Gun Muffler CFD Simulation: Acoustic and Dynamic Mesh Analysis by Ansys Fluent

$160.00 $80.00 Student Discount

- his report presents the simulation and analysis of a gun muffler using ANSYS Fluent

- The objective is to compare the acoustic parameters of a gunshot with and without a muffler

- The study involves creating the geometry in SpaceClaim, meshing in ANSYS Meshing, and using dynamic mesh and broadband acoustic models to simulate the bullet’s movement and sound propagation

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Gun Muffler ANSYS Fluent CFD Simulation Using Dynamic Mesh and Broadband Acoustic Model

Introduction

This report presents the simulation and analysis of a gun muffler using ANSYS Fluent. The objective is to compare the acoustic parameters of a gunshot with and without a muffler. The study involves creating the geometry in SpaceClaim, meshing in ANSYS Meshing, and using dynamic mesh and broadband acoustic models to simulate the bullet’s movement and sound propagation.

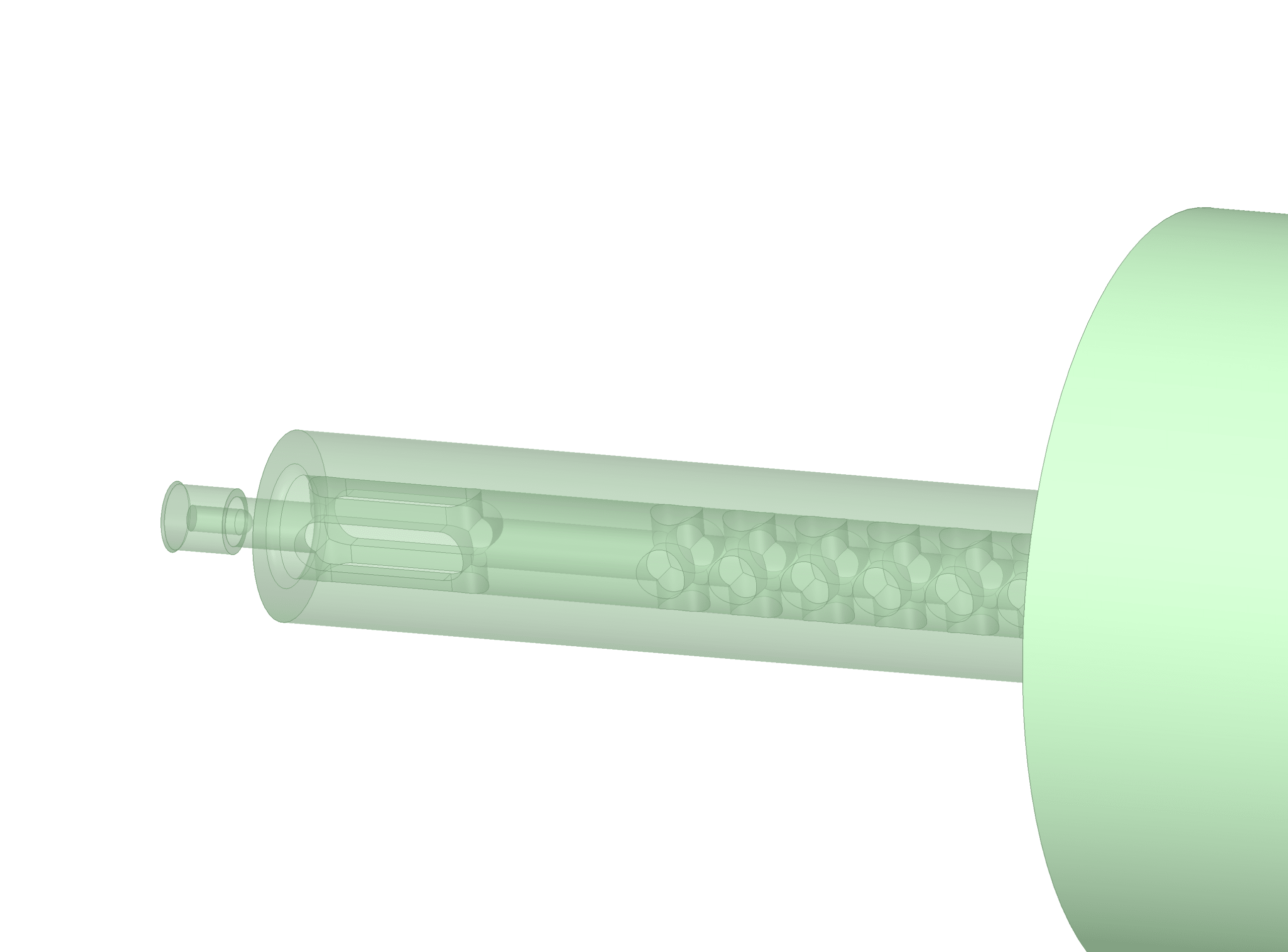

The geometry of the gun and muffler was created in SpaceClaim. The design includes the barrel, bullet, and muffler components. The muffler is designed to reduce the noise by altering the sound wave

A fine mesh was generated to capture the intricate details of the sound wave interaction with the muffler. The mesh was refined in areas where high gradients of pressure and velocity are expected, such as the muzzle and within the muffler.

Methodology

Dynamic Mesh: To simulate the bullet’s movement through the barrel and muffler.

Broadband Acoustic Model: To capture the acoustic signature of the gunshot and assess the muffler’s effectiveness.

Boundary Conditions: Appropriate inlet and outlet conditions were set to simulate the firing of the bullet and the subsequent sound wave propagation.

Solver Settings: Pressure-based solver with transient analysis was used to account for the dynamic nature of the problem.

Results

Acoustic Parameters Comparison

Without Muffler: The simulation of the gunshot without a muffler showed high sound pressure levels, indicating significant noise generation.

With Muffler: The inclusion of the muffler resulted in a noticeable reduction in sound pressure levels, demonstrating its effectiveness in noise suppression.

Visualization

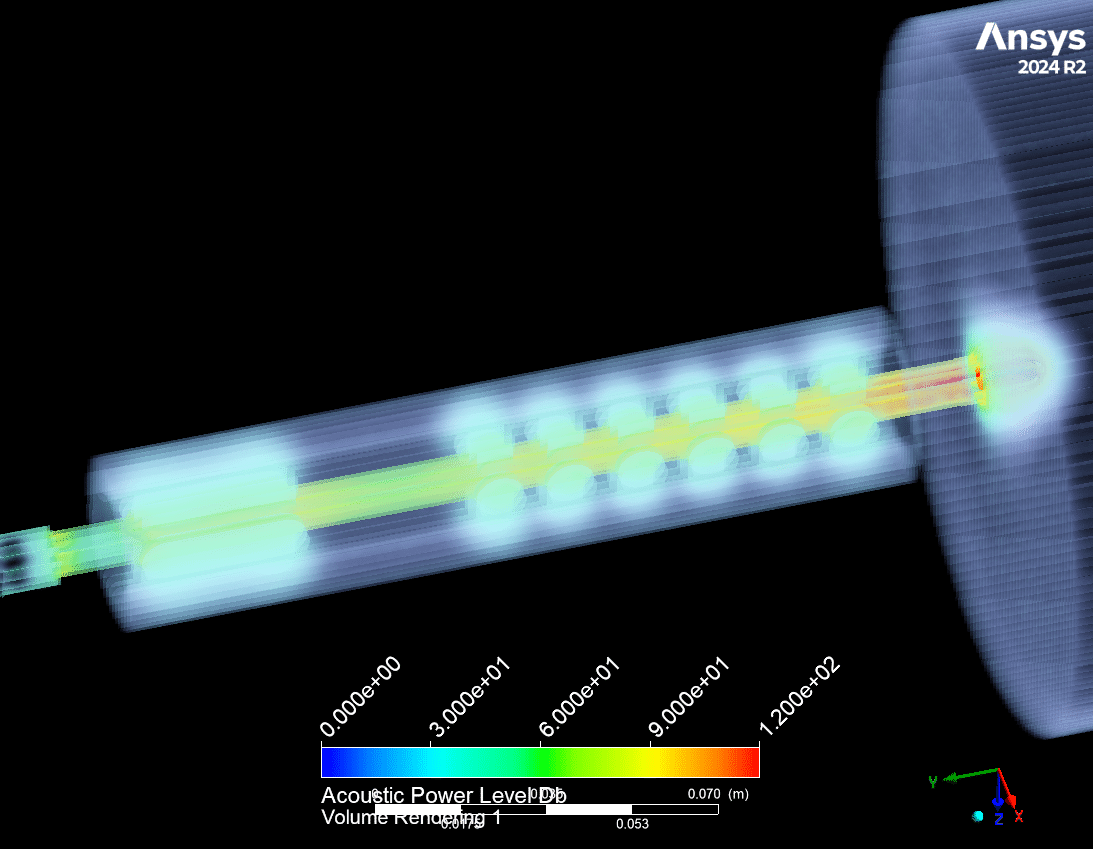

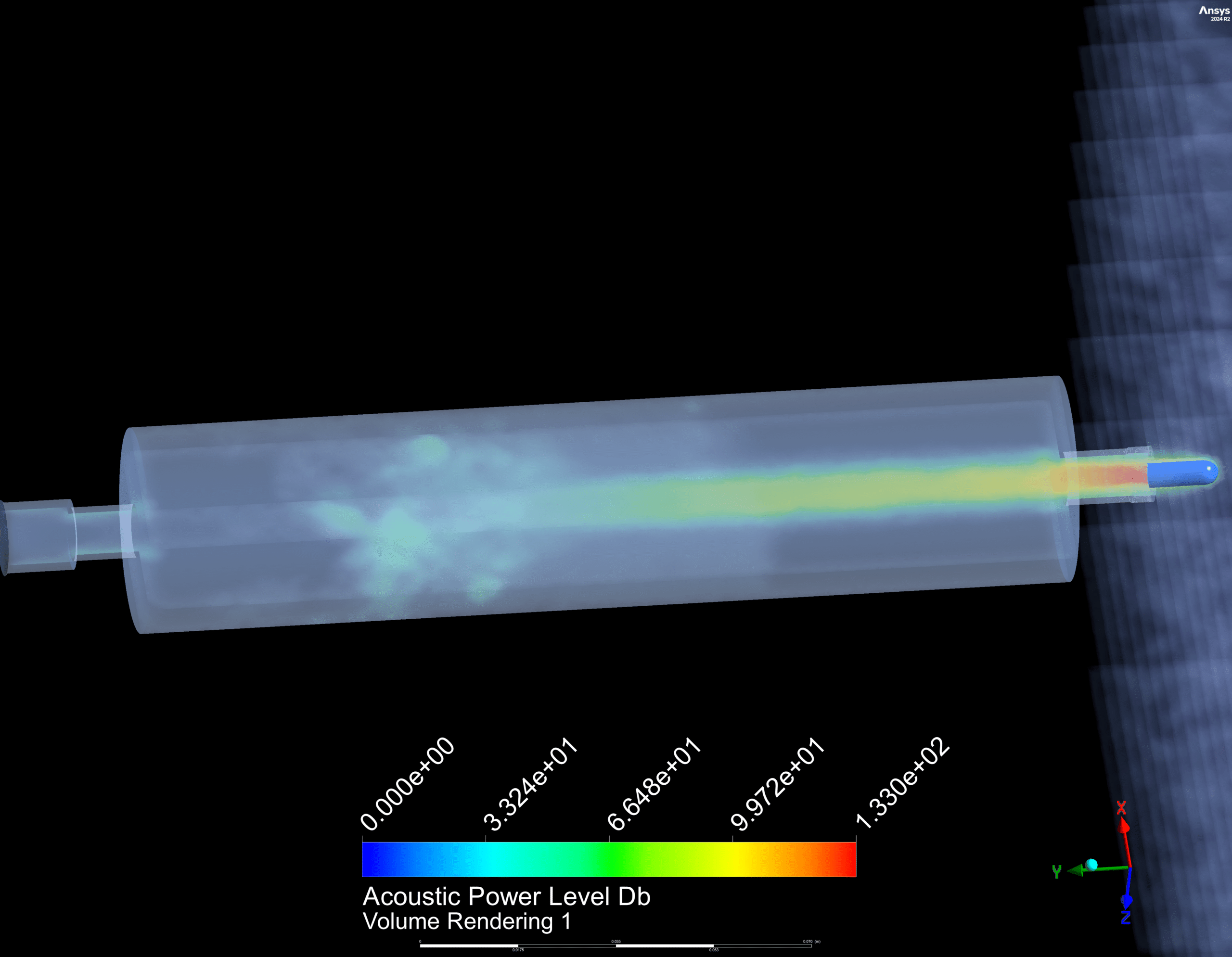

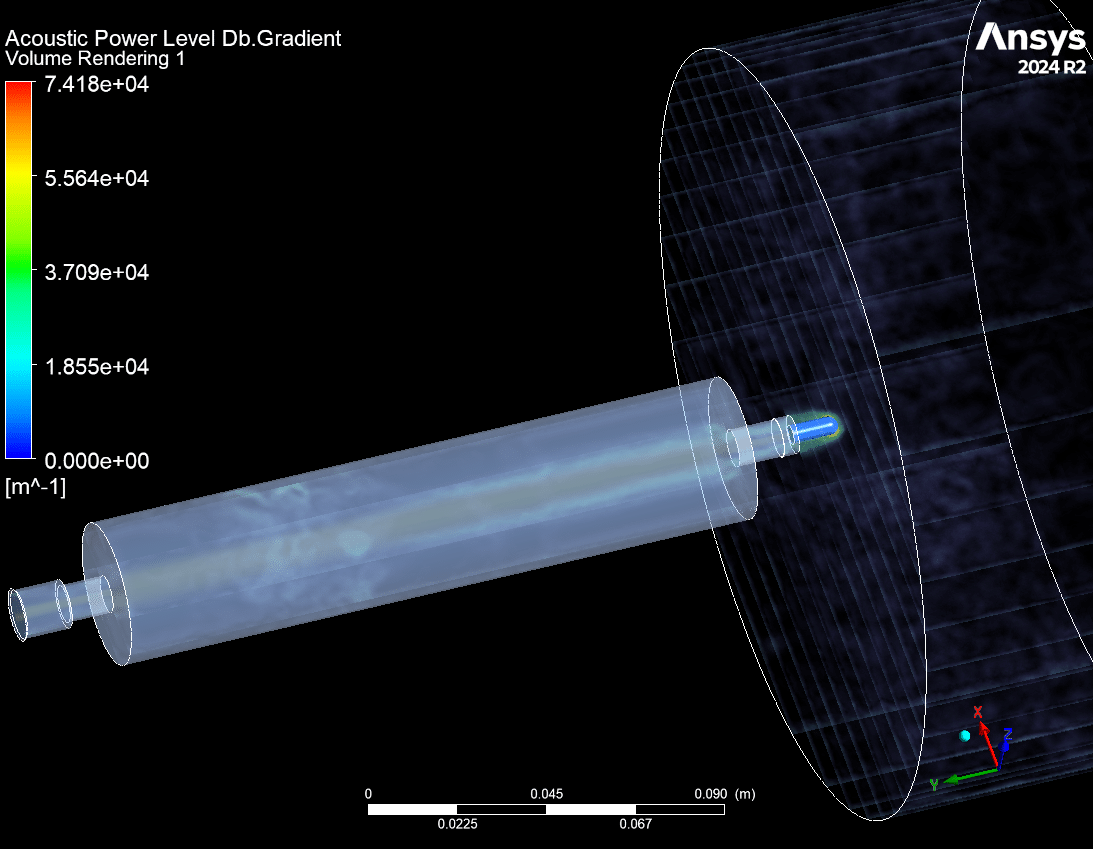

Acoustic Power Level (dB):

With muffler: The acoustic power level peaks around 1.29e+02 dB near the muffler outlet and dissipates to around 9.00e+01 dB downstream.

Without muffler (simple cylinder): The acoustic power level is much higher, peaking at 1.33e+02 dB at the cylinder outlet and remaining elevated above 1.00e+02 dB further downstream.

The muffler provides a significant reduction in acoustic power level compared to the simple cylinder case.

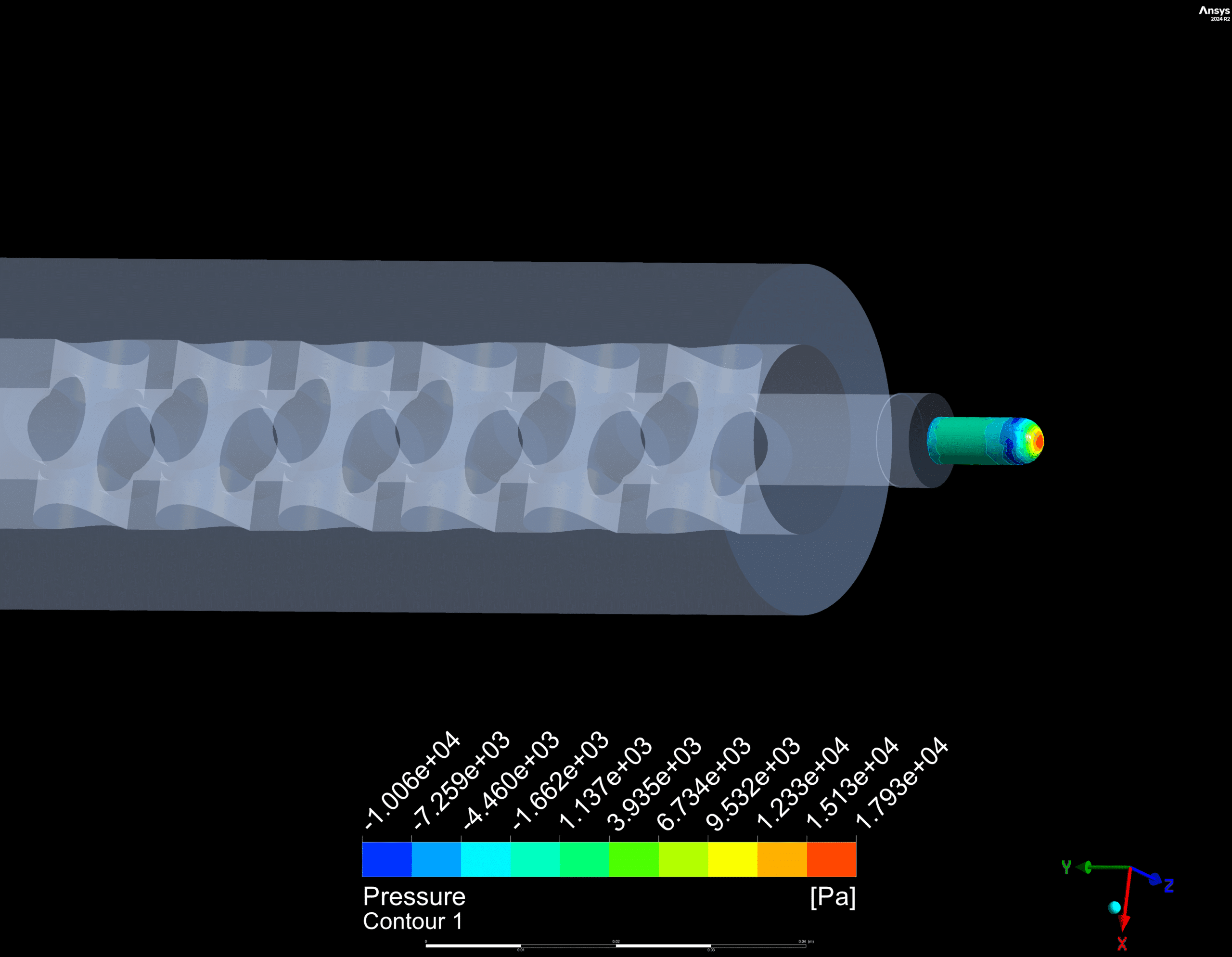

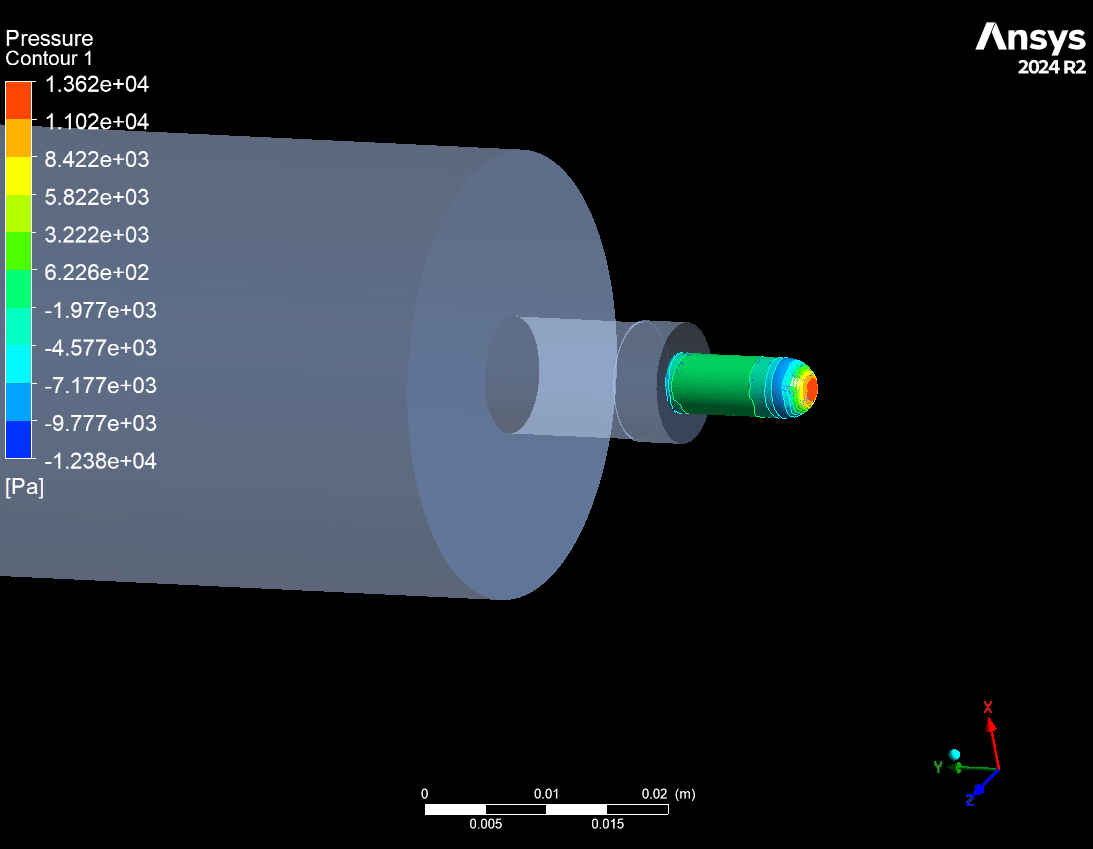

Pressure (Pa):

With muffler: The pressure fluctuations are dampened, peaking around 1.10e+04 Pa near the muffler outlet and decreasing to near atmospheric pressure downstream.

Without muffler: Much larger pressure fluctuations are seen, with positive pressure peaks over 1.36e+04 Pa and negative swings to -1.24e+04 Pa. The fluctuations persist further downstream.

The muffler greatly reduces the amplitude of the pressure waves compared to the no muffler case.

In summary, the gun muffler provides substantial noise reduction benefits by lowering the acoustic power level and dampening the pressure fluctuations compared to firing without a muffler. The CFD simulation quantifies the effectiveness of the muffler design for acoustic suppression.

Conclusion

The simulation of the gun muffler using ANSYS Fluent provided valuable insights into its acoustic performance. The dynamic mesh and broadband acoustic models effectively captured the complex interactions between the bullet, muffler, and sound waves. The results confirmed that the muffler significantly reduces the noise generated by a gunshot, making it an effective tool for noise control. Future work could involve optimizing the muffler design for further noise reduction and exploring different materials and configurations.

Reviews

There are no reviews yet.