Heller Dry Cooling Tower CFD Simulation

$100.00 $50.00 Student Discount

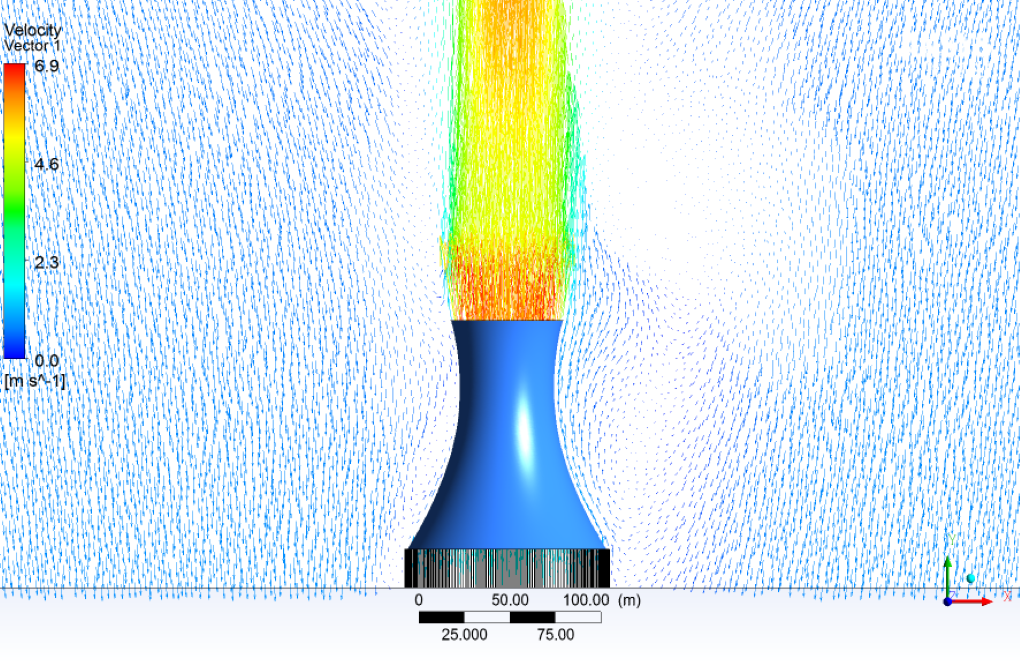

In this project, the airflow inside a dry cooling tower (HELLER) is simulated and analyzed by ANSYS Fluent.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Heller Dry Cooling Tower CFD Simulation, ANSYS Fluent Training

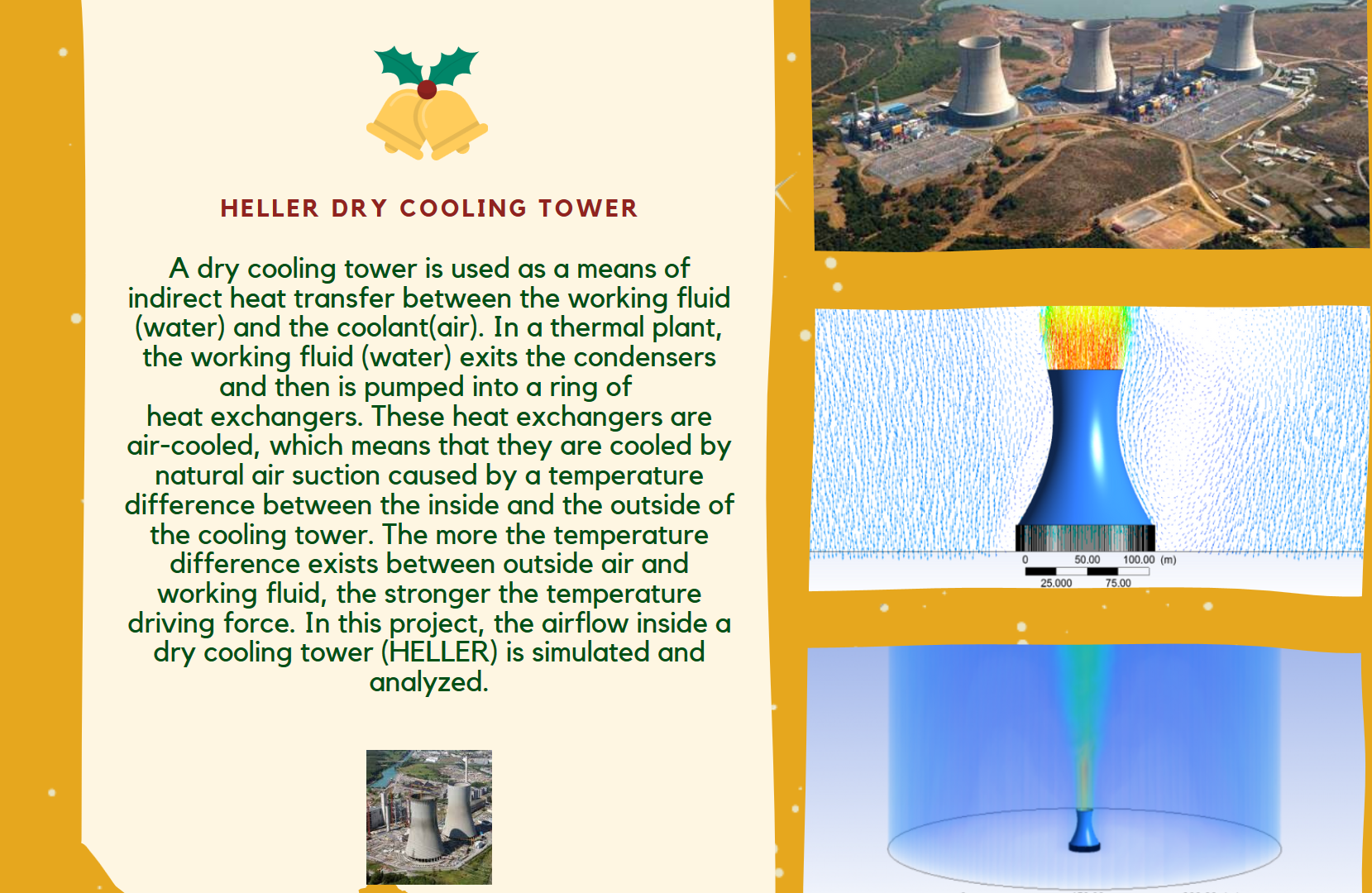

A dry cooling tower is used as a means of indirect heat transfer between the working fluid (water) and the coolant(air). In a thermal plant, the working fluid (water) exits the condensers and then is pumped into a ring of heat exchangers. These heat exchangers are air-cooled, which means that they are cooled by natural air suction caused by a temperature difference between the inside and the outside of the cooling tower.

The more the temperature difference exists between outside air and working fluid, the stronger the temperature driving force. In the summer, the temperature difference between the working fluid and the ambient air decreases, which will result in a reduction in temperature driving force, making the cooling tower’s efficiency to decrease.

Therefore, the thermal unit has to lower its power production, and the rate of water consumption will increase drastically to cool the heat exchangers. In this project, the airflow inside a dry cooling tower (HELLER) is simulated and analyzed by ANSYS Fluent.

Heller Geometry & Mesh

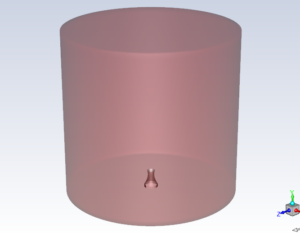

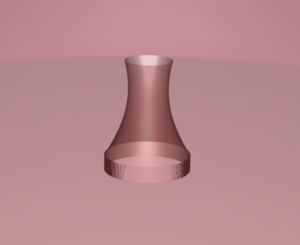

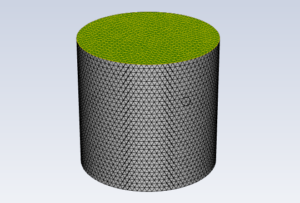

The geometry of this project includes a cooling tower, heat exchanger, flow domain, and an air inlet. The geometry is designed and meshed inside GAMBIT. The mesh type used for this geometry is unstructured and the total element number is 1343988 cells.

CFD simulation

The assumptions considered in this project are:

- Simulation is done using a pressure-based solver.

- The present simulation and its results are considered to be steady and do not change as a function time.

- The effect of gravity has been taken into account and is equal to -9.81m/s2 in the Y direction.

The applied settings are recapitulated in the following table.

| (Heller) | Models | |

| Viscous model | k-epsilon | |

| k-epsilon model | standard | |

| near-wall treatment | standard wall function | |

| Energy | on | |

| (Heller) | Boundary conditions | |

| Inlet | Pressure inlet | |

| Gauge total pressure | 0 Pa | |

| Direction specification method | Normal to boundary | |

| Outlet | Pressure outlet | |

| Gauge pressure | 0 Pa | |

| Backflow direction specification method | Normal to boundary | |

| temperature | 303 K | |

| Walls | ||

| Heller, Heller shadow | wall motion | stationary wall |

| Wall, wall shadow | heat flux | 0 W/m-2 |

| wall motion | stationary wall | |

| Radiator | Temperature | 318 K |

| Heat generation rate | 14861.52 W/m3 | |

| wall motion | stationary wall | |

| Radiator shadow | Temperature | 313 K |

| Heat generation rate | 14861.52 W/m3 | |

| (Heller) | Solution Methods | |

| Pressure-velocity coupling | SIMPLE | |

| Spatial discretization | pressure | standard |

| density | first-order upwind | |

| momentum | first-order upwind | |

| energy | first-order upwind | |

| turbulent kinetic energy | first-order upwind | |

| turbulent dissipation rate | first-order upwind | |

| (Heller) | Initialization | |

| Initialization method | Standard | |

| gauge pressure | 0 Pa | |

| velocity (x,y,z) | 0 m/s-1 | |

| temperature | 303.0806 K | |

| Turbulent kinetic energy | 1 m2/s2 | |

| Turbulent dissipation rate | 1 m2/s3 |

Heller Results

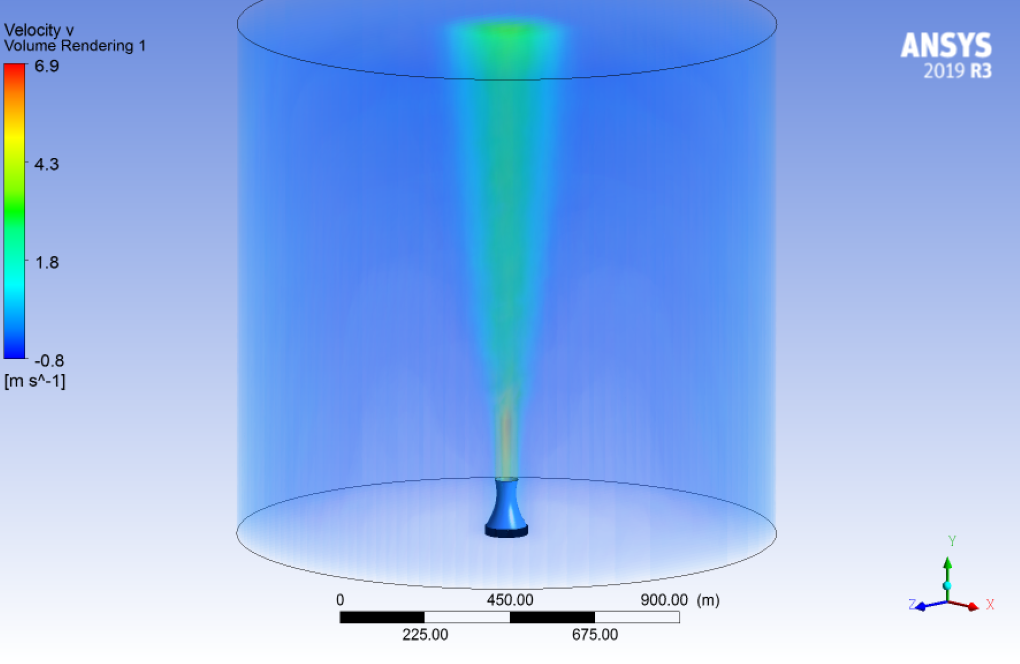

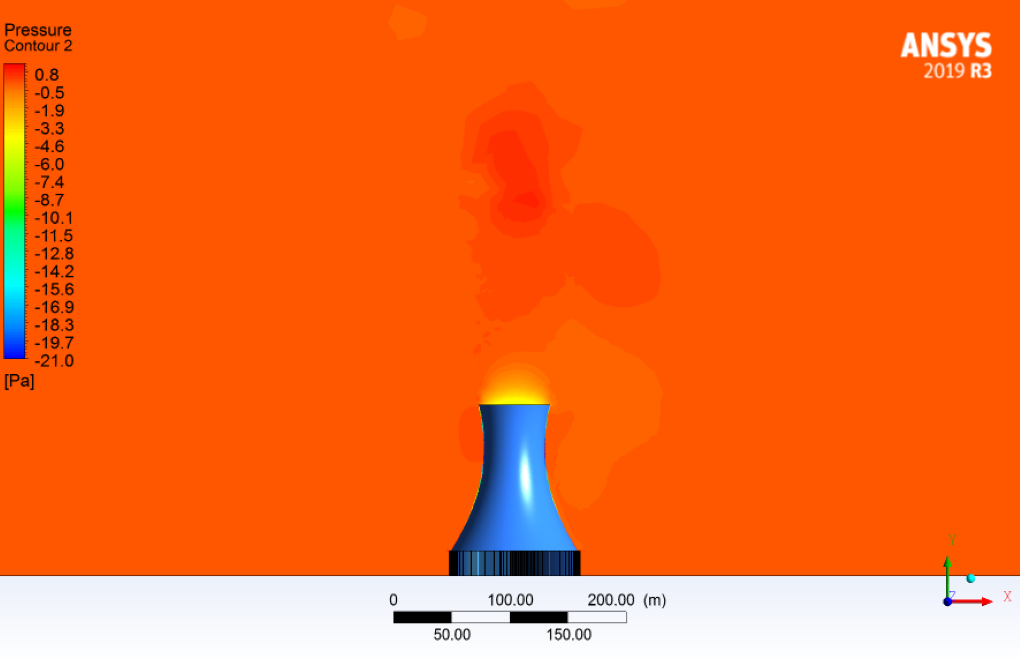

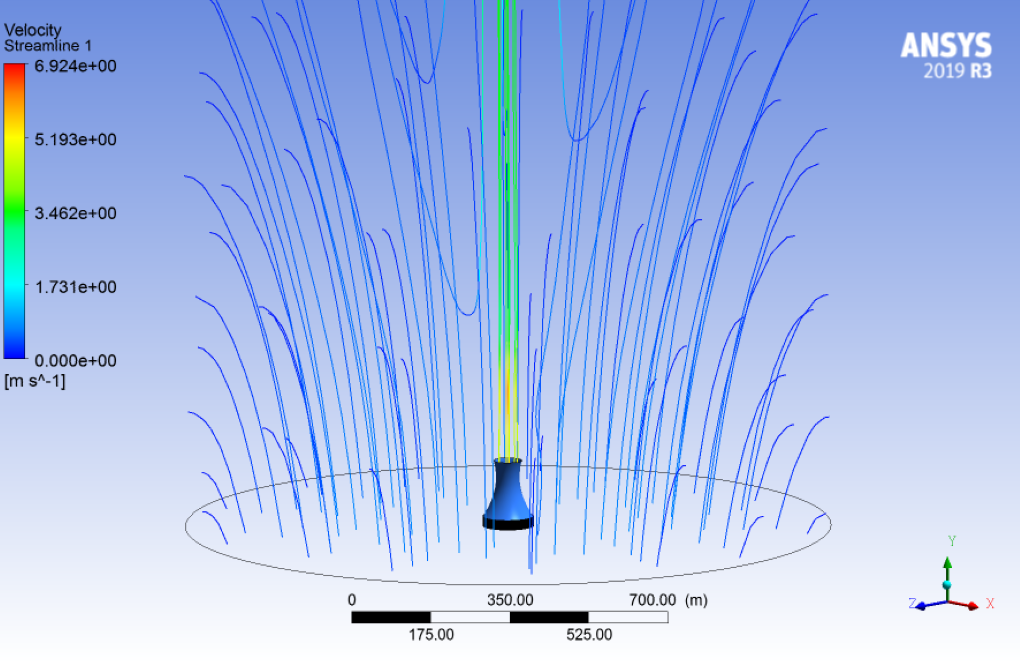

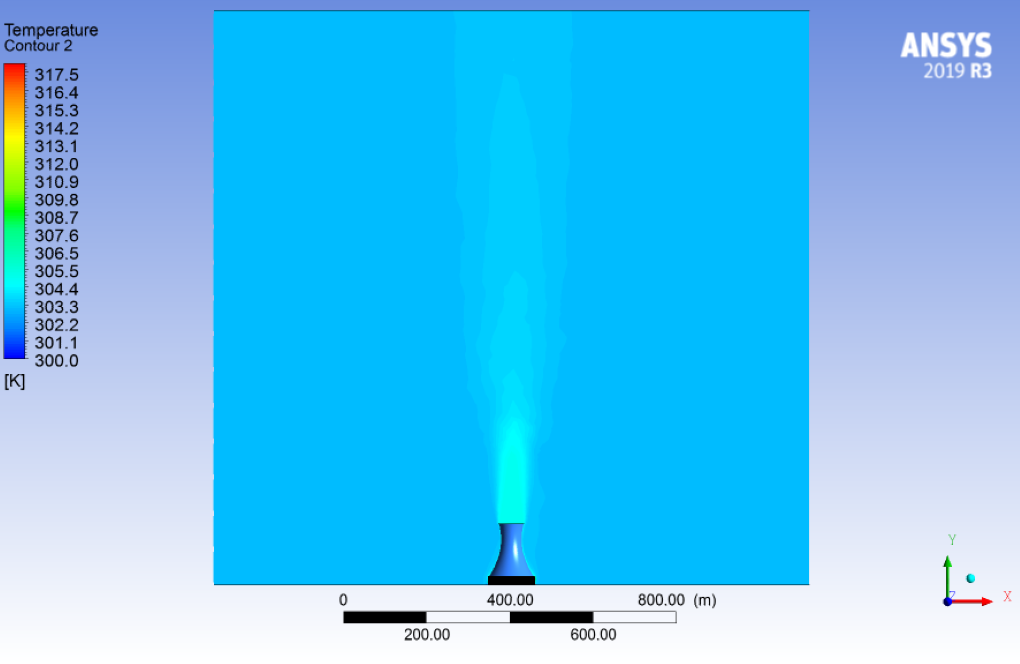

The contours of velocity, pressure, temperature, and flow streamlines are obtained at the end of the solution process.

Summer Kilback –

Can the simulation model the effects of different fan speeds on the cooling tower performance?

MR CFD Support –

Yes, the simulation can be adjusted to simulate the effects of different fan speeds, which can significantly impact the cooling tower’s performance.

Brando Pagac –

Can this simulation model consider the effects of ambient wind on the cooling tower performance?

MR CFD Support –

Absolutely, the simulation can be adjusted to account for the effects of ambient wind, which can influence the performance of the cooling tower.

Jaiden Wintheiser –

Can this model simulate the effects of different weather conditions on the cooling tower performance?

MR CFD Support –

Sure, the simulation can be adjusted to account for various weather conditions, which can significantly impact the performance of the cooling tower

Aisha Champlin Jr. –

I’m really impressed with the detail of the CFD simulation for the Heller Dry Cooling Tower! How does the k-epsilon model contribute to the accuracy of the simulation?

MR CFD Support –

Thank you for your compliment! The k-epsilon model is a commonly used turbulence model that calculates the turbulent viscosity by solving two separate transport equations for kinetic energy (k) and its dissipation rate (epsilon). In the context of the Heller Dry Cooling Tower, this model allows us to account for the effects of turbulence in the airflow through the cooling tower and the heat exchangers accurately. It’s essential for predicting the thermal efficiency of the cooling system and ensuring that the airflow patterns are appropriately simulated.

Brigitte West –

Does this model take into account the effect of the sun’s heat on the tower?

MR CFD Support –

Yes, the simulation can factor in the effect of solar heating on the tower, which can impact the cooling efficiency.

Loren Cole –

The training material was incredibly comprehensive and user-friendly. The easy-to-follow steps and clear explanations helped me grasp the nuances of simulating a Heller type dry cooling tower. I appreciated the detailed walkthrough of the process and boundary conditions setup, which contributed immensely to my understanding of temperature gradients and how they affect cooling tower efficiency.

MR CFD Support –

Thank you for the positive feedback! We’re delighted to hear our training materials and the detailed explanations on dry cooling tower simulations were helpful to you. It’s our goal to provide a user-friendly experience that empowers our customers to deepen their understanding of CFD. If you have any other questions or need further assistance, feel free to reach out.

Alize Pagac –

The Heller Dry Cooling Tower’s simulations sound quite complex—could you elaborate on how the air’s temperature change impacts overall cooling effectiveness?

MR CFD Support –

The provided simulation training is set up to examine the performance of a Heller Dry Cooling Tower. As ambient temperatures increase, the temperature difference between the working fluid and the air decreases. This smaller temperature gradient results in diminished cooling effectiveness because the heat transfer is driven by the difference in temperature. Consequently, the system needs to increase water consumption or reduce power production to maintain its cooling performance.

Prof. Devonte Kunde –

I am entirely fascinated by how you manage to detail complicated systems and make sense of them! The Heller Dry Cooling Tower simulation sounds incredibly thorough.

MR CFD Support –

Thank you for your positive feedback. We strive to provide detailed and comprehensive simulations that are both informative and practical for real-world applications. It’s great to hear that you appreciate the effort to clarify complex engineering concepts.

Kelley Tillman PhD –

I just completed the Heller Dry Cooling Tower CFD Simulation training using ANSYS Fluent, and I am impressed with the level of detail it covers. The setup instructions were clear, which made it easy to understand the complex interactions between the airflow and the heat exchangers. The outcome of the project is indeed fascinating – observing the temperature and velocity distributions was truly insightful.

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that you found the training comprehensive and beneficial. Understanding the intricacies of a dry cooling system is essential for realistic simulation, and it’s great to know our materials aided in your learning journey. Should you have any more insights or require further assistance, don’t hesitate to reach out to us!

Prof. Michale Johnston –

Can i ask if if the simulation is capable of simulating the heat transfer process between the tower’s air and water?

MR CFD Support –

the simulation is proficient in accurately representing the heat transfer dynamics between the air and water within the tower.

Jaren Wintheiser –

I am truly impressed by the level of detail in the Heller Dry Cooling Tower simulation project using ANSYS Fluent. The careful consideration of boundary conditions and the incorporation of gravity speak to the thoroughness of the simulation process. The use of the k-epsilon viscosity model and SIMPLE algorithm for pressure-velocity coupling shows an adept choice for computational fluid dynamics analysis. Excellent job at providing an insight into the effects of temperature differences on cooling tower efficiency. Fantastic work!

MR CFD Support –

Thank you for your positive feedback! We are delighted to hear that you acknowledge and appreciate the complexity and attention to detail in our Heller Dry Cooling Tower CFD Simulation project. It is gratifying to know that the choices of models and algorithms met your expectations and provided meaningful insights. If you need further information or have any more questions, please do not hesitate to ask. We look forward to assisting you in your future learning endeavors!