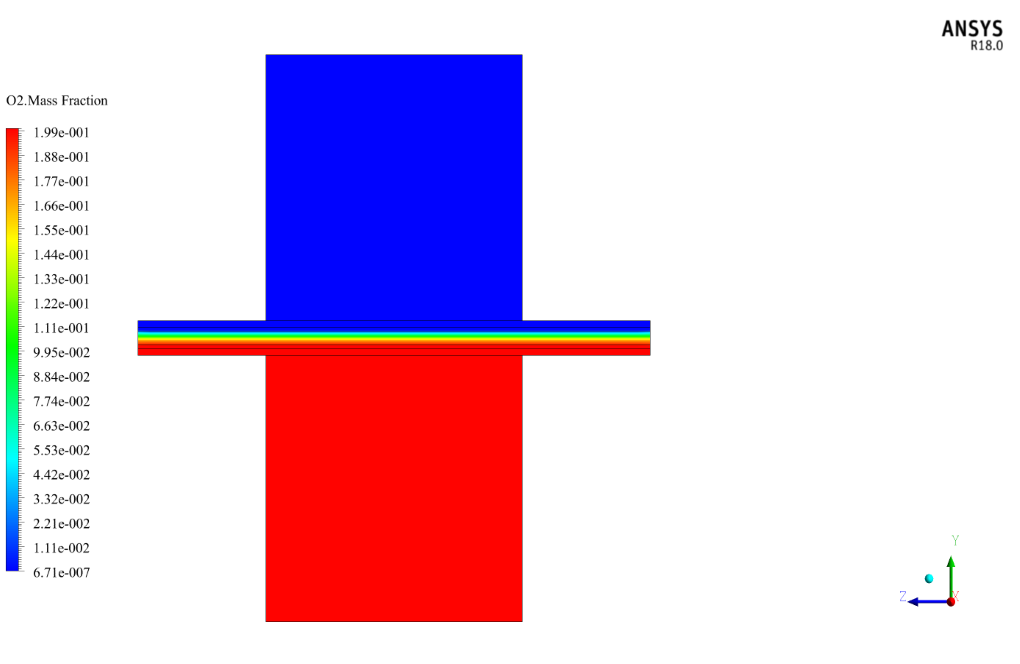

The potential value in the anode is assumed to be zero, and as a result, only 0.5 is defined for the cathode electrical potential. Also, at the anode inlet, hydrogen mass fraction is 0.7 and water is 0.3 and oxygen and nitrogen are zero; at the cathode inlet, hydrogen mass fraction is zero and water is 0.14 and nitrogen is 0.66 and oxygen is 0.2.

The Design Modeler software designs the 3-D geometry of the present model. The present model has a symmetrical structure and consists of nine regions of seven specific fluid zones (cathode and anode flow channel, cathode and anode gaseous region, cathode and anode catalytic domain and polymeric membrane), as well as two solid zones.

The solid zone consists of a cathodic and anodic current collector. The mesh of the present model is carried out by ANSYS Meshing software. The mesh type is structured and the element number is 142000.

Methodology: Fuel Cell (PEMFC)

The flow channels carry a mixture of gaseous species, including oxygen, hydrogen, and water. The catalytic part consists of a porous medium with a porosity coefficient of 0.5 and contains mass sources, thermal energy, electrical potential, proton potential, saturated water, hydrogen, oxygen, and water.

The gaseous diffusion zone comprises a porous medium with a porosity coefficient of 0.5 and contains mass sources, thermal energy, electrical potential, saturated water, and hydrogen, oxygen, and gaseous water species. The polymer membrane region also consists of a porous medium with a porosity coefficient of 0.5 and has thermal energy sources and proton potentials.

In this project, the flow equations and the Energy equation are solved. Several modules are used, including Species Transport, Porous & Fuel cell and electrolysis.

Conclusion

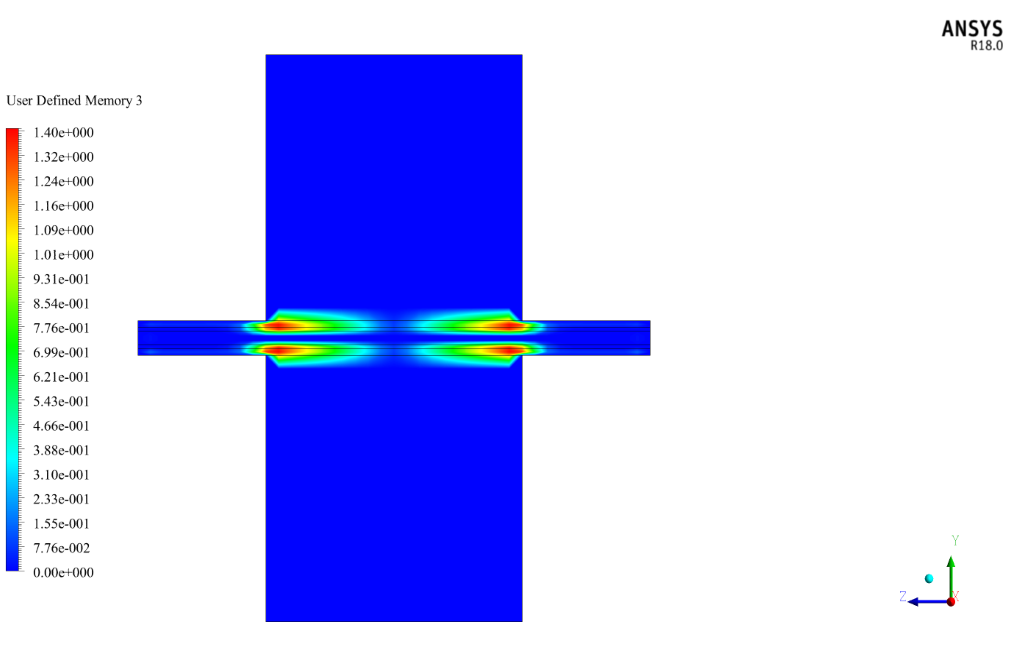

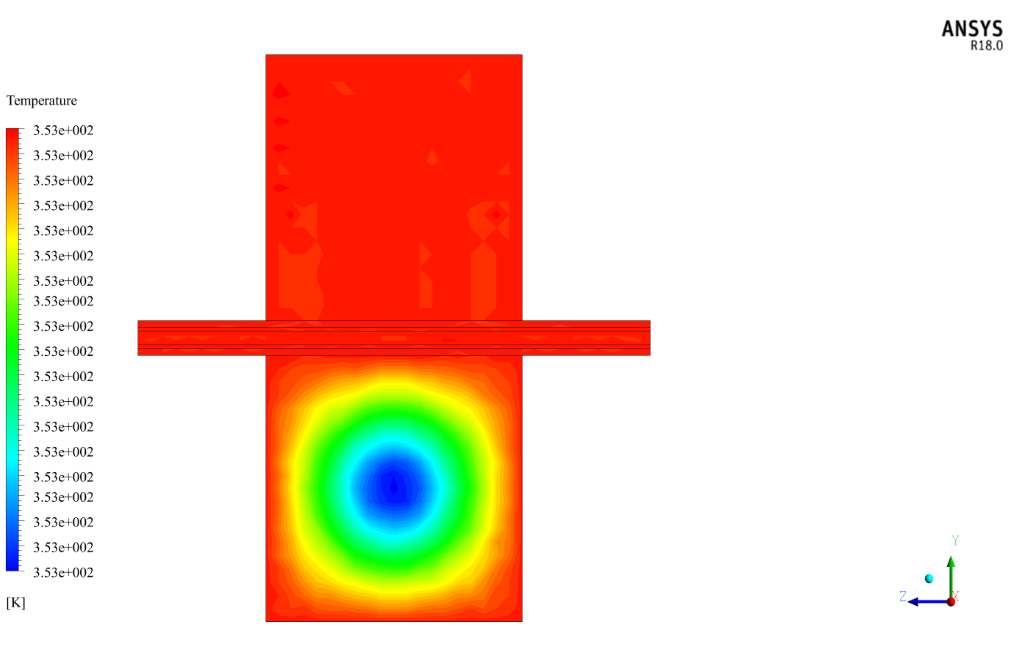

This study aims to investigate the fluid behavior and thermal conductivity of a polymer fuel cell and its effect on the mass fraction of gaseous species and the amount of electricity produced in the cell. After the simulation process, results are shown in the form of contours. As expected, hydrogen and oxygen ions transfer through the electrolyte membrane. Besides, the catalyst could hasten the process, so the reactions occur faster and result in an electric current.

Milford Hoeger –

I have a specific simulation in mind involving a different type of fuel cell. Can you accommodate custom simulation requests?

MR CFD Support –

Absolutely! We’re always open to new ideas. Please provide more details about the simulation you’re interested in, and we’ll do our best to accommodate your request

Magali Block –

Your website is a fantastic resource for CFD simulations. I’m particularly impressed with the range of fuel cell simulations you offer.

MR CFD Support –

We appreciate your feedback! We aim to offer a wide range of CFD simulations to cater to various needs.

Miss Ebba Heaney –

This Polymer Electrolyte Membrane Fuel Cell simulation tutorial seems very thorough. I was curious about how you’ve managed to accurately model the chemical reactions within the catalytic sections?

MR CFD Support –

The chemical reactions within the catalytic sections of the Polymer Electrolyte Membrane Fuel Cell are modeled using the species transport module incorporated within ANSYS Fluent. The module can consider detailed reaction mechanisms, allowing for specification of reactions doing electrolytic and non-electrolytic domains. This allows for an accurate prediction of reaction kinetics and mass transfer of hydrogen and oxygen ions, among other species within the cell.

Sally Rodriguez –

The detailed description and methodology explanation has really helped envision the intricacies involved in such a complex CFD Simulation for a PEMFC. The results indicating ion transfer and catalyst effects are particularly interesting. Well done on such comprehensive training material!

MR CFD Support –

Thank you for your positive feedback on the Polymer Electrolyte Membrane Fuel Cell CFD Simulation training material! We are happy to hear that you found the description clear and the methodology comprehensive. Your encouraging words are much appreciated and they help us continue to deliver high-quality CFD training.

Reta Wolf –

I was amazed by the detail that went into simulating the fuel cell. Learned tons on how mass fractions affect the electricity production. Top-notch training!

MR CFD Support –

Thank you for your feedback! We’re thrilled to hear the PEMFC CFD Simulation training was both informative and impressive in its detail. It’s fantastic to know that it enhanced your understanding of fuel cell operations. If you have any further questions or need additional training, feel free to reach out!

Caitlyn Lockman –

I am fascinated by the comprehensive approach taken for this simulation study on PEMFC. The structured mesh allows detailed analysis, and considering proton potentials and catalytic reaction rates offers deep insights into the fuel cell’s performance.

MR CFD Support –

Thank you so much for your kind words! We’re thrilled to hear that you found the simulation study detailed and insightful. Our goal is to provide comprehensive and high-quality CFD simulation services that exceed your expectations, and we’re delighted that we could do just that. If you have any more questions or need further assistance in the future, we’re here to help!

Sandra Sawayn –

This training module on Polymer Electrolyte Membrane Fuel Cell CFD simulation seems incredibly insightful. The depth of analysis and direct application to a real-world sustainable technology makes it fascinating!

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that you found our training module on PEMFC simulation informative and applicable to real-world situations. We strive to provide comprehensive and practical CFD education. If you have any more questions or need further assistance, feel free to reach out!

Damion Marvin –

How does the polymer electrolyte membrane affect the performance of the fuel cell, and what kind of maintenance does it require over long-term use?

MR CFD Support –

The polymer electrolyte membrane, commonly known as the proton exchange membrane, is central to the operation of a PEM fuel cell. It affects performance by allowing protons to pass through while being impermeable to gases such as hydrogen and oxygen, which helps to avoid mixing and maintain separation of reactants. Its ionic conductivity, water management, and durability directly impact the fuel cell efficiency and power output. Over long-term use, the membrane may degrade due to chemical or mechanical stresses, thus regular monitoring is important. Maintenance can involve hydration management, ensuring operation within optimal temperature ranges, and checking for contamination or damage. Preventive maintenance schedules can prolong the membrane life and sustain high fuel cell performance.

Ms. Ashleigh Jenkins DVM –

The PEMFC training product was really thorough! Is there any consideration of thermal effects in the membrane, or is it assumed to be isothermal?

MR CFD Support –

The Polymer Electrolyte Membrane Fuel Cell (PEMFC) simulation model considers thermal effects in addition to the proton and electron transport. This allows for the evaluation of changes in temperature across the membrane, which can affect the performance and efficiency of the fuel cell.

Elva Carter –

The course content on Polymer Electrolyte Membrane Fuel Cell using ANSYS Fluent was incredibly insightful. The systematic breakdown of each segment and the detailed explanation of methodologies enhanced my understanding of fuel cell simulation. Seeing the fluid behavior and thermal dynamics visualized through the contours solidified complex theoretical concepts into practical knowledge. This CFD training has greatly contributed to my academic growth and potentially to my future research projects.

MR CFD Support –

Thank you so much for your kind words and for sharing your positive experience with our Polymer Electrolyte Membrane Fuel Cell (PEMFC) course. We pride ourselves on providing comprehensive and practical training, and it’s wonderful to hear that it’s making a significant impact on your learning and research. If there’s anything more we can do to support your academic journey, please feel free to reach out. We wish you the best of luck in your future CFD simulations and projects!

Prof. Terrence Sporer –

The training material was very detailed, providing a comprehensive understanding of CFD simulation of a PEMFC in ANSYS Fluent. The structured meshing approach and porosity settings for various regions were crucial in accurately capturing the behavior of the fluid and the thermal conductivity. Observing the ion transfer and the effects of the catalyst on the reaction rates was fascinating and increased my knowledge on fuel cell functionality.

MR CFD Support –

Thank you for your positive feedback! We’re glad to hear that our training material on Polymer Electrolyte Membrane Fuel Cell (PEMFC) conveyed a thorough understanding and helped enlighten you on the simulation intricacies. Your acknowledgment of the detailed meshing approach and specific simulation settings highlights the depth of our tutorial. We are pleased to know it enhanced your knowledge of fuel cell operations and simulations!

Jasen Feeney –

I’m blown away by the details and clarity of the results. This CFD simulation really highlights the importance of reaction kinetics in PEMFC systems.

MR CFD Support –

Thank you for your positive feedback. We’re glad to know that the CFD simulation met your expectations and was able to clearly demonstrate the intricate processes within a PEMFC system.

Alyson Rath –

Super impressed with your simulation of the fuel cell using the PEMFC model in ANSYS Fluent! Learned so much, and the visuals really helped me understand the behavior of the various gas species within the system. Great job!

MR CFD Support –

Thank you for your kind words! We’re thrilled to know that our Polymer Electrolyte Membrane Fuel Cell (PEMFC) training was not only informative but also provided clear visuals to aid your understanding. We’re proud to aid in advancing your knowledge in CFD simulations. If you have any more questions or need further help, please feel free to reach out.

Ellis Kulas –

The explanation about the fuel cell simulation was thorough! Very informative.

MR CFD Support –

Thank you! We’re happy to hear that you found the details of the PEMFC CFD simulation informative. If you need further training or resources, feel free to explore more of our learning products!

Connor Donnelly –

I’ve completed the PEMFC simulation course and used my knowledge in my research. The level of detail in both geometry and setup was impressive, leading to valuable insights on fluid behavior and electricity generation within fuel cells.

MR CFD Support –

Thank you for your positive feedback! We’re pleased to hear that our PEMFC simulation course provided you with in-depth knowledge that could be beneficial to your research. At MR CFD, our goal is to deliver informative and detailed training for practical applications. If your study yields new findings or if you require further assistance, please feel free to reach out!

Jasen Little –

I am highly impressed by the level of detail in this simulation, especially the careful setup of different material properties within the various layers!

MR CFD Support –

Thank you for your positive feedback! We’re glad you appreciate the comprehensive setup and attention to detail in our simulations. We aim to create the most realistic and meticulous models to provide an educational and practical experience for our users.

Miss Janessa Trantow MD –

What impressed me the most was how well the simulation showcased the species transfer through the membrane. Could you explain how the PEMFC model accounts for the electrolyte resistance?

MR CFD Support –

The polymer membrane’s conductivity within the PEMFC model is characterized to include electrolyte resistance. The resistance is taken into account in the calculation of proton potential and the resulting voltage losses. A conductivity value is specified for the membrane, which directly affects how protons transfer across the membrane and impacts the cell’s overall efficiency.

Mallory Muller –

The training descriptions are very educational! I just want to say thank you for helping me grasp the complexities of fuel cell simulations.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to know our training materials are helpful and clearly explain fuel cell simulations. If you have any more questions or need further assistance, feel free to reach out. Your success is our success!

Georgiana Heidenreich –

I’m thoroughly impressed by how comprehensive the simulation of the PEMFC model is. The detailed analysis of gaseous behaviors and thermal conductivity in correlation with the electric productivity of the cell is commendable. The layers and modular representations within the software lend fantastic insights for anyone keen on understanding fuel cell mechanics or looking to optimize similar models.

MR CFD Support –

Thank you so much for your kind words! We’re delighted to hear that you found the PEMFC model simulation comprehensive and insightful. Our goal is to provide detailed and accurate simulations to help our users fully understand complex systems. If you have any further questions or need assistance in optimizing your fuel cell models, please don’t hesitate to reach out to us!

Ms. Sandra Ratke IV –

How do you model the proton exchange membrane in this simulation?

MR CFD Support –

We model the proton exchange membrane using the Nernst equation in ANSYS Fluent. This equation describes the voltage produced by the fuel cell as a function of temperature and reactant concentrations.

Porter Torp –

Very impressed with the intricacy involved in modeling the Polymer Electrolyte Membrane Fuel Cell (PEMFC) in ANSYS Fluent. The use of different zones for the flow channels, catalytic parts, and the polymer membrane seems to neatly segment the processes and provide clarity on the simulation. I appreciate how the complexity of real-world conditions has been broken down and simulated with precision!

MR CFD Support –

Thank you! We’re thrilled to hear that the simulation details of the Polymer Electrolyte Membrane Fuel Cell impressed you. It’s our mission to provide intricate and realistic simulations that can be understood and appreciated by our clients. Your feedback validates the hard work our team puts into creating these comprehensive training materials. If you have any more questions or need further assistance with your simulations, don’t hesitate to reach out.

Destany Corwin –

I’m thrilled with how the PEMFC CFD simulation captures the complex interactions within the fuel cell. The detailed analysis of gas mixtures and the functionality of each layer successfully demonstrated the chemical processes and their impact on electricity generation. The inclusion of species transport and thermodynamic behavior provided in-depth insights into the performance of the PEMFC. Truly enlightening learning material!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that our PEMFC CFD simulation has provided you with a comprehensive understanding of the intricate workings of polymer electrolyte membrane fuel cells. It’s great to know that you found the analysis of the gas mixtures and the detailed exploration of each functional layer informative and helpful. We take pride in delivering high-quality learning materials that enhance knowledge and are glad to have achieved this with our simulation. We look forward to continuing to support your learning journey!

Magnolia Barton –

I really learned a lot about PEMFC from this simulation! The detail in the contours and the reaction visualization was particularly impressive. Great training material.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to know that the simulation was informative and that you appreciated the detailed visualizations. If you have any further questions or need more resources, feel free to reach out!

Dr. Ramona Yundt III –

Very impressed with how the PEMFC model captures the intricate workings of fuel cells. The detailed results on ion transfer and the catalyst’s efficiency are remarkable. Hats off to MR CFD for their excellent work on this simulation!

MR CFD Support –

Thank you for your kind words! We are thrilled to hear that our Polymer Electrolyte Membrane Fuel Cell (PEMFC) simulation has met your expectations and provided the detailed insights you were looking for. We take pride in our commitment to accurate and thorough analyses. Your satisfaction with our product is the best reward for our efforts!

Colin Hamill –

I was thrilled with the level of detail in the PEMFC simulation training module. The step-by-step guidance really helped me understand the complexities behind the fuel cell operations!

MR CFD Support –

We’re delighted to hear that our PEMFC simulation training module was helpful to you. Understanding the complexities of fuel cell operation can be challenging, and we’re glad our detailed approach made a difference in your learning experience. Thank you for your positive feedback!

Dr. Jonatan Spinka –

I’m thrilled to share my positive experience with MR CFD’s course on Polymer Electrolyte Membrane Fuel Cell simulation using ANSYS Fluent. The clarity in explaining the setup of the catalytic sections, flow channels, and proton exchange was exceptional!

MR CFD Support –

Thank you for your kind words! We’re delighted to know that our training program was insightful and helpful in understanding the details of PEMFC simulation. Your satisfaction with the clarity of our course materials is a great encouragement to us.

Yolanda Will –

The training material sounds thorough. I was wondering which specific version of ANSYS Fluent was used to perform the simulations? This may help me anticipate the relevance of the training to the software I have access to.

MR CFD Support –

The PEMFC CFD simulation training was performed on a recent version of ANSYS Fluent compatible with current industry standards. While we do not have the specific version number provided in the description, rest assured that MR CFD Company uses up-to-date software for these simulations. If you need exact version compatibility, please let us know and we can provide you with that information.

Raul Moen –

I’ve just completed the PEMFC CFD Simulation training using the ANSYS Fluent software from MR CFD, and I must say, the experience was enlightening! Thank you for providing such a detailed and practical learning opportunity.

MR CFD Support –

We’re thrilled to hear about your positive experience with the PEMFC CFD Simulation training! It’s always rewarding to know that our instructional materials are helping learners develop practical skills in complex simulations. Thank you for taking the time to compliment our product. Your feedback is truly appreciated, and we look forward to providing you with more educational experiences in the future.

Jaquan Bartell –

This training was incredibly comprehensive. It facilitated not only understanding the fundamental principles behind PEMFC but also mastering the practical application of CFD analysis in ANSYS Fluent for fuel cell simulations. The clearly divided layers and components within the model made it easier to visualize the conversion processes and diffusion phenomena occurring within the fuel cell. The step-by-step approach married theoretical knowledge with the hands-on computational experience flawlessly.

MR CFD Support –

We are truly grateful for your positive feedback. It’s great to hear that our training material on Polymer Electrolyte Membrane Fuel Cell (PEMFC) CFD simulation was helpful to you. Your ability to grasp both the theoretical concepts and practical applications provides us with great encouragement to continue offering detailed and practical learning experiences. Thank you for choosing our training resources, and we hope you’ll find our other products just as beneficial.

Georgette Klein –

The training for the PEMFC simulation was fascinating! The step-by-step methodology really helped me comprehend the flow process in the fuel cell, and the visuals made it easy to follow.

MR CFD Support –

Thank you for your positive feedback. We’re glad to hear that our approach to teaching the PEMFC simulation through ANSYS Fluent was helpful and the visuals added to your understanding. We appreciate you taking the time to communicate your satisfaction with our training materials. If you have any more insights or need further assistance, please don’t hesitate to reach out to us.

Dr. Fannie Schulist DDS –

The presentation provides a clear overview of the comprehensive CFD study conducted in ANSYS Fluent software on a Polymer Electrolyte Membrane Fuel Cell. The results seem very conclusive for understanding the flow and electrochemical behavior within the cell.

MR CFD Support –

Thank you for your positive feedback on the PEMFC learning material! We’re glad to hear that the information was clear and helpful for understanding the complex functioning of a Polymer Electrolyte Membrane Fuel Cell. Your satisfaction boosts our commitment to delivering high-quality educational content. If you have any more questions or need further assistance, please don’t hesitate to contact us.

Ms. Annabelle Hermiston II –

Is this PEMFC model able to predict the lifespan of the fuel cell, or is it solely for fluid behavior and thermal analysis?

MR CFD Support –

The PEMFC CFD Simulation model primarily focuses on analyzing fluid behavior, thermal properties, and electricity production within the cell. It is not directly designed to predict lifespan but provides detailed insights into the operational characteristics that might indirectly inform durability assessments.

Ms. Marcelle Aufderhar –

I’m consistently impressed by the way the detailed simulation replicates the complex function of a real PEMFC. The visualization aids in understanding the flow and thermal transitions within the cell. Exceptional instructional material!

MR CFD Support –

Thank you for your positive feedback! We’re very pleased to hear that our PEMFC CFD simulation and training materials helped enhance your understanding of fuel cell mechanics. Should you require further insight or assistance, do not hesitate to reach out. Happy learning!