Generator Room Ventilation, Industrial Application

$240.00 $120.00 Student Discount

In this project, an industrial generator room ventilation has been simulated, and the results of this simulation have been investigated.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Generator Room Ventilation, Numerical Study, Industrial Application

Abstract Generator Room

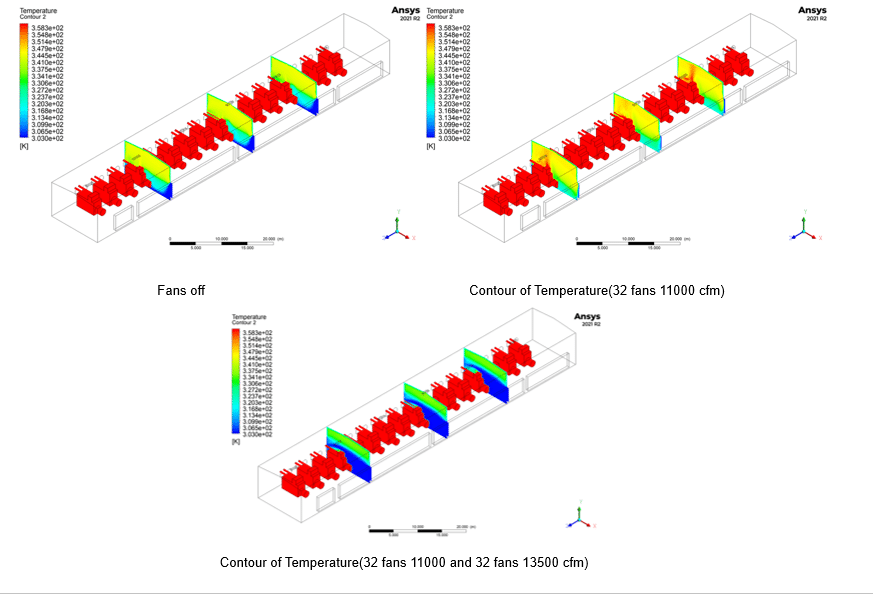

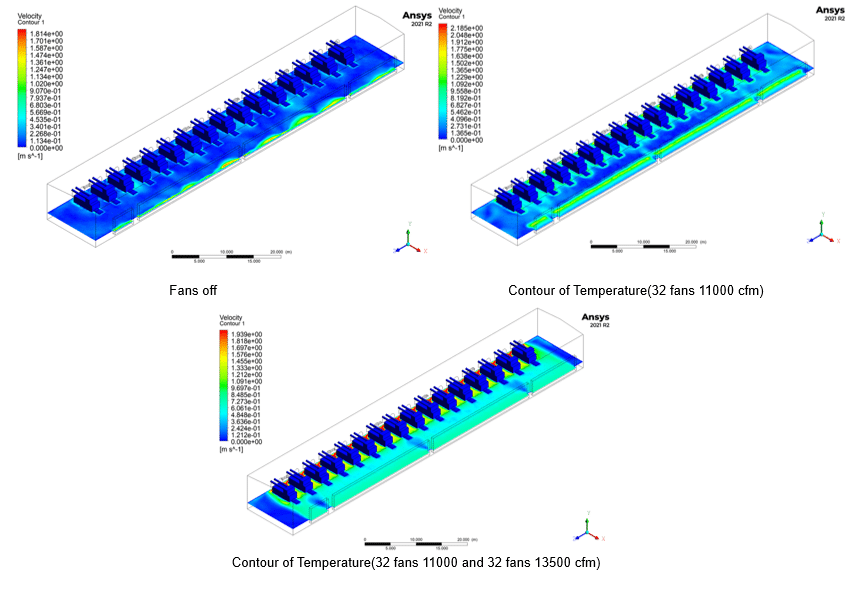

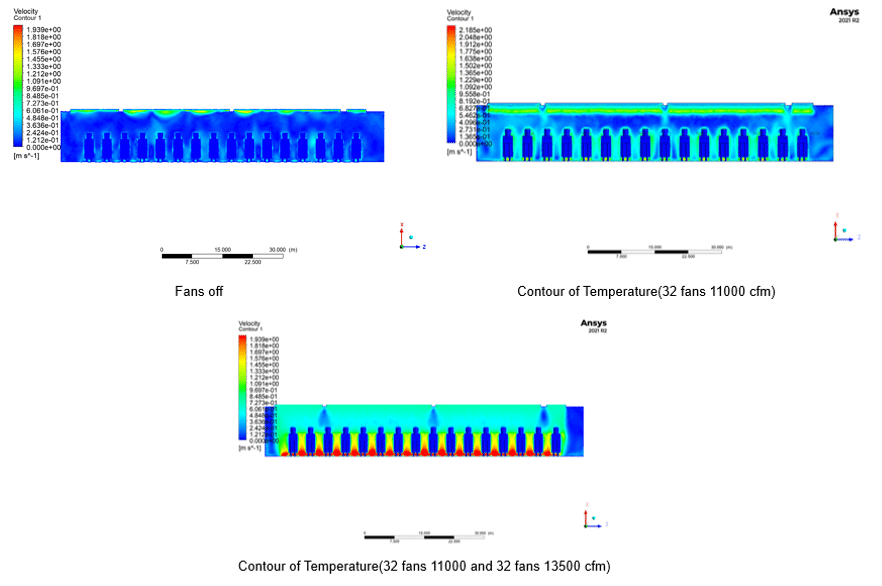

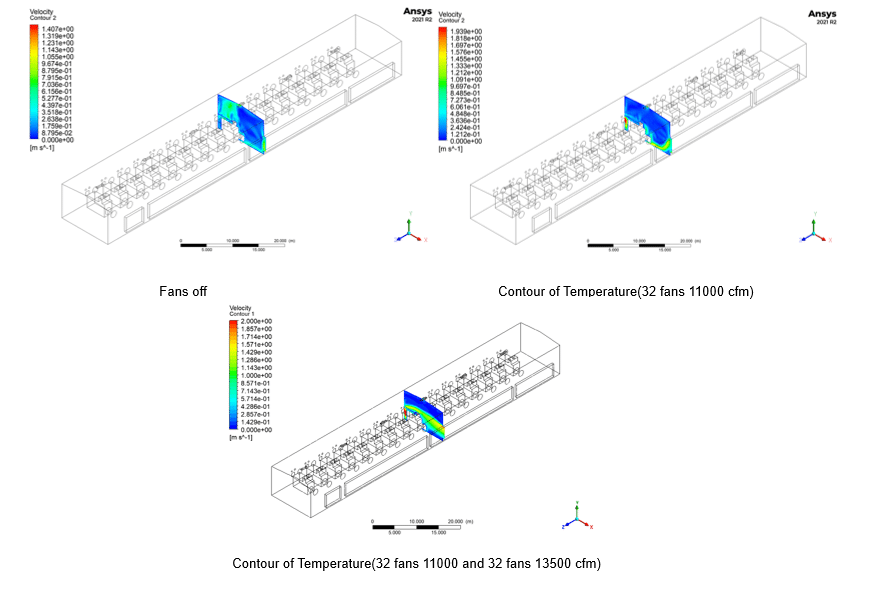

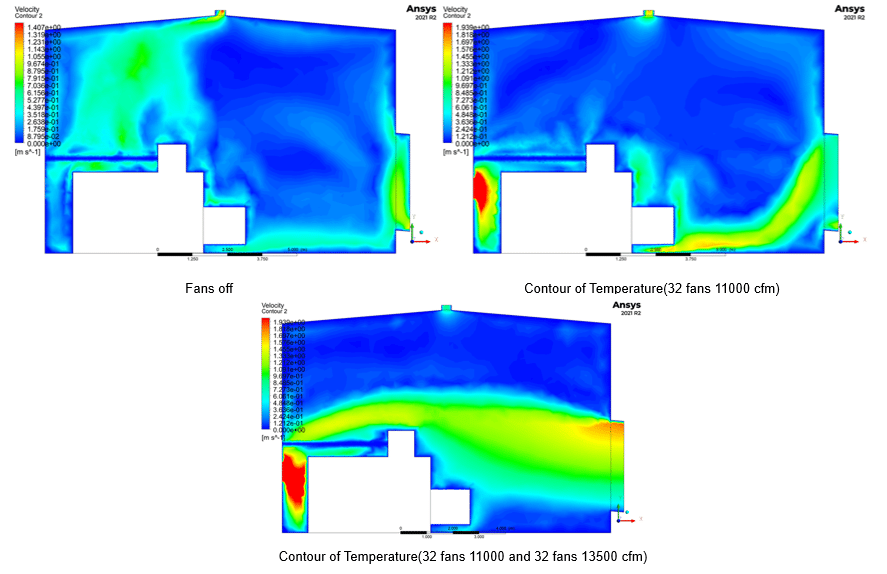

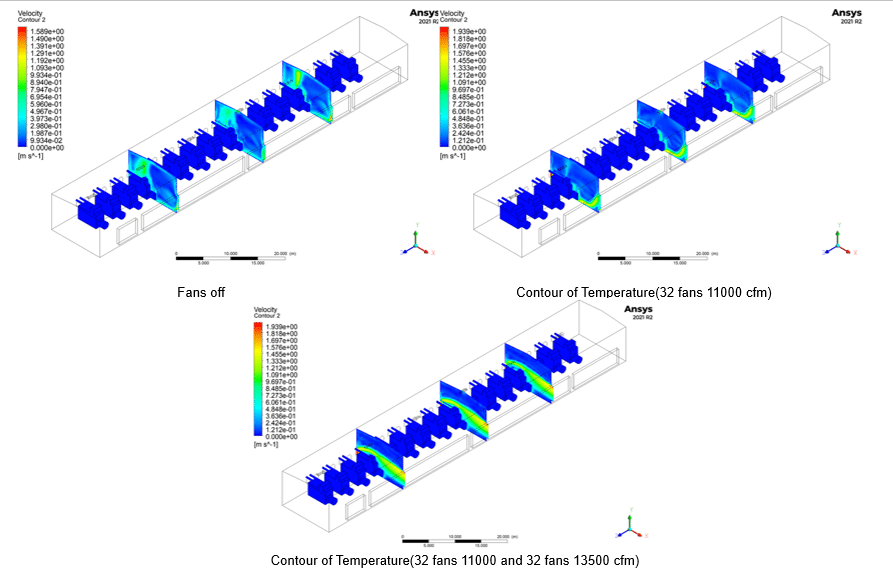

In this project, the heating, ventilation, and Air Conditioning (HVAC) of a generator room are simulated using Ansys Fluent software. After completing the simulations, in which a generator room is initially simulated without a fan, it is observed that the room temperature with 32 generators is very high. 32 fans with 11,000 CFM are used, which decreases the Temperature considerably. But to improve ventilation and Temperature and obtain the desired thermal comfort between generator rows, 32 fans with 36,500 CFM have been added.

Purpose Generator Room

Generators are one of the most widely used and essential sources of Electricity in various industries. Generators generate much heat, affecting thermal comfort if several generators are together. Therefore, operators can not approach the generators in summer due to extreme heat. So to solve this problem, we used several fans to make the room temperature of the generator suitable for the operators.

Introduction Generator Room

In 1845, Michael Faraday, a prominent English physicist and chemist, showed that light and magnetic force are related and thus discovered Faraday’s work. Faraday’s discovery paved the way for the construction of the generator. About 50 years later, a German inventor named Carl Diesel revolutionized the electricity industry with the invention of the diesel engine. Diesel generator or diesel generator machine has been used for many years in all places, whether in hospitals or remote villages and in any place where access to Electricity from power plants is impossible.

Diesel generators generate emergency power and supply the necessary power continuously, either during peak consumption or even when the shortage of Electricity is felt. Ships and many large land vehicles, such as trains, also use diesel generators to provide lighting power and provide the propulsion they need. With electric propulsion, more constant and powerful movement can be done, and more appropriate use of space. Electric propulsion was used in ships before World War I and evolved during World War II. Power generation devices are classified and named in kilowatts based on average to maximum production capacity and based on generating power and are selected for continuous or emergency depending on the type of consumption.

A high-speed and robust industrial fan is one of the essential pieces of equipment in large industrial environments. Because despite the number of personnel, the presence of large devices, the entry of gases and pollutants, and other reasons, the oxygen in industrial environments is reduced. To increase the work efficiency of all departments, a high-speed industrial fan with high suction is needed.

An industrial fan or industrial ventilator is an important device in large work environments such as sheds, factories, greenhouses, industrial halls, clubs, large centers, etc. Since to increase work efficiency and better breathing, air circulation is needed to supply the required oxygen and create good air, the existence of devices that can rotate a large volume of trapped air and clean the air. A high-speed industrial fan device should be included in the agenda from this purchase.

Generator

A generator is a machine that converts mechanical energy into electrical energy through electromagnetic induction. A diesel generator is also a generator that uses diesel fuel to generate Electricity.

A diesel generator combines a diesel engine with an electric generator (often a dynamo) to generate electrical energy.

Diesel generators today have many applications in industry and even in everyday life. These motors are usually used in places with no access to Electricity. The primary purpose of diesel generators is to generate Electricity.

Diesel generators are usually produced and supplied in different dimensions for different applications. These dimensions are determined based on their apparent power. The generator used in this project is CAT C175-20 which has a power of 4000 kW.

Advantages of Diesel Generator

It is known that diesel generators require less maintenance than other generators on the market. Because the generator engine requires fewer components to start, you no longer have to worry about replacing spark plugs or rebuilding carburetors.

They are less sensitive to fuel and can use cheaper fuels such as diesel, oil, and fuel oil. Fuel should be one of the most important items for anyone buying a generator. Although diesel prices may be slightly higher than other fuel sources, these generators consume less than gas generators when doing the same job.

Diesel fuel storage is much safer than other fuel types, such as gasoline, which explodes quickly and catches fire easily if spilled. On the other hand, diesel has a much lower risk of ignition. It also lasts longer than gasoline to get better quality fuel from your stored source.

Increase life expectancy

Continuous power supply

When you experience a shutdown, an excellent and reliable diesel generator proves to work and your vital power systems for a long time. It minimizes downtime so that your facility does not experience significant financial losses while you wait for power to return.

Diesel generators can control larger loads and operate for longer than other existing generators. It makes them viable for remote sites where the power grid may be unreliable.

Disadvantages of Diesel Generators

- Noise

- Cost

- Pollution

- Large-Volume

Fan

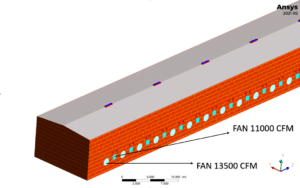

A high-speed centrifugal blower and an industrial suction fan are used in polluted, dirty, and impure air. In addition, this industrial fan is used for areas with high temperatures. In this project, TPI Commercial Belt Drive Drum Fan model CPB 42-B with a capacity of 13,500 CFM and AEROVENT model fan with 11,000 CFM have been used.

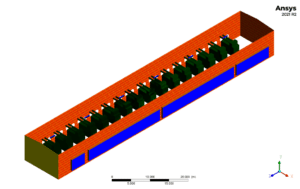

Simulation

The Design Modeler Software designs the geometry. The meshing of this present model has been generated by Ansys Meshing software. The mesh grid is structured, and the total cell number is more than 3854957. generator room simulations are performed steadily with the energy equation, and the k-ε model is Realizable as the turbulence model. The fluid used in this simulation is air for the continuous phase. Coupling of velocity and pressure equations is also performed using the Coupled algorithm. (It should be noted that to reduce the computational cost due to the symmetry of half of the geometry being simulated.

Generator Room Result

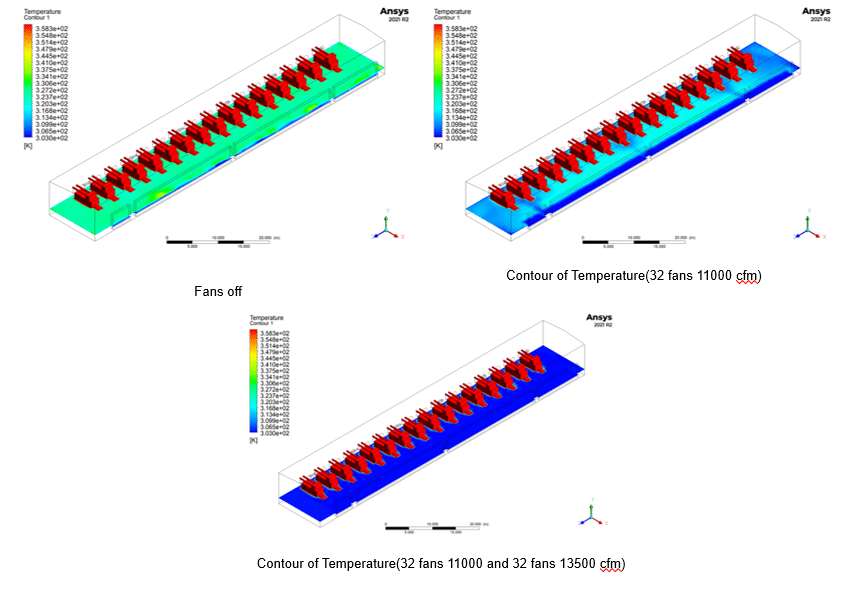

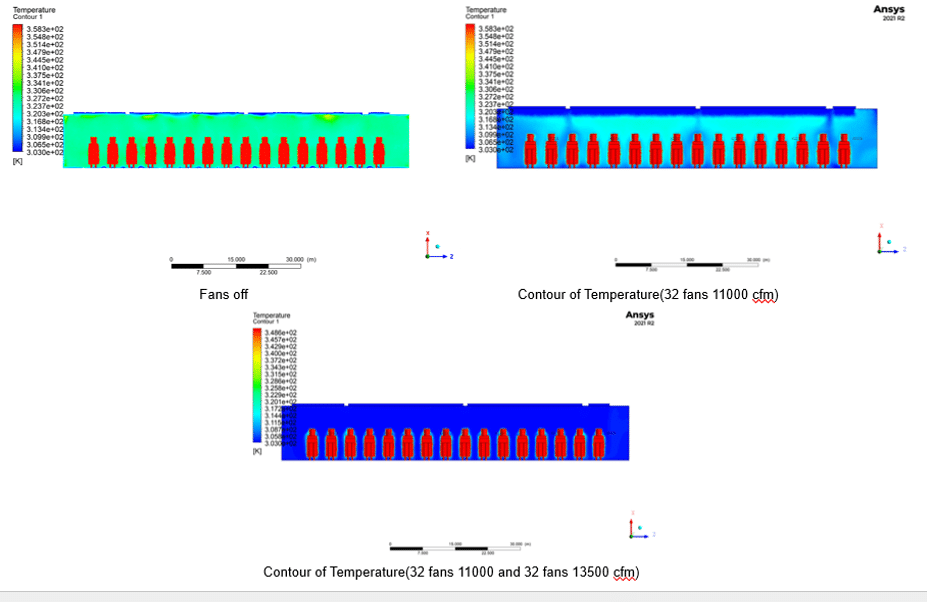

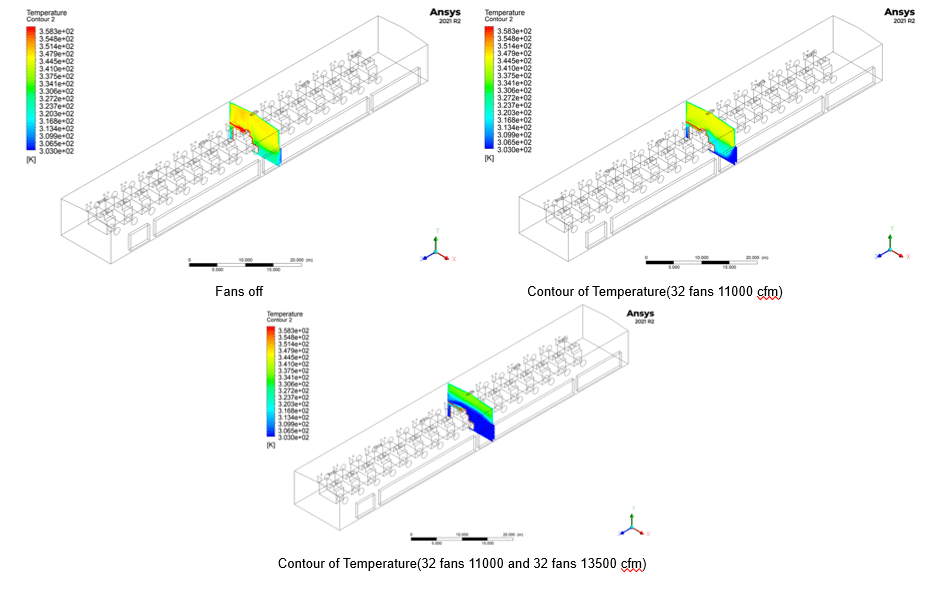

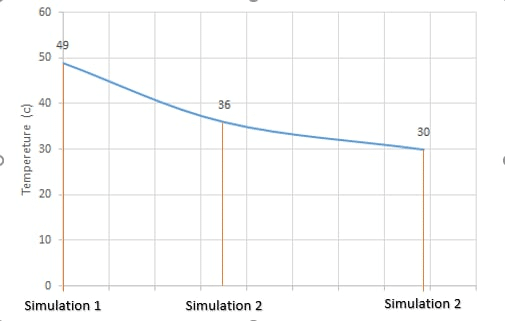

This project aimed to provide suitable thermal comfort for the generator room. In the first simulation, when no fan was on, it was observed that the Temperature between the generators was more than 49 ° C. Therefore, it was decided to use a fan to reduce the Temperature. Thus, in the second simulation, 32 small fans are used, each with 11,000 CFM. We concluded that the room temperature is improved and reduced to 36 ° C. Then it was decided to use 64 fans (32 fans 11,000 CFM and 32 fans 13,500 CFM) to improve the thermal comfort of the generator room in the next simulation. The latest simulation results show that the airflow velocity inside the room has improved compared to the previous simulation, and the Temperature between the generators is equal to the outside Temperature (30 ° C).

Temperature(fan off)

Contour of Temperature (32 fans 11000 CFM)

The contour of Temperature (32 fans 11000 and 32 fans 13500 CFM)

Eunice Hackett –

I’m really impressed by the thorough HVAC analysis for the generator room! Could you tell me if the simulation was calibrated with any real-world data or running conditions for better accuracy?

MR CFD Support –

Thank you for your kind words! Unfortunately, as an AI, I’m not equipped with specifics regarding the calibration processes or real-world testing applied by the MR CFD Company for this particular simulation. However, in typical computational fluid dynamics studies, simulations are often validated using experimental data or actual operating conditions. This ensures that the model accurately represents the physical scenario being analyzed and that the simulation results are reliable.

Mr. Doris Waters –

The product description was incredibly thorough and enlightening. Using simulation to improve the thermal comfort in a generator room is impressively practical. The step-by-step increase in fan power to refine temperature regulation provides valuable insights for HVAC design in industrial settings.

MR CFD Support –

Thank you for your positive feedback. It’s gratifying to know that you found the description informative and applicable to real-world HVAC challenges. Your recognition of the structured approach in improving temperature controls underscores the value we aim to deliver. We appreciate your review!

Krystel Harber I –

I found the study on the generator room ventilation fascinating! Can you elaborate on how symmetry was applied to reduce the computational cost? Also, what was the final distribution of Temperature across different parts of the generator room with all fans working?

MR CFD Support –

Dear customer, we’re glad you found the study informative! For reduction in computational cost, symmetry allowed us to model only half of the actual physical space since the other half would behave identically, eliminating the need to calculate the entire space. Concerning the final Temperature distribution, once all fans were operational, airflow velocity was enhanced, creating a uniform temperature distribution equivalent to the ambient outside Temperature of 30 °C across the generator room.

Prof. Agnes Gottlieb V –

I’m thinking about purchasing the Generator Room study. Can the simulation account for different types of generators with other heat outputs, or is it tailored specifically to the CAT C175-20 model mentioned in the description?

MR CFD Support –

The Generator Room Ventilation simulation provided by MR CFD is specifically tailored to the CAT C175-20 model as mentioned in the description. However, the methodology used can be tailored to other types of generators by adjusting input parameters such as the heat output of the generators, their size, and arrangement in the room. For custom simulations catering to different generator models and specifications, you would need to contact MR CFD to discuss the scope and requirements of your specific project.

Skyla Lockman –

Extremely comprehensive study on generator room HVAC! The thorough approach to simulate ventilation before and after fan implementation shows a commitment to optimizing working conditions. Fantastic job showcasing the impact of CFD in industrial applications.

MR CFD Support –

Thank you for your positive feedback! We’re delighted to know that our CFD study on generator room ventilation has provided you with valuable insights. It’s wonderful to see our work being appreciated and we strive to continue delivering high-quality, impactful simulations that can enhance industrial applications.

Vida Yost –

This review is a heartfelt compliment! The CFD simulation of the Generator Room Ventilation was exemplary. By successively improving the ventilation system, until thermal comfort was achieved, the study’s approach robustly mirrors real-world engineering problem solving. Particularly impressive was how the complex interactions of airflow and temperature were modeled and visualized to guide crucial HVAC design decisions.

MR CFD Support –

Thank you for your encouraging review! We’re elated to hear that you found the Generator Room Ventilation CFD simulation to be thorough and representative of practical engineering challenges. Our commitment is to provide realistic and valuable simulations that aid in understanding and solving complex issues. Your acknowledgement of our visualization and modeling efforts is greatly appreciated. We look forward to bringing you more high-quality simulations in the future!

Miss Stefanie Yost –

I’ve found the information about diesel generators’ advantages and disadvantages very insightful. Your study is quite thorough, and the ventilation solutions you’ve simulated sound effective in improving thermal comfort. Thank you for sharing the specifics of the HVAC improvements and simulations.

MR CFD Support –

Thank you for your kind words! We’re glad to hear that you appreciated the detailed analysis of diesel generators and the HVAC simulation study we carried out for the generator room ventilation project. Our goal is to provide comprehensive insights and practical solutions to our users. If you have any further queries or need assistance with similar projects, feel free to reach out to us!

Ms. Jana Nolan –

What does CFM stand for, and why is it significant for fans in the context of this simulation of the generator room?

MR CFD Support –

CFM stands for Cubic Feet per Minute, which is a measure of air volume flow rate. In the context of this simulation, CFM is significant because it indicates the efficiency of the fans in ventilating the generator room, ensuring the effective dispersal of heat generated by the generators and maintaining suitable thermal comfort.

Garrison Rutherford I –

Great in-depth analysis on the generator room ventilation. The inclusion of both small and large-volume fans really demonstrates the improvement in air circulation and temperature control. Did the second simulation involving 32 fans at 11,000 CFM each also look at changes in humidity or just temperature?

MR CFD Support –

The focus of the second simulation with the 32 fans at 11,000 CFM was primarily on improving the room temperature and ensuring effective air circulation for better thermal comfort. Changes in humidity were not specifically mentioned, but often, ventilation improvements can also help stabilize humidity levels indirectly.

Abraham Connelly –

I am amazed by how profound the impact of adding more fans was on the temperature control of the generator room. Great study!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you found the study on generator room ventilation impactful and informative. It’s fantastic to know that the results resonated with you. If you ever have any questions or need further assistance, please don’t hesitate to reach out.

Jewel Carroll –

The work you’ve done on simulating the ventilation of a generator room is very impressive! The detailed analysis and addition of two sets of fans to reach the target temperature shows the depth of understanding in HVAC systems for industrial applications.

MR CFD Support –

Thank you for your kind words! We always strive to provide detailed and accurate simulations to ensure that industrial environments like generator rooms achieve optimal conditions for both machines and operators. We appreciate your feedback!

Jayda Prohaska II –

The project really seems to have tackled the ventilation issues effectively. It’s quite impressive how the combination and placement of fans not only optimized airflow but also brought temperatures down to match the outdoor conditions, thus ensuring comfort and safety in the generator room. Definitely, a testament to careful planning and detailed CFD analysis. Great job on designing an efficient HVAC system for such a critical facility!

MR CFD Support –

Thank you for your positive review! It’s rewarding to know our CFD analysis and design have contributed to creating an efficient and safe environment in the generator room. Your appreciation of the practical application of fan placement and the effective reduction in temperature affirms the importance of our work in industrial settings. We’re glad the ventilation issues have been comprehensively addressed, and thank you for recognizing our efforts!

Makenna Kovacek –

Absolutely splendid! The clear focus on achieving thermal comfort in the generator room through simulation and the systematic increase in fan CFM shows a deep understanding of HVAC needs in industrial settings. The progression from a fan-free state to optimal temperature conditions bridges theory and practical application seamlessly in a complex environment. Kudos to the MR CFD’s comprehensive simulation solution!

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you appreciate the detailed work and careful attention to thermal management in industrial applications. Our goal is to provide realistic and impactful simulation solutions, and we’re glad that this has resonated with you. Your feedback is invaluable to us. Thanks again for taking the time to share your thoughts!

Ransom Keebler –

What a well-structured CFD project! The addition of the fans reflects significant improvement in the generator room’s ventilation. Well done on the detailed analysis. I’m impressed by how the introduction of both smaller and larger fans helps achieve the desired temperature. A real boon for maintaining both equipment and operator comfort!

MR CFD Support –

Thank you for your positive review! We’re glad to know that the detailed explanation of the simulation and the solutions we implemented served well to improve the generator room’s ventilation to your satisfaction. At MR CFD, ensuring clear and practical results is our top priority. We appreciate you taking the time to provide feedback.

Jennings Denesik III –

I’m curious about how the fans were specifically positioned and integrated into the simulation to reduce the temperature efficiently. It sounds like a complex scenario requiring precise distribution. How were the positions and angles for the fans determined?

MR CFD Support –

In this simulation, the 64 fans were carefully positioned to ensure efficient airflow through the generator room. The positions and angles were likely determined through preliminary tests and computational trials, optimizing air distribution to reduce hot spots and facilitate temperature homogeneity across the room. This is a standard practice in CFD analyses for HVAC systems, where both empirical data and simulation results guide the placement of ventilation equipment for optimal performance.

Mr. Jairo Goodwin –

The simulations provided insight into the ideal ventilation configuration needed for maintaining thermal comfort in the generator room. What evidence is there in the report to suggest that temperature reduction and improved airflow have a significant impact on the operational environment and safety?

MR CFD Support –

The report demonstrates that without fans, the room temperature reaches above 49 °C which can lead to overheating and potential malfunctioning of generators or discomfort for operators. Adding fans lower the Temperature to safer, more comfortable levels, indicating enhanced operational safety and working conditions. Furthermore, the resulting Temperature after introducing fans is equal to the outside Temperature, confirming significant environmental improvement.

Trevor Corkery –

I was rather impressed with the generator room ventilation project’s attention to detail, especially regarding optimizing the ventilation system’s efficiency. Quick question: Were there any significant challenges or limitations encountered with regard to simulating the HVAC system? It would be interesting to learn about any complexities that arose, especially considering the precision needed to ensure operator safety and equipment functionality.

MR CFD Support –

Thank you for your positive feedback on our generator room ventilation project. We encountered a balanced share of challenges, mostly related to accurately modeling the thermal dynamics within the generator room and ensuring that the simulations provided reliable data for HVAC optimization. There were complexities in fine-tuning the model to reflect real-world conditions, to account for all thermal inputs and outputs, and in managing the extensive computational resources needed for such detailed simulations. Our team ensured that every aspect of the generators’ operations, as well as the room’s specific structural features, was precisely accounted for to ensure a safe and functional environment for the operators and equipment.

Eve Labadie –

The results of the final simulation with all 64 fans sound promising! Do you provide step-by-step tutorials for setting up similar HVAC simulations for individuals not familiar with the software?

MR CFD Support –

We are glad to hear that you find the results of the final simulation promising! Yes, MR CFD Company offers comprehensive tutorials that guide users through the process of setting up HVAC simulations in Ansys Fluent. These tutorials include step-by-step instructions, from geometry creation and meshing to setting up boundary conditions, choosing appropriate solvers, and analyzing the results. Whether you are a beginner or have some experience, our tutorials are designed to help you master the software for various applications in the field of CFD.