Hydraulic Jump of Water in Rectangular Channel, ANSYS Fluent Training

$100.00 $50.00 Student Discount

In this project, hydraulic jump of water flow in a rectangular channel is analyzed.

Click on Add To Cart and obtain the Geometry file, Mesh file, and a Comprehensive ANSYS Fluent Training Video.To Order Your Project or benefit from a CFD consultation, contact our experts via email (info@mr-cfd.com), online support tab, or WhatsApp at +44 7443 197273.

There are some Free Products to check our service quality.

If you want the training video in another language instead of English, ask it via info@mr-cfd.com after you buy the product.

Description

Hydraulic Jump Problem description

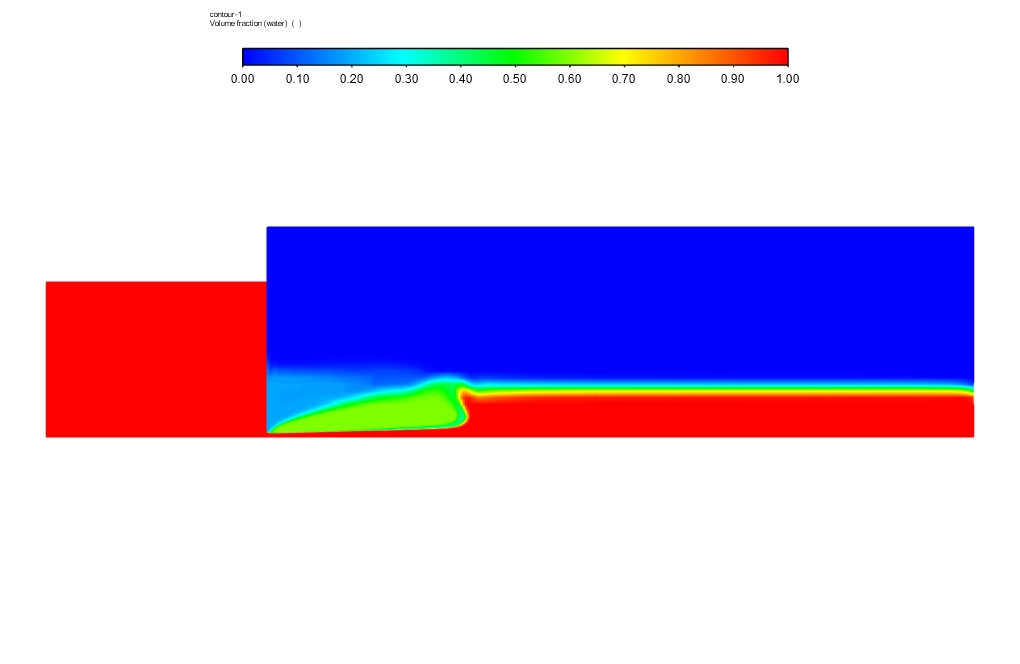

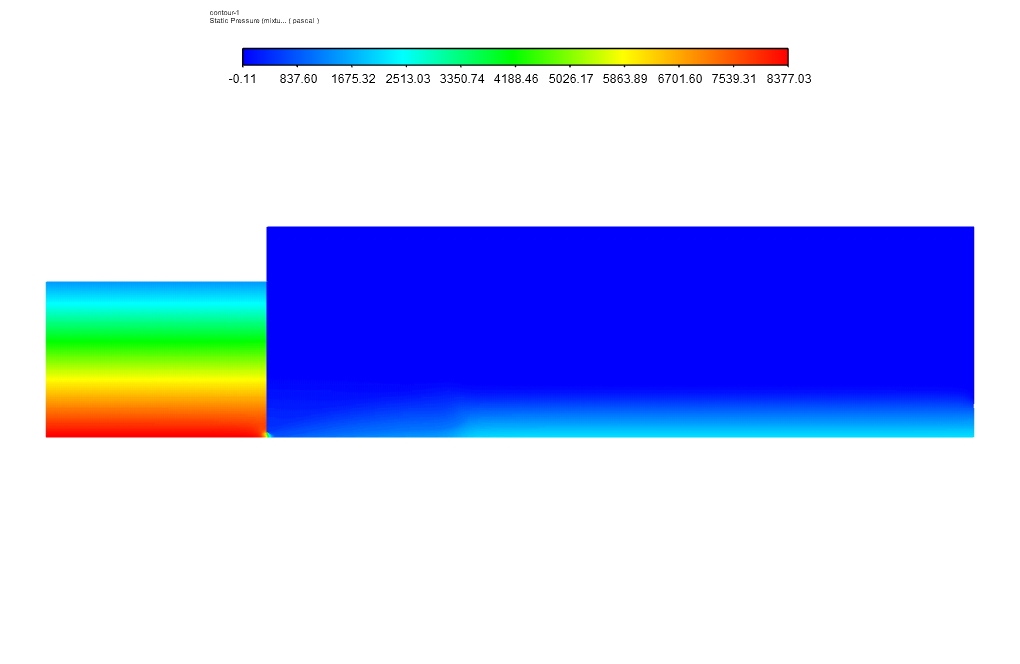

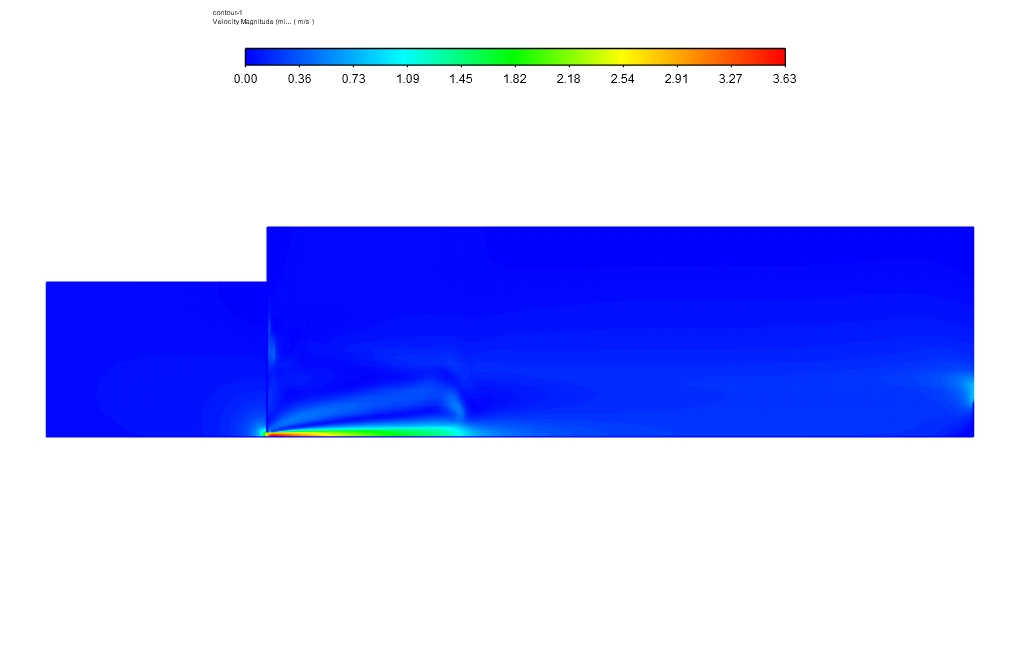

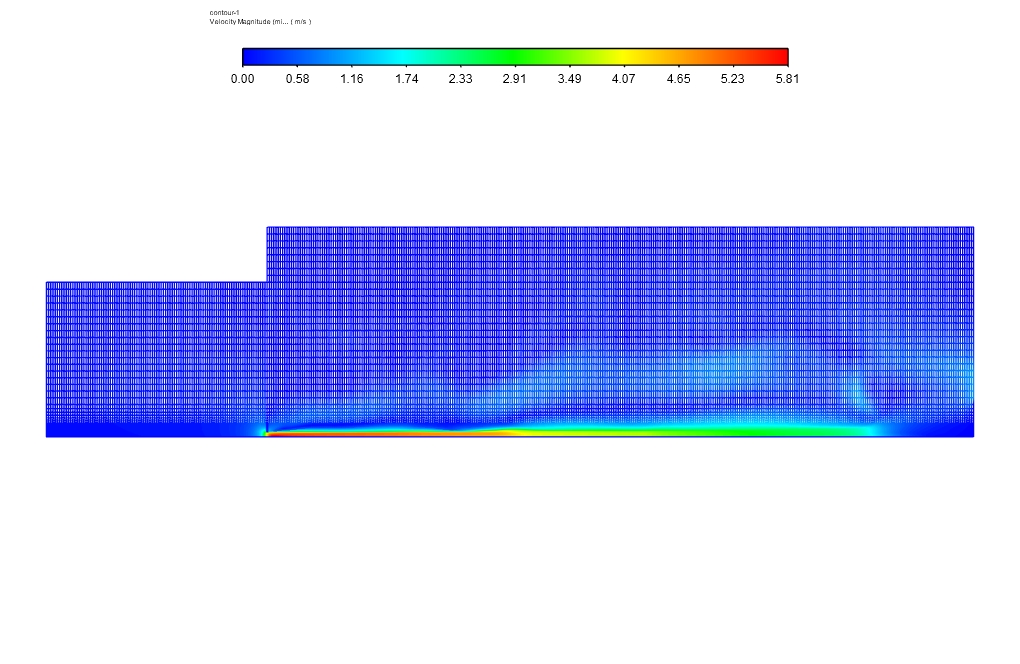

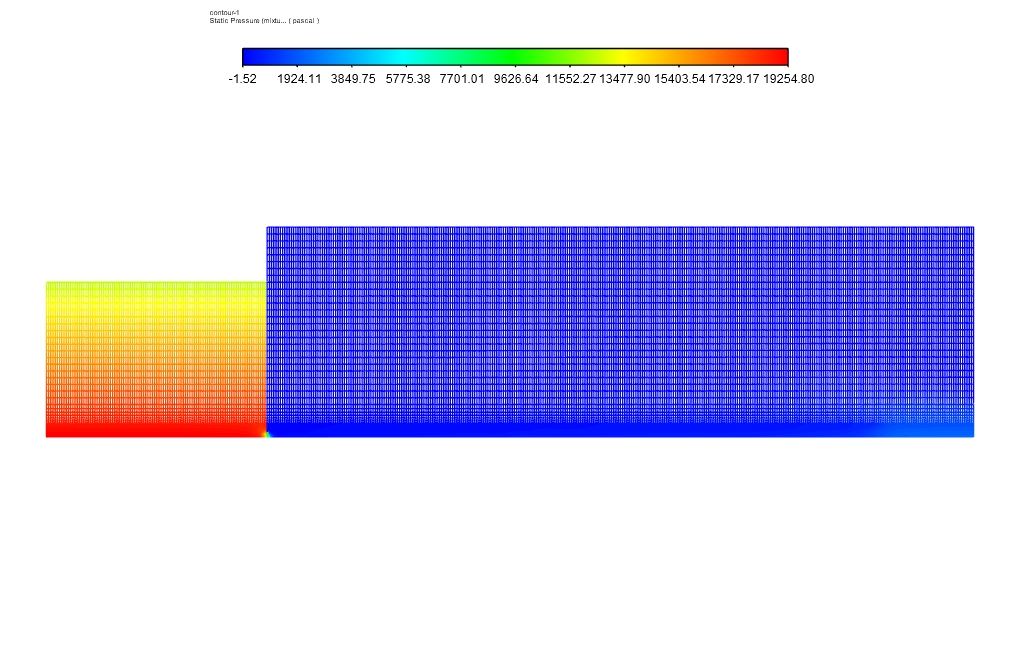

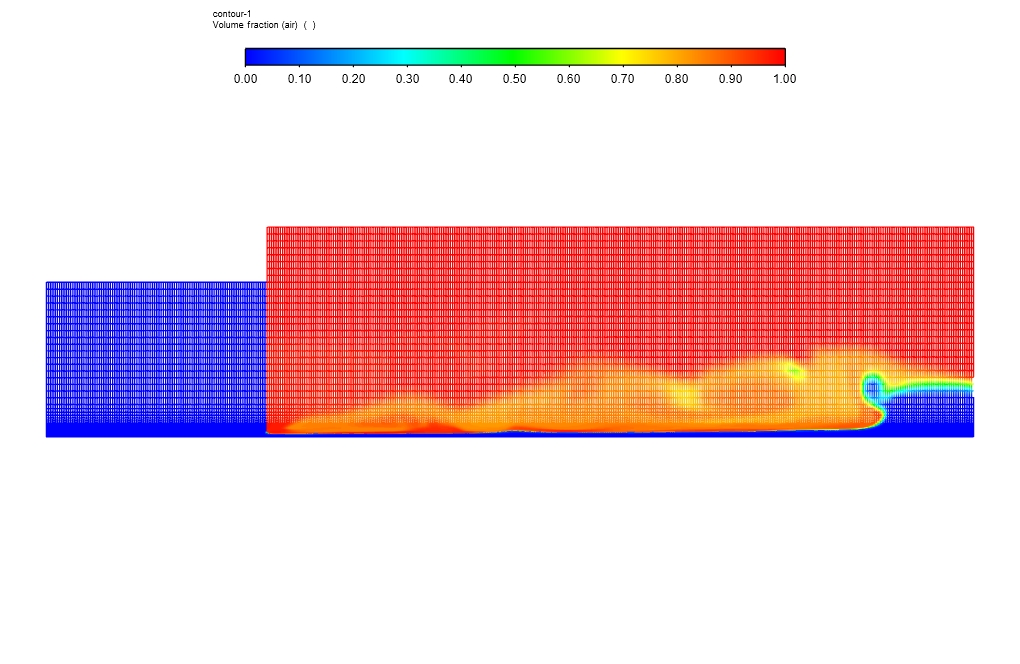

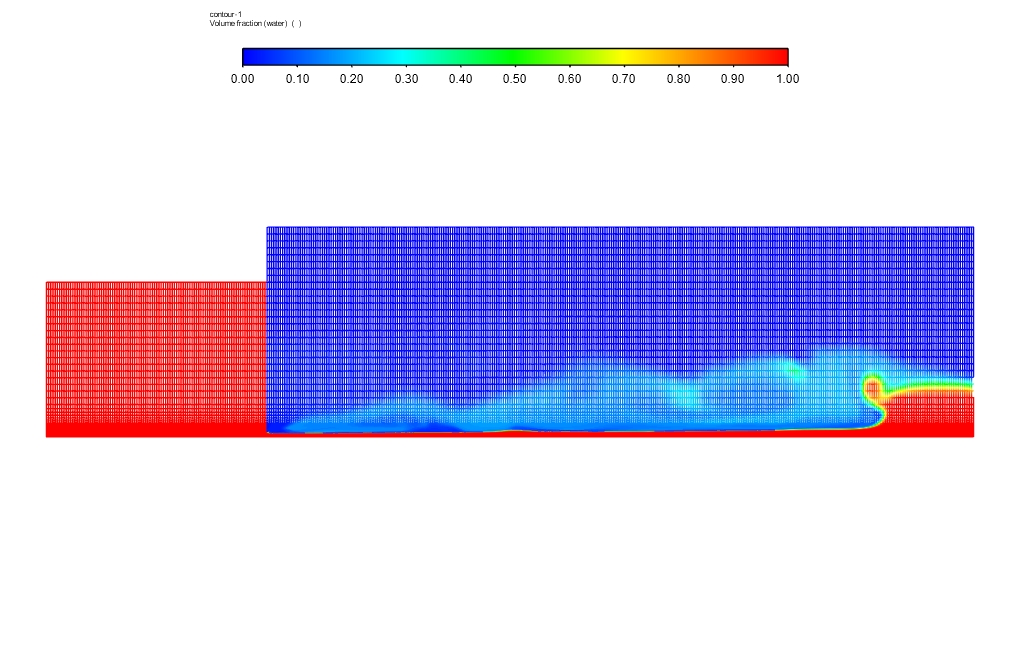

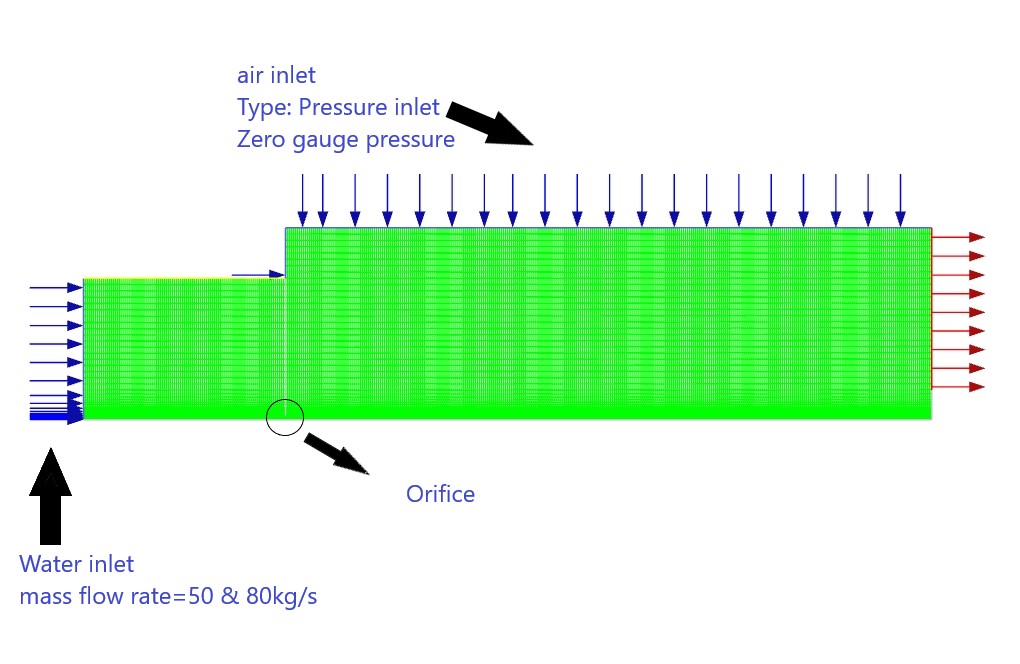

In this project, hydraulic jump of water flow is analyzed by ANSYS Fluent software. The VOF approach is utilized in order to efficiently simulate the water flow inside ambient air. Hydraulic jump is of great importance in agricultural applications and open channel flows where water flow, after certain distance which can be solved for using analytical equation, undergoes significant decrease in velocity and increase in flow height. In the present work, water flow with two different mass flow inlets is analyzed, 50 and 65 kg/s. hydraulic jump occurs in 0.9 and 2.8 m downstream the flow for cases with water mass flow rate equal to 50 and 65 kg/s.

Geometry and mesh

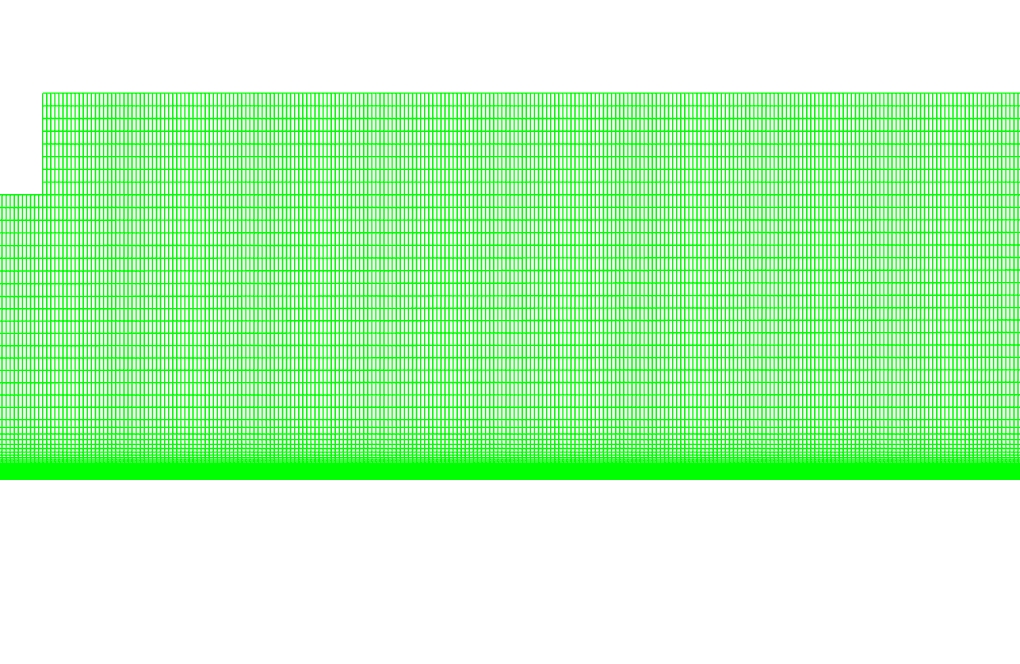

Geometry of fluid domain is designed in Design Modeler and computational grid is generated using ANSYS Meshing. Mesh type is structured and element number is 231,646.

Solver configuration

Critical assumptions:

- Solver type is assumed Pressure Based.

- Time formulation is assumed Steady.

- Gravity effects are considered as -9.81 m/s2 in Y direction.

The following table a summary of the defining steps of the problem and its solution.

| Models | ||

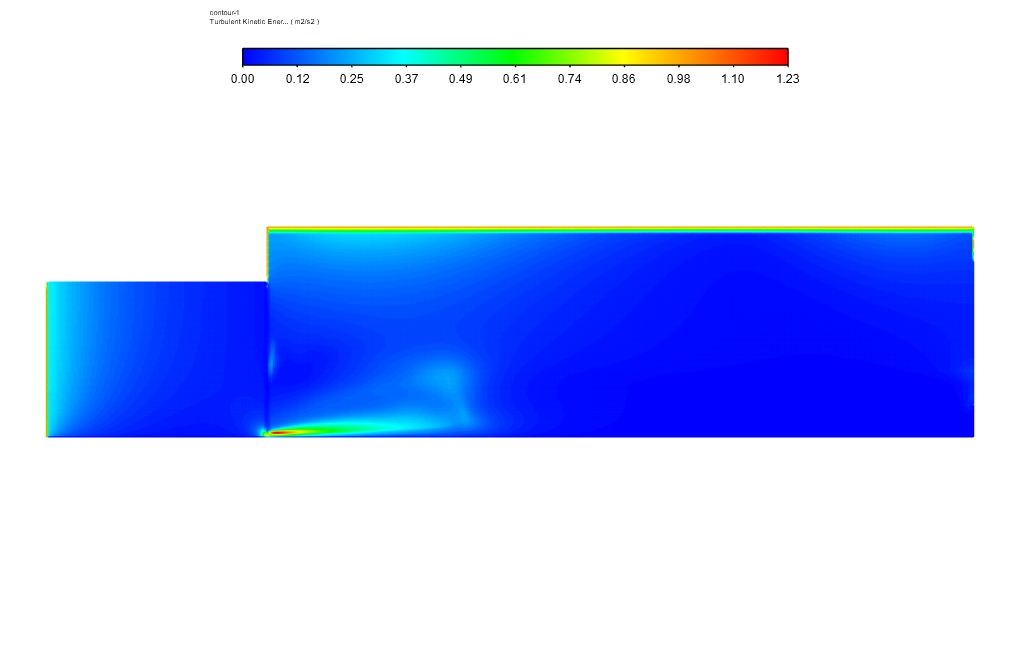

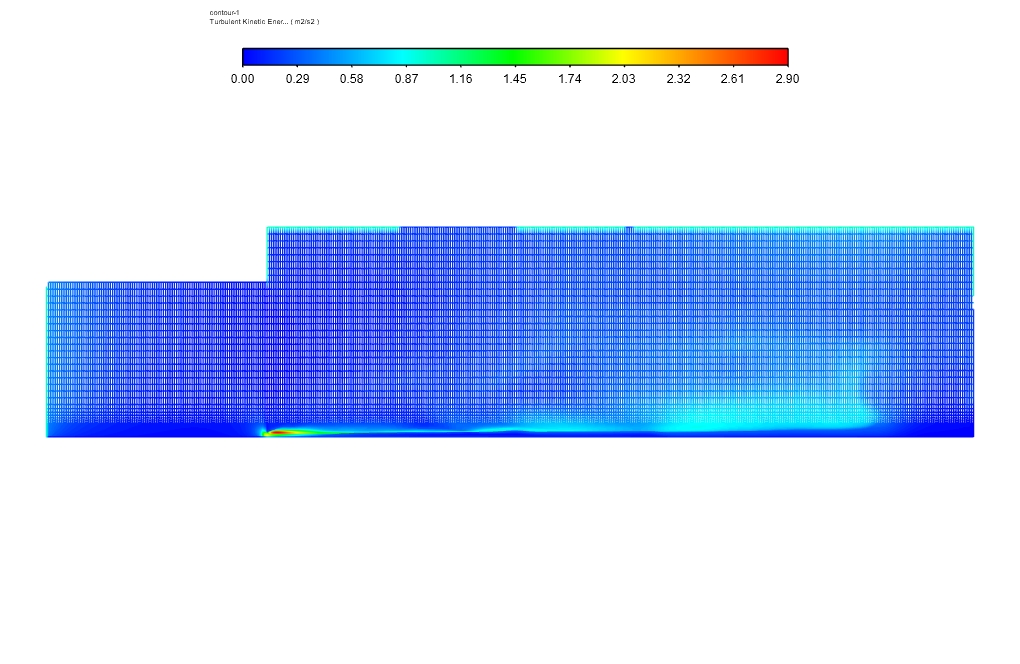

| Viscous | K-epsilon model | Standard |

| Near wall treatment | standard wall treatment | |

| Multiphase (Volume of Fluid) | Volume fraction parameters | Implicit |

| Body force formulation | Implicit body force | |

| Number of Eulerian phases | 2 | |

| Materials | ||

| Fluid | Definition method | Fluent Database |

| Material name | Air | |

| Material name | Water | |

| Boundary conditions | ||

| Inlet_air | Type | Pressure inlet |

| Gauge pressure | zero | |

| Inlet_water | Type | Mass flow inlet |

| Mass flow | 50 and 80 kg/s | |

| Solver configurations | ||

| Pressure-velocity coupling | Scheme | SIMPLE |

| Spatial discretization | Gradient | Least square cell-based |

| Pressure | PRESTO! | |

| Momentum | Second order Upwind | |

| Volume fraction | Modified HRIC | |

| K | First order Upwind | |

| Epsilon | First order Upwind | |

Hydraulic Jump Results and discussion

Distance downstream of water flow where hydraulic jump takes place is equal to 0.9 and 2.8 m for water flows equal to 50 and 80 kg/s.

Dr. Virgil Boyle –

Can the simulation model the effects of different upstream flow conditions on the hydraulic jump?

MR CFD Support –

Yes, the simulation can be adjusted to model different upstream flow conditions, such as flow depth and velocity. This allows for a comprehensive analysis of the hydraulic jump under various operating conditions.

Llewellyn Harber –

Can the simulation model the effects of different channel slopes on the hydraulic jump?

MR CFD Support –

Yes, the geometry of the channel in the simulation can be easily modified to study the effects of different channel slopes on the hydraulic jump.

Katelyn Bergnaum –

How does the simulation handle the turbulence generated by the hydraulic jump?

MR CFD Support –

The simulation uses a turbulence model, such as the k-epsilon or k-omega model, to accurately capture the turbulence generated by the hydraulic jump. This ensures an accurate prediction of the flow behavior downstream of the jump.

Christopher Lang –

Can this simulation predict the location of the hydraulic jump?

MR CFD Support –

Yes, the simulation can predict the location of the hydraulic jump based on the upstream flow conditions. It provides detailed information about the water depth and velocity, which can be used to identify the location of the hydraulic jump.