Helical Wind Turbine, ANSYS Fluent CFD Simulation Training

$140.00 $70.00 Student Discount

- The problem numerically simulates the Helical Wind Turbine using ANSYS Fluent software.

- We design the 3-D model with the Design Modeler software.

- We mesh the model with ANSYS Meshing software, and the element number equals 2129987.

- We perform this simulation as unsteady (Transient).

- We use the Mesh Motion model to define rotational motion.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Description

This simulation is about a helical wind turbine via ANSYS Fluent software.

Vertical Axis Wind Turbine (VAWT) is becoming ever more important in wind power generation thanks to their adaptability for domestic installations. However, it is known that VAWTs have lower efficiency, above all, if compared to HAWTs.

To improve VAWTs performance, industries and researchers are trying to optimize the design of the rotors. This project will simulate an airflow field close to a helical wind turbine.

The inlet is considered to wind at 1 m/s, and the turbine zone rotates with 120 RPM. This paper investigates the behavior of airflow and pressure distribution and studies drag force.

The geometry of the present model is drawn by Design Modeler software. This geometry included a rotary zone for the turbine walls and a stationary zone for the rest of the domain.

The model is then meshed by ANSYS Meshing software. The model mesh is unstructured, and 2129987 cells have been created.

Helical Wind Turbine Methodology

In this simulation, the rotational motion of the turbine blades must be defined. But instead of applying rotational motion to the blades, rotational motion is applied to the field around the blades. So, it is necessary to separate a distinct zone as the moving zone from the total computing zone.

Since this turbine is one of the vertical axis turbines, the behavior of the fluid is dependent on time; because the position of the turbine blades varies over time. Then the mesh motion is used in cell zone conditions. In this method, the rotation axis and rotation speed must be determined.

Helical Wind Turbine Conclusion

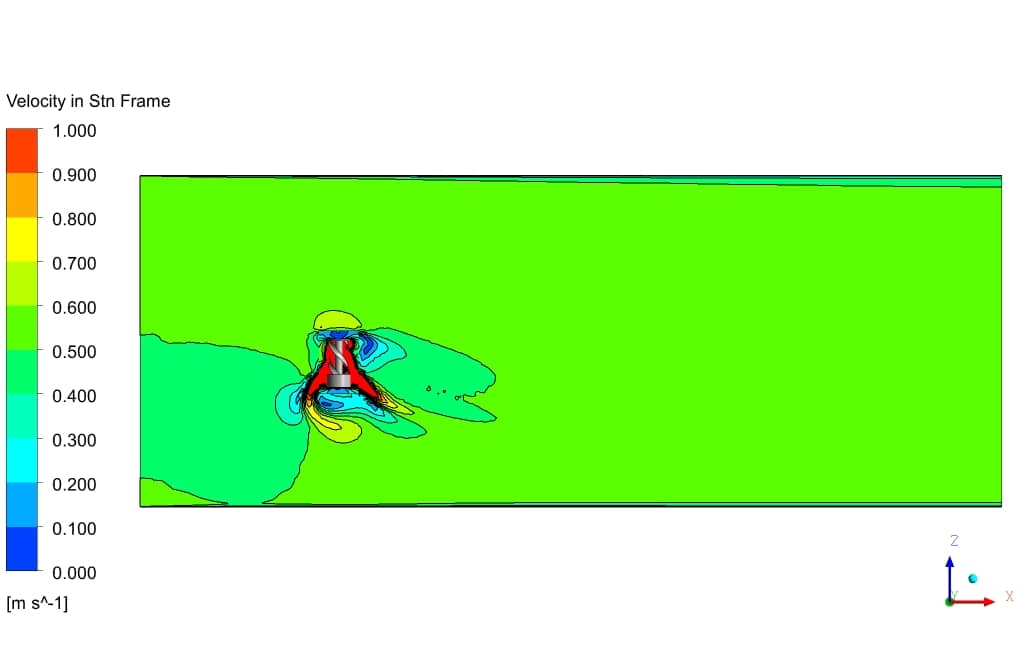

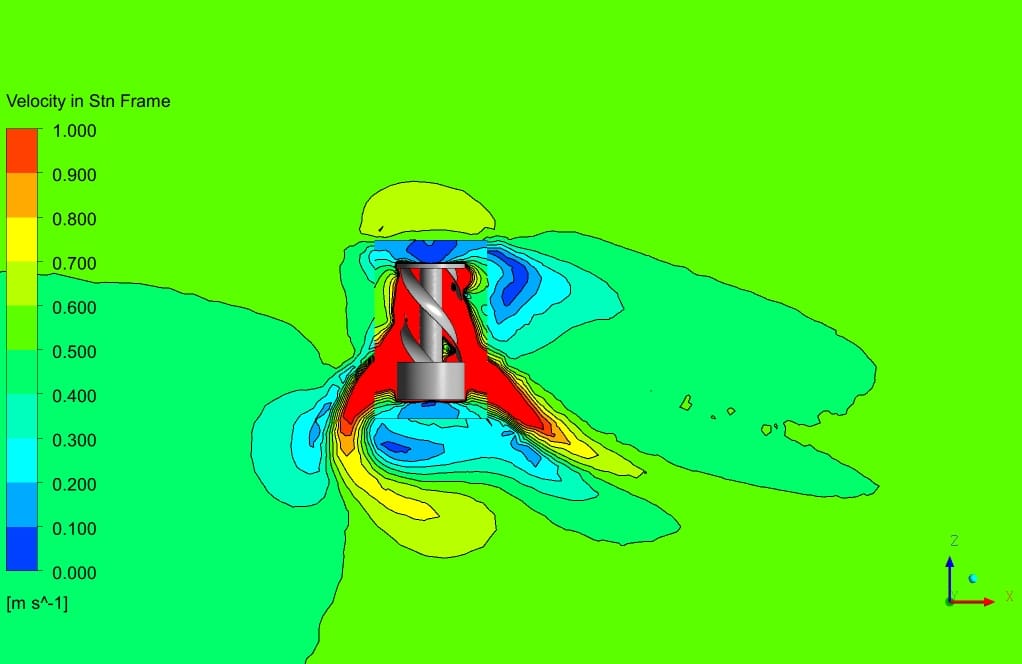

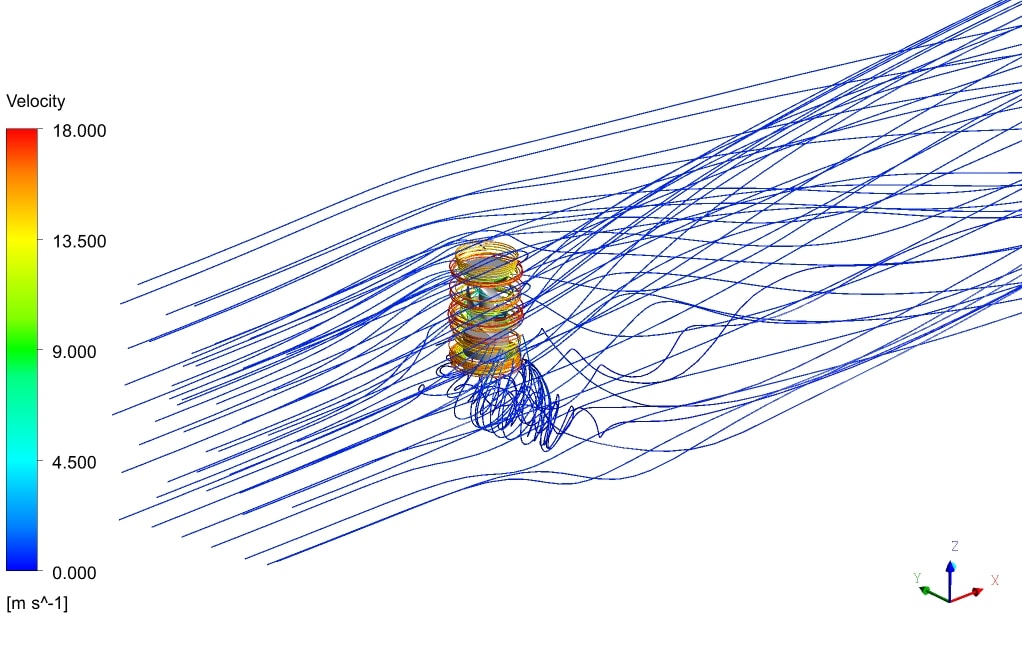

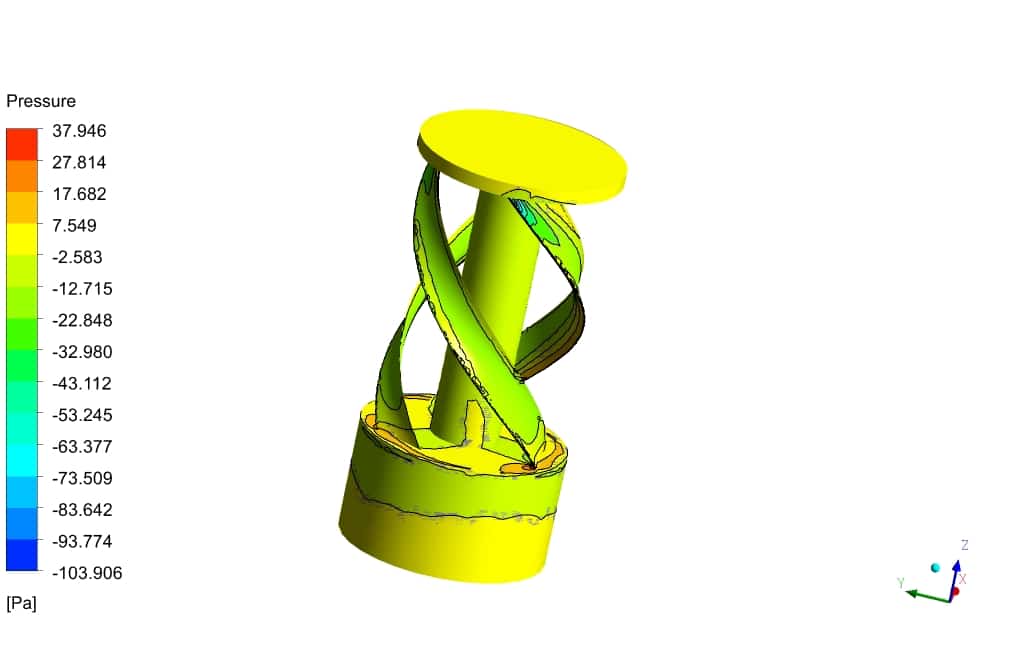

After simulation, the contours of velocity and pressure are obtained. Also, velocity vectors around the turbine blades are obtained. The results show that the wind flow around the turbine blades has a rotational movement. The velocity field adjacent to the wall of the turbine has the highest gradient.

Also, The leading edge of the turbine wall suffers from the highest-pressure gradient, which is logical since the velocity has just met zero. Additionally, the streamlines illustrate the quality of the flow streams resolved in the wake section, which is the core challenge of aerodynamic simulation.

Finally, the drag force is 2.3 (N), which is accurate for a turbine with the noted specifications.

Caitlyn Armstrong –

I appreciate the dedication to accuracy and validation in this simulation.

Ms. Leora Schroeder –

Does this simulation account for the effects of wind shear and turbulence intensity on the performance of the wind turbine?

MR CFD Support –

Yes, this simulation takes into account the effects of wind shear and turbulence intensity on the performance of the wind turbine. These effects are included in the turbulence model and are crucial for accurately predicting the power output of the turbine.

Aracely Kirlin –

I noticed that this simulation uses the k-ε turbulence model. Can you explain why this model is chosen over others for this specific application?

MR CFD Support –

The k-ε turbulence model is a popular choice for wind turbine simulations due to its robustness and efficiency. It’s particularly well-suited for predicting the flow over bluff bodies, such as the blades of a Darrieus wind turbine. However, it’s worth noting that the choice of turbulence model can depend on the specific details of the simulation.

Dr. Amiya Nienow IV –

Can this simulation be used to optimize the design of the Darrieus wind turbine?

MR CFD Support –

Absolutely! The results of this simulation can provide valuable insights into the performance of the Darrieus wind turbine under different operating conditions. This information can be used to identify areas of the design that could be improved to increase efficiency and power output.