Heat Transfer on Serrated Finned Tube, Paper Validation

Free

- The problem numerically simulates Heat Transfer Over a Serrated Finned Tube using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We Mesh the model with ANSYS Meshing software, and the element number equals 356240.

- This project is simulated and validated with a reference article.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Heat Transfer Over a Serrated Finned Tube CFD Simulation, Paper Numerical Validation by ANSYS Fluent

The present problem simulates the cooling process of a finned tube by air flow using ANSYS Fluent software. The simulation is based on the data in the reference article “A characteristic correlation for heat transfer over serrated finned tubes.”

The results are compared and validated with the results in the paper. In the real model, there is a tube with a certain length, in the direction of which several rows of fins are placed around the tube. So there is a tube with several rows of steel fins in the general model.

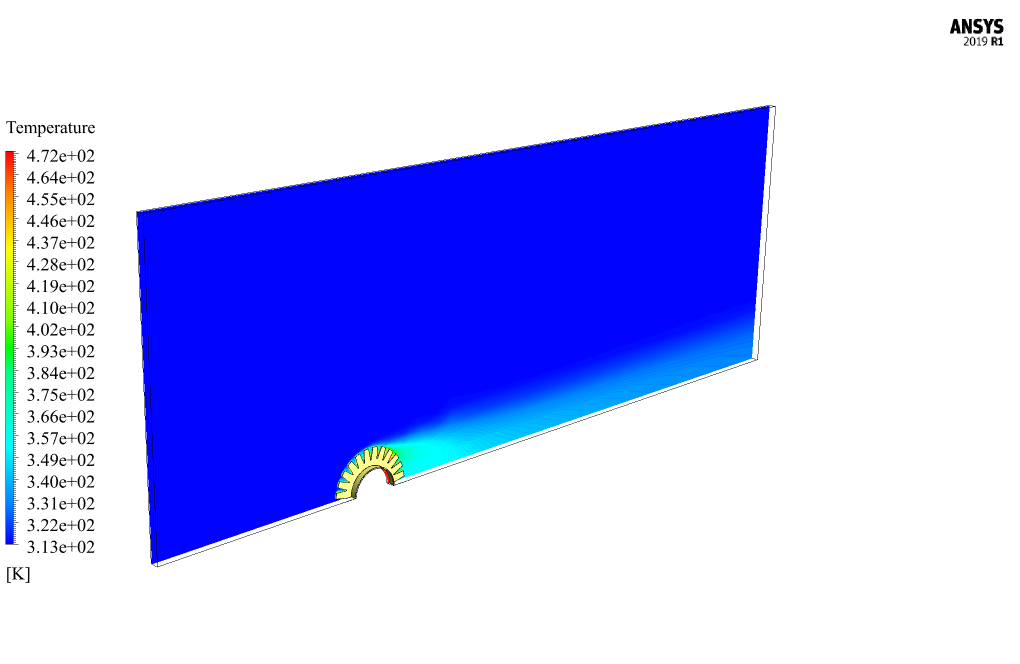

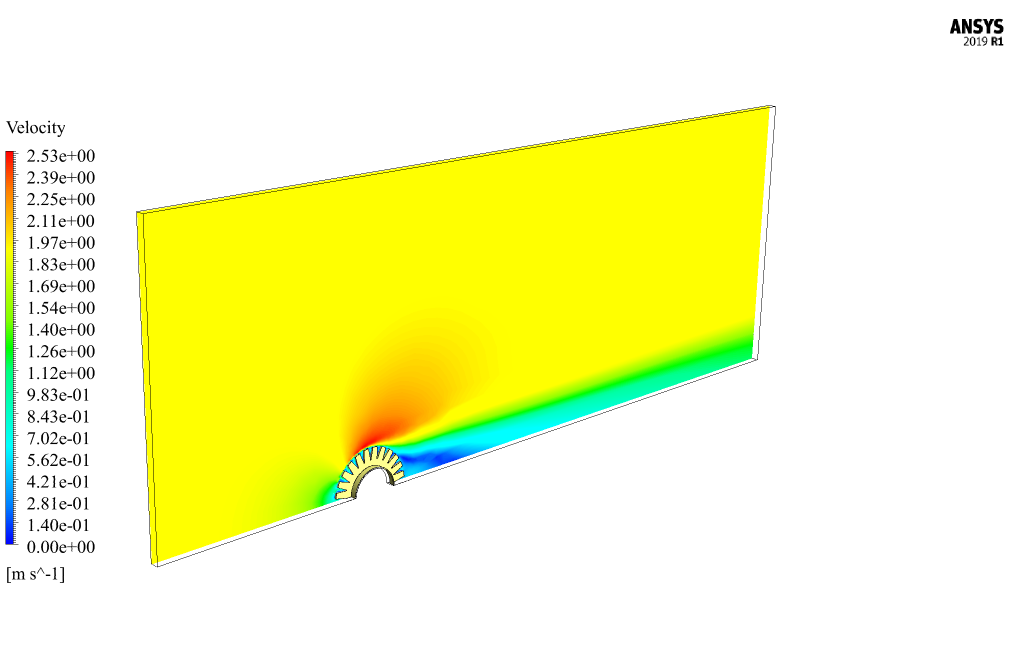

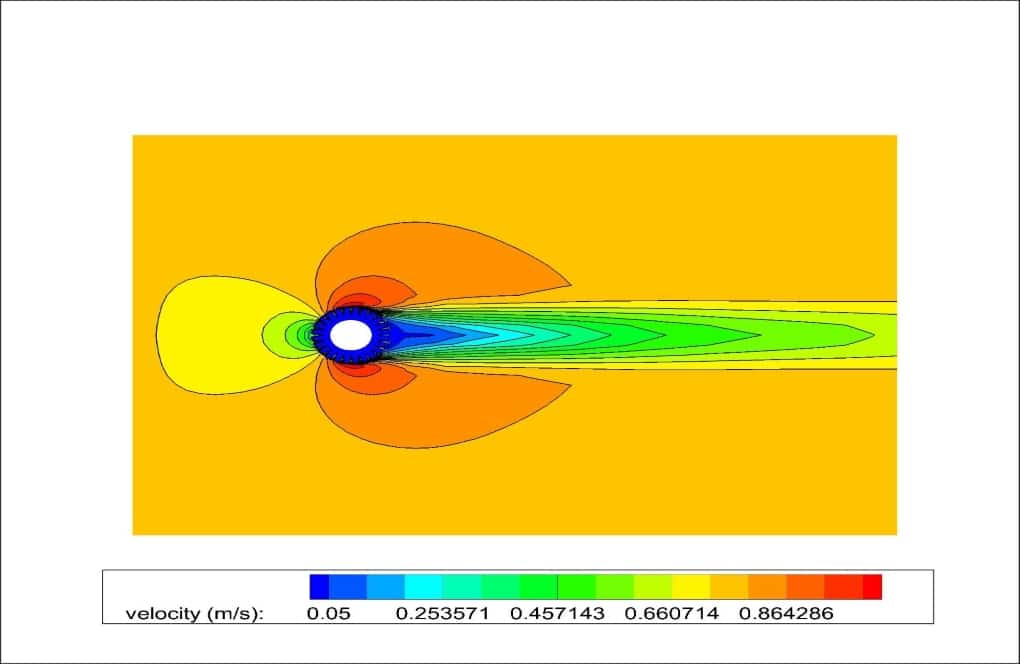

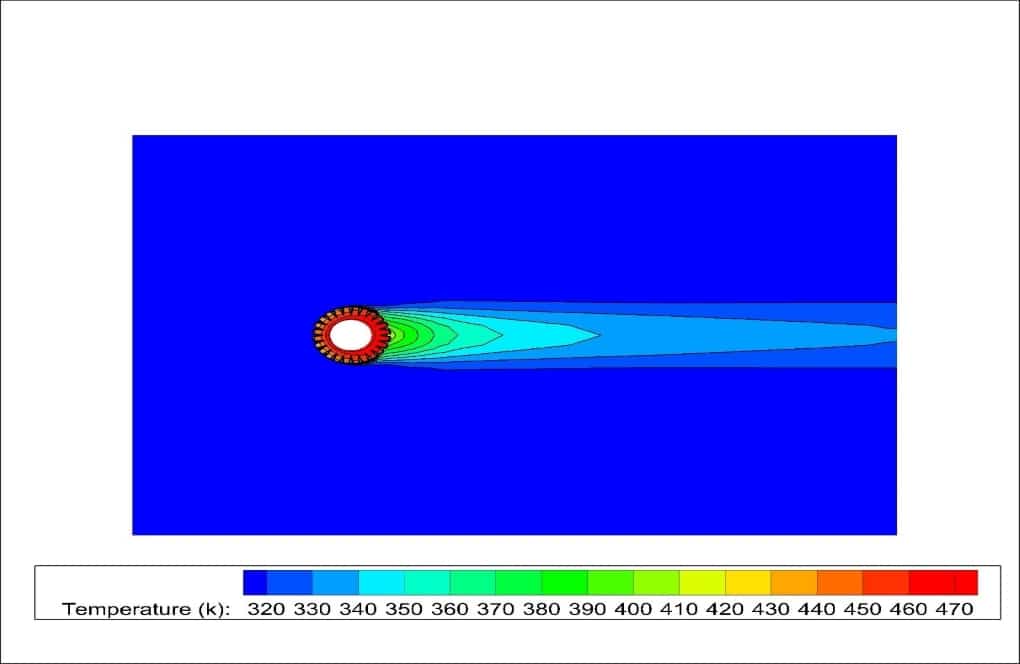

The open airflow with a temperature of 313.15 K and a velocity according to the defined Reynolds value moves towards the tube fins and performs the heat transfer process. The current model is designed in three dimensions using Design Modeler software.

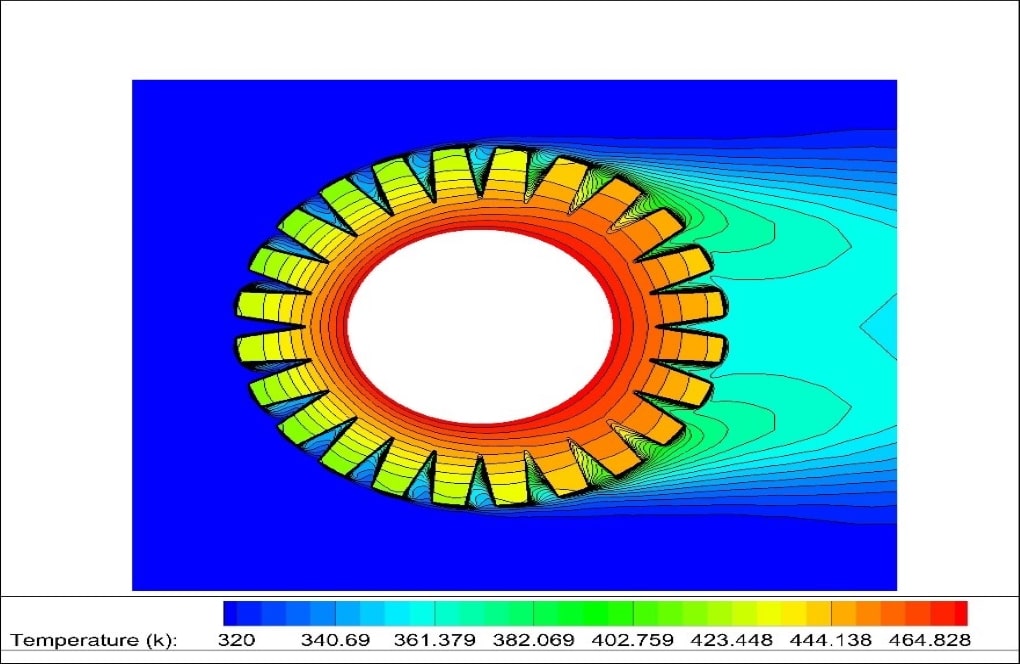

The model includes a shallow rectangular area as a special area for free airflow around the serrated finned tube. Also, a tube with fins located on its outer wall is defined inside this air flow space, the number of fins of which is 24, and they are drawn smoothly and without angles.

The meshing of the present model has been done using ANSYS Meshing software. The mesh type is structured, and the element number equals 356240.

Methodology

In this simulation, only part of it is modeled using the symmetric boundary condition. It is assumed that the pipe’s inner wall has a constant temperature boundary condition equal to 473.15 K.

Conclusion

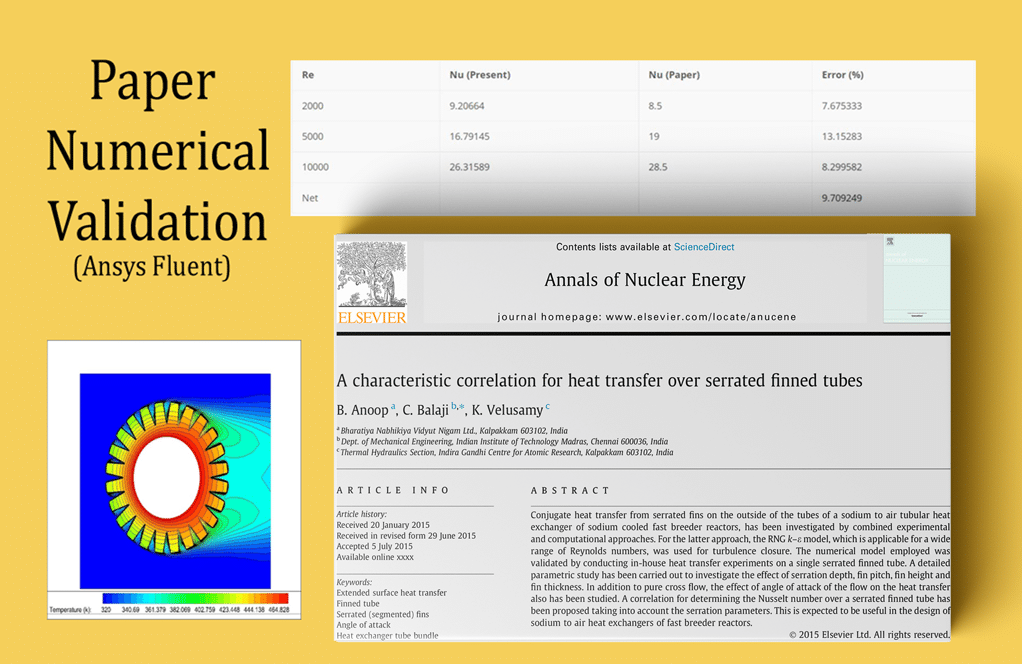

This work aims to investigate the heat transfer process and the cooling rate of the serrated finned tube in different Reynolds numbers, which are determined using the value of the Nusselt number.

At the end of the simulation process, the value of the Nusselt number on the tube wall was calculated and compared and validated with the values in the diagram in Figure 6 of the article.

This comparison of Nusselt number values has been performed in three different Reynolds numbers, including 2000, 5000, and 10000.

| Re | Nu (Present) | Nu (Paper) | Error (%) |

| 2000 | 9.20664 | 8.5 | 7.675333 |

| 5000 | 16.79145 | 19 | 13.15283 |

| 10000 | 26.31589 | 28.5 | 8.299582 |

| Net | 9.709249 |

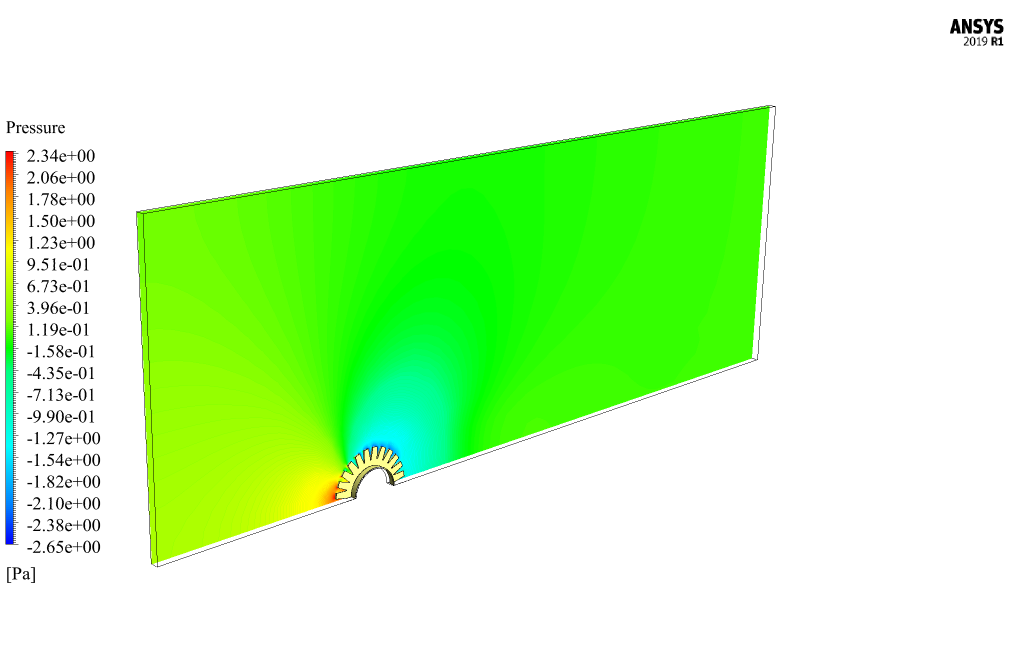

Also, after the completion of the solution process, we obtain two-dimensional contours related to pressure, velocity, and temperature, as well as two-dimensional velocity vectors.

Mr. Sheldon Pollich –

I’m impressed with how the simulation matches the research paper’s results! The error margin seems quite low. Can you tell us more about the accuracy of simulation in terms of predicting the heat transfer over serrated finned tubes?

MR CFD Support –

Thank you for your positive feedback! We’re glad you appreciated the accuracy of our simulation. ANSYS Fluent is an advanced tool for precise simulations, allowing us to predict the heat transfer with high accuracy. In this case, the comparison between these study and the reference paper shows good agreement with relatively low error percentages across all Reynolds numbers tested. The verification through numerical validation enhances the credibility of the simulation outcomes for practical applications.

Dannie Gottlieb MD –

I’m extremely impressed by the precision of this simulation for validating the paper’s data. The comparison of Nusselt number values across different Reynolds numbers demonstrates a commendable level of accuracy!

MR CFD Support –

Thank you for recognizing the effort put into validating the simulation results with the reference paper. We strive to provide accurate and reliable comparisons to ensure our simulations meet high standards of quality.

Haylee Torphy Jr. –

My simulation times seem longer than expected, especially when running at high Reynolds numbers like 10000. Is there an optimization method recommended within this study to enhance computation efficiency without compromising result accuracy?

MR CFD Support –

For enhancing computation efficiency in simulations at high Reynolds numbers while maintaining accuracy, it’s advisable to refine your mesh around areas with high gradients, utilize parallel processing if available, and potentially apply a higher convergence criterion cautiously if it doesn’t negatively affect the results. Make sure to fine-tune these approaches according to your hardware capabilities and specific simulation setup.

Orlo Conroy –

Great job on demonstrating the heat transfer validation on serrated finned tubes. The accuracy and thorough methodology tied with quantitative validation provide immense value for researchers and engineers alike!

MR CFD Support –

We’re glad to hear that our product has provided valuable insight and proved useful in your research. Thank you for the positive feedback regarding the validation process and methodology. We continually strive to offer high-quality simulations that help professionals in their work. Your recognition is sincerely appreciated!

Cora Crooks –

The tutorial was brilliant, bringing theory and practice together excellently! I could adjust the serrated fin geometry with ease for my simulations. Thank you for a clear comparison with the research paper values.

MR CFD Support –

We appreciate your kind words and are delighted to hear that the tutorial was helpful to you! It’s great to know that you were able to adjust the geometry for your own simulations and found the comparison useful. Should you need any further guidance, feel free to reach out. Thank you for choosing our product, and we look forward to assisting you in the future!

Raphaelle Abbott III –

I’ve always wondered, how accurate is an ANSYS simulation compared to actual experimental results? This validation with the paper seems to indicate close results, but more generally, can one trust the simulation data for practical applications?

MR CFD Support –

ANSYS simulations, when performed accurately with the right boundary conditions and physical models, can yield results that are very close to experimental data. In computational fluid dynamics, numerical validation against experimental results or established papers is essential for ensuring accuracy. The trust in simulation data for practical applications depends heavily on the initial setup and consideration of all relevant physics in the model. The closer the simulation parameters follow real-world conditions, the more dependable the results will be for practical use.