Greenhouse Ventilation and Design Improvement, Industrial Application

$240.00 $120.00 Student Discount

- In this project, an industrial Greenhouse has been numerically simulated by ANSYS Fluent.

- Studying relative humidity, airflow velocity and thermal condition.

- Removing Ammonia as a pollutant.

- Greenhouse design improvement.

- HVAC analysis.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Greenhouse Ventilation and Design Improvement, Industrial Application, Numerical Study

Introduction

A greenhouse refers to a glass or plastic structure that separates part of a field from the ambient. It provides shelter and protects plants against severe climate changes and disruptive factors like insects and animals, for instance, in excessive cold or hot seasons.

Thus, designing a greenhouse environment aims to provide a safe and ideal condition for sensitive plants to grow steadily, which may be challenging and hard to control based on limitations and facilities!

Project Description

In this project, we set the target to design a greenhouse in a 5*10meter rectangular field that provides standard environmental conditions in the summer, such as acceptable temperature range (294~298K) and high humidity (25%<Mass fraction of H2O<30%) along with low ammonia fraction(<15 ppm).

On the other hand, Several limitations set by the client, like dense vegetation and sensitive plants, led us to have 6 rows of longitudinal carriers implemented at two different heights.

The greenhouse has two industrial fans with a 0.5kg/s mass flow rate, but they couldn’t satisfy the client’s demand. Thus, we have completed the mission of providing optimal conditions using numerical methods (CFD simulation) by ANSYS Fluent software. We perform the project in three steps, which we will explain in detail.

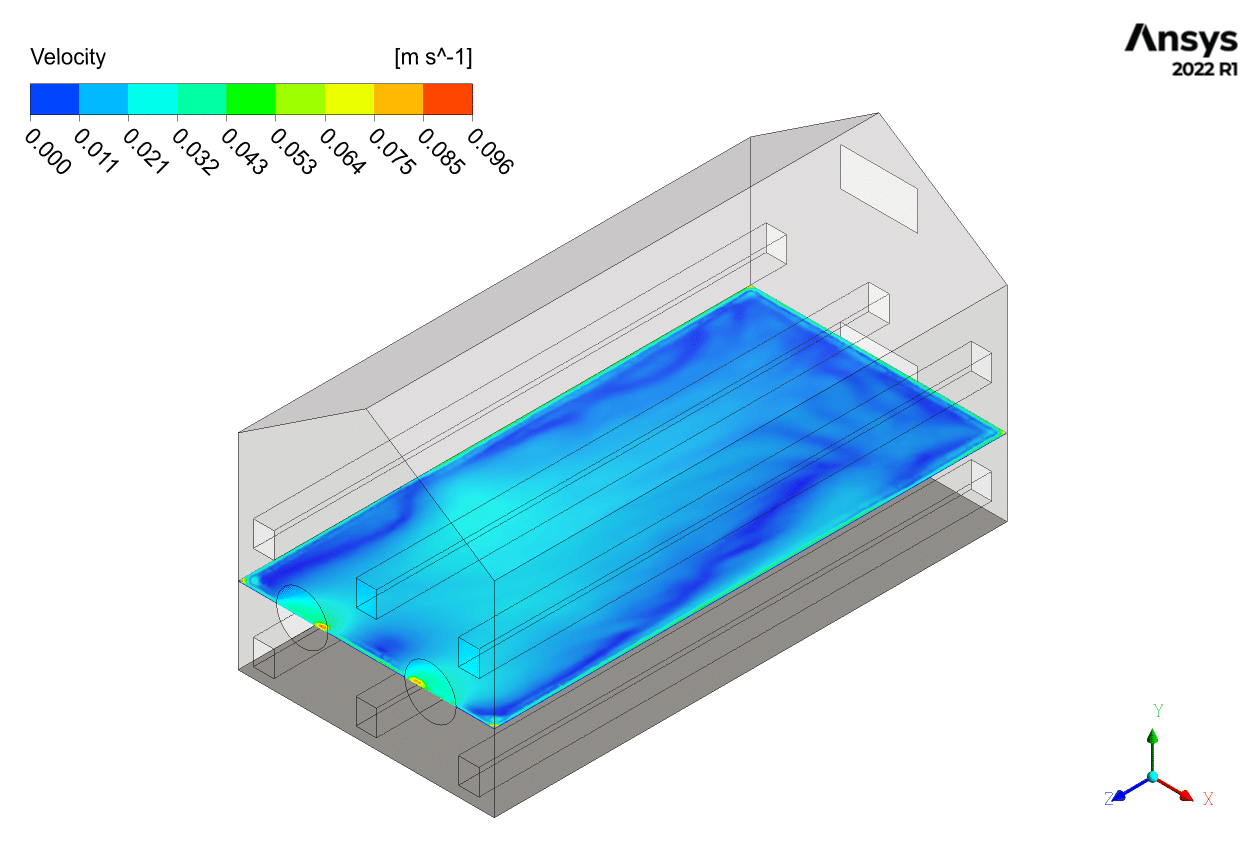

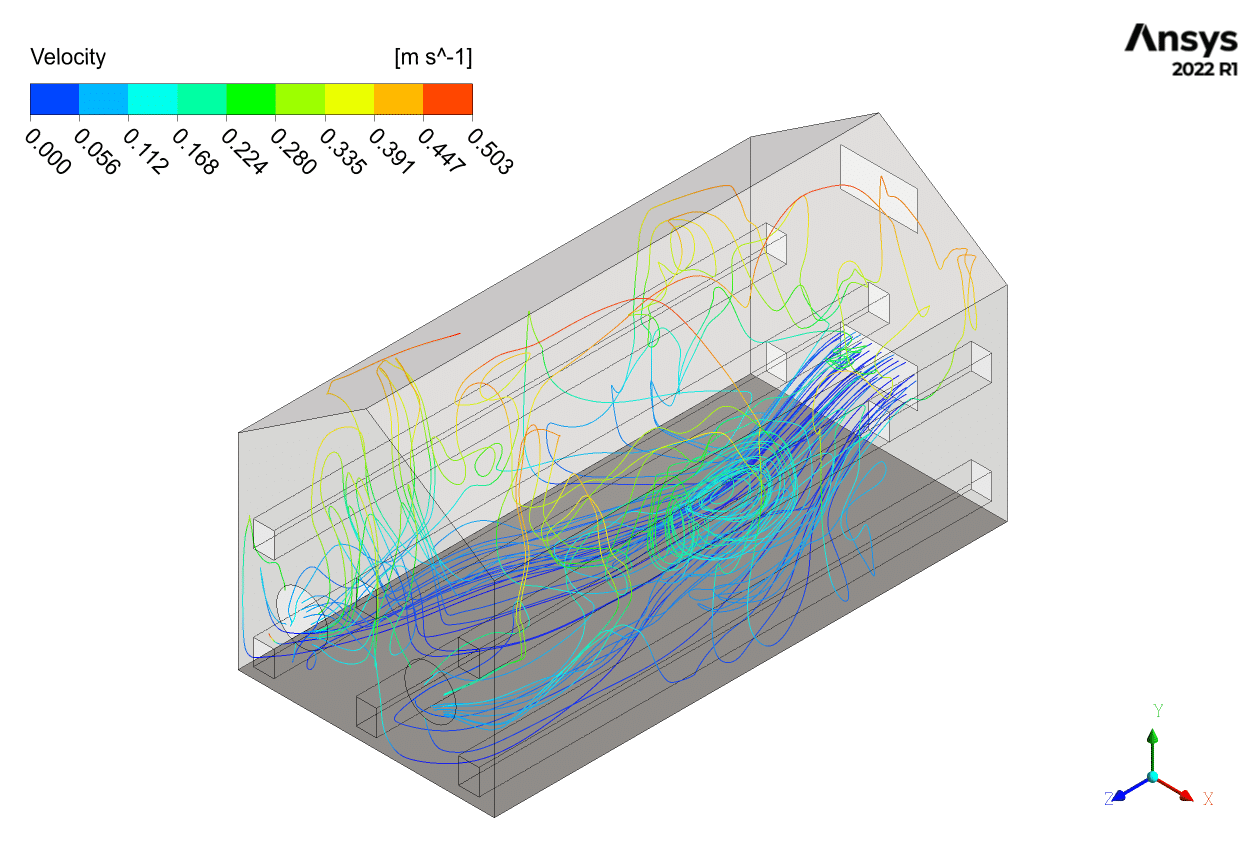

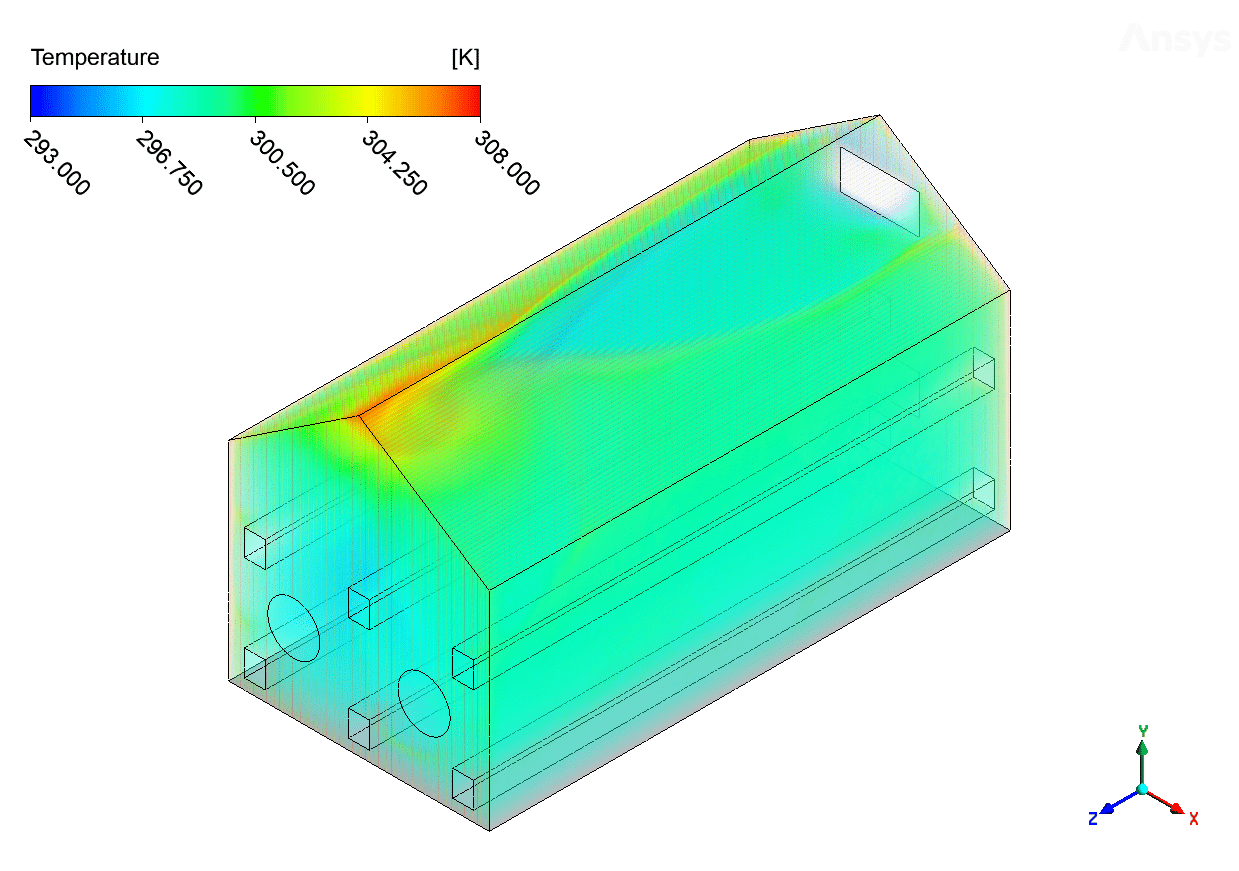

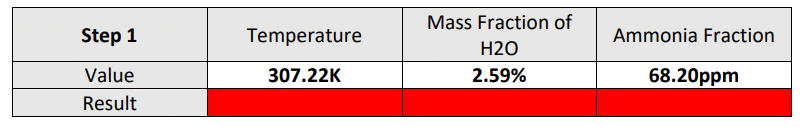

Greenhouse Step 1: (Considering Industrial fans)

In the first step, we simulate the greenhouse in its initial condition considering two industrial fans. After the simulation, the volume average temperature is reported as 307.22K and an H2O mass fraction of 2.59% & 68.20 ppm ammonia, revealing the greenhouse’s critical condition.

Also, the extracted temperature and velocity contours show the inefficient ventilation system. This couldn’t recirculate air effectively, and the bulk air remains constant except around the fan’s height region. This couldn’t satisfy either of the criteria.

Note that we employ simplification due to high computational cost and considering an engineering point of view. The effect of industrial fans was applied by using negative pressure in the outlet boundary illustrated below.

Temperature Contour :

Velocity Contour :

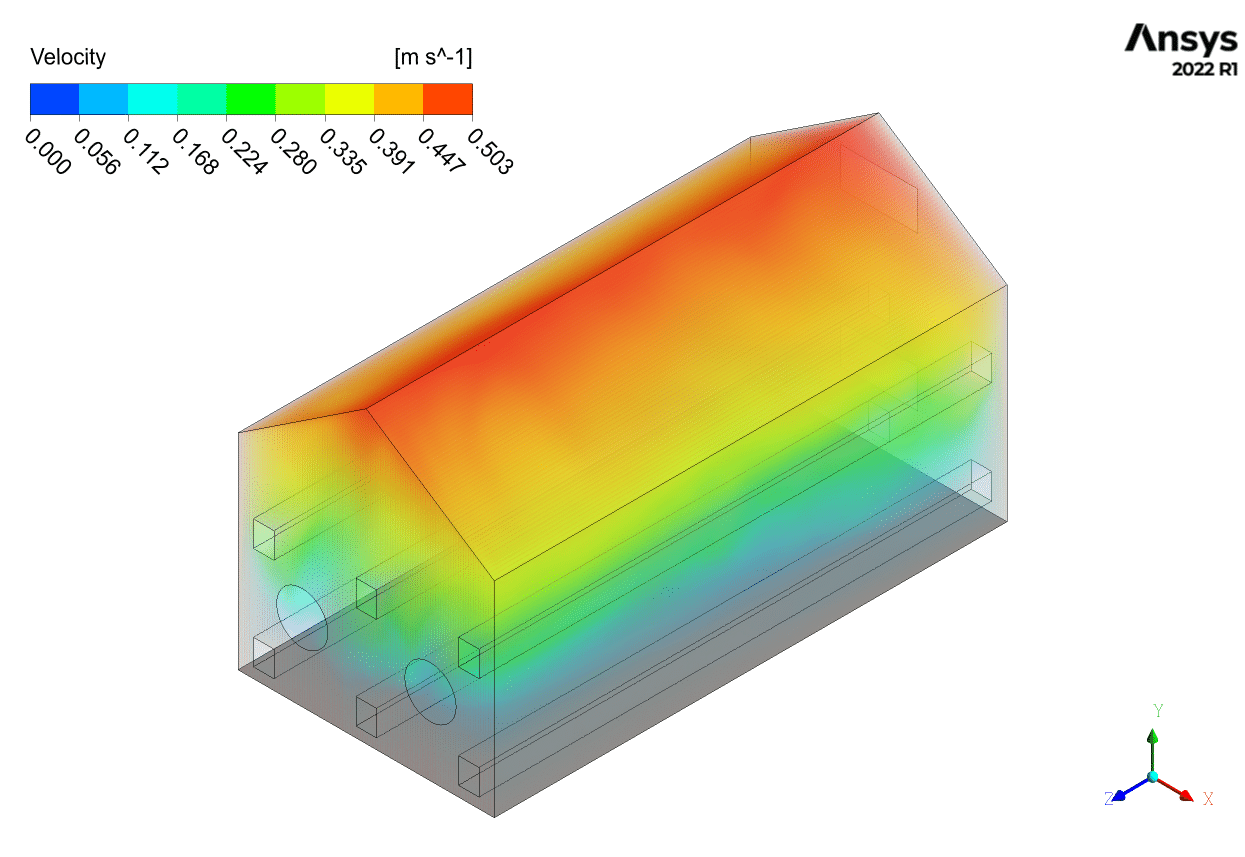

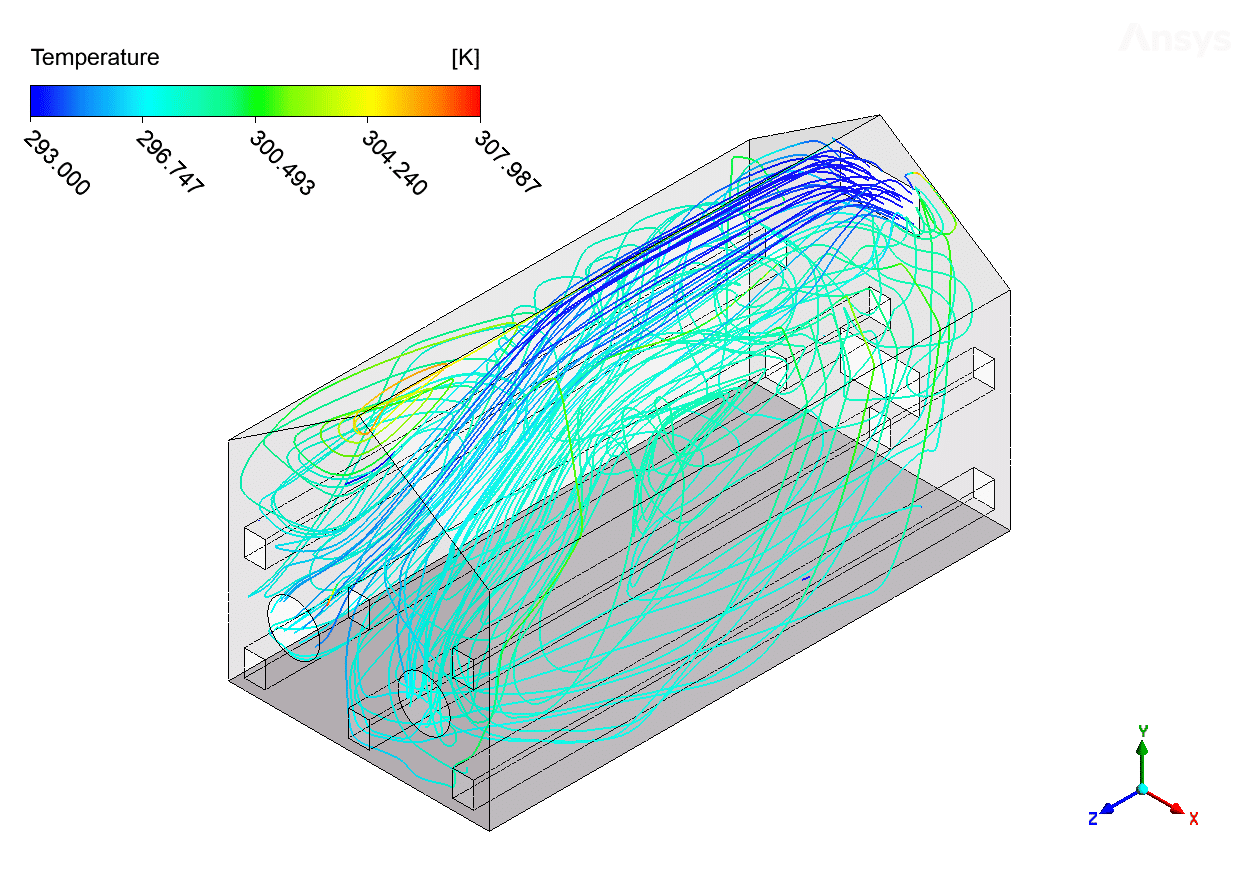

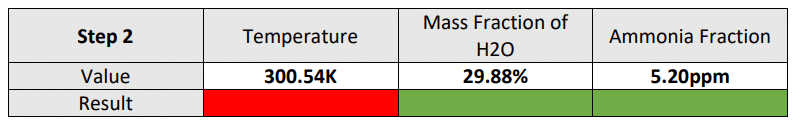

In the second step, we propose a water-cooled air conditioner to install in front of the fans on the other wall of the greenhouse. This helps air circulation and decreases the temperature along with increasing H2O.

The mentioned idea was applied, and the results show an improvement in temperature and H2O mass fraction, and NH3 by 300.54K & 29.88% & 5.20ppm respectively. The humidity and ammonia fraction get in the acceptable range, but still, the temperature needs to decrease.

Furthermore, as depicted in the contours, the air conditioner couldn’t help efficiently with circulation. Hot air got stuck under the roof because the cool inlet air mostly flows through the fans, as seen in the streamlined contour.

Therefore, we suggest increasing the inlet velocity of the air conditioner. Still, as mentioned, the plants are very sensitive and can be harmed by direct contact with high-speed air. So we’ve faced another limitation here, leading to the relocation of the air conditioner.

Velocity Contour :

Velocity Streamline :

Animations :

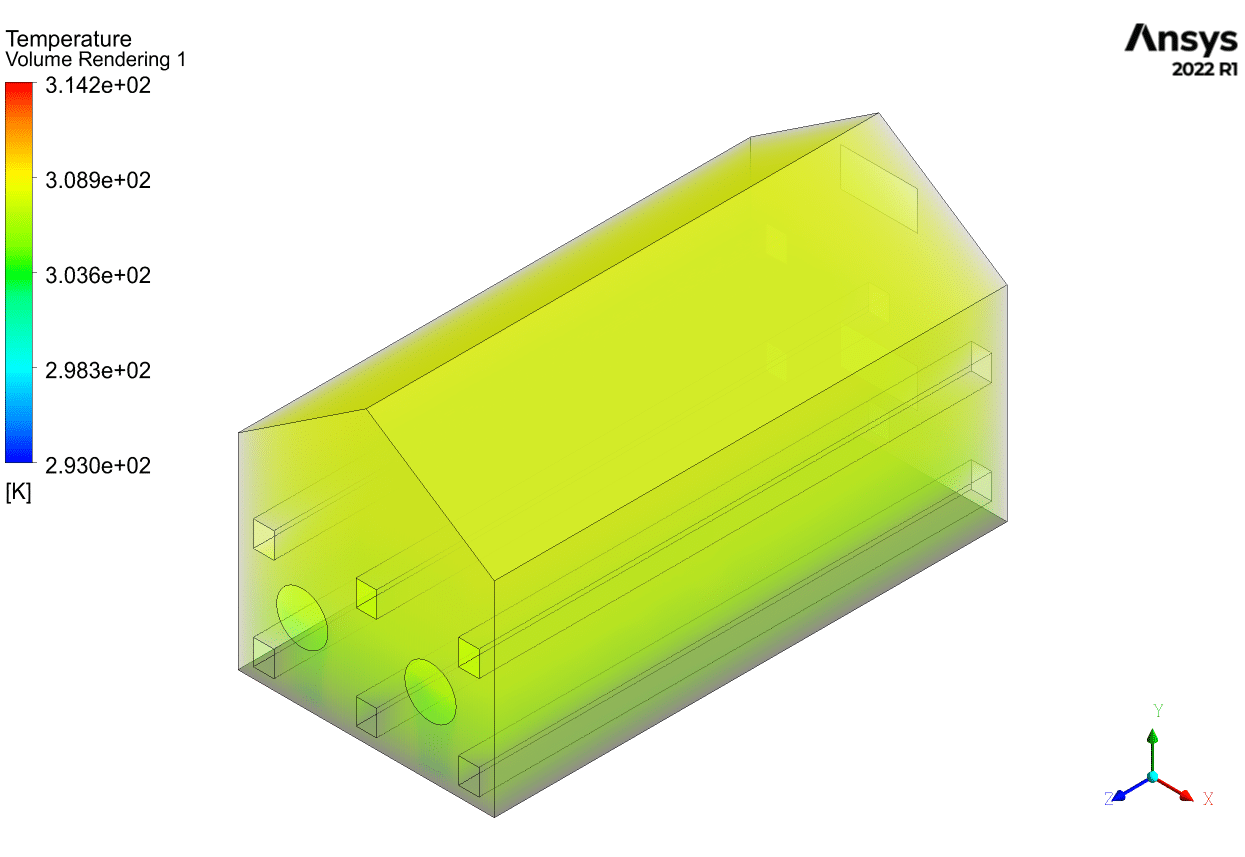

Greenhouse Step 3: (Considering New position)

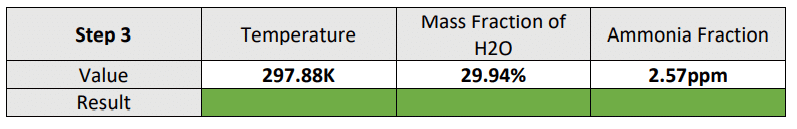

Considering the objectives and limitations, we have proposed to install the water-cooled air conditioner near the ceiling. Thus, it would be possible to increase the velocity and benefit from the natural convection. As a result, we achieved all targets, and values reached 297.88K, 29.94% and 2.57ppm.

Importantly, the temperature contour illustrates how the air circulation significantly improved, all rows experienced similar conditions, and the plants were not in direct contact with high-speed air, preventing any probable damage. The reason behind this is visible in the streamlined contour.

The cold air enters the domain near the ceiling, and due to the density gradient between hot and cold air, it falls. The repetitive process causes optimal recirculation in the greenhouse.

Temperature Contour :

Temperature Streamline :

Animations :

Conclusion

In this industrial project, we investigated greenhouse ventilation and design improvement. The employer presented a plan for the interior space of a greenhouse. The important factors for the ventilation of this space include a suitable temperature range, high acceptable humidity, and maximum reduction of ammonia.

The basic design of this greenhouse only consists of two industrial fans. In the first step, the MR-CFD simulation expert group performed a numerical simulation and analyzed its results. The experts concluded that the present design does not satisfy the three objective factors. So, fans alone cannot improve the greenhouse’s air condition.

Therefore, the CFD team suggested to the client install a water-cooled air conditioner on the wall in front of the fans. In the second step of the simulation, promising results were obtained. The use of coolers has significantly helped to increase air humidity and reduce ammonia. However, this method was insufficient because the temperature was still in the upper range.

This is because the hot air accumulates near the greenhouse ceiling due to the buoyancy effect and stagnation, and the cooling system installed in the middle height of the space cannot circulate it.

The easiest solution is to increase the speed of the cold air in the cooling system, which is harmful to greenhouse products. So, the MR-CFD group suggested to the project’s client to change the location of installing the water-cooled air conditioner. So we started the third step of the simulation with this idea.

The final results of the third step were extremely satisfying. We were able to satisfy all three factors by presenting suitable ideas.

You may be wondering how the temperature range was reduced. Note natural convection heat transfer and buoyancy effect. Warm air moves to the environment’s top due to its lightness and less density. So the hot air accumulates in the vicinity of the roof of the greenhouse.

Now, it is enough to install the cooling system on top of the greenhouse’s interior. The cooling airflow reduces the temperature of the accumulated air. As the temperature increases and becomes heavier, the air falls again, and as a result, continuous air recirculation is created.

Ralph Hauck –

The simulations show a dramatic improvement after relocating the cooler. How exactly was the air conditioner repositioned to achieve these optimal results?

MR CFD Support –

The air conditioner was repositioned near the ceiling to take advantage of natural convection. The cooler’s inlet velocity was increased, which allowed the colder, denser air to fall, creating a continuous air recirculation throughout the greenhouse, thus efficiently distributing temperature-controlled air without causing harm to the plants.

Prof. Nicklaus Hagenes Jr. –

The simulation adjustments seem effective, but I’m curious about the impact they have on the electrical consumption of the greenhouse. Does the redesign with the new air conditioner position increase overall energy costs significantly?

MR CFD Support –

In our CFD studies, we focus on optimizing the design for the required parameters, including temperature, humidity, and gas concentrations. An energy consumption analysis is a different aspect that typically requires a comprehensive study considering the power rating and operational cycle of the air conditioning system and fans, as well as the greenhouse insulation factors. Our simulation results ensure the design meets the environmental requirements, but for a detailed cost analysis related to energy consumption, we typically recommend a specific energy audit or simulation.

Shayne Zulauf Sr. –

After studying your report on the successful greenhouse ventilation design, I am interested in learning more about the water-cooled air conditioner system you proposed. How exactly does this system integrate with the fans, and what are its operating parameters to achieve such impressive results?

MR CFD Support –

Thank you for your kind words. We’re glad to hear the handbook provided valuable insights for you. Using the proposed water-cooled air conditioner in conjunction with efficient planning proved significant in achieving successful simulation and creating an optimized interior greenhouse environment.

Jameson Howe –

I recently purchased the MR CFD product for simulating greenhouse ventilation and design improvement. I am so impressed with how the CFD simulations guided the changes that led to achieving the desired environmental conditions in the greenhouse! The step-by-step approach to problem-solving was particularly helpful in understanding the complexities involved in creating optimal conditions for temperature, humidity, and minimizing ammonia levels. What an effective application of computational tools in tackling real-world problems!

MR CFD Support –

Thank you so much for taking the time to leave us a review and for your kind words about the greenhouse ventilation and design improvement CFD simulation! We’re thrilled to hear how impressed you are with the step-by-step application of CFD in addressing complex environmental challenges. It’s gratifying for our team to see our product play a role in attaining the optimal conditions needed for growth within a greenhouse. Your success with our product motivates us to continue providing valuable tools and insights for our clients. We appreciate your support and look forward to serving you with more innovative solutions in the future!

Stefanie Legros Jr. –

Can you explain how the issue with the hot air getting stuck under the roof was resolved without increasing the velocity that might harm sensitive plants?

MR CFD Support –

The solution involved moving the water-cooled air conditioner closer to the ceiling. By situating the cooler at this elevated position, it leveraged natural convection currents, allowing for an increase in air velocity without the high-speed air directly impacting the plants. The cooler air, being denser, would fall and displace the warmer air, which rises due to reduced density. This dynamic created a more efficient air circulation pattern within the greenhouse, maintaining optimal conditions while ensuring the sensitive plants were not exposed to potentially damaging direct airflow.

Samanta Hackett –

I’m very impressed with the methodology and results of the CFD simulation for the greenhouse. However, I’d like to know if the project accounted for the impact of changing seasons and variable external temperatures on the greenhouse’s internal environment.

MR CFD Support –

Thank you for your kind words and insightful question. In this specific project simulation, the focus was predominantly on creating ideal conditions during the summer season, as detailed in the project description. Seasonal changes and variations in external temperatures are significant factors in greenhouse design and operation. These aspects would indeed require additional modelling scenarios accounting for the respective external conditions of other seasons. Simulations could be conducted by updating boundary conditions to reflect seasonal temperatures and sunlight differences, which would impact the greenhouse’s heat load and internal environment.

Prof. Alexandrine Watsica PhD –

I’m extremely impressed with the three-step process outlined to improve the greenhouse’s ventilation. It was especially smart to address the unique needs for temperature, humidity, and reducing ammonia concentration. I noticed a big factor was the relocation of the water-cooled air conditioner. Was this primarily motivated by avoiding damage to the plants from direct high-speed air exposure?

MR CFD Support –

Thank you for your kind words and your attention to detail in the design process! Indeed, the primary motivation for relocating the water-cooled air conditioner closer to the ceiling was to prevent potential harm to the sensitive plants from direct exposure to high-speed cold air. This strategic move exploited the natural convection process fully and resulted in not just overall improved air circulation but helped us meet set objectives while ensuring the delicate plants remained undisturbed.

Prof. Wilburn Brakus V –

I’m impressed with the level of detail in the greenhouse ventilation improvement project. Can you tell me more about how the simulations ensured that sensitive plants weren’t harmed by the high-velocity cool air from the air conditioner?

MR CFD Support –

In the greenhouse ventilation project, the simulations carefully considered the sensitive nature of the plants. To avoid harm from high-velocity cool air, the air conditioner was strategically placed near the ceiling. This utilized the natural convection phenomena that caused cold air to descend gently due to the density gradient between the hot and cold air, ensuring that plants were not in direct contact with high-speed airflow. MR CFD’s simulation experts paid attention to avoiding direct exposure of plants to strong air currents, allowing optimal air recirculation and temperature control without damaging the plants.

Jaron Ruecker –

The suggested modifications definitely seem to have achieved the intended results. It’s impressive how relocating the water-cooled air conditioner near the ceiling created optimal recirculation without damaging the sensitive plants. Well done on achieving such detailed and precise modifications through CFD analysis!

MR CFD Support –

Thank you for recognizing the hard work that went into achieving the greenhouse’s optimal environmental conditions with our CFD analysis. We appreciate your feedback and are pleased to hear the results met your expectations after relocating the air conditioner. Your satisfaction is paramount to us, and we’re thrilled we could assist in the successful design improvement for the greenhouse.

Emanuel Marvin –

Fantastic results on the greenhouse project! Just a question for future projects: was there an analysis on the type of plants being grown influencing the design, or is the improvement a general approach for various plant types?

MR CFD Support –

Thank you for your positive feedback and interesting question! The improvements made in this greenhouse project through the CFD simulation were general optimizations intended to stabilize temperature, humidity, and reduce ammonia levels within ranges suitable for various sensitive plant types. For specific plants with unique requirements, further customized modifications and simulations could be performed to ensure an optimal growing environment tailored to those particular plants.

Damien Herman –

Very impressed with the step-by-step improvement in greenhouse design. Haven’t seen such a perfect balance and attention to detail in other reports. The simulated streamline animations must be pretty insightful!

MR CFD Support –

Thank you for your positive feedback on our work! We’re glad to hear that you appreciated the attention to detail and the balance achieved in the greenhouse design project. It’s wonderful to know the streamline animations provided valuable insights. At MR CFD, we strive to deliver high-quality and detailed simulations to assist with complex problems. If you need further assistance with any other projects or have questions, feel free to reach out!

Dr. Krystina Cruickshank –

What specific characteristics does MR CFD’s team consider when proposing design changes to improve greenhouse conditions?

MR CFD Support –

The MR CFD team takes into account various essential factors when proposing design changes, such as ensuring a suitable temperature range for plant growth, achieving high and acceptable humidity levels, and reducing ammonia concentration for plant safety, while also considering constraints related to sensitive vegetation and the internal greenhouse layout.

Pat Cummerata –

Excellent product! The clarity of the steps described for the greenhouse design improvement is truly remarkable. It seems the MR CFD team’s approach to solving the ventilation issues was both systematic and innovative, gradually achieving the desired environmental conditions while balancing the sensitivities of the plants. The detail included in explaining the role of the water-cooled air conditioner and its relocation is particularly helpful. It gives a thorough understanding of how they utilized the principles of natural convection to enhance air circulation without damaging the plants. Fantastic work!

MR CFD Support –

Thank you so much for your wonderful feedback! We are thrilled to hear that you found the step-by-step project description for the greenhouse design enhancement elucidating and valuable. Our team at MR CFD Company strives to deliver detailed and innovative solutions through our simulations, keeping in mind not just the final objectives but also the critical intricacies involved in sensitive environments like greenhouses. Your appreciation truly motivates us to continue providing top-notch products and services. We look forward to assisting you in future projects as well.

Ms. Anya Dare –

This comprehensive project for improving greenhouse ventilation sounds very impressive! The attention to detail in achieving the desired climate conditions with constraints like sensitive plants is quite commendable. It’s excellent to see such thorough simulation work leading to successful results. Well done to the MR CFD team on optimizing this climate-sensitive environment!

MR CFD Support –

We appreciate your compliment on the project work for the greenhouse ventilation and design improvement. Our team is dedicated to finding tailor-made solutions within given constraints to ensure optimal environment conditions. Your acknowledgment motivates us to continue delivering high-quality and precise simulation studies to our clients. Thank you for your kind words!

Quincy Casper –

How did changing the position of the water-cooled air conditioner affect the airflow and temperature distribution in the greenhouse?

MR CFD Support –

Moving the water-cooled air conditioner closer to the ceiling leveraged natural convection currents, causing the cooler, denser air to flow downward. This prevented direct contact with the plants and ensured a more uniform distribution of temperature throughout the greenhouse. Translated into improved thermal comfort and better fulfillment of the environmental criteria.

Delilah Roberts –

The solution with relocating the water-cooled air conditioner sounds fascinating. After this adjustment, how evenly distributed is the temperature across different parts of the greenhouse?

MR CFD Support –

Admin_Response

Peyton Walker –

Truly a fantastic accomplishment by MR CFD! The methodology for improving the greenhouse ventilation was articulated well and the steps taken to arrive at the optimal solution were diligent and finely tuned to the project’s specific needs. Kudos to the team for achieving the perfect balance between temperature, humidity, and air quality – that’s no small feat with such sensitive parameters!

MR CFD Support –

Thank you for your kind words and recognition of our team’s efforts! We’re glad to hear you appreciate the detail and thoroughness that went into optimizing the greenhouse ventilation. At MR CFD, we always strive to deliver solutions that precisely meet our clients’ needs, and it’s rewarding to know when we have made a valued impact.

Isobel Marvin IV –

The greenhouse project’s approach seems comprehensive. Do the simulation steps detailed indicate a specific software version of ANSYS Fluent? Or can the described steps and designs be replicated with any version?

MR CFD Support –

The project description doesn’t mention a particular software version, implying that the methodological steps in the CFD simulation can generally be applied to any recent version of ANSYS Fluent that supports the necessary features, such as the multiphase flow model, the Dynamic Mesh, and System Coupling functionalities. While certain interfaces might differ slightly among versions, the core procedures should remain effective.

Dr. Arvel Paucek III –

Is the software used customized for greenhouse simulations, or is it a general-purpose CFD software? Curious about its adaptability to other unique agricultural environments.

MR CFD Support –

ANSYS Fluent is a general-purpose computational fluid dynamics (CFD) software widely used for simulating fluid flow, heat and mass transfer, and other related physical phenomena. It can adapt to various applications, including those in agriculture, by adjusting the simulation parameters and inputs to suit different environments and conditions. Thus, while the software itself isn’t specific to greenhouse simulations, its flexibility allows it to be applied successfully to such cases by experienced simulation experts.

Ms. Itzel Harvey DVM –

I was really impressed by how the team adapted their strategy over three steps to overcome the limitations and drastically improve the greenhouse conditions. This case study clearly shows their expertise in simulations to optimize environmental control. Great work introducing the water-cooled air conditioner while paying close attention to the sensitive plants. Does this assessment also take into account the energy efficiency of the final setup?

MR CFD Support –

Thank you for highlighting our adaptive approach and showing your appreciation! We are indeed proud of the achieved balance between plant safety and climate control optimisation. Regarding your question about energy efficiency, the CFD project mainly focused on achieving the specific environmental targets while adhering to the client’s constraints. However, energy efficiency is a valuable aspect, and we always aim to recommend solutions with energy-saving potential. Please note that while energy efficiency wasn’t explicitly stated in the case study, it is generally considered typically in the holistic assessment of any industrial project like this.

Suzanne Collins –

Fantastic depth of research and simulation work! It’s inspiring to see how MR CFD addressed each problem step by step with innovative solutions and achieved optimal conditions in the greenhouse.

MR CFD Support –

Thank you for your kind words! We’re thrilled to hear that you appreciate the methodology and dedication invested in achieving the best possible simulation outcomes.

Daisy Eichmann –

What an incredible approach to greenhouse design optimization! It’s satisfying to see CFD used in such practical applications to enhance plant growing conditions. The step-by-step improvement and attention to plant safety is commendable!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear you appreciated the attention to detail and our step-by-step approach in optimizing greenhouse conditions using CFD simulations. Your recognition motivates us to keep delivering high-quality service and solutions.

Lane McLaughlin –

I am impressed by the thorough approach and creativity used in tackling the greenhouse ventilation issues. Your detailed CFD simulations demonstrated a solid understanding of the real-world applications and the careful considerations in improving environmental conditions for sensitive plants. Excellent work on achieving all targets for temperature, humidity, and reduced ammonia!

MR CFD Support –

Thank you for your positive feedback! We are thrilled to hear that our work met your expectations. It’s gratifying to know that the careful planning and simulations paid off in solving complex real-world problems. Should you have any further inquiries or require assistance in future projects, don’t hesitate to reach out.

Prof. Nikki Nicolas I –

I’m impressed with the methodical approach shown by MR CFD in improving greenhouse ventilation. Can I adapt these simulation steps to any type of greenhouse, even with different dimensions and plant types?

MR CFD Support –

Each greenhouse project may have unique characteristics such as different dimensions, types of plants, and climate conditions. The steps performed in this project provide a framework that can be customized for other conditions. It’s essential to analyze the specific requirements and constraints of your greenhouse and adjust the modeling and simulation strategy accordingly. MR CFD can assist with this customization for your particular project needs.