Hourglass CFD Simulation Using DDPM and DEM

$220.00 $110.00 Student Discount

- The problem numerically simulates the Hourglass using ANSYS Fluent software.

- We design the 3-D model by the Design Modeler software.

- We Mesh the model by ANSYS Meshing software.

- The mesh type is Structured, and the element number equals 244675.

- We perform this simulation as unsteady (Transient).

- We use the Discrete Concentrated Phase Method (DDPM).

To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

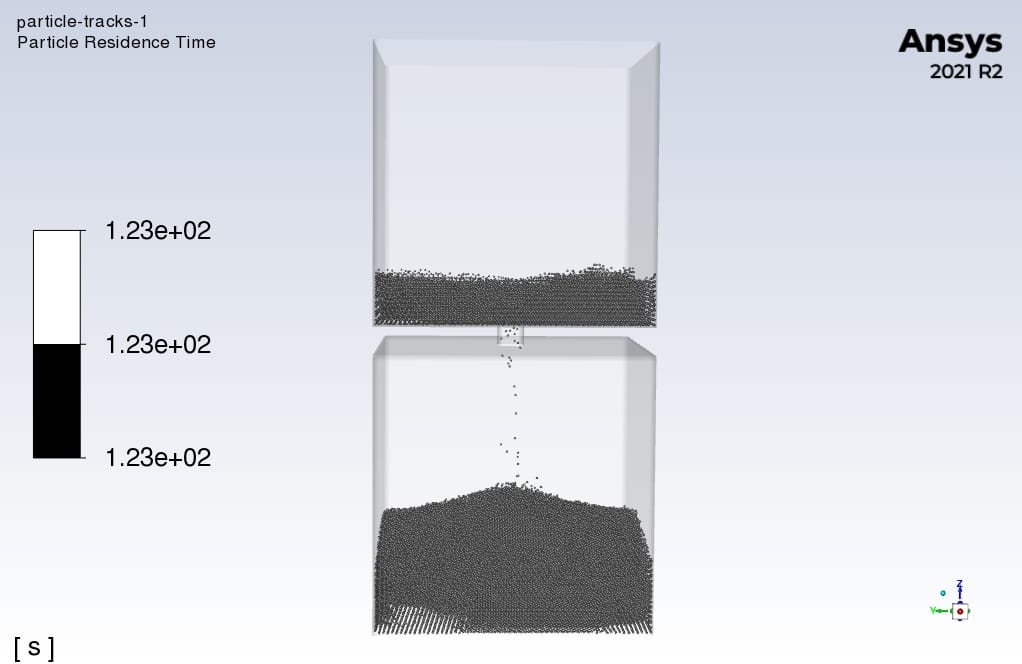

Hourglass CFD Simulation Using DDPM and DEM, ANSYS Fluent Training

In this project, an Hourglass with the DPM model was simulated, and the results were investigated using ANSYS Fluent software. We perform this CFD project and investigate it by CFD analysis. The present model is designed in 3-D using SpaceClaim.

The meshing of this present model has been generated by ANSYS Meshing software. The mesh type is Structured, and the total cell number is 244675. Also, due to the nature of the present problem, the transient solver has been enabled.

Methodology

In this research, hourglass simulation was investigated using the DPM model. The particle path inside the hourglass was also observed using Ansys Fluent software. While the DPM strategy for CFD solutions is a great way to compute particle flow studies that reduce computational costs, this approach fails to provide reliable answers for simulating dense particles with concentrations greater than 10% by volume.

DDPM (Discrete Concentrated Phase Method) is used in CFD projects to solve this problem. The discrete element method, or DEM, is a numerical method for calculating the interaction of large numbers of small particles.

Despite the very close relationship between DEM and the “Molecular Dynamics” simulation method, features such as degree of rotational freedom, particle contact, and complex geometry generally distinguish this approach from other options.

This method is based on an explicit numerical procedure examining the interaction between particles through contact and particle motion. The ability of the DEM model allows the user to consider the motion of particles as the mass of a moving point, which includes the shape and volume of the particles.

In addition, an injection-type file was used to insert 92,000 particles into the hourglass in zero seconds. Moreover, the laminar model is used to solve the fluid flow equations.

Conclusion

After the simulation, the particle tracking values in the hourglass are extracted, and the animation is attached.

Yvette Armstrong –

I’m interested in the Discrete Element Method (DEM) used in this package. Could you provide more information?

MR CFD Support –

Sure! The DEM used in our simulation is a numerical method typically used to compute the motion and effect of a large number of small particles. If you have specific requirements or scenarios you’d like to explore, we can customize the simulation accordingly.

Gardner Lowe –

How does this package handle the simulation of granular flow?

MR CFD Support –

This package includes exercises that cover granular flow simulation. It provides insights into how different factors, like particle size and shape, can impact the flow behavior. We are also open to modifying the simulations to cater to your particular requirements

Gavin Witting –

What principles are the particle-particle interaction simulations in this package based on?

MR CFD Support –

The particle-particle interaction simulations in this package are based on fluid dynamics principles and discrete element methods. They provide a detailed understanding of how particles interact with each other within a fluid medium. We can tailor these simulations to align with your specific needs.

Ms. Justine Weimann –

Can you elaborate on the methodology used for the hourglass shape simulation?

MR CFD Support –

Certainly! The hourglass shape simulation in this package is based on real-world scenarios. It helps you understand how different factors can affect the flow of granular materials through a narrow opening. We can also adapt the simulation to fit your unique needs.

Cole Hessel IV –

Could you explain more about how the DEM is able to represent the shape and volume of particles?

MR CFD Support –

In the DEM component of the simulation, each particle is represented as a separate entity with its own shape, volume, and rotational freedom. Particles are allowed to interact with one another and with surrounding boundaries via contacts and collisions, ensuring a detailed approximation of their actual behavior in an hourglass. The DEM can also track the position and rotation of each particle, which enables the calculation of velocities, collisions, and the exertion of forces. This results in a realistic representation of the granular flow in the hourglass simulation.

Dr. Declan Hackett –

Fantastic understanding of complex simulations in ANSYS Fluent using the DDPM and DEM models! Thank you for showcasing how to decipher interactions between dense particle flows. Clearly, significant talent and expertise went into crafting and executing this project.

MR CFD Support –

We appreciate your kind words and recognition of the effort that went into this sophisticated simulation. Thank you for taking the time to review and complement our Hourglass CFD Simulation using DDPM and DEM. Our team continually strives for excellence in CFD training and we’re delighted to know that our commitment to accurate and detailed analysis is resonating with our customers. Thank you for choosing our learning products!

Hannah Price –

The simulation looks incredibly detailed. Great work on demonstrating the interaction of particles using DDPM and DEM. Can you tell me if the hourglass simulation can also account for varying particle sizes and how it affects the simulation?

MR CFD Support –

Thank you for your positive feedback! Yes, the hourglass simulation using DDPM and DEM in ANSYS Fluent can account for varying particle sizes. The interaction between different-sized particles and their influence on the flow dynamics, collisions, and overall performance of the system are factors that can indeed be studied using the DEM model within ANSYS Fluent.

Armand Purdy –

Can you share more about the Discrete Phase Model (DPM) used in this simulation?

MR CFD Support –

Absolutely! The DPM used in our simulation allows for a detailed analysis of particulate flows. It’s a powerful tool for understanding the behavior of particles within a fluid medium and can be customized to match your specific requirements.

Jude Bednar –

How exactly does DEM differ from Molecular Dynamics when simulating particles in the hourglass scenario?

MR CFD Support –

DEM, or Discrete Element Method, and Molecular Dynamics both simulate particle interactions, but DEM is more suited for macroscopic particles and includes collision modeling, accounting for particle shape, size, and other bulk material properties. DEM typically handles particle contacts, collisions, and accounts for the rotational degrees of freedom. Conversely, Molecular Dynamics is more relevant for atomic or molecular simulations where quantum interactions and thermal vibrations are significant. In the hourglass scenario, DEM effectively captures how thousands of sand grains interact, accounting for factors like friction, restitution, and cohesiveness between the particles.

Zoila Hartmann –

The presentation is excellent, yet I’m curious—how does the software handle the collision and interaction between such a large number of particles in the DEM part of the simulation?

MR CFD Support –

ANSYS Fluent utilizes the DEM part to calculate the trajectory of each particle, taking into account the particle-particle and particle-wall collisions. Newton’s laws of motion are applied to each particle and collisions are modeled using a soft-sphere approach which accounts for overlaps, allowing for the forces and moments from collisions to be properly calculated while maintaining computational efficiency.

Jannie Wolff –

I’m curious about the degree of detail in regards to particle interaction captured by the DDPM and DEM methods. Can you provide some insights into how these methods account for particle collisions and friction within the hourglass CFD simulation?

MR CFD Support –

The DDPM and DEM methods in the hourglass CFD simulation account for particle interactions such as collisions and friction by explicitly calculating the forces and moments acting between particles. DEM, in particular, considers each particle’s position, velocity, and rotation, and applies contact models to resolve collisions, including coefficients for restitution, static and rolling friction. DDPM extends traditional DPM by allowing for dense particle loadings and interactions with continuous phases. Together, they provide a detailed description of particle behavior in environments like the hourglass simulation.

Ernesto Denesik –

I found the topic of using DDPM and DEM for the hourglass simulation fascinating! I am curious about how well it can predict the particle collisions and overall flow pattern in such complex geometries. Does the model accurately represent the intricate behavior of an hourglass compared to experimental data?

MR CFD Support –

The DDPM and DEM methods combined in this hourglass simulation are well-suited for capturing the complex behaviors of the granular flow, including particle collisions and interactions. By correctly setting up the particle properties, material interactions, and computational parameters, these methods can yield accurate predictions of the flow patterns. While validations against experimental data are crucial for verifying simulation accuracy, the provided description does not specify such comparisons. For robust accuracy assessment, it would indeed be essential to perform validations with experimental results.

Destiney Swift –

I absolutely loved the Hourglass CFD Simulation training. I was able to gain a solid understanding of DDPM and DEM and seeing particle tracking in action was truly insightful. It’s incredible how detailed the simulation is with all 92,000 particles in motion!

MR CFD Support –

Thank you for your positive feedback! We’re delighted to hear that you found the Hourglass CFD Simulation training course valuable and insightful. It’s our pleasure to provide quality educational materials that help our customers succeed in their learning endeavors.

Ms. Loyce Mraz –

This simulation sounds fascinating! Was there any specific challenge faced while ensuring that the particles behaved realistically within the hourglass simulation?

MR CFD Support –

Thank you for your interest! In these types of simulations, accurately predicting the particle behavior can indeed be challenging. One of the primary challenges is to ensure that the particles’ interactions, such as collisions and friction, are accurately modeled. Utilizing the DEM within the DDPM framework addresses these challenges by taking into account both the forces acting on the particles and the particles’ contacts and movement, providing more realistic simulation results for densely populated granular flows.

Ransom Bechtelar I –

The training exceeded my expectations! The graphical representation of particle paths clearly demonstrates the capabilities of DDPM and DEM within ANSYS Fluent.

MR CFD Support –

We’re so glad to hear that our training on Hourglass CFD Simulation using DDPM and DEM with ANSYS Fluent met and exceeded your expectations. Your positive feedback means a lot to us, and we’re thrilled that the graphical representations were effective in demonstrating the concepts. Thank you for taking the time to share your experience!

Prof. Valentin Nienow V –

After completing the hourglass simulation, were there any insights on optimal particle sizes or types that ensure the most accurate simulation results?

MR CFD Support –

Thank you for your interest in the Hourglass CFD simulation using DDPM and DEM. Our simulation aim was to replicate the hourglass dynamics accurately, and throughout the project, we observed how different sizes and types of particles behaved under gravity and interacting with each other. Generally, the particle types and sizes we choose to model need to represent the physical properties of the granular material in a real hourglass to ensure the reliability of the results.

Ivy Sporer –

What is the main difference between DDPM and DEM in terms of simulating particle interactions, and how does it affect the outcomes of this hourglass simulation?

MR CFD Support –

The main difference between DDPM (Discrete Dense Phase Model) and DEM (Discrete Element Method) is how they approach particle interactions. DDPM applies a volume averaging technique suitable for dense particulate flows without explicitly calculating forces between particles, thus, simplifying computations. DEM, on the other hand, explicitly calculates forces between individual particles, making it more accurate for simulations where particle-to-particle interaction and their effects on motion are important. In the case of the hourglass simulation, the combination of both methods allowed for efficiently simulating dense particle movements within the hourglass while accounting for the particle interactions, resulting in a more precise model of how particles flow through a restrictive geometry like an hourglass.